Professional Documents

Culture Documents

Amc Qap

Uploaded by

Sasanka SekharOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Amc Qap

Uploaded by

Sasanka SekharCopyright:

Available Formats

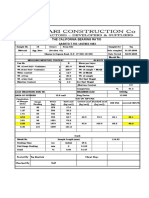

QUALITY ASSURANCE PLAN

CLIENT: VEDANTA ALUMINIUM PLANT LTD.

SUBJECT: QUALITY ASSURANCE PLAN OF AMC CIVIL TYPE OF JOBS FOR PLANT I/II/BOP/CPP REV. (00)

Agency

Extent of Reference Records to

Sl. No Item Category Type / Method of check Acceptance norms Format of record Remarks

check document be furnished CONTRACTOR TPIA CLIENT

A B C D E F G H I J L

1 Survey

Co-ordinates / Levels of

a) Bench Mark recoding of all Critical Visual checks 100% Approved Drg. As per approved Drg. Joint Record Yes P RW W Site Verification/Review

effected working area

Checking of bottom levels Verifiaction of Calibartion

b) Critical 100% Approved Drg. As per approved Drg. Calibration report Yes External Agency RW W Site Verification/Review

& marked C/L by TS system certifiacte

Verifiaction of Calibartion

c) Prizom Checking Critical 100% Approved Drg. As per approved Drg. Prizom repprt Yes External Agency RW W Site Verification/Review

certifiacte

2 Surface dressing

Specifications/ Specifications/

a) Checking for layout Major Dimensional check 100% Joint Records Yes P RW RW Site Verification/Review

Methodology Methodology

Breaking with proper side

Specifications/ Specifications/

b) slopes, Shoring Removing Major Visual Checks 100% Joint Records No P RW RW Site Verification/Review

Methodology Methodology

of Water, etc.

Checking location, firm bed, Specifications/ Specifications/

c) Major Visual Checks 100% -- yes P RW RW Site Verification/Review

levels, free from slush Methodology Methodology

Disposal/proper stacking of

Specifications/ Specifications/

d) breaking materials in Minor Visual Checks 60% -- No P RW RW Site Verification/Review

Methodology Methodology

demarked area.

3 Base Preparation

Core Cutter Method as per IS

Base should be compacted

sepcification wise, 03 No pit

as per MPDD 95% (Lab test Specifications/ As per IS 2720 Part 8 & Joint Records (Compaction

a) Critical reqd. in 500 SQM area as per 100% Yes External Agency RW RW Site Verification/Review

report for MDD & OMC by Methodology Part 29 Resgister)

IRC standard specification

Modified Proctor)

wise

4 Subgrade Preparation (If reqd.)

Subgarde should be 500 mm

thickness (as per IRC 15-

2017 Clause 6.1) in two

layers as per standard

Core Cutter Method as per IS

specification wise &

sepcification wise, 03 No pit

according to MORT&H 5th Specifications/ As per IS 2720 Part 8 & Joint Records (Compaction

a) Critical reqd. in 500 SQM area as per 100% Yes External Agency RW RW Site Verification/Review

revision, also the MDD will Methodology Part 29 Resgister)

IRC standard specification

be min 1.75 gm/cc as per

wise

standard specification wise,

also CBR value reqd. min

8% as per IRC 15-2017

page no-18 (Clause 6.3.5)

Checking of thickness Thickness checked by Auto Specifications/ As per IRC 15-2017,

b) Critical 100% Joint Record Yes P RW RW Site Verification/Review

tolerence Level Methodology Table 10 page no-75

5 GSB 1st/2nd layer (as per approved Drg. Single or Double layer) with min 98 % Compaction as per IRC 15-2017/MORT&H 5th revision

Filling & compcation (in Sand Replacement Method as

layers not more than 200 per IS 2720 part 28, for density For each & every layer of

Specifications/ As per IS 2720 Part 8 & Joint Records (Compaction

a) mm) with min 98% reqd. as Critical with compaction test one test 100% Yes P RW RW GSB bed compaction test

Methodology Part 28 Resgister)

per standard IRC 15-2017 to be conducted every 2000 reqd.

specificatio wise SQM

Specifications/ Specifications/

b) Check for pre & final level Critical Auto Level 100% Joint Records Yes P RW RW Site Verification/Review

Methodology Methodology

Lab test report with Agg. AIV, LL

Lab Test for gradation of GSB

& PL, CBR more than 30% with

Test of GSB (Gradation V) as per IRC 15-2017 & Gradation of GSB will be

Specifications/ As per MORT&H 98% Dry density, Gradation I (or as

c) Materials as per IRC 15- Critical according to quantum of job 100% Yes External Agency RW RW conducted as per mentioned

Methodology Section 400 mentioned in approved BOQ) as per

2017 Table 4 will be check for every three frequecy

IRC 15-2017 Table 4 wise, once for

months periodical basis

each source

Checking of thickness Thickness checked by Auto Specifications/ As per IRC 15-2017,

d) Critical 100% Joint Record Yes P RW RW Site Verification/Review

tolerence Level Methodology Table 10 page no-75

6 WMM laying over compacted base of GSB area with min 98 % Compaction as per IRC 109-2015/MORT&H 5th revision

Filling & compcation of the

layer (thickness as per Sand Replacement Method as

approved Drg. Wise, but in per IS 2720 part 28, for density For each & every layer of

Specifications/ As per IS 2720 Part 8 & Joint Records (Compaction

a) layers not more than 250 Critical with compaction test one test 100% Yes P RW RW WMM bed compaction test

Methodology Part 28 Resgister)

mm & not less than 75 mm) to be conducted every 2000 reqd.

reqd. with min 98% as per SQM

IRC 109-2015

Check for pre & final level,

also checking the thickness

Specifications/ Specifications/

b) tolerence of WMM as per Critical Auto Level 100% Joint Records Yes P RW RW Site Verification/Review

Methodology Methodology

IRC 15-2017 Table 10, page

no-75 wise

Test of WMM (Gradation Lab Test for gradation of

Lab test report with Agg. AIV, LL

Test); materials must be as WMM as per IRC 109-2015 & Gradation of WMM will be

Specifications/ As per MORT&Hth & PL, 98% Dry density & gradation

c) per IRC 109-2015, Table 2 Critical according to quantum of job 100% Yes External Agency RW RW conducted as per mentioned

Methodology revision Section 400 test as per IRC 109 -2015 Table 1, 2

specifiaction wise for will be check for every three frequecy

& 3, once for each source

uniform Grading purpose months periodical basis

7 PCC M 10 (1:3:6)/M 15 (1:2:4) Grade of Concrete as per approved Drg.

Free fall Height should be

Before Pouring of Concrete Lab Test report with proper MTC

mainted at site for avoiding

thickness 100 mm Specifications/ As per IS 456, IS 4031 & reqd . (NC, setting time of Cement,

a) Critical Visual Check 100% Yes External Agency RW RW any kind of Seggregation.

(compacted) or as per Methodology IS 10262 Compressive Strength, Soundness &

Reports are submitted before

approved Drg. Wise Fineness Test of Cement)

working at site.

Checking of vibrating by

Site Verification/Review &

neddle / plate Vibrator Specifications/

b) Major Visual Check 80% As per IS 2505/2506 -- Yes P RW RW minimum 14 days Curing

before & during the pouring Methodology

reqd.

of concrete

Checking of Camber, as per

Checking of dimension & Specifications/ Specifications/

c) approved Drg. during Critical 100% Joint Records Yes P RW RW Site Verification/Review

levels by Auto levels Methodology Methodology

pouring of concrete

8 Reinforcement (Fe-500 D) or as per mentioned in BOQ

Lab Test report with proper MTC

Checking of reinforcement As per IS 1786-2008, External Agency

Visual Check with dimensions Specifications/ (BendTest, Rebend Test, Carbon

a) (Fe-500D) & BBS, also Critical 100% For Dowel bar IS 432 Yes (Provided by RW RW Site Verification/Review

as per approved BBS Methodology Content & UTS with YS &

IMIR reqd. for every lot. Part 1 & IS 2502 Manufracture )

Elongation)

9 Curing (Water Ponding/Sparying with Hessian cloths)

Minimum 28 days reqd.

unless any other special cases

Curing is essential for 28 Specifications/

a) Major Visual Check 100% As per IS 456 As per site surveillance wise Yes P RW RW curing must be maintain 14

days minimum Methodology

days as per decide the EIC of

VAL

10 Back filling (If applicable in Road work as per approved Drg.)

Filling and compaction in

As per IS 2720 Part 7, Joint Records (Compaction Layer thickness as per site

a) layers not more than 500mm Critical Visual Checks 100% Specifications Yes External Agency RW RM

Part 16 & Part 29 Resgister) requirements

& CBR value not less than 5

Filling & Compaction of

b) sand & aggregate around the Major Visual Checks 100% Specifications Specifications Joint Records Yes P RW RW Site Verification/Review

PVC pipe

c) Check for final level Major Visual Checks 100% Drawings Drawings Joint Records Yes P RW RW Site Verification/Review

11 M 40 Grade of RCC comcrete (If reqd.)

Lab Test report with proper MTC

reqd . (NC, setting time of Cement,

Compressive Strength, Soundness &

Fineness Test of Cement) &

As per IS 456, IS 4031, Free fall Height should be

detailed Mix Design report with

IS 10262 - 2019 & IRC mainted at site for avoiding

Before Pouring of Concrete Specifications/ trial mix. Also Agg. Mechanical

a) Critical Visual Check 100% 15 - 2017, (clause 12.4) Yes External Agency RW RW any kind of Seggregation.

as per approved Drg. wise Methodology properties (Crushing value, Impact

for Flexrula Strength min Reports are submitted before

Value with Combined Flakiness &

4.5 N/mm2 at 28 days working at site.

Elongation index, Gradation of 10

mm,20mm & Sand Zone II) must be

mentioned in Design Mix report as

per IS 383 - 2016 wise

Checking Slump test as per

Visual check reqd. fro every As per IRC 15-2017 Clause 4.5 at

IRC 15-2017 before & Specifications/

b) Critaical transit mixer or per batch of 100% As per IRC 15-2017 page no-12, Slump range will be 60- Yes P RW RW Site Verification/Review

during the pouring of Methodology

Ajax machine 80 mm

concrete

Checking vibrating

Specifications/

c) needle/plate vibrator before Critical Visual Check 100% As per IS 2505/2506 -- No P RW RW Site Verification/Review

Methodology

the pouring of concrete

Visual Check, dimension As per MORT&H section 900

checking reqd. for cube moulds Compressive strength checking at 7 Quality Control Tabl 900-6-

Cube/Beam sampling &

150 mm standard Size & Specifications/ & 28 days basis.Flexrual Strength 5.2 wise, beam sample reqd.

d) testing during the pouring of Critical 100% As per IS 456 & IS 516 Yes External Agency RW RW

Beam moulds (150 * 150 * Methodology checking reqd. at age of 28 days per150 m3 freuency wise &

concrete

700) mm as per IS 10086 & curing as per IS 516 part 1 wise for taking cube sample as per

IRC 15-2017 wise IS 456 reference

Checking of Transverse joint

should not more than 4.5 m as Joint Records (Maintained in Pour

Size of Panels as per IRC 15- Specifications/

e) Critical per IRC 15-2017 Clause 8.3 100% IRC 15-2017 Card & Cube test register in panel Yes P RW RW Site Verification/Review

2017 wise Methodology

wise or as per Design wise)

specifiaction wise.

Checking Dowel Bars & Tie Checking of Dowel bars as per

Bars as per IRC 15-2017 or approved Drg. or IRC-15-2017

Specifications/ IRC 15-2017, IS 432 Joint records (also maintained in the

f) as per approved Drg. wise Critical Clause 8.3.6 to 8.3.11 & For 100% Yes P RW RW Site Verification/Review

Methodology Part 1 & IS 1786-2008 Pour Card as per Panel wise)

before the pouring of Tie bars as per IRC -15-2017

concrete Table 8 wise

Checking of thickness

Thickness checked by Auto Specifications/ As per IRC 15-2017,

g) tolerence during & after the Critical 100% Joint Record Yes P RW RW Site Verification/Review

Level Methodology Table 10 page no-75

pouring of concrete

Checking of Camber, as per

Checking of dimension & Specifications/ Specifications/

h) approved Drg. during Critical 100% Joint Records Yes P RW RW Site Verification/Review

levels by Auto levels Methodology Methodology

pouring of concrete

12 Sand filling

As per IRC SP 65, bedding

Sand filling of Zone II As per IRC SP 65,

Specifications/ materials specifiaction, Lab Test

a) Grade based on BOQ Major Visual Checks 100% bedding materials Yes P RW RW Site Verification/Review

Methodology report for Gardadtion & Silt Content

thicknesss specifiaction

reqd.

13 Tiles/Paver blocks

For Paver Blocks,

specifiaction

Visual Check, Checking

followed as per IS

Laying Tiles over PCC area comressive strength of Paver External Agency

15658 or for cement Joint Records & Lab test report of

a) or Sand filling layer as per Major Blocks & others paarameters as 100% Specifications Yes (Provided by RW RW Site Verification/Review

concrete flooring Paver Blocks

drg. Wise per IS 15658-2021 or IS 1237 Manufracture )

tiles IS 1237 & for

& IS 1443-2018 wise

lyaing IS 1443 -

2018 wise

14 Gull Trap Pipe Connection (If reqd.)

Gully Chamber

(500*300*450 as per

Testing of bricks reqd. as

standard) mm made by

per IS 3495 Part 1 to Joint Records (All relavant test

Brick work with Cement

a) Critical Visual Check 100% Specifications Part 4 wise, reports of Bricks reqd. as per IS Yes P RW RW Site Verification/Review

Mortar (1:4), Inside

Specification reqd. as code 3495)

plastering with same ratio &

per IS 12894 wise

isntalled MS Flat Grating

Cover with Angle Frame

Specifications/ Specifications/ Specifications/ Minimum 07 days (as per IS

b) Curing of Brick work Critical Visual Check 100% - P RW RW

Methodology Methodology Methodology 2212) reqd.

15 kerb Stone fixing

Kerb Stone (500*550*150)

mm or as per mentioned in

BOQ; Factory made with M

a) Major Visual Check 100% Specifications Specifications Joint Records Yes P RW RW Site Verification/Review

25 grade Cement Concrete

& jointed by Cement Mortar

1:3 ratio

16 Hume Pipe NP 3/ NP 4 Grade laying & installtion or as per mentioned in BOQ (If reqd.)

Specially in joint portion of

NP 3 or NP 4 grade of Visual Checking in joint As per IS 458 Joint Records (MTC of Hume Pipe External Agency

As per IS 458 2003, Hume pipes; Wire mesh reqd.

a) Hume Pipe installed reqd. at Major portion for per Caulking Space 100% 2021,specifiaction reqd. with mentioned the relavant Yes (Provided by RW RW

specifiaction followed with rich cement mortar as per

joint portion as per IS 458 followed parameters) Manufracture )

satndard specifiaction wise

17 Brick Work

Brick work where ever Testing of bricks reqd. as

Visual Check, before start of

reqd. as per site basis, with per IS 3495 Part 1 to Joint Records (All relavant test

the Brick Works, it must be in As per IS 12894

a) Cement Mortar (1:4), Inside Critical 100% Part 4-2019 wise, reports of Bricks reqd. as per IS Yes External Agency RW RW Site Verification/Review

staturated condition based by 2002 & IS 2212

& outside plastering with Specification reqd. as code 3495)

water sprinking

same ratio per IS 12894-2002 wise

Specifications/ Specifications/ Minimum 07 days (as per

b) Curing of Brick work Critical Visual Check 100% - Yes P RW RW

Methodology Methodology IS 2212) reqd.

18 Shuttering for Raft/Columns & etc. with checking of alignments

Shuttering stripping time must be

maintained as per IS 456 (Clause

Shuttering of Raft &

Dimensional checking reqd. by 11.1) wise, for better stability

Columns & any other samll Specifications/ As per IS 456 Amnd 4

a) Critical tape measurement according to 100% purpose for heavy structures, MS Yes P RW RW Site Verification/Review

structures Methodology 2013 & IS 14687 wise

approved Drg. shuttering boards & for Drain work

& any raft or columns (Ply Boards)

may be used at site

Checking of Raft & Coulmn Checking reqd. by TS system Specifications/ Specifications/

b) Critical 100% Joint Records with sketch reqd. Yes P RW RW Site Verification/Review

alignment as per Drg. to ensuring proper alignmnent Methodology Methodology

19 RCC M 20/ M 25/ M 30 & M 35 Grade of Concrete as per approved Drg.

Lab Test report with proper MTC Free fall Height should be

(for cement only) reqd . (NC, mainted at site for avoiding

setting time of Cement, any kind of Seggregation.

Compressive Strength, Soundness & Reports are submitted before

As per IS 456, IS 4031 & Fineness Test of Cement as per IS working at site. Also

IS 10262-2019. For Agg. 4031 Part 1 to Part 6) & detailed mechanical properties of Agg.

Before Pouring of Concrete Visual Check, batch report of

Specifications/ Mechnaical properties IS Mix Design report with trial mix. As per IS 2386 Part 1, Part 3

a) thickness as per approved Critical concrete must be checking 100% Yes External Agency RW RW

Methodology 2386 Part 1 to Part 4 & Also Agg. Mechanical properties & Part 4 checking reqd. & for

Drg. Wise reqd. as per IS 4925-2004 wise

IS 383-2016 Table 7 & (Crushing value, Impact Value with Fine pariticales Silt content

Table 9 reqd. Combined Flakieness & Elongation with Gardation test reqd. as

index, Gradation of 10 mm,20mm & per IS 383-2016 Table 9 &

Sand Zone II) must be mentioned in Ag.. gradation as per Table 7

Desin Mix report as per IS 383 - wise to maintain three months

2016 wise periodical basis for AMC job.

Checking vibrating

needle/plate vibrator before Specifications/

b) Critical Visual Check 100% As per IS 2505/2506 -- No P RW RW Site Verification/Review

& during the pouring of Methodology

concrete

Visual Check as per IS 456 As per IS 456 Amnd 5

Cube sampling & testing Specifications/ Compressive strength checking at 7

c) Critical Amnd 5 2019 & 516 part 1 100% 2019 & IS 516 Part 1 Yes P RW RW Site Verification/Review

after the pouring of concrete Methodology & 28 days basis.

2021 wise 2021

Checking the Slump randomly for

Ajax or Transit mixer for every time

Slump test/ Consistency

of casting as per approved design

Test of Concrete during & Visual Check at site with Specifications/ As per IS 1199 Part 1 &

d) Critical 100% mix; with tolerence as per IS 4925- Yes P RW RW Site Verification/Review

before the pouring of Slump cone appratus Methodology 2-2018 wise

2004 (SP. of Batching Plant) & IS

concrete

4926-2003 (SP. of RMC) wise, also

slump test register reqd. at site

20 Emulsion Paint/Synthetic Enamel Paint/Waether Coat as per BOQ

Mixing the water with paints as

per mentioned by mfg. Guide External Agency

Applying Paint as per Specifications/ As per IS 15489 2013 & Joint Records with sketch reqd. &

a) Major line wise & specification as per 100% Yes (Provided by RW RW Site Verification/Review

requriment of site Methodology IS 2932 2013 wise mention the layer of coating

IS 15489 2013 & IS 2932 2015 Manufracture )

wise

Specifications/ Specifications/

b) Check th finishing Major Visula Check 100% - Yes P RW RW Site Verification/Review

Methodology Methodology

21 Vetrified Floor Tiles as per BOQ

Laying tiles as per As per IS 15622 2017

Cement Mortar with 1:3 as per External Agency

specification, before laying Specifications/ specification & as per IS MTC review reqd.as per IS 15622

a) Major BOQ & site condition basis for 100% Yes (Provided by RW RW Site Verification/Review

the tiles check the dimesions Methodology 1443 2018 laying 2017 wise

bedding materials Manufracture )

as per reqd. Wise procedures

Not less than 07 days as per

Specifications/ Specifications/

b) Curing of laid tiles Major standard practice with wet or 100% - Yes P RW RW Site Verification/Review

Methodology Methodology

moist cloths or covers

22 Boulder soiling as per BOQ

Filling not more than 300

mm & compcation reqd. by Specifications/ Specifications/ Joint Records (Compaction

a) Critical Visual Checks 100% Yes P RW RW Site Verification/Review

plate compactor or any type Methodology Methodology Resgister)

of mechanical compactors

Specifications/ Specifications/

b) Check for pre & final level Critical Auto Level 100% Joint Records Yes P RW RW Site Verification/Review

Methodology Methodology

Test report of Boulders (size

Specifications/ As per MORT&H Lab Test report with Sp. Gravity,

c) of boulders not more than Critical Lab Test 100% Yes External Agency RW RW Site Verification/Review

Methodology Section 400 crushing value & Impact Value

300 mm)

23 Soil/Embankment filling as per BOQ or approved Drg. Basis

Embankment filling with Core Cutter Method as per IS

not more than 300 mm layer sepcification wise, 03 No pit

Specifications/ As per IS 2720 Part 8 & Joint Records (Compaction

a) thickness as per MORT&H Major reqd. in 500 SQM area as per 100% Yes P RW RW Site Verification/Review

Methodology Part 29 Resgister)

5th rev. & IRC 36 2010 IRC standard specification

wise wise

MPDD will be check for

once for specific source, If

source changed MPDD test Specifications/ As per IS 2720 Part 8 & Joint Records (Compaction

b) Major As per Lab Test 100% Yes P RW RW Site Verification/Review

reqd. for revised value of Methodology Part 29 Resgister)

MDD & OMC as per IS

2720 part 8

24 Bonding Agent (SIKA -LATEX-SBR)/PERMA MASTER BOND (If reqd.)

External Agency

Lab Test report with

a) Using Bonding Agent Major Visual Check 100% Specifications Joint Records Yes (Provided by RW RW Site Verification/Review

proper MTC reqd.

Manufracture )

Legends: P PERFORM

R RANDOM Prepared By: Sasanka Dey

W WITNESS General Manager

RW RANDOM WITNESS

RM RANDOM MONITORING

THIRD

PARTY

TPIA

INSPECTION

AGENCY

STANDARD

PROCTOR

SPDD

DRY

DENSITY

You might also like

- Adaptive Tests of Significance Using Permutations of Residuals with R and SASFrom EverandAdaptive Tests of Significance Using Permutations of Residuals with R and SASNo ratings yet

- Quality Assurance PlanDocument4 pagesQuality Assurance PlanSasanka SekharNo ratings yet

- Building a Successful Board-Test StrategyFrom EverandBuilding a Successful Board-Test StrategyRating: 4 out of 5 stars4/5 (1)

- Client: Nlcil Subject: Quality Assurance Plan For Side Drain (Rev-00)Document2 pagesClient: Nlcil Subject: Quality Assurance Plan For Side Drain (Rev-00)Sasanka SekharNo ratings yet

- Vedanta Aluminium Plant Ltd. Quality Assurance Plan For Buildinng Construction Job (Rev-00)Document4 pagesVedanta Aluminium Plant Ltd. Quality Assurance Plan For Buildinng Construction Job (Rev-00)Sasanka SekharNo ratings yet

- Vedanta Aluminium Plant Ltd. Quality Assurance Plan For Pot Line Maintenance Job (Rev-00)Document3 pagesVedanta Aluminium Plant Ltd. Quality Assurance Plan For Pot Line Maintenance Job (Rev-00)Sasanka SekharNo ratings yet

- PMO Office Building JobDocument3 pagesPMO Office Building JobSasanka SekharNo ratings yet

- QAP For Bitumen JobDocument2 pagesQAP For Bitumen JobSasanka SekharNo ratings yet

- Proposed QAP For Adani Internal CTR JobDocument2 pagesProposed QAP For Adani Internal CTR JobSasanka SekharNo ratings yet

- Road Bitumen Work QAP No 02Document2 pagesRoad Bitumen Work QAP No 02Sasanka SekharNo ratings yet

- J213-AHC-EMD-MS-C-01-R0 ITP For Excavation and BackfillingDocument2 pagesJ213-AHC-EMD-MS-C-01-R0 ITP For Excavation and BackfillingKafeel AbbasNo ratings yet

- Quality assurance plan for civil construction projectsDocument11 pagesQuality assurance plan for civil construction projectsDeviPrasadNathNo ratings yet

- Magnetic Level Gauge: DOC NO. QR/QC/F/14Document1 pageMagnetic Level Gauge: DOC NO. QR/QC/F/14sunshine dreamNo ratings yet

- SR No Activity Characteristics To Be Checked Quantum of Check Inspection / SignDocument1 pageSR No Activity Characteristics To Be Checked Quantum of Check Inspection / SignAlpine ProjectsNo ratings yet

- QAP N2 Generator & N2 VesselDocument2 pagesQAP N2 Generator & N2 VesselVijay - Spantech EngineersNo ratings yet

- Steel TankDocument4 pagesSteel TankRanu JanuarNo ratings yet

- Shop Inspection Test and PlanDocument1 pageShop Inspection Test and PlanJeffrey HallNo ratings yet

- L&T GeoStructure casing inspection planDocument2 pagesL&T GeoStructure casing inspection plansanil50% (2)

- QAP1Document2 pagesQAP1akshaymehra2354No ratings yet

- In Process Inspection Stage Flow Chart: Spacechem EnterprisesDocument6 pagesIn Process Inspection Stage Flow Chart: Spacechem EnterprisesSourav SharmaNo ratings yet

- M/s-PINAX STEEL ITP for Fabricated DUCT & HOPPERSDocument1 pageM/s-PINAX STEEL ITP for Fabricated DUCT & HOPPERSStructures ProductionNo ratings yet

- Attach-2 ITP For Building WaterDocument29 pagesAttach-2 ITP For Building WaterSukalyan BasuNo ratings yet

- Saudi Aramco Typical Inspection Plan: Soil Improvement (Vibro Replacement & Vibro Compaction) 31-Nov-2018 CivilDocument10 pagesSaudi Aramco Typical Inspection Plan: Soil Improvement (Vibro Replacement & Vibro Compaction) 31-Nov-2018 CivilTariqMalik0% (1)

- Ongoing Road Inspection ReportDocument13 pagesOngoing Road Inspection ReportARTI PALEKARNo ratings yet

- Inspection Test Plan PV Nozzle Modification/AlterationDocument4 pagesInspection Test Plan PV Nozzle Modification/AlterationMohd Shafuaaz KassimNo ratings yet

- Inspection MatrixDocument2 pagesInspection MatrixFabian BellNo ratings yet

- Quality Assurance Plan for Metallic Expansion Joint ManufacturingDocument1 pageQuality Assurance Plan for Metallic Expansion Joint Manufacturingdemas100% (1)

- Satip-A-000-01 Rev 8 Soil Improvement (Vibro Replacement - Vibro Compaction FinalDocument2 pagesSatip-A-000-01 Rev 8 Soil Improvement (Vibro Replacement - Vibro Compaction FinalTarek YehiaNo ratings yet

- Qap - Sail-WbDocument2 pagesQap - Sail-WbRiyu RathodNo ratings yet

- Section C - Preparation and Coating Audit TemplateDocument7 pagesSection C - Preparation and Coating Audit TemplateAnnNo ratings yet

- CDP RDC Ar Mal Qac 0001Document5 pagesCDP RDC Ar Mal Qac 0001ElvinNo ratings yet

- ITP-MEP-003 Water Supply Connection To Landlord NetworkDocument1 pageITP-MEP-003 Water Supply Connection To Landlord Networkjagathmukundhan00No ratings yet

- 8 Field Quality PlanDocument18 pages8 Field Quality PlanRamaKrishna ANo ratings yet

- Pressure Vessel ITP Rev 0Document10 pagesPressure Vessel ITP Rev 0SLC HosurNo ratings yet

- Navsari Div - Box Culvert On Hansapore Flag Station RoadDocument14 pagesNavsari Div - Box Culvert On Hansapore Flag Station RoadartiNo ratings yet

- Boxt Field Quality PlanDocument86 pagesBoxt Field Quality PlanHariom GuptaNo ratings yet

- Saudi Aramco Soil Improvement Inspection PlanDocument10 pagesSaudi Aramco Soil Improvement Inspection PlanAkansha SharmaNo ratings yet

- Ongoing Work Inspection FormatDocument12 pagesOngoing Work Inspection FormatARTI PALEKARNo ratings yet

- QAPDocument6 pagesQAPRahul ChandanNo ratings yet

- Satip A 000 01 Rev 7 (Final)Document2 pagesSatip A 000 01 Rev 7 (Final)faisalNo ratings yet

- WHRS QapDocument31 pagesWHRS Qapmd shahabuddeenNo ratings yet

- Quality PlanDocument2 pagesQuality PlanSekar KrishNo ratings yet

- Prds & Piping QapDocument2 pagesPrds & Piping QapPavul RajNo ratings yet

- Itp For Site Preparation & Earth WorksDocument17 pagesItp For Site Preparation & Earth WorksDaniel Martinez100% (1)

- Saudi Aramco Typical Inspection Plan: Soil Improvement (Vibro Replacement & Vibro Compaction) 30-Oct-17 CivilDocument10 pagesSaudi Aramco Typical Inspection Plan: Soil Improvement (Vibro Replacement & Vibro Compaction) 30-Oct-17 CivilJagdishNo ratings yet

- Inspection & Test Plan (Itp) - Iso 5167 - Fittings (SC / DC)Document1 pageInspection & Test Plan (Itp) - Iso 5167 - Fittings (SC / DC)Guru DevaNo ratings yet

- J-2441 Ci-Sg DRG-C2 Rev.0Document2 pagesJ-2441 Ci-Sg DRG-C2 Rev.0BINOY DASNo ratings yet

- SAIC-A-1015 Rev 8 HDPE Liner Receic Ving and Storage Insp Final.Document1 pageSAIC-A-1015 Rev 8 HDPE Liner Receic Ving and Storage Insp Final.Tito GarciaNo ratings yet

- Field Inspection &test PlanDocument4 pagesField Inspection &test PlanSofda ImelaNo ratings yet

- Inspection Testing Plan (ITP)Document1 pageInspection Testing Plan (ITP)Kdown 99100% (1)

- FQP For AAC Block WorkDocument1 pageFQP For AAC Block WorkHimanshu ChaudharyNo ratings yet

- Itp PRDSDocument3 pagesItp PRDSDwi Mulyanti Dwimulyantishop100% (1)

- 2.8.2. Indicative QAP - ColumnsDocument12 pages2.8.2. Indicative QAP - ColumnsAshish Dhok0% (1)

- Ecc Mech Sharq 22 016 Rev 01Document6 pagesEcc Mech Sharq 22 016 Rev 01Muthu SaravananNo ratings yet

- QAP - Invest Energy Group (10.0 TPH)Document3 pagesQAP - Invest Energy Group (10.0 TPH)chanjunkaiNo ratings yet

- Shic A 0005Document2 pagesShic A 000501095902062ahmedNo ratings yet

- Malod Kheralia RoadDocument12 pagesMalod Kheralia RoadartiNo ratings yet

- Inspection Test Plan (Itp) at Shop: Natural Gas Transportation Development Project - Siak RiauDocument4 pagesInspection Test Plan (Itp) at Shop: Natural Gas Transportation Development Project - Siak Riauanang_priNo ratings yet

- Jash Engineering LTD.: Quality Assurance PlanDocument3 pagesJash Engineering LTD.: Quality Assurance PlanShree ConstructionNo ratings yet

- QUALITY ASSURANCE PROTOCOLDocument2 pagesQUALITY ASSURANCE PROTOCOLShah Newaz KabirNo ratings yet

- Road and infrastructure upgradesDocument7 pagesRoad and infrastructure upgradesSasanka SekharNo ratings yet

- Rate CardsDocument32 pagesRate CardsSasanka SekharNo ratings yet

- Highway Rating CircularDocument18 pagesHighway Rating CircularSasanka SekharNo ratings yet

- Approximate BOQ For Limestone Crusher & Load CentreDocument8 pagesApproximate BOQ For Limestone Crusher & Load CentreSasanka SekharNo ratings yet

- Work Schedule BANJARI DEVELOPMENT JOBDocument4 pagesWork Schedule BANJARI DEVELOPMENT JOBSasanka SekharNo ratings yet

- NDT PPT ShubhamDocument34 pagesNDT PPT ShubhamSasanka SekharNo ratings yet

- BBS of Foundation (Material Gate)Document2 pagesBBS of Foundation (Material Gate)Sasanka SekharNo ratings yet

- Nov 18Document1 pageNov 18Sasanka SekharNo ratings yet

- The California Bearing Ratio: Aashto T 193 / Astm D 1883Document13 pagesThe California Bearing Ratio: Aashto T 193 / Astm D 1883mdalgamouniNo ratings yet

- Astm C 1074-04Document9 pagesAstm C 1074-04Vasco SorteNo ratings yet

- BBS For Kerb Wall Material GateDocument9 pagesBBS For Kerb Wall Material GateSasanka SekharNo ratings yet

- 10C... For PF WithdrwalDocument2 pages10C... For PF WithdrwalSasanka SekharNo ratings yet

- Bar Bending Schedule for Material Gate Road PanelDocument2 pagesBar Bending Schedule for Material Gate Road PanelSasanka SekharNo ratings yet

- Moisture Correction SheetDocument4 pagesMoisture Correction SheetSasanka SekharNo ratings yet

- Mix Design For PQCDocument20 pagesMix Design For PQCSasanka SekharNo ratings yet

- BBS of Kerb WallDocument3 pagesBBS of Kerb WallSasanka SekharNo ratings yet

- Weight Bridge Exit RampDocument12 pagesWeight Bridge Exit RampSasanka SekharNo ratings yet

- Sale Deed of Dipannita Construction Legal (Dilip Show)Document20 pagesSale Deed of Dipannita Construction Legal (Dilip Show)Sasanka SekharNo ratings yet

- JP AUTOCLAVERS Level Sheet ReportDocument12 pagesJP AUTOCLAVERS Level Sheet ReportSasanka SekharNo ratings yet

- California Bearing Ratio Test Data Sheets & GraphsDocument4 pagesCalifornia Bearing Ratio Test Data Sheets & GraphsSaad JuventinoNo ratings yet

- Coal Entry Road Bbs1Document9 pagesCoal Entry Road Bbs1Sasanka SekharNo ratings yet

- AnalysisOfDesignOfAFlexiblePavementWithCementedBaseAndGranularSubbase (187 192)Document6 pagesAnalysisOfDesignOfAFlexiblePavementWithCementedBaseAndGranularSubbase (187 192)Sasanka SekharNo ratings yet

- Adani LetterDocument2 pagesAdani LetterSasanka SekharNo ratings yet

- B.B.S (300 Dia Hume Pipe)Document2 pagesB.B.S (300 Dia Hume Pipe)Sasanka SekharNo ratings yet

- Coal Truck Parking Exit Road Bbs2Document7 pagesCoal Truck Parking Exit Road Bbs2Sasanka SekharNo ratings yet

- Laying of Approach Road Tender for Talabira Mines ProjectDocument9 pagesLaying of Approach Road Tender for Talabira Mines ProjectSasanka SekharNo ratings yet

- Client Letter No 09Document2 pagesClient Letter No 09Sasanka SekharNo ratings yet

- Client Letter No 06Document2 pagesClient Letter No 06Sasanka SekharNo ratings yet

- ASHRAE Standard 55-2004 For High Performance Buildings: Brian Lynch, Brian LynchDocument23 pagesASHRAE Standard 55-2004 For High Performance Buildings: Brian Lynch, Brian LynchanuruddhaeNo ratings yet

- Mass Timber Design Manual 2Document118 pagesMass Timber Design Manual 2Ahmed Abo El-SoudNo ratings yet

- Design Manual Chapter 6 - Geotechnical 6G - Subsurface Drainage SystemsDocument11 pagesDesign Manual Chapter 6 - Geotechnical 6G - Subsurface Drainage Systemsbilisuma sebokaNo ratings yet

- Concrete Technology: No. of TestDocument10 pagesConcrete Technology: No. of TestJayHatNo ratings yet

- Final DP-I ST0301 - IU175121009Document38 pagesFinal DP-I ST0301 - IU175121009Nandpal PrashantNo ratings yet

- 8525 Baxter Place - Fire Safety Plan 2015Document56 pages8525 Baxter Place - Fire Safety Plan 2015api-576583097No ratings yet

- Architects KolkataDocument6 pagesArchitects Kolkatadhwani.talati5920100% (1)

- Centrifugal Pump Troubleshooting Guide - 1Document1 pageCentrifugal Pump Troubleshooting Guide - 1BhaiJan59No ratings yet

- ISO Poster - Damage Bearing - 15840 ENDocument1 pageISO Poster - Damage Bearing - 15840 ENangel017No ratings yet

- #Rfi-Alv01111-t1-Ar-0218 Admin Office Requesting For Wall Ceiling Finishes-SignedDocument4 pages#Rfi-Alv01111-t1-Ar-0218 Admin Office Requesting For Wall Ceiling Finishes-Signedian.premium2021No ratings yet

- Bituminous MixDocument5 pagesBituminous MixCaleb KhisaNo ratings yet

- Reliable, Efficient Air-Cooled Water Chillers up to 400HPDocument22 pagesReliable, Efficient Air-Cooled Water Chillers up to 400HPHakki ComertpinarNo ratings yet

- Updated Product List 30.09.2021Document10 pagesUpdated Product List 30.09.2021sabhay2No ratings yet

- Catalogo Kunkle ValveDocument32 pagesCatalogo Kunkle ValveKelvyn RochaNo ratings yet

- Grundocrack ManualDocument66 pagesGrundocrack ManualKevin H A NoelNo ratings yet

- Piping BasicsDocument3 pagesPiping BasicsWinston RajNo ratings yet

- BP 220 - Part 02 PDFDocument26 pagesBP 220 - Part 02 PDFJohann Sebastian M MontalesNo ratings yet

- ScariDocument64 pagesScariancutza_schNo ratings yet

- Evacuation Center (Design of Beam2)Document35 pagesEvacuation Center (Design of Beam2)jerick calingasanNo ratings yet

- DPApp LLDA-CPD-Form 11 (Aug2022)Document2 pagesDPApp LLDA-CPD-Form 11 (Aug2022)jeromemcasinoNo ratings yet

- Georgia Construction MonitorDocument67 pagesGeorgia Construction Monitorluke elbertNo ratings yet

- Aerospace Material Specification: AMS4311™ Rev. FDocument7 pagesAerospace Material Specification: AMS4311™ Rev. FMohammad LavasaniNo ratings yet

- Thomson Neff Series Screw Drives en 05-2008Document76 pagesThomson Neff Series Screw Drives en 05-2008Branimir TadićNo ratings yet

- Chemical Design and Distillation Column 2 ParametersDocument6 pagesChemical Design and Distillation Column 2 ParametersPaen ZulkifliNo ratings yet

- National Oil Corporation Transmission Line Pole SpecificationDocument24 pagesNational Oil Corporation Transmission Line Pole SpecificationYousab JacobNo ratings yet

- All Pipe ClampsDocument6 pagesAll Pipe ClampsLord DracoNo ratings yet

- WS5-Chapter 18 Floor Plan LayoutDocument2 pagesWS5-Chapter 18 Floor Plan LayoutJCNo ratings yet

- XT - Company ProfileDocument23 pagesXT - Company Profiletưng_tửng_4No ratings yet

- McCook - Filter Design 2003Document15 pagesMcCook - Filter Design 2003ועדת איכות הסביבה חייםNo ratings yet

- Vinylex Petrostop engineered for secondary containmentDocument8 pagesVinylex Petrostop engineered for secondary containmentJuan Carlos Romero LaraNo ratings yet