Professional Documents

Culture Documents

Safety Syllabus

Uploaded by

RIDDHI MANIKTALIA 20BCE2045Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Safety Syllabus

Uploaded by

RIDDHI MANIKTALIA 20BCE2045Copyright:

Available Formats

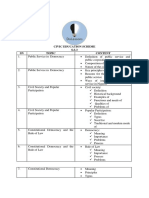

CHE1007 SAFETY AND HAZARD ANALYSIS L T P J C

2 0 0 4 3

Pre-requisite NIL Syllabus version

1.1

Course Objectives:

1. Critically understand the importance of safety in process industries

2. Assess and identify the potential hazards in process industries

3. Identify and evaluate the causes of accident in a chemical industry

Course Outcomes :

1. Distinguish the typical sources of risk in a process plant by hazard identification and

examination of case studies

2. Assess the severity of the consequences of incidents

3. Identify a Hazard and Operability Study (HAZOP)

4. Explain the legal framework controlling process plant safety in industries

5. Demonstrate how the root cause of incidents can be investigated and analysed and the

various human and technical aspects of such causes

6. Identify hazard and conduct safety audit.

Student Learning Outcomes 6,9,10

(SLO):

Module:1 Introduction to Safety in Chemical process Industries 5 Hours

Need for Development of Safety Consciousness in Chemical Industries - Hazard, Risk, Danger,

Accident; Promotion of industrial safety, extreme operating conditions, toxic chemicals - safe

handling; Psychological attitude towards safety.

Module:2 Safety Programs in Industries 5 Hours

Importance of Safety Programs in industries; Elements of Safety Program; Effective Realization;

Economic and Social Benefits from Safety Program; Effective Communication Training at

various levels of Production and Operation. Accidents identification and prevention.

Module:3 Potential Hazards in Chemical Process Industries 4 Hours

Chemical and Physical job Safety Analysis; High pressure and Temperature Operation;

Dangerous and Toxic Chemicals; Routes of entry, Effects of toxicants and its elimination. Toxic

release and dispersion models. Radio Active materials; Safe Handling and Operation of materials

and Machinery; periodic inspection and replacement.

Module:4 Risk assessment 4 hours

Quantitative risk assessment - rapid and comprehensive risk analysis; Risk due to Radiation,

explosion due to over pressure, plant layout Personnel Safety and Protective Equipment;

Occupational health and safety.

Module:5 Hazard Identification 4 hours

Introduction to Hazard identification - Overall risk and hazard analysis - Emergency planning -

On site & off site emergency planning - Risk management - ISO 14000 - Safety audits

Checklist - What if analysis Vulnerability models - Event tree analysis - Fault tree analysis.

Module:6 HAZOP 4 hours

HAZOP study - case studies-pumping system-reactor-mass transfer system. Hazard

Identification and Assessment; Involvement of Human factors and Errors- Hazard

Quantifications-disaster management; Occupational and Industrial Health Hazards; Safety

Systems.

Module:7 Case studies 2 hours

Dominos effect, Worst case scenario, Fire, Accidents, Chemical release, Explosion, Petroleum,

Commercial, Natural disasters, EMS models case studies

Module:8 Contemporary Issues 2 hours

Total Lecture hours: 30 hours

Text Books

1. Ericson C.A., Hazard Analysis Techniques for System Safety, 2nd ed., Wiley, USA, 2015.

2. Gupta A., Industrial Safety and Environment, 2nd ed., Laxmi Publications, India, 2015

Reference Books

1. Hyatt, N., Guidelines for process hazards analysis, hazards identification & risk analysis, 1 st

ed., CRC Press, USA, 2003.

Mode of evaluation: Continuous Assessment Test, Quizzes, Assignments, Final Assessment Test

Recommended by Board of Studies 15.04.2019

Approved by Academic Council 55 Date 13.06.2019

You might also like

- Lesson 1-2 CH4101 Intro, Inherent SafetyDocument47 pagesLesson 1-2 CH4101 Intro, Inherent SafetyTang Voon HaoNo ratings yet

- 2160504Document3 pages2160504Shilen PatelNo ratings yet

- Risk Analysis and Control for Industrial Processes - Gas, Oil and Chemicals: A System Perspective for Assessing and Avoiding Low-Probability, High-Consequence EventsFrom EverandRisk Analysis and Control for Industrial Processes - Gas, Oil and Chemicals: A System Perspective for Assessing and Avoiding Low-Probability, High-Consequence EventsNo ratings yet

- S205 SA633 Industrial HygieneDocument2 pagesS205 SA633 Industrial Hygienegerson floresNo ratings yet

- Dynamic Risk Analysis in the Chemical and Petroleum Industry: Evolution and Interaction with Parallel Disciplines in the Perspective of Industrial ApplicationFrom EverandDynamic Risk Analysis in the Chemical and Petroleum Industry: Evolution and Interaction with Parallel Disciplines in the Perspective of Industrial ApplicationNicola PaltrinieriRating: 5 out of 5 stars5/5 (1)

- 1 Introduction To Maintenance and Process SafetyDocument28 pages1 Introduction To Maintenance and Process SafetyMuhammad SalmanNo ratings yet

- Safety in the Chemical Laboratory and Industry: A Practical GuideFrom EverandSafety in the Chemical Laboratory and Industry: A Practical GuideNo ratings yet

- Final Print 23113 QUALITY CONTROL IN OCCUPATION SAFTY, HEALTH AND ENVRIOMENTDocument125 pagesFinal Print 23113 QUALITY CONTROL IN OCCUPATION SAFTY, HEALTH AND ENVRIOMENTARIF100% (1)

- Practical 01 (Emergency and Laboratory Safety)Document28 pagesPractical 01 (Emergency and Laboratory Safety)Mr. GoogleNo ratings yet

- Chemical & Process Safety ManagementDocument190 pagesChemical & Process Safety ManagementAdilsha shaikhNo ratings yet

- Ientification of Electrical HazardsDocument6 pagesIentification of Electrical HazardsCecília MeloNo ratings yet

- PreliminariesDocument5 pagesPreliminariesrome reyesNo ratings yet

- Paper-4Document179 pagesPaper-4RahulNo ratings yet

- System Safety and Risk AssessmentDocument2 pagesSystem Safety and Risk AssessmentSHERAZNo ratings yet

- Hazard Risk Assessment ProcedureDocument6 pagesHazard Risk Assessment ProcedureSatyajit DangeNo ratings yet

- Minor Industrial SafetyDocument13 pagesMinor Industrial Safetyvishnu682004No ratings yet

- Nptel Safety PDFDocument2 pagesNptel Safety PDFSindhu ShijuNo ratings yet

- Industrial Safety Course PlanDocument11 pagesIndustrial Safety Course Planpradeep Y DNo ratings yet

- Unit 1 and 2Document57 pagesUnit 1 and 2AKNo ratings yet

- Paper-6Document126 pagesPaper-6RahulNo ratings yet

- Maharashtra State Board of Vocational Education Examination, Mumbai-51Document5 pagesMaharashtra State Board of Vocational Education Examination, Mumbai-51MithileshNo ratings yet

- Safety and Security Review for the Process Industries: Application of HAZOP, PHA, What-IF and SVA ReviewsFrom EverandSafety and Security Review for the Process Industries: Application of HAZOP, PHA, What-IF and SVA ReviewsRating: 4 out of 5 stars4/5 (1)

- Open Elective: Course OutcomesDocument4 pagesOpen Elective: Course OutcomesPURUSHOTHAMNo ratings yet

- SylDocument2 pagesSylrijintomNo ratings yet

- IntroductionDocument47 pagesIntroductionarpna sjsNo ratings yet

- Annamalai University: P.G.Diploma in Health, Safety & EnvironmentDocument8 pagesAnnamalai University: P.G.Diploma in Health, Safety & EnvironmentKannan Jagan50% (2)

- Hazard and Risk Management - Yadav Pooja.S.Document30 pagesHazard and Risk Management - Yadav Pooja.S.Shivali PatilNo ratings yet

- Course Content PDFDocument2 pagesCourse Content PDFmohitreddyNo ratings yet

- Handbook of Nanosafety: Measurement, Exposure and ToxicologyFrom EverandHandbook of Nanosafety: Measurement, Exposure and ToxicologyUlla VogelRating: 4 out of 5 stars4/5 (1)

- Risk analysis of a chemical industry using ORA procedureDocument17 pagesRisk analysis of a chemical industry using ORA procedureUsama NiaziNo ratings yet

- Basics of Risk Management Article GuideDocument157 pagesBasics of Risk Management Article Guidemohammed minhajNo ratings yet

- Chemical Plant Safety PDFDocument7 pagesChemical Plant Safety PDFwaheed2286No ratings yet

- Introduction To OhsDocument17 pagesIntroduction To OhsKladees WorldNo ratings yet

- ASP Preparation Workshop - 23rd Sep. 2022Document74 pagesASP Preparation Workshop - 23rd Sep. 2022MohamedSaidNo ratings yet

- Oil Gas Offshore Safety Case (Risk Assessment) : August 2016Document44 pagesOil Gas Offshore Safety Case (Risk Assessment) : August 2016Andi SuntoroNo ratings yet

- SHDocument6 pagesSHJustin ChongNo ratings yet

- Nebosh Element - 1 AnswersDocument4 pagesNebosh Element - 1 AnswersSatish KumarNo ratings yet

- Osha HirarcDocument62 pagesOsha HirarcanesseNo ratings yet

- Safety & Environmental ControlDocument120 pagesSafety & Environmental ControlSufian R Ellabbad100% (1)

- Gujarat Technological UniversityDocument2 pagesGujarat Technological UniversityshyamNo ratings yet

- 1 s2.0 S0925753522002570 MainDocument14 pages1 s2.0 S0925753522002570 MainneckitoNo ratings yet

- Element 3 (3.4)Document51 pagesElement 3 (3.4)Arianna KhanNo ratings yet

- Eohsforbos 2016Document24 pagesEohsforbos 2016sairam smartNo ratings yet

- NMISHRAG AppendicesDocument48 pagesNMISHRAG Appendicesapi-3733731No ratings yet

- Basics of Risk Management: An Introductory GuideDocument106 pagesBasics of Risk Management: An Introductory GuideElçin ElçinNo ratings yet

- Domino Effects in the Process Industries: Modelling, Prevention and ManagingFrom EverandDomino Effects in the Process Industries: Modelling, Prevention and ManagingRating: 3 out of 5 stars3/5 (1)

- The Handbook of Safety Engineering: Principles and ApplicationsFrom EverandThe Handbook of Safety Engineering: Principles and ApplicationsRating: 4 out of 5 stars4/5 (1)

- Idse Unit 2Document207 pagesIdse Unit 2farhan AliNo ratings yet

- W1 Intro To PSLPDocument66 pagesW1 Intro To PSLPThivNo ratings yet

- Syllabus PDFDocument1 pageSyllabus PDFfantin amirtharajNo ratings yet

- PE 6801-Risk Assessment and Safety Engineering PDFDocument66 pagesPE 6801-Risk Assessment and Safety Engineering PDFAnonymous U7yp0x100% (2)

- Notes 3Document6 pagesNotes 3moraine.hills3No ratings yet

- Hazard and Risk Analysis Lls 9-22-2011Document34 pagesHazard and Risk Analysis Lls 9-22-2011AlberipaNo ratings yet

- SPE - DescriptionDocument5 pagesSPE - DescriptionJuan VelasquezNo ratings yet

- Guidance On The Safe Operation of Oil Pollution Combating EquipmentDocument47 pagesGuidance On The Safe Operation of Oil Pollution Combating EquipmentNikolay DimovNo ratings yet

- Flashcards 44Document6 pagesFlashcards 44Ajay PatelNo ratings yet

- VIT - School of Computer Science and Engineering (SCOPE)Document1 pageVIT - School of Computer Science and Engineering (SCOPE)RIDDHI MANIKTALIA 20BCE2045No ratings yet

- Paper AnotherDocument1 pagePaper AnotherRIDDHI MANIKTALIA 20BCE2045No ratings yet

- VL2021220501298 DaDocument1 pageVL2021220501298 DaRIDDHI MANIKTALIA 20BCE2045No ratings yet

- Final Assessment Test - November 2018Document2 pagesFinal Assessment Test - November 2018RIDDHI MANIKTALIA 20BCE2045No ratings yet

- Team 4's INNEED App Helps Girls & Those in DistressDocument23 pagesTeam 4's INNEED App Helps Girls & Those in DistressRIDDHI MANIKTALIA 20BCE2045No ratings yet

- Titan Industries LimitedDocument7 pagesTitan Industries Limitedrajeshreepstel777No ratings yet

- Wipro Research PaperDocument14 pagesWipro Research PaperRIDDHI MANIKTALIA 20BCE2045No ratings yet

- Wipro LimitedDocument5 pagesWipro LimitedRIDDHI MANIKTALIA 20BCE2045No ratings yet

- SS3 Civic EducationDocument2 pagesSS3 Civic EducationAyomide Ikuomenisan100% (1)

- Call Fiche - Just 2023 Jtra - enDocument31 pagesCall Fiche - Just 2023 Jtra - enRobothoodNo ratings yet

- Assessment 1 CitizenshipDocument2 pagesAssessment 1 CitizenshipWILJOHN DE LA CRUZNo ratings yet

- Criminal Law 1 NotesDocument7 pagesCriminal Law 1 NotesMaki CabuenaNo ratings yet

- Discussion 5611 W5Document1 pageDiscussion 5611 W5Christian MirandaNo ratings yet

- Civil Rights and Due Process Protections in the Bill of RightsDocument18 pagesCivil Rights and Due Process Protections in the Bill of RightssebNo ratings yet

- ADR Criminal Cases BangladeshDocument18 pagesADR Criminal Cases BangladeshMH MOHSINNo ratings yet

- MELENCIO SAYO v. CHIEF OF POLICE, GR No. L-2128, 1948-05-12Document2 pagesMELENCIO SAYO v. CHIEF OF POLICE, GR No. L-2128, 1948-05-12Bobet AtendidoNo ratings yet

- Module 1 (Student Behavior)Document5 pagesModule 1 (Student Behavior)Nina LimNo ratings yet

- Chemical Process Risk AssessmentDocument26 pagesChemical Process Risk AssessmentAMOL RASTOGI 19BCM0012No ratings yet

- Almeda Vs CADocument2 pagesAlmeda Vs CAJessNo ratings yet

- DM Ce511oe-BitDocument8 pagesDM Ce511oe-BitBalajiNo ratings yet

- Trends_Q2_Module2-DECEMBER-11Document18 pagesTrends_Q2_Module2-DECEMBER-11magnothea2005No ratings yet

- Ohara V Chief Constable of The Royal Ulster ConstabularyDocument14 pagesOhara V Chief Constable of The Royal Ulster ConstabularyCapt. Paul BeswickNo ratings yet

- Petitioner Respondent: Marvin Porteria Y Manebali, The PhilippinesDocument17 pagesPetitioner Respondent: Marvin Porteria Y Manebali, The PhilippinesJakie CruzNo ratings yet

- Chinese Administrative Law and Its ReformDocument3 pagesChinese Administrative Law and Its ReformyesuicoolNo ratings yet

- The Code of Criminal Procedure, 1973: Chapter Wise InterpretationDocument8 pagesThe Code of Criminal Procedure, 1973: Chapter Wise InterpretationAshwanth M.SNo ratings yet

- Formation of A CompanyDocument3 pagesFormation of A CompanyMorttahNo ratings yet

- 07f5c Indias Third Gender - From Recognition To EmancipationDocument11 pages07f5c Indias Third Gender - From Recognition To EmancipationRAHUL HEERADASNo ratings yet

- Booking Report 1-21-22Document4 pagesBooking Report 1-21-22WCTV Digital TeamNo ratings yet

- CIS Client InformationDocument4 pagesCIS Client InformationCamila PereiraNo ratings yet

- CLARIFICATIONS- 3RD IMCC 2021Document7 pagesCLARIFICATIONS- 3RD IMCC 2021Antra AzadNo ratings yet

- Landmark Arbitration Cases: Dubai Courts: Samer Abou SaidDocument64 pagesLandmark Arbitration Cases: Dubai Courts: Samer Abou SaidChakrala Rama SandeepNo ratings yet

- 2020 UP BOC Criminal Law SupplementDocument10 pages2020 UP BOC Criminal Law SupplementAngel TolentinoNo ratings yet

- Agbayani v. Lupa Realty Holding CorporationDocument13 pagesAgbayani v. Lupa Realty Holding CorporationAnonymousNo ratings yet

- SABIC-LDPE-HP0722NDF-REACH Declaration-GlobalDocument2 pagesSABIC-LDPE-HP0722NDF-REACH Declaration-GlobalchinchotarngNo ratings yet

- Mirza Ghani Baig VDocument2 pagesMirza Ghani Baig VrajNo ratings yet

- Disney Motion Re: HammondDocument18 pagesDisney Motion Re: HammondTHROnlineNo ratings yet

- Unclaimed Property for VillanuevaDocument4 pagesUnclaimed Property for VillanuevaAndres VillanuevaNo ratings yet

- Updated and Corrected MOA 23Document4 pagesUpdated and Corrected MOA 23halona nevaNo ratings yet