Professional Documents

Culture Documents

Mix Design of DBM With Rap Aggregates Construction Materials IJERTCONV11IS02019

Uploaded by

bineetmishra1990Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Mix Design of DBM With Rap Aggregates Construction Materials IJERTCONV11IS02019

Uploaded by

bineetmishra1990Copyright:

Available Formats

Special Issue - 2023 International Journal of Engineering Research & Technology (IJERT)

ISSN: 2278-0181

ICART - 2023 Conference Proceedings

Mix Design of DBM with RAP

Aggregates

(Construction Materials)

Vijil A Jose Dr. P Swaminathan

M.Tech student Associate professor

Department of Civil Engineering Dept. of civil engineering

Mangalam college of engineering Mangalam college of engineering

Kottayam India Kottayam India

Abstract— Recycling of asphalt pavements (RAP) is an percentage RAP use.

economical, reasonable and environmentally friendly method According to Federal Highway Administration, the graph

material. In the face of rising asphalt prices, low availability of shows the pavement condition, recycling and sustainability

similar products, and extrusion to protect the environment, using relationship.

RAP is superior to raw materials. So with this project, we can

reduce the use of natural resources without compromising the

specifications. Recycling the used aggregates with its properties

can last for long years of life span of pavement. The main factor

driving renewal in recent years is the product, including the price

of asphalt and the absence of similar products. Therefore,

recycling helps reduce costs, conserve scarce materials and lower

labor costs. Thus recycling has an advantage of reducing the

budget, protect limited material and decrease the amount of

energy requisite.

By the time goes, new recycling innovations has been acquiring

the word of Technology of different levels of construction. With

the recycled materials with minimum content of binder contents

can elaborate the usage of materials

Keywords- Asphalt, RAP, DBM, Mix Design, Binder Content,

Marshall Stability Fig No: 1 Graph showing Pavement condition, recycling

and sustainability relationship

I. INTRODUCTION Recovered or reclaimed Asphalt Pavement (RAP) refers to

asphalt and aggregate and paving contents of coarse aggregates

Reclaimed Asphalt Pavement (RAP) has been used as a and asphalt binder. These materials are formed from asphalt

valuable factor of new asphalt mix for many ages. Most RAP is pavements which are removed for repair, resurfacing, or

produced from milling. RAP is milled from surviving pavement service. RAP consists of fine, fine grade aggregate and asphalt

by producing to an appropriate size for using which used as a cement when properly crushed and analyzed.

component for new asphalt mixture. Economically, there is an

advantage for using RAP till these modules can be reused, thus Asphalt pavements are usually separated by milling or full

can decrease the expenditure of purchasing and use less new depth exclusion. Milling takes place in removing the coating

virgin materials. In spite to economic benefits, the RAP usage using a milling machine that can capture up to 50 mm of

has environmental positive. Recycling resource can lessens the thickness in one go. The whole decision involves crushing and

reduction of consumption of non-renewable natural resources breaking the pavement using a truck horn and/or pneumatic

such as aggregates and asphalt binder. A RAP obtained from pavement breakers. In the best example, crushed material is

different purposes can have different asphalt binder content and picked up by a front loader and loaded onto a truck and then

properties, aggregate physical and gradation. Some of designers transported to the main production area for processing. In this

fractionate the RAP through one or more screens to have coarse area, RAP is processed by processes such as crushing,

and fine stockpiles, which will can increase the higher screening, transport and stacking. Although most of the old

asphalt pavement is reused.

Volume 11, Issue 02 Published by, www.ijert.org 99

Special Issue - 2023 International Journal of Engineering Research & Technology (IJERT)

ISSN: 2278-0181

ICART - 2023 Conference Proceedings

At large construction sites, asphalt pavements will be

pulverized on site and mixed into a granular or stabilized base Stockpile Aggregates

using self-propelled grinders. The process of heating-in-place

and cooling-in-place provides continuous progress towards the

rail, including cutting deep into the pavement to increase Properties Of Aggregate To Meet

adhesive strength, mixing new recycled materials with Rap Aggregates

aggregates, binders and/or useful products such as softeners or

regenerators and place and compact the resulting mixture in one

pass. Rap Binder Virgin Binder

Yuetan Ma, S.M.ASCE, 2023 studied the mobility of

mobile and immobilized RAP binders, showing that fixed RAP Combine Asphalt

binders can enhance asphalt-aggregate interaction and increase

the overall asphalt content, together with increasing the strength

of 100% recycled asphalt. Shenghua Wu, M. ASCE, 2022 Opt For Highest Percentage Rap That

scholarly analyzed the utilization of RAP at low temperatures Satiate Aggregate And Asphalt Requirement

with 100% coldmix and rejuvenator. The results provides that

rutting resistance and dampness resistance were good. Mansour

Solaimanian and Xuan Chen, 2021 investigated the degree of

blending. The research was unique and innovative volumetric Perform Mix Design

mix design estimated that relatively 75% lingering RAP binder

cooperated with the virgin binder and contributed to the final

mix. Amal Abdelazia; Eyad Masad, 2021 inquested the Flow Chart of First Stage

procedure of extraordinary volumes of RAP in asphalt

pavements and exhibited the effect of the efficiency of

recycling agents in enlightening blending and sinking stiffness

and aging susceptibility. Ramya Sri Mullapudi, 2020 studied

the healing properties of bituminous mixes by means of RAP Laboratory Mix Design

and emanated with the result that with increasing the proportion

of RAP in the mix can increase the fatigue life of mix.

Plant Trial

Common RAP Enactment In Pavements

The special effects of RAP have been appraised by many Testing Gradation With Tolerance & Fixing Tph Value

researchers, research societies and engineering establishments,

some of the discoveries are offered here in this division. The Extraction

valuation of missions based on binder properties, structural

analysis, serviceability and mix by the Louisiana Department Temperature Check Up

of Transportation and Development in the United States. The Field Trial

research specifies an assuasive presentation as compared to the

use of ceremonious materials, about 20 to 50% of RAP was

used on these projects. Innumerable of projects are Transportation, Spreading & Laying

accomplished by means of RAP with proportions ranging

between 8% to 79% were appraised by the Washington State Rolling

Department of Transportation and established that out of 16

projects, the principal two preliminary projects performed well

at the time of assessment. The remaining were completed at Temperature Check Up

about 2.5 years before the study, the results indicated a

promising result. However, the results indicated that pavement

with RAP showed more longitudinal cracking distresses. A Mix Test Requirements

study by Jorisa et al (2019), using 30% RAP and measured

indicated that pavement roughness was low-slung, no rutting

Core Cutting In Rolled Surface Within 24 Hrs

noticed and viscosity was upper than that of control asphalt mix.

Flow Chart of Second stage

II. OBJECTIVES

To evaluate the final Mix design of DBM with RAP percentage

and minimum binder content which is lesser than least content.

III. METHODOLOGY

Volume 11, Issue 02 Published by, www.ijert.org 100

Special Issue - 2023 International Journal of Engineering Research & Technology (IJERT)

ISSN: 2278-0181

ICART - 2023 Conference Proceedings

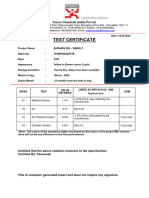

JOB MIX FORMULA

The job mix formula has to approved before the work

heretofore to start. So, below mentioning reports have to be

submit with the job mix formula.

Source and location of all materials.

Asphalt content, type and percentage by weight of total mix.

Aggregate (coarse and fine), filler proportions by weight of Fig No: 2 RAP Gradation

total aggregate mix.

Physical Properties of Virgin aggregates

Design mix definite percentage for aggregates.

The Aggregates from crusher located at Theodical, Ranni were

Gradation of aggregates and filler. tested for physical properties in the laboratory located at

Test reports of weight of each fraction of aggregates and binder. Perumthuruthy. The test Results are summarized as detailed

below:

Reports of tests taken for physical properties of the aggregates

heretofore in the work. Table No: 1 Physical properties of Virgin aggregates

REQUIR

Test results for measurement of mixture such as maximum EMENT

gravity (Gmm) of loose mixture, density of compacted sample TEST TEST

NAME OF TEST AS PER

METHOD RESULTS

for various binders, voids in mineral aggregates (VMA), air MORT&

voids in compressed mixtures (Va), Void filled in bitumen H

(VFB). Aggregate Impact Value IS:2386 21.97 Max:27

Part-4 %

Marshall Stability, stability and flow reports.

Flakiness & Elongation IS:2386 Max:35

Mixing and compacted temperature. 22.94

Index Part-1 %

Marshall Design curves plotted for different binder standards

showing stability, flow, velocity, volume, VMA, and VFB. Coating and stripping of IS:6241 98% Max:95

Bitumen aggregate %

MATERIAL PROPERTIES mixture

3.2.1 RAP properties Max:5%

Cleanliness for 3mm Passing

For any mix designing, one should know the asphalt binder Down Aggregate IS:2386

0.54 0.075

content and gradation as well as physical properties for Part-1

mm

blending charts used to choice the applicable grade of virgin or Sieve

freshly added asphalt binder. IS 2386 Max 35

Loss Angeles 22.2

Part-4 %

RAP binder content and aggregate gradation

AASHTO Min:80

Water Sensitivity 93.6

There are two main methods for determining the RAP binder 283 %

content: the electrical extraction method (following the IS:2720

Plasticity Index NP Max:4%

procedure in AASHTO T 308) and heavy extraction (AASHTO Part-5

T 164). The extract was then put to the test. The RAP binder

content is determined by solvent extraction using a solvent such

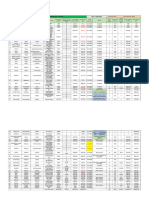

as petroleum (AASHTO T 164 or ASTM D-2172). Table No: 2 Average Individual Hot Bin Gradation For

Average Binder Content is 2.80%. DBM (Rap)

RAP Gradation IS

Sieve 32-19 19-10 10-4 4mm RAP

This facilitates the determination of aggregate grain size, which Filler

(mm) mm mm mm down material

is the most important characteristic of coarse or fine aggregates

that dominate the maintenance of hot asphalt mixes. A study by 37.5 100 100 100 100 100 100

Roberts et al. (1996) discussed that stability, durability, rigidity, 26.5 100 100 100 100 100 100

workability, fatigue and permeability are exaggerated by

gradation in hot mix asphalt mixture. ASTM C136 and 19.00 35.81 100 100 100 100 100

AASHTO T27 are standard gradation references and sieve 13.20 2.31 55.68 100 98 100 98.1

analysis for coarse and fine aggregates. RAP mix performs

4.75 0 15.22 42.2 54 100 54.3

better than other products in cleaning and RAP processes due

to poor performance in hot asphalt products. The types of 2.36 0 1.06 32.3 82.2 100 29.9

materials and aggregates used in RAP production determine the

0.300 0 0 1.2 35.3 100 9.3

size of the aggregates obtained by grinding.

0.075 0 0 0 9.8 100 2.7

Volume 11, Issue 02 Published by, www.ijert.org 101

Special Issue - 2023 International Journal of Engineering Research & Technology (IJERT)

ISSN: 2278-0181

ICART - 2023 Conference Proceedings

Properties of Bitumen Filler (Cement) B5

The Bitumen Grade of VG-30 brought from BPCL used for RAP R1

carrying out the laboratory design mix. The specific gravity of

Bitumen is 1.05 and the other properties like penetration,

softening point, specific gravity are also accordance with the

under quality requirement as per is 73-2013 indicated below:

Table No: 3 Bitumen Test Results

TEST TEST REQUIREME

NAME OF TEST METHO RESU NT AS PER

D LTS IS:73

Specific Gravity at IS:1202-

1.05 Minimum 0.99

25 ⁰C 1978

Fig No: 3 Trial & Error method for fixing blending

Penetration at 25⁰ C IS:1203-

49 Minimum 35 proportions

,mm 1978

IS:1205- Size of aggregates Mix proportion (%)

Softening point, ⁰C 51 Minimum 50

1978

32-19 mm 24

IS:1208-

Ductility in CM 90 Minimum 25 19-10 mm 13

1978

10-4 mm 15

Viscosity(Absolute), IS:1208-

3490 2400-3600

Poise 1978 4 mm DOWN 26

CEMENT 2

MIX DESIGN RAP 20

Mix design starts with individual gradation of virgin materials Job Mix Formula on Asphalt Mixtures with 20% Reclaimed

available at stockpiles. Desired mix design is Dense Graded Asphalt Pavement (RAP) Dense Graded Bituminous Macadam

Bituminous Macadam (DGBM) which is well compacted,

densely graded ready mix asphalt mix to create a good For recycled materials, defined as the percentage of the total

pavement substrate. The Dense Bituminous Macadam consists weight, the amount of raw bitumen should be added to the test

of proportioned mixture of Coarse aggregate, Fine aggregates, mix. Using an aggregate blend of 20% RAP aggregate and 80%

Bitumen VG-30 and Recycled Asphalt Pavement (RAP) of new aggregate, trial mixes of different asphalt content

material to meet the requirements of mix gradation, Stability, (varying in 0.5% increment) are prepared according to standard

Flow, Density and Voids analysis. The Laboratory Marshall method. The binder content of normal DBM is 4.5%

determination of "Job Mix Formula" for Dense Graded but in this project, content is reduced to 4.25% as part of cost

Bituminous Macadam course was carried out for the source of friendly as well as comsumption.

bitumen from BPCL, Aggregates obtained from the Amity Average % of Bitumen content in Rap Material from

Crusher and Rap material of Existing Road from RKI Package Extraction, Rib = 2.8%

IV-Road 7- Rehabilitation and Up-gradation of

Thattararmbalam - Michel junction - Kochalummood - Table No: 4 Percentage proportion of Bitumen and

Mangankuzhy - Pandalam Road (Length 18.657 Km) in Aggregates

Alappuzha District.

Asphalt Content, BP 4.25

Proposed Aggregates for Mix Design

Total Aggregate Pa (%) 95.75

Source of Aggregates: Amity Crusher Plant Located at Ranni Virgin Aggregate%=(Pa*80/100) 76.60

Theodical. The Selected Aggregates for Dense Graded

Bituminous Macadam Design are Crushed Stone Aggregate Rap Aggregate Ra %=(Pa*20/100) 19.15

and Size as Follows.

Hot Bin No B1 32 - 19 mm Rap Material after adjusting for bitumen, % =

19.71

(Ra+((20*Rib)/100))

Hot Bin No B2 19 - 10 mm New Bitumen Content (%) = (BP-

3.69

((20*Rib)/100))

Hot Bin No B3 10 - 4 m

DBM Grade-2 with Rap Mix (%) 100

Hot Bin No B4 4 mm DOWN

Volume 11, Issue 02 Published by, www.ijert.org 102

Special Issue - 2023 International Journal of Engineering Research & Technology (IJERT)

ISSN: 2278-0181

ICART - 2023 Conference Proceedings

PREPARATION OF MIX Table No: 5 Mix requirements of DBM

The Dense Graded Bituminous Macadam (DGBM) mix shall Properties Viscosity Modified bitumen Code

be produced from the hot mix plant, which is located at grade Hot Cold

Perumthuruthy. The plant was calibrated for weight batches of paving climate climate

aggregates, Bitumen was found satisfactory. bitumen

Compaction 75 blows on each face of the specimen

level

Minimum

stability (KN

at 60 0C) AASHTO

9.0 12.0 10.0

T245

Marshall AASHTO

flow (mm) 2-4 2.5 - 4 3.5 - 5

T245

Marshall

quotient MS-2 and

(stability / 2-5 2.5 - 5 ASTM D

Fig No: 4 HM Plant flow) 2041

According to the Australian document: Draft Engineering Road

Note 13 B-Asphalt Mix Design with RAP, the percentage of Air voids %

3-5

RAP in HMA is divided into three levels:

Level - 1: ≤ 10% RAP Voids filled

Level - 2: 11% - 25% RAP with bitumen

Level - 3 : 26% - 40% RAP (VFB)% 65 - 75

Max. 15% RAP for heavy vehicles and polymer surfaces. For

mid-range traffic max. 20% RAP. Max 25% Discount on RAP

Light Vehicle Crash Route, 40-55% for middle and primary Coating of

school grades. aggregate

particle 95 % (Min) IS: 6241

Tensile AASHTO

strength ratio 80 % (Min)

T 283

Voids in

mineral

aggregate Minimum percent voids in mineral aggregate

(VMA) % (VMA) are set out in table 500-12 of MoRTH

Fig No: 5 Laying

Fig No: 7 Extraction Test

Fig No:6 Spreading

Volume 11, Issue 02 Published by, www.ijert.org 103

Special Issue - 2023 International Journal of Engineering Research & Technology (IJERT)

ISSN: 2278-0181

ICART - 2023 Conference Proceedings

Table No:6 Combined Gradation after Mix Preparation

Sample weight gm 15000

Cumul

Weig Cumul

IS ative

ht ative Achieved Specifi

Sieve Weight

Retai Weight Gradatio cation

Retain

ned Retain n Limits

(mm) ed

(gm) ed (%)

(gm)

Fig No: 8 Density Checking 37.50 100.00 100

26.50 100.00 90-100

19.00 2312 2312 15.41 84.59 71-95

13.20 2633 4945 32.97 67.03 56-80

4.75 3261 8206 54.71 45.29 38-54

2.36 1685 9891 65.94 34.06 28-42

0.30 3021 12912 86.08 13.92 7.-21

0.075 1334 14246 94.97 5.03 2.-8

Fig No: 9 Core Cutting

This gradation graph represents the range of material sizes

involved in the mixes and upper and lower limits in the graph

compares the specifications as per Mo&RTH. As per the result

obtained, the percentage of aggregates blended in the design are

in correct proportion and good parameter for well graded

asphalt mix.

Fig No: 10 Marshall Stability Testing

IV. RESULT AND DISCUSSION

Volume 11, Issue 02 Published by, www.ijert.org 104

Special Issue - 2023 International Journal of Engineering Research & Technology (IJERT)

ISSN: 2278-0181

ICART - 2023 Conference Proceedings

Table No: 4.2 Results of DBM Mix with RAP @ OBC

Marshall The air voids in aggregates is the air void in between the body

Parameters skeletons twisted by coarse aggregates, the asphalt binder, fine

@ aggregates and air voids. The air void remunerations a role in

Sl Specification

no:

Description

limits

Optimum determining the aggregate interconnecting between them, and

binder directly reflects on aggregate compaction. To some extent,

Content compaction of pavement decreases the volume of air voids in

4.25% mixture thereby packing of pavement mix. Therefore, the

Bitumen representative of apprehension is the volume of air within the

1 4.5 4.25

Content(OBC) %

compacted package of pavement, which is characteristically

Bulk Density of enumerated as a percentage of air voids in relation to total

2 - 2.456

mix(g/cc) volume and expressed as “percent air voids”. With effect of

Max. Specific Gravity RAP mix in asphalt mixes, have high fine contents can

3 - 2.548

of Mix(GMM) eliminate the air voids to some extent. This phenomena can

Marshall Stability in increase the strength of pavement.

4 9 13.65

KN

V. CONCLUSIONS

5 Marshall Flow in mm 2-4 2.95

Marshall As an upshot, the subsequent conclusions and

6 quotient(stability/flow 2-5 4.6 recommendations are,

Ratio) With increased percentage of RAP in Asphalt mixes can

7 % Air Voids(VIM) 3-5 3.62 increase the environmental pollution and impact the durability

of pavement. So, always considered to be precise with our

Voids in Mineral requirements and limitations for the mix design and

8 Min 12 % 12.77

Aggregates(VMA) specifications. The balanced mix design procedure is mostly

Voids Filled With based on determining OBC, specified density, rutting and

9 65-75 % 71.67 fatigue criteria.

Bitumen(VFB)

Usage of rejuvenators initiated to proliferatiing the moisture

10 Water Sensitivity Min 80 % 94.5 resistance, cracking resistance nevertheless can impact the

rutting resistance of recycled mixture, and hence here the mix

design is free from rejuvenators. In many places, availability of

This is result obtained after the field trial mix laid with paver at

these rejuvenators is also not convenient and compactable.

site for compaction study as well as blending nature of mix.

Entry into the RAP area indicates continued use of the product

With good texture of mix, without any segregation and bleeding

of the mix while avoiding the use of virgin natural aggregates

the mix is laid at high temperature specified in Mo&RTH. The

and therefore requiring less energy and handling. This method

quality tests results are given above. The results showing that

reduces transportation costs, affects less traffic, takes less time,

with 20% RAP with DBM mix design gives a good mixture of

but requires the use of bulky machinery. The Eco friendly

Asphalt mix at minimum binder content which is economical

resources consumption can increase green technology use of

as well as environmental friendly.

materials, increases the life of ecosystem. According to the

results obtained, RAP can be used as a non-binding material in

The procedure of higher proportion of RAP in mixtures can

all areas except acidic areas (eg pH ≤ 4). These acidic areas

ultimately increases the virgin binder content because the finer

include, but are not limited to, mines containing sulfur-

materials will consume more binders than other coarse

containing minerals and landfills where organic matter

materials. With comparative amount of RAP with asphalt mixes

decomposes to create an acidic environment.

and minimum binder content can results required to meet the

Reuse of a resource such as aggregates of RAP lessens the

parameters needed for the pavement design. Hence, it will

depletion of non-renewable natural resources and low

increase the durability and compaction of pavement. Bleeding

consumption of natural resources. Limited RAP usage can

phenomena in pavements occurs during high temperatures due

increase life of pavement and reduce land fill consumption. The

to the overuse of binder content. The RAP binder content and

use of RAP reduces the need for new fuel in the asphalt process.

virgin binder in required minimum amounts can eliminate this

Recycled asphalt is 100% recyclable and renewable so it has a

phenomena.

very long life. It reduces other waste in the landfill. Sidewalks

Research on the distribution of recycled material, showing that

and other RAP are made from a combination of recycled

the perfect mix of old and virgin is wrong in every case. There

materials, including glass, rubber, metal and cement.

are some combinations of these adhesives depending on the

involvement temperature and some other factors like age and

TECHNICAL REFERENCES

viscosity of the original bonding agent, percentage of RAP

modified, type of mix, selection of plant, timing of mixing

1. MORT&H 5th Revision

engines. Older and unused binders may be found in recycled

2. IRC 111:2009

materials in separate stages. The degree of mixing of the two

3. MS-2

mixtures will depend on the temperature, the viscosity of the

4. IS 73:2013

adhesive, and the biochemical composition of the material.

More budgeting and cost-effective installation with minimal

details..

Volume 11, Issue 02 Published by, www.ijert.org 105

Special Issue - 2023 International Journal of Engineering Research & Technology (IJERT)

ISSN: 2278-0181

ICART - 2023 Conference Proceedings

References

1. AASHTO, 1996. Standard Test Method for the Quantitative

Extraction and Recovery of Asphalt Binder from Hot Mix

Asphalt (HMA).

2. AASHTO, 2002. Standard Practice for Mixture Conditioning

of Hot Mix Asphalt (HMA).

3. AASHTO, 2007. Standard Method of Test for Penetration of

Bituminous Materials.

4. Amal Abdelazia, Eyad Masad, Amy Epps Martin, Edith

Arambula Mercado, Multiscale Characterization of Aging and

Rejuvenation in Asphalt Binder Blends with High RAP

Contents, Journal of Materials in Civil Engineering, Volume 33

Issue 10 - October 2021.

5. Behnam Ghorbani; Ehsan Yaghoubi; Arul Arulrajah; and

Sam Fragomeni, Long –Term Performance Analysis of

Demolition Waste Blends in Pavement Bases Using

Experimental and Machine Learning Techniques, International

Journal of Geomechanics, Volume 23 Issue 6- March 2023.

6. Huanan Yu ; Ming Yang; Guoping Qian, Gradation

Segregation Characteristics and its Impact on Performance of

Asphalt Mixture, Journal of Materials in Civil Engineering

Volume 33 Issue 3 - March 2021.

7. Hesham A.Ali; Louay Mohammad, Ph.D; Mojtaba

Mohammadafzali, Ph.D; Farshad Haddadi, Investigating the

Effect of Degree of Blending on Performance of High RAP

Content Mixtures, Journal of Materials in Civil Engineering

Volume 33 Issue 4 - April 2021.

8. Mansour Solaimanian and Xuan Chen, Determine the Degree

of Blending between RAP and Virgin Binder Using the

Superpave Volumetric Mixture Design, International Airfield

and Highway Pavements Conference 2021.

9. Mohammed Alsalihi, S.M. ASCE, and Ahmed Faheem Ph.D,

Compaction and performance of Warm Mix Asphalt with High

Reclaimed Asphalt Pavement, Journal of Materials in Civil

Engineering Volume 32 Issue 4 - April 2022.

10. Ramya Sri Mullapudi; Satya Lakshmi Aparna Noojilla and

Kusam Sudhakar Reddy, Fatigue and Healing characteristics of

RAP Mixtures, Journal of Materials in Civil Engineering

Volume 32 Issue 12 - December 2022.

11. Reza Soltanabadi, Ph.D; Kiachehr Behfarnia, Evaluation of

Mechanical properties of Concrete Containing Recycled

concrete Aggregate and Recycled Asphalt Pavement, Journal of

Materials in Civil Engineering Volume 34 Issue 12 - December

2022.

12. Shenghua Wu, M.ASCE; Omar Tahri, A.M. ASCE; Colton

Spell A.M.ASCE and Luke Montalvo A.M.ASCE; Case Study

on Forensic Evaluation of Field Performance of 100%

Reclaimed Asphalt Pavement Cold Mix with Rejuvenator in a

Low-Volume Road, Journal of Transportation Engineering

Part:B Pavements, Volume 148 Issue 3- September 2022.

13.Shuai Yu; Ping Li; Zhidong; and Shihui Shen, Virgin Binder

Determination for High RAP Content Mixture Design, Journal

of Materials in Civil Engineering Volume 33 Issue 6 - June

2022.

Volume 11, Issue 02 Published by, www.ijert.org 106

Special Issue - 2023 International Journal of Engineering Research & Technology (IJERT)

ISSN: 2278-0181

ICART - 2023 Conference Proceedings

Volume 11, Issue 02 Published by, www.ijert.org 107

You might also like

- APPROVED BUDGET FOR CONSTRUCTION OF DIVERSION ROADDocument48 pagesAPPROVED BUDGET FOR CONSTRUCTION OF DIVERSION ROADamroussyNo ratings yet

- Testing Application Standard No 112-95 PDFDocument12 pagesTesting Application Standard No 112-95 PDFAlvin BadzNo ratings yet

- Fireproofing SpecificationDocument48 pagesFireproofing SpecificationEsteban Castellano100% (12)

- WIRTGEN Foamed BitumenDocument32 pagesWIRTGEN Foamed BitumenLuis Jorge Nahle Ortiz100% (1)

- IS 1200 Method of Measurement Standard for Construction MaterialsDocument11 pagesIS 1200 Method of Measurement Standard for Construction MaterialsShantanu DuttaNo ratings yet

- Pit & QuarryDocument132 pagesPit & Quarrybeto pagoadaNo ratings yet

- BS 1881 Part 124Document33 pagesBS 1881 Part 124Malaz Abdul Jalil71% (7)

- DocDocument27 pagesDocNana BarimaNo ratings yet

- JETIR1901809Document5 pagesJETIR1901809Nirman rodNo ratings yet

- Micro-Surfacing Mixtures With Reclaimed Asphalt PavementDocument11 pagesMicro-Surfacing Mixtures With Reclaimed Asphalt PavementEva SmithNo ratings yet

- Minor ProjectDocument30 pagesMinor ProjectSanjayChauhanNo ratings yet

- RAP Utilization in WMMDocument8 pagesRAP Utilization in WMMAmanulla KhanNo ratings yet

- Icid-2018 Te 201Document4 pagesIcid-2018 Te 201vara prasadNo ratings yet

- Evaluating The Effects of Using Reclaimed Asphalt Pavement and Recycled Concrete Aggregate On The Behavior of Hot Mix AsphaltsDocument11 pagesEvaluating The Effects of Using Reclaimed Asphalt Pavement and Recycled Concrete Aggregate On The Behavior of Hot Mix AsphaltsKaren EstradaNo ratings yet

- 8.18.meghnaijaerv13n7spl 35Document6 pages8.18.meghnaijaerv13n7spl 35Man Bdr. MagarNo ratings yet

- Content ServerDocument15 pagesContent Servercinthya tesen bravoNo ratings yet

- Performance of Warm Mix Asphalt with RAPDocument8 pagesPerformance of Warm Mix Asphalt with RAPShahbaz ButtNo ratings yet

- 1 s2.0 S0950061820333419 MainDocument10 pages1 s2.0 S0950061820333419 MainZaid Al SaffarNo ratings yet

- Performance of Recycled Asphalt Mixtures Formulated With Modified BitumenDocument9 pagesPerformance of Recycled Asphalt Mixtures Formulated With Modified BitumenPhearüm PotNo ratings yet

- Recycling: Performance Assessment of Reclaimed Asphalt Pavement (RAP) in Road Surface MixturesDocument17 pagesRecycling: Performance Assessment of Reclaimed Asphalt Pavement (RAP) in Road Surface MixturesCristián JiménezNo ratings yet

- Evaluation On The Mechanical Performance of Recycled Asphalt MixturesDocument10 pagesEvaluation On The Mechanical Performance of Recycled Asphalt MixturesJulian CamachoNo ratings yet

- Gireesh Kumar 2020 IOP Conf. Ser. Mater. Sci. Eng. 1006 012041Document7 pagesGireesh Kumar 2020 IOP Conf. Ser. Mater. Sci. Eng. 1006 012041Mallesh MaranurNo ratings yet

- Effect On Pavement Performance of A Subbase Layer Composed by Natural Aggregate and RAPDocument10 pagesEffect On Pavement Performance of A Subbase Layer Composed by Natural Aggregate and RAPHawa KadiriNo ratings yet

- Investigation On Performances of Asphalt Mixtures Made With Reclaimed Asphalt Pavement: Effects of Interaction Between Virgin and RAP BitumenDocument11 pagesInvestigation On Performances of Asphalt Mixtures Made With Reclaimed Asphalt Pavement: Effects of Interaction Between Virgin and RAP BitumenVidhi VyasNo ratings yet

- UntitledDocument16 pagesUntitledsuneet kuma meenaNo ratings yet

- Experimental Study On The Use of Rejuvenators and Plastomeric PolymersDocument8 pagesExperimental Study On The Use of Rejuvenators and Plastomeric Polymersh.afsharipor89No ratings yet

- Characterizationof Recycled Asphalt Pavement RAPfor Usein Flexible PavementDocument14 pagesCharacterizationof Recycled Asphalt Pavement RAPfor Usein Flexible Pavementmohd waseemNo ratings yet

- Irjet V6i11331Document5 pagesIrjet V6i11331094-STEVEN EDWARD WINDARTONo ratings yet

- Ijciet 07 05 041 PDFDocument11 pagesIjciet 07 05 041 PDFThushara V T ce18d004No ratings yet

- A Laboratory and Filed Evaluation of Cold Recycled Mixture For Base Layerentirely Made With Reclaimed Asphalt PavementDocument8 pagesA Laboratory and Filed Evaluation of Cold Recycled Mixture For Base Layerentirely Made With Reclaimed Asphalt PavementharNo ratings yet

- 7 Comparative Evaluation For The Effect of Particles Size ofDocument14 pages7 Comparative Evaluation For The Effect of Particles Size ofkomalNo ratings yet

- Polymers 14 04736Document24 pagesPolymers 14 04736MedNo ratings yet

- Accelerated Testing Shows Recycled Road Structure with RAP Performs SatisfactorilyDocument16 pagesAccelerated Testing Shows Recycled Road Structure with RAP Performs SatisfactorilyZeyad F SaadNo ratings yet

- Content ServerDocument16 pagesContent Servercinthya tesen bravoNo ratings yet

- chamod paperDocument5 pageschamod paperThiranka AriyarathnaNo ratings yet

- Construction and Building Materials: Muhammad ArshadDocument14 pagesConstruction and Building Materials: Muhammad Arshadchristian ricaldiNo ratings yet

- Use of Reclaimed Asphalt Pavement in Bituminous Road: February 2018Document8 pagesUse of Reclaimed Asphalt Pavement in Bituminous Road: February 2018komalNo ratings yet

- Performance Evaluation of Environmentally Sustainable Waste Polythene Fiber Reinforced Bituminous Mix For RoadsDocument3 pagesPerformance Evaluation of Environmentally Sustainable Waste Polythene Fiber Reinforced Bituminous Mix For RoadsEditor IJTSRDNo ratings yet

- Construction and Building MaterialsDocument12 pagesConstruction and Building MaterialsApoorva AgarwalNo ratings yet

- IJSDR180402Document6 pagesIJSDR180402Legesse AbrehamNo ratings yet

- Construction and Building Materials: Xunhao Ding, Luchuan Chen, Tao Ma, Haixia Ma, Linhao Gu, Tian Chen, Yuan MaDocument6 pagesConstruction and Building Materials: Xunhao Ding, Luchuan Chen, Tao Ma, Haixia Ma, Linhao Gu, Tian Chen, Yuan MaCamila GómezNo ratings yet

- Utilization of Higher Percentages of RAP For Improved Mixture Performance by Adopting The Process of FractionationDocument18 pagesUtilization of Higher Percentages of RAP For Improved Mixture Performance by Adopting The Process of Fractionationvishnu RNo ratings yet

- Utilizing Reclaimed Asphalt Pavement (RAP) Materials in New Pavements - A ReviewDocument7 pagesUtilizing Reclaimed Asphalt Pavement (RAP) Materials in New Pavements - A Reviewanonymousdi3noNo ratings yet

- Sustainable Applications of Asphalt Mixes With Reclaimed Asphalt Pavement (RAP) Materials: Innovative and New Building BrickDocument11 pagesSustainable Applications of Asphalt Mixes With Reclaimed Asphalt Pavement (RAP) Materials: Innovative and New Building BrickPl TorrNo ratings yet

- Crude Palm OilDocument15 pagesCrude Palm OilDoris AsmaniNo ratings yet

- AY 2020-21 - DR VVR - Rochishnu MTPDocument9 pagesAY 2020-21 - DR VVR - Rochishnu MTPramayya77No ratings yet

- Laboratory investigations on the utilization of RCA in asphalt mixturesDocument12 pagesLaboratory investigations on the utilization of RCA in asphalt mixturesMohammad Asad FirdausNo ratings yet

- Experimental Study of Recycled Asphalt Mixtures With High Percentages of Reclaimed Asphalt Pavement (RAP)Document9 pagesExperimental Study of Recycled Asphalt Mixtures With High Percentages of Reclaimed Asphalt Pavement (RAP)ANKIT SHARMANo ratings yet

- Applsci 11 05226 v2Document16 pagesApplsci 11 05226 v2villaganasjayveeNo ratings yet

- IJRET - 110213031 - Published Paper PDFDocument7 pagesIJRET - 110213031 - Published Paper PDFAyyanna HabalNo ratings yet

- RAP Usage Study for Sustainable Road ConstructionDocument10 pagesRAP Usage Study for Sustainable Road ConstructionBeerappa RamakrishnaNo ratings yet

- Enieb 2021 J. Phys. Conf. Ser. 1973 012242Document17 pagesEnieb 2021 J. Phys. Conf. Ser. 1973 012242Ahmed S. EltwatiNo ratings yet

- Laboratory Investigation of RAP For Various Layers of Flexible and Concrete PavementDocument15 pagesLaboratory Investigation of RAP For Various Layers of Flexible and Concrete PavementAbinash Chandra PalNo ratings yet

- Aeron 2022 IOP Conf. Ser. Mater. Sci. Eng. 1248 012099Document11 pagesAeron 2022 IOP Conf. Ser. Mater. Sci. Eng. 1248 012099Lokesh KNo ratings yet

- Performance Evaluation of Microsurfacing Mixture Cointaining RAPDocument15 pagesPerformance Evaluation of Microsurfacing Mixture Cointaining RAPCristian OJNo ratings yet

- Construction of Water Absorbing Pavements by UsingDocument3 pagesConstruction of Water Absorbing Pavements by UsingAmmulu 123No ratings yet

- 10 1016@j Conbuildmat 2020 119891Document10 pages10 1016@j Conbuildmat 2020 119891Zaid Al SaffarNo ratings yet

- Effect of Chemical Warm Mix Additive OnDocument21 pagesEffect of Chemical Warm Mix Additive OnMILON KUMAR HORENo ratings yet

- Asphalt RecyclibilityDocument8 pagesAsphalt RecyclibilityRAJAT MURJANINo ratings yet

- George 2019Document12 pagesGeorge 2019B RAMUNo ratings yet

- Utilization of alternative aggregates for roller compacted concreteDocument19 pagesUtilization of alternative aggregates for roller compacted concreteRidwanNo ratings yet

- 1 s2.0 S0950061821016263 MainDocument13 pages1 s2.0 S0950061821016263 MainKarlvon TerghaziNo ratings yet

- Towards-very-high-RAP-content-asphalt-mixes-_2021_Journal-of-Traffic-and-TraDocument14 pagesTowards-very-high-RAP-content-asphalt-mixes-_2021_Journal-of-Traffic-and-TraRidwanNo ratings yet

- Eltwati 2021 J. Phys. Conf. Ser. 1973 012241Document10 pagesEltwati 2021 J. Phys. Conf. Ser. 1973 012241Ahmed S. EltwatiNo ratings yet

- Formulating PCC Mixtures with RAP AggregatesDocument13 pagesFormulating PCC Mixtures with RAP AggregatesSahnoune Ben sahnouneNo ratings yet

- A Laboratory Investigation On Dense Bituminous Macadam Containing Different Fractions of Coars and Fine RAPDocument12 pagesA Laboratory Investigation On Dense Bituminous Macadam Containing Different Fractions of Coars and Fine RAPRobel TeweldeNo ratings yet

- Use of Rejuvenators in Reclaimed Asphalt Pavement and Aged BitumenDocument28 pagesUse of Rejuvenators in Reclaimed Asphalt Pavement and Aged BitumenVinu T KumarNo ratings yet

- Advances in Materials Science for Environmental and Energy Technologies VIFrom EverandAdvances in Materials Science for Environmental and Energy Technologies VITatsuki OhjiNo ratings yet

- PANAKAJ ResumeDocument2 pagesPANAKAJ Resumebineetmishra1990No ratings yet

- 04.01.24 MCW Profile -382+510 (1)Document1 page04.01.24 MCW Profile -382+510 (1)bineetmishra1990No ratings yet

- RHEOCURE RBDocument2 pagesRHEOCURE RBbineetmishra1990No ratings yet

- RTPL BIS - 23-28Document1 pageRTPL BIS - 23-28bineetmishra1990No ratings yet

- 13-04-2024 Red Soil DPRDocument2 pages13-04-2024 Red Soil DPRbineetmishra1990No ratings yet

- Auramix 500 848577BDocument1 pageAuramix 500 848577Bbineetmishra1990No ratings yet

- 19-03-2024 Red Soil DPR (1)Document2 pages19-03-2024 Red Soil DPR (1)bineetmishra1990No ratings yet

- 19-03-2024 Red Soil DPR (1)Document2 pages19-03-2024 Red Soil DPR (1)bineetmishra1990No ratings yet

- 13-04-2024 Red Soil DPRDocument2 pages13-04-2024 Red Soil DPRbineetmishra1990No ratings yet

- 28-03-2024 Red soil DPR (1)Document2 pages28-03-2024 Red soil DPR (1)bineetmishra1990No ratings yet

- 26-03-2024 Red Soil DPR (1)Document2 pages26-03-2024 Red Soil DPR (1)bineetmishra1990No ratings yet

- Absolute Viscosity of BitumenDocument1 pageAbsolute Viscosity of Bitumenbineetmishra1990No ratings yet

- 02-04-2024 Red Soil DPR (1)Document2 pages02-04-2024 Red Soil DPR (1)bineetmishra1990No ratings yet

- 26-03-2024 Red Soil DPR (1)Document2 pages26-03-2024 Red Soil DPR (1)bineetmishra1990No ratings yet

- 28-03-2024 Red soil DPR (1)Document2 pages28-03-2024 Red soil DPR (1)bineetmishra1990No ratings yet

- Ori 2400957Document1 pageOri 2400957bineetmishra1990No ratings yet

- Week No.05-28Days Updated - 1707204787769Document1 pageWeek No.05-28Days Updated - 1707204787769bineetmishra1990No ratings yet

- 28-03-2024 Red soil DPR (1)Document2 pages28-03-2024 Red soil DPR (1)bineetmishra1990No ratings yet

- MSDS of RHEOCURE RBDocument3 pagesMSDS of RHEOCURE RBbineetmishra1990No ratings yet

- WMM RfiDocument1 pageWMM Rfibineetmishra1990No ratings yet

- Specific Gravity of Fine AggregateDocument1 pageSpecific Gravity of Fine Aggregatemanish upadhyayNo ratings yet

- Week No.05-28Days Updated - 1707204787769Document1 pageWeek No.05-28Days Updated - 1707204787769bineetmishra1990No ratings yet

- Week No.05-28Days Updated - 1707204787769Document1 pageWeek No.05-28Days Updated - 1707204787769bineetmishra1990No ratings yet

- Week No.05-28Days Updated - 1707204787769Document1 pageWeek No.05-28Days Updated - 1707204787769bineetmishra1990No ratings yet

- Key Performance Indicator For Measuring and Improving Quality of Construction ProjectsDocument7 pagesKey Performance Indicator For Measuring and Improving Quality of Construction ProjectsGokul KrishnanNo ratings yet

- 4 Strengths of Recycled Aggregate Concrete Made Using Field-Demolished Concrete As AggregateDocument9 pages4 Strengths of Recycled Aggregate Concrete Made Using Field-Demolished Concrete As Aggregateget100% (2)

- Pangasinan State University Department of Architecture Research on Masonry and ConcreteDocument21 pagesPangasinan State University Department of Architecture Research on Masonry and ConcreteNowella MendozaNo ratings yet

- Manish Kumar Singh-2014 PDFDocument5 pagesManish Kumar Singh-2014 PDFsuguna0% (1)

- Pow 17J00012Document41 pagesPow 17J00012amroussyNo ratings yet

- Recycled Concrete AggregatesDocument17 pagesRecycled Concrete AggregatesAnkit SinghaiNo ratings yet

- Input DataDocument1 pageInput DataForood Torabian IsfahaniNo ratings yet

- Green CementDocument15 pagesGreen Cementsaranya rNo ratings yet

- Building 2020-2021 Final - M SAND-FinalDocument95 pagesBuilding 2020-2021 Final - M SAND-FinalkamalgkNo ratings yet

- Artigo Mehta - Aitcin - HPCDocument9 pagesArtigo Mehta - Aitcin - HPCMarciano TonattoNo ratings yet

- KONVERTORSKA TROSKA Steel - Slag - BOS PDFDocument1 pageKONVERTORSKA TROSKA Steel - Slag - BOS PDFAmelZahirovićNo ratings yet

- Glass Wastes As Coarse Aggregate in ConcreteDocument5 pagesGlass Wastes As Coarse Aggregate in Concretepuspa2305No ratings yet

- Concrete SpecificationDocument28 pagesConcrete SpecificationAsad Jamil JawandaNo ratings yet

- 4-Loss Angeles Abrasion TestDocument4 pages4-Loss Angeles Abrasion Testisraksiam311No ratings yet

- Activity Part 2Document9 pagesActivity Part 2Mark Edison ReganitNo ratings yet

- Engineering: Pervious ConcreteDocument6 pagesEngineering: Pervious ConcreteDusmanta Kumar BeheraNo ratings yet

- Technical SpecificationsDocument23 pagesTechnical SpecificationsZaid KhanNo ratings yet

- Abstract Municipal RoadsDocument8 pagesAbstract Municipal RoadsYhanilyn MasacoteNo ratings yet

- Aggregate Abrasion Value Test ReportDocument12 pagesAggregate Abrasion Value Test ReportOlowoniwa MarvellousNo ratings yet

- Characterization of Bayongan Capayas and Malinao Dam SedimentsDocument64 pagesCharacterization of Bayongan Capayas and Malinao Dam SedimentsAriel EspinosaNo ratings yet

- ICC (Final Requirement)Document4 pagesICC (Final Requirement)Nicole TorresNo ratings yet

- Retaining Walls and Road PavementDocument14 pagesRetaining Walls and Road PavementPraise SamuelNo ratings yet