Professional Documents

Culture Documents

Vedanta Aluminium Plant Ltd. Quality Assurance Plan For Pot Line Maintenance Job (Rev-00)

Uploaded by

Sasanka SekharOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Vedanta Aluminium Plant Ltd. Quality Assurance Plan For Pot Line Maintenance Job (Rev-00)

Uploaded by

Sasanka SekharCopyright:

Available Formats

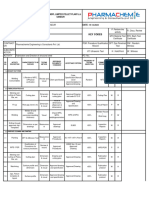

VEDANTA ALUMINIUM PLANT LTD.

QUALITY ASSURANCE PLAN FOR POT LINE MAINTENANCE JOB (REV- 00)

Records Agency

Sl. No Item Category Type / Method of check Extent of Reference Acceptance Format of record to be Remarks

check document norms furnishe CONTRACTOR TPIA CLIENT

d

A B C D E F G H I J K

1

Surface dressing

Specifications/ Specifications/ Site

a) Checking for layout Major Dimensional check 100% Joint Records Yes P RW RW

Methodology Methodology Verification/Review

Breaking with

proper side slopes, Specifications/ Specifications/ Site

b) Major Visual Checks 100% Joint Records No P RW RW

Shoring Removing Methodology Methodology Verification/Review

of Water, etc.

Checking location,

Specifications/ Specifications/ Site

c) firm bed, levels, free Major Visual Checks 100% -- yes P RW RW

Methodology Methodology Verification/Review

from slush

Disposal/proper

stacking of breaking Specifications/ Specifications/ Site

d) Minor Visual Checks 60% -- No P RW RW

materials in Methodology Methodology Verification/Review

demarked area.

2 Base preparation

Base should be

compacted as per

Specifications/ As per IS 2720 Joint Records (Compaction Site

a) SPDD 95% (Lab Major Core Cutter Method 100% Yes External Agency RW RW

Methodology Part 7 & Part 29 Resgister) Verification/Review

test report for MDD

& OMC)

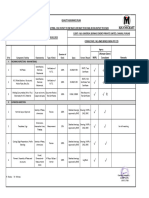

3 Boulder soiling

Filling &

compcation reqd. by

plate compactor or Specifications/ Specifications/ Joint Records (Compaction Site

a) Critical Visual Checks 100% Yes P RW RW

any type of Methodology Methodology Resgister) Verification/Review

mechanical

compactors

Check for pre & Specifications/ Specifications/ Site

b) Critical Auto Level 100% Joint Records Yes P RW RW

final level Methodology Methodology Verification/Review

Test report of

Lab Test report with Sp.

Boulders (size of Specifications/ As per MORT&H Site

c) Critical Lab Test 100% Gravity, crushing value & Yes External Agency RW RW

boulders not more Methodology Section 400 Verification/Review

Impact Value

than 300 mm)

4 PCC M 15 (1:2:4) Grade of Concrete

Free fall Height should

Lab Test report with proper

be mainted at site for

Pouring of Concrete MTC reqd . (NC, setting time

Specifications/ As per IS 456, IS avoiding any kind of

a) thickness 100 mm Critical Visual Check 100% of Cement, Compressive Yes External Agency RW RW

Methodology 4031 & IS 10262 Seggregation. Reports

(compacted) Strength, Soundness &

are submitted before

Fineness Test of Cement)

working at site.

Site

Checking of

Specifications/ As per IS Verification/Review &

b) vibrating by neddle / Critical Visual Check 80% -- No P RW RW

Methodology 2505/2506 minimum 14 days

plate Vibrator

Curing reqd.

5 RCC M25/M30 & M35 Grade of Concrete

Lab Test report with proper

MTC reqd . (NC, setting time

of Cement, Compressive

Strength, Soundness &

Fineness Test of Cement) &

Free fall Height should

detailed Mix Design report

be mainted at site for

Pouring of Concrete with trial mix. Also Agg.

Specifications/ As per IS 456, IS avoiding any kind of

a) 250 mm thickness Critical Visual Check 100% Mechanical properties Yes External Agency RW RW

Methodology 4031 & IS 10262 Seggregation. Reports

(compacted) (Crushing value, Impact Value

are submitted before

with Combined Flakieness &

working at site.

Elongation index, Gradation

of 10 mm,20mm & Sand Zone

II) must be mentioned in

Desin Mix report as per IS

383 - 2016 wise

Checking vibrating Specifications/ As per IS Site

b) Critical Visual Check 100% -- No P RW RW

needle/plate vibrator Methodology 2505/2506 Verification/Review

Cube sampling & Specifications/ As per IS 456 & Compressive strength Site

c) Critical Visual Check 100% Yes External Agency RW RW

testing Methodology IS 516 checking at 7 & 28 days basis. Verification/Review

6 Reinforcement (Fe-500 D)

Checking of Lab Test report with proper

Specifications/ As per IS 1786 & Site

a) reinforcement (Fe- Critical Visual Check 100% MTC (BendTest, Rebend Yes External Agency RW RW

Methodology IS 2502 Verification/Review

500D) & BBS Test, Carbon Content & UTS)

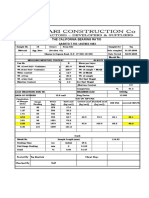

7 Curing (water Ponding/Sparying with Hessian cloths)

Minimum 28 days

reqd. unless any other

Curing is essential

Specifications/ special cases curing

a) for 28 days Major Visual Check 100% As per IS 456 Joint Records Yes P RW RW

Methodology must be maintain 14

minimum

days as per decide the

EIC of VAL

8 Brick Work

Brick work where As per IS 2212 for

ever reqd. as per site Brick work & IS

Joint Records (All relavant

basis, with Cement Specifications/ 12894, IS 1077 & Site

a) Critical Visual Check 100% test reports of Bricks reqd. as Yes External Agency RW RW

Mortar (1:4), Inside Methodology IS 3495 for Verification/Review

per IS code 3495)

& outside plastering specification &

with same ratio testing of Bricks

Curing of Brick Specifications/ Specifications/ Minimum 07 days (as

b) Critical Visual Check 100% - Yes P RW RW

work Methodology Methodology per IS 2212) reqd.

9 Back filling in foundation and trenches

Filling and

compaction in layers

As per IS 2720 Joint Records (Compaction Layer thickness as per

a) not more than Critical Visual Checks 100% Specifications Yes External Agency W/R RM

Part 7 & Part 29 Resgister) site requirements

300mm & CBR

value not less than 5

Filling &

Compaction of sand Site

b) Critical Visual Checks 100% Specifications Specifications Joint Records Yes P RM R

& aggregate around Verification/Review

the PVC pipe

Site

c) Check for final level Critical Visual Checks 100% Drawings Drawings Joint Records Yes P RM R

Verification/Review

10 IPS (minimum thickness of 60 mm to 75 mm)

Existing IPS Specifications/ Specifications/ Site

a) Critical Visual Checks 100% Joint Records Yes P RM R

breaking Methodology Methodology Verification/Review

Cleaning surface

Specifications/ Specifications/ Site

b) with water & blower Critical Visual Checks 100% - No P RM RM

Methodology Methodology Verification/Review

machine

Applying bonding Specifications/ Specifications/ Site

c) Critical Visual Checks 100% - Yes P RM R

agent Methodology Methodology Verification/Review

Pouring M-50 grade

As per Design mix (certified Specifications/ Specifications/ Site

d) concrete as per Critical 100% Joint Records Yes

by NABL Labs) Methodology Methodology Verification/Review

drawing

Minimum 28 days

reqd. unless any other

Curing is essential

Specifications/ special cases curing

e) for 28 days Major Visual Check 100% As per IS 456 Joint Records Yes P RW RW

Methodology must be maintain 14

minimum

days as per decide the

EIC of VAL

Checking of

Compressive Specifications/ As per IS 456 & Compressive strength Site

f) Major Laboratory Test 100% Yes External Agency RW RW

Strength of taken Methodology IS 516 checking at 7 & 28 days basis. Verification/Review

cube

Legends: P PERFORM

R RANDOM

W WITNESS

RW RANDOM WITNESS

RM RANDOM MONITORING

TPIA THIRD PARTY INSPECTION AGENCY

SPDD STANDARD PROCTOR DRY DENSITY

You might also like

- Amc QapDocument8 pagesAmc QapSasanka SekharNo ratings yet

- QAP For Bitumen JobDocument2 pagesQAP For Bitumen JobSasanka SekharNo ratings yet

- Quality Assurance PlanDocument4 pagesQuality Assurance PlanSasanka SekharNo ratings yet

- Vedanta Aluminium Plant Ltd. Quality Assurance Plan For Buildinng Construction Job (Rev-00)Document4 pagesVedanta Aluminium Plant Ltd. Quality Assurance Plan For Buildinng Construction Job (Rev-00)Sasanka SekharNo ratings yet

- Client: Nlcil Subject: Quality Assurance Plan For Side Drain (Rev-00)Document2 pagesClient: Nlcil Subject: Quality Assurance Plan For Side Drain (Rev-00)Sasanka SekharNo ratings yet

- PMO Office Building JobDocument3 pagesPMO Office Building JobSasanka SekharNo ratings yet

- Road Bitumen Work QAP No 02Document2 pagesRoad Bitumen Work QAP No 02Sasanka SekharNo ratings yet

- Proposed QAP For Adani Internal CTR JobDocument2 pagesProposed QAP For Adani Internal CTR JobSasanka SekharNo ratings yet

- Magnetic Level Gauge: DOC NO. QR/QC/F/14Document1 pageMagnetic Level Gauge: DOC NO. QR/QC/F/14sunshine dreamNo ratings yet

- Quality Assurance Plan - CivilDocument11 pagesQuality Assurance Plan - CivilDeviPrasadNathNo ratings yet

- Qap - NRLDocument1 pageQap - NRLStructures ProductionNo ratings yet

- SR No Activity Characteristics To Be Checked Quantum of Check Inspection / SignDocument1 pageSR No Activity Characteristics To Be Checked Quantum of Check Inspection / SignAlpine ProjectsNo ratings yet

- J213-AHC-EMD-MS-C-01-R0 ITP For Excavation and BackfillingDocument2 pagesJ213-AHC-EMD-MS-C-01-R0 ITP For Excavation and BackfillingKafeel AbbasNo ratings yet

- QAP1Document2 pagesQAP1akshaymehra2354No ratings yet

- J-2441 Ci-Sg DRG-C2 Rev.0Document2 pagesJ-2441 Ci-Sg DRG-C2 Rev.0BINOY DASNo ratings yet

- Shop Inspection Test and PlanDocument1 pageShop Inspection Test and PlanJeffrey HallNo ratings yet

- QAP N2 Generator & N2 VesselDocument2 pagesQAP N2 Generator & N2 VesselVijay - Spantech EngineersNo ratings yet

- Steel TankDocument4 pagesSteel TankRanu JanuarNo ratings yet

- Ecc Mech Sharq 22 016 Rev 01Document6 pagesEcc Mech Sharq 22 016 Rev 01Muthu SaravananNo ratings yet

- Vishwabalaa Engineering Private Limited, Thirumazhisai, Chennai - 600124Document2 pagesVishwabalaa Engineering Private Limited, Thirumazhisai, Chennai - 600124sanil50% (2)

- Road Work For GSB, WMM & Bitumen Job QAPDocument2 pagesRoad Work For GSB, WMM & Bitumen Job QAPSasanka SekharNo ratings yet

- WHRS QapDocument31 pagesWHRS Qapmd shahabuddeenNo ratings yet

- Saudi Aramco Typical Inspection Plan: Soil Improvement (Vibro Replacement & Vibro Compaction) 31-Nov-2018 CivilDocument10 pagesSaudi Aramco Typical Inspection Plan: Soil Improvement (Vibro Replacement & Vibro Compaction) 31-Nov-2018 CivilTariqMalik0% (1)

- SATIP-A-000-01 Rev 7Document1 pageSATIP-A-000-01 Rev 7Zuhaib KhanNo ratings yet

- Satip-A-000-01 Rev 8 Soil Improvement (Vibro Replacement - Vibro Compaction FinalDocument2 pagesSatip-A-000-01 Rev 8 Soil Improvement (Vibro Replacement - Vibro Compaction FinalTarek YehiaNo ratings yet

- Satip A 000 01Document10 pagesSatip A 000 01Akansha SharmaNo ratings yet

- Quality Assurance Protocol: Raw MaterialDocument2 pagesQuality Assurance Protocol: Raw MaterialShah Newaz KabirNo ratings yet

- Field Inspection &test PlanDocument4 pagesField Inspection &test PlanSofda ImelaNo ratings yet

- Satip A 000 01 Rev 7 (Final)Document2 pagesSatip A 000 01 Rev 7 (Final)faisalNo ratings yet

- Format For Information For Inspection of Ongoing /completed WordDocument13 pagesFormat For Information For Inspection of Ongoing /completed WordARTI PALEKARNo ratings yet

- Inspection Testing Repair FormDocument1 pageInspection Testing Repair FormVajid MadathilNo ratings yet

- QAP FormatsDocument13 pagesQAP Formatsavvari sureshNo ratings yet

- Indicative Inspection Test Plan For Mechanical WorksDocument8 pagesIndicative Inspection Test Plan For Mechanical WorksSukalyan BasuNo ratings yet

- Inspection MatrixDocument2 pagesInspection MatrixFabian BellNo ratings yet

- Qap - Structural Mechanical FabricationDocument8 pagesQap - Structural Mechanical Fabricationbharathi_pmNo ratings yet

- Inspection and Test Paln For LSAWDocument4 pagesInspection and Test Paln For LSAWkbpatel123No ratings yet

- Field Quality PlanDocument2 pagesField Quality PlanPurnima VermaNo ratings yet

- Vibrating Screen QAP-17Document8 pagesVibrating Screen QAP-17Mohammad AdilNo ratings yet

- Saudi Aramco Typical Inspection Plan: Soil Improvement (Vibro Replacement & Vibro Compaction) 30-Oct-17 CivilDocument10 pagesSaudi Aramco Typical Inspection Plan: Soil Improvement (Vibro Replacement & Vibro Compaction) 30-Oct-17 CivilJagdishNo ratings yet

- QAP General For Ref.Document2 pagesQAP General For Ref.AMIT SHAHNo ratings yet

- Qap ReactorDocument6 pagesQap ReactorPARMAR MUKESHNo ratings yet

- 8 Field Quality PlanDocument18 pages8 Field Quality PlanRamaKrishna ANo ratings yet

- QAP - Invest Energy Group (10.0 TPH)Document3 pagesQAP - Invest Energy Group (10.0 TPH)chanjunkaiNo ratings yet

- ITP For Sprinkler and Spary SystemDocument6 pagesITP For Sprinkler and Spary System梁奇龙100% (2)

- Attach-2 ITP For Building WaterDocument29 pagesAttach-2 ITP For Building WaterSukalyan BasuNo ratings yet

- Qap-324-03 01 2024Document3 pagesQap-324-03 01 2024qcNo ratings yet

- SFDSF PDFDocument3 pagesSFDSF PDFbishnu sahNo ratings yet

- Inspection Test Plan PV Nozzle Modification/AlterationDocument4 pagesInspection Test Plan PV Nozzle Modification/AlterationMohd Shafuaaz KassimNo ratings yet

- Field Quality Plan: KSK Power Company LimitedDocument6 pagesField Quality Plan: KSK Power Company LimitedGayatree RathoreNo ratings yet

- QAPDocument6 pagesQAPRahul ChandanNo ratings yet

- L - FA - Niel T. - WK 06 - Power Cable On Reel Continuity and IR Test.Document1 pageL - FA - Niel T. - WK 06 - Power Cable On Reel Continuity and IR Test.NIEL TANEDONo ratings yet

- ITP-MEP-003 Water Supply Connection To Landlord NetworkDocument1 pageITP-MEP-003 Water Supply Connection To Landlord Networkjagathmukundhan00No ratings yet

- FQP For AAC Block WorkDocument1 pageFQP For AAC Block WorkHimanshu ChaudharyNo ratings yet

- Bhagod Navinagri Naykiwad Road.: ValsadDocument12 pagesBhagod Navinagri Naykiwad Road.: ValsadARTI PALEKARNo ratings yet

- Controlplan enDocument1 pageControlplan enRaquel MungcalNo ratings yet

- Pressure Vessel ITP Rev 0Document10 pagesPressure Vessel ITP Rev 0SLC HosurNo ratings yet

- Incoming Material ChecklistDocument1 pageIncoming Material ChecklistPrathvi Raj SinghNo ratings yet

- ITP - ErectionDocument6 pagesITP - ErectionvijayNo ratings yet

- Flow Measurement: By Square-Edged Orifice Plate Using Corner TappingsFrom EverandFlow Measurement: By Square-Edged Orifice Plate Using Corner TappingsRating: 5 out of 5 stars5/5 (1)

- Work Schedule Banjari Development JobDocument7 pagesWork Schedule Banjari Development JobSasanka SekharNo ratings yet

- Work Schedule BANJARI DEVELOPMENT JOBDocument4 pagesWork Schedule BANJARI DEVELOPMENT JOBSasanka SekharNo ratings yet

- NDT PPT ShubhamDocument34 pagesNDT PPT ShubhamSasanka SekharNo ratings yet

- Highway Rating CircularDocument18 pagesHighway Rating CircularSasanka SekharNo ratings yet

- The California Bearing Ratio: Aashto T 193 / Astm D 1883Document13 pagesThe California Bearing Ratio: Aashto T 193 / Astm D 1883mdalgamouniNo ratings yet

- Rate CardsDocument32 pagesRate CardsSasanka SekharNo ratings yet

- Approximate BOQ For Limestone Crusher & Load CentreDocument8 pagesApproximate BOQ For Limestone Crusher & Load CentreSasanka SekharNo ratings yet

- Nov 18Document1 pageNov 18Sasanka SekharNo ratings yet

- BBS of Foundation (Material Gate)Document2 pagesBBS of Foundation (Material Gate)Sasanka SekharNo ratings yet

- BBS of Material GateDocument2 pagesBBS of Material GateSasanka SekharNo ratings yet

- BBS For Kerb Wall Material GateDocument9 pagesBBS For Kerb Wall Material GateSasanka SekharNo ratings yet

- Moisture Correction SheetDocument4 pagesMoisture Correction SheetSasanka SekharNo ratings yet

- 10C... For PF WithdrwalDocument2 pages10C... For PF WithdrwalSasanka SekharNo ratings yet

- BBS of Kerb WallDocument3 pagesBBS of Kerb WallSasanka SekharNo ratings yet

- Astm C 1074-04Document9 pagesAstm C 1074-04Vasco SorteNo ratings yet

- California Bearing Ratio Test Data Sheets & GraphsDocument4 pagesCalifornia Bearing Ratio Test Data Sheets & GraphsSaad JuventinoNo ratings yet

- Coal Truck Parking Exit Road Bbs2Document7 pagesCoal Truck Parking Exit Road Bbs2Sasanka SekharNo ratings yet

- Mix Design For PQCDocument20 pagesMix Design For PQCSasanka SekharNo ratings yet

- AnalysisOfDesignOfAFlexiblePavementWithCementedBaseAndGranularSubbase (187 192)Document6 pagesAnalysisOfDesignOfAFlexiblePavementWithCementedBaseAndGranularSubbase (187 192)Sasanka SekharNo ratings yet

- Weight Bridge ENTRY RampDocument12 pagesWeight Bridge ENTRY RampSasanka SekharNo ratings yet

- Sale Deed of Dipannita Construction Legal (Dilip Show)Document20 pagesSale Deed of Dipannita Construction Legal (Dilip Show)Sasanka SekharNo ratings yet

- Weight Bridge Exit RampDocument12 pagesWeight Bridge Exit RampSasanka SekharNo ratings yet

- Client Letter No 09Document2 pagesClient Letter No 09Sasanka SekharNo ratings yet

- Adani LetterDocument2 pagesAdani LetterSasanka SekharNo ratings yet

- Coal Entry Road Bbs1Document9 pagesCoal Entry Road Bbs1Sasanka SekharNo ratings yet

- B.B.S (300 Dia Hume Pipe)Document2 pagesB.B.S (300 Dia Hume Pipe)Sasanka SekharNo ratings yet

- Client Letter No 06Document2 pagesClient Letter No 06Sasanka SekharNo ratings yet

- Tendernotice 1Document9 pagesTendernotice 1Sasanka SekharNo ratings yet

- Patches That Work - Utility Cuts and Pavements: The T-SectionDocument4 pagesPatches That Work - Utility Cuts and Pavements: The T-SectionAnilduth BaldanNo ratings yet

- Life Cycle Assessment For Soil Stabilization Dosages A Study For Del Chaco ParaguyDocument10 pagesLife Cycle Assessment For Soil Stabilization Dosages A Study For Del Chaco ParaguyLolitaNo ratings yet

- Review On Treatment Methods of Soft Soil SubgradeDocument3 pagesReview On Treatment Methods of Soft Soil SubgradeEmilio ArroyoNo ratings yet

- Flyash ReviewDocument10 pagesFlyash Reviewhsajesh2011No ratings yet

- COMPACTION OF SOILS (Loiza)Document2 pagesCOMPACTION OF SOILS (Loiza)Loiza Joi MulanoNo ratings yet

- Compaction EquipmentsDocument31 pagesCompaction EquipmentsPandi AnNo ratings yet

- Cast Stone Masonry - Common Problems and Solutions by M. Farmer PEDocument10 pagesCast Stone Masonry - Common Problems and Solutions by M. Farmer PEHeilbrunnNo ratings yet

- Densimetro Electrico H-4114C - EDGDocument2 pagesDensimetro Electrico H-4114C - EDGgiampaoloNo ratings yet

- Concrete Mix DesignDocument19 pagesConcrete Mix DesignObaidurRahamanNo ratings yet

- Is 9214 1979 Indian Standard Methods of Determination of Modules of Subgrade Reaction K Value of Soils in Field PDFDocument23 pagesIs 9214 1979 Indian Standard Methods of Determination of Modules of Subgrade Reaction K Value of Soils in Field PDFshubham jainNo ratings yet

- Quality Control Process, Documentation, Policies and IssuancesDocument77 pagesQuality Control Process, Documentation, Policies and IssuancesKryle Dayle VillanuevaNo ratings yet

- 8015 0151 SC03 00 000 CN MS 00003 - 01Document33 pages8015 0151 SC03 00 000 CN MS 00003 - 01Mohanad GanemNo ratings yet

- M2Document100 pagesM2Mena G PillaiNo ratings yet

- 28-4ECEM18 EarthworksDocument5 pages28-4ECEM18 EarthworksAbdul BasithNo ratings yet

- Experiment No. 5 Unit Weight and Voids of Coarse AggregatesDocument7 pagesExperiment No. 5 Unit Weight and Voids of Coarse AggregatesMeriann May Sacayan DivinagraciaNo ratings yet

- 6) Proctor Compaction TestDocument7 pages6) Proctor Compaction TestPn Ekanayaka100% (4)

- Tugasan SubgradeDocument31 pagesTugasan SubgradeSyihabuddin YusoffNo ratings yet

- GET Draft ISSB Construction Manual (Final - 2)Document35 pagesGET Draft ISSB Construction Manual (Final - 2)Crystal Waddell-Gardiner100% (1)

- Biju Patnaik University of Technology, Orissa: Civil EngineeringDocument10 pagesBiju Patnaik University of Technology, Orissa: Civil Engineeringjshankar84No ratings yet

- Book - 1986 - Estimating Embankment Damage Due To Flood OvertoppingDocument220 pagesBook - 1986 - Estimating Embankment Damage Due To Flood Overtoppingbabak60100% (1)

- Method Statement Structural Excavation BackfillingDocument16 pagesMethod Statement Structural Excavation Backfillingthelast_aienNo ratings yet

- Ground Improvement Techniques by Grouting A.I.T.ChikmagalurDocument20 pagesGround Improvement Techniques by Grouting A.I.T.ChikmagalurJayakumarNo ratings yet

- Characterization of Hydrated Lime Stabilized Brown Kaolin Clay IJERTV2IS111095Document6 pagesCharacterization of Hydrated Lime Stabilized Brown Kaolin Clay IJERTV2IS111095Saddam HusienNo ratings yet

- Types of Soil Tests For Building ConstructionDocument7 pagesTypes of Soil Tests For Building Constructionlewis100% (1)

- Usama WorkDocument378 pagesUsama Workshahid aliNo ratings yet

- Installation Guideline - UG PipingDocument11 pagesInstallation Guideline - UG PipingPRADEEP S PILLAI100% (1)

- Sustainable Resources For Tackling Low Cost Housing Challenges in The Benin MetropolisDocument8 pagesSustainable Resources For Tackling Low Cost Housing Challenges in The Benin MetropolisInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Effectiveness of Stone Dust As An Expansive Soil StabilizerDocument8 pagesEffectiveness of Stone Dust As An Expansive Soil StabilizerArham SheikhNo ratings yet

- BW211 40 Specs PDFDocument4 pagesBW211 40 Specs PDFarfa ujiantoNo ratings yet

- Field Engineer Manual Soils EngineeringDocument408 pagesField Engineer Manual Soils EngineeringWayne Duval100% (1)