0% found this document useful (0 votes)

2K views2 pagesQAP For Bitumen Job

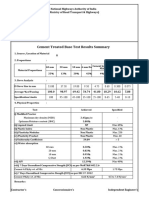

This document provides a quality assurance plan for bitumen work on an IPP aluminium plant project. It outlines 4 key items - surface dressing, crack repairing, tack coat application, and DBM/SDBC laying. For each item, it specifies the parameters to be checked, extent of checking, acceptance criteria, responsible parties, and records to be maintained to ensure the work meets specifications. Checks include dimensional measurements, visual inspections, material testing, and verifying quantities used meet standards. Records like joint records and lab test reports will be furnished and signed off by the contractor, third party inspector and client to ensure quality standards are achieved.

Uploaded by

Sasanka SekharCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as XLSX, PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

2K views2 pagesQAP For Bitumen Job

This document provides a quality assurance plan for bitumen work on an IPP aluminium plant project. It outlines 4 key items - surface dressing, crack repairing, tack coat application, and DBM/SDBC laying. For each item, it specifies the parameters to be checked, extent of checking, acceptance criteria, responsible parties, and records to be maintained to ensure the work meets specifications. Checks include dimensional measurements, visual inspections, material testing, and verifying quantities used meet standards. Records like joint records and lab test reports will be furnished and signed off by the contractor, third party inspector and client to ensure quality standards are achieved.

Uploaded by

Sasanka SekharCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as XLSX, PDF, TXT or read online on Scribd

- Quality Assurance Plan: Details a comprehensive quality assurance plan including reference documents, acceptance criteria, and inspection requirements.