Professional Documents

Culture Documents

GroutPlant Zameka

Uploaded by

pankaj bansal0 ratings0% found this document useful (0 votes)

10 views4 pagesZ Makina produces a wide range of grout mixing plants with capacities ranging from 5 m3/h to 30 m3/h. The plants can be mounted on open skids or containerized, and include options for manual or fully automatic controls. The mixing units precisely dose ingredients, mix them for a controlled time period, and transfer the slurry to an agitator tank. The control panel is located separately in a comfortable working environment. Z Makina's grout plants are designed for applications such as anchor injection, jet grouting, drilling, concreting, and cavity filling.

Original Description:

Zameka grout umit

Original Title

GroutPlant-Zameka

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentZ Makina produces a wide range of grout mixing plants with capacities ranging from 5 m3/h to 30 m3/h. The plants can be mounted on open skids or containerized, and include options for manual or fully automatic controls. The mixing units precisely dose ingredients, mix them for a controlled time period, and transfer the slurry to an agitator tank. The control panel is located separately in a comfortable working environment. Z Makina's grout plants are designed for applications such as anchor injection, jet grouting, drilling, concreting, and cavity filling.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

10 views4 pagesGroutPlant Zameka

Uploaded by

pankaj bansalZ Makina produces a wide range of grout mixing plants with capacities ranging from 5 m3/h to 30 m3/h. The plants can be mounted on open skids or containerized, and include options for manual or fully automatic controls. The mixing units precisely dose ingredients, mix them for a controlled time period, and transfer the slurry to an agitator tank. The control panel is located separately in a comfortable working environment. Z Makina's grout plants are designed for applications such as anchor injection, jet grouting, drilling, concreting, and cavity filling.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 4

GROUT PLANTS

Z Makina produces a wide variety of mixing units. De-

pending on the customer requirements, the mixing

units can be mounted on open skids or containerized,

and endowed with manual or fully automatic controls.

Z Makina produces compact injection plant units for

colloidal mixing and injection of suspensions for a

range of different applications as well. Combination

of mixing units and grout pumps can be configured as

per special projects. The system can consist of water

tanks, horizontal/vertical silo, conveyor, etc. depen-

ding on the customized solutions on request.

The mixing plants’ automatic operation is equipped with electro-pneumatic system upon load

cells and a PLC that monitors the ingredient dosing, mixing time and slurry transfer to the agi-

tator tank.

The control panel is located in separate with comfortab-

le working conditions based on the climate conditions. The

compressor and the electrical connections mounted in iso-

lated conditions. That equipment can be manufactured for

Zone 0, 1, 2 to follow the ATEX standards for equipment in-

tended for use in areas at risk of explosion.

Z Makina offers a selection of jet grout plants with volumetric

flow rates from 20 to 30 m³/h. Registration of desired num-

ber of mixes and rates of the ingredients for each single mix

enables the continuous production. Mixing occurs in a high

turbulence in primary mixer. At the end of the primary mixing

cycle, the mixture is conveyed to agitator tank then to the

pump. It enables high mixing capacity due to short mixing

time. The control panel is located in separate with comfor-

table working conditions. It is equipped with manual or fully

automatic controls.

Applications:

Anchor injection - Jet grouting - Drilling - Concreting - Cavity filling

Bottom injection - Tunnel applications - Dam injection applications

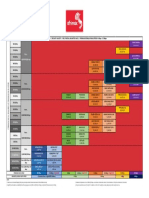

ZM 20 ZM 25 ZM 30

Mixer Capacity m3/h 1400 1750 2000

Agitator Capacity lt 2750 3000 3400

Water Tank Capacity lt 3000 3000 3000

Power kW 40 45 45

Mixing Capacity m/h 20 25 30

Hydraulic Tank lt 200 200 200

Dimensions mm 6000x2400x2600 6000x2400x2600 6000x2400x2600

Weight lt/min 6000 6400 6800

They are especially designed for construc-

tion sides. The mixers/mixing units are ava-

ilable in manual operation, semi-automatic

dosage of mixing components.

Z Makina supplies two types of mini grout

plants as ZM5 and ZM10 with adequate te-

chnology incorporated to maximize equip-

ment efficiency, yet not so much as to com-

promise ease of operation or maintenance.

The concepts of ease of maintenance are

focused in the design of Z Makina grouting

systems.

Possible application areas are:

Anchor, rock injection

Ground stabilization

Geothermal applications

Well building

Sewer renovation

Sealing grouting

Gap sealing

Contact grouting

Pipe roof grouting

Sleeve pile injection

Backfilling

Cavity filling

Special civil engineering

Seal water sealing

Mixer ZM5 ZM10

Mixer Tank Capacity lt 350 500

Agitator Tank Capacity lt 550 700

Mixing Capacity m3/h 5 10

Hydraulic System

Electric Motor kW 7,5/15 11/22

Dimensions mm 2200x1800x2000 2500x1800x2000

Weight kg 2250 2500

Z MAKINA TEKNOLOJISI A.S

S.S. İstanbul Mermerciler Küçük Sanayi Sitesi Yapı Kooperatifi

29. Sokak No: 9 Köseler Mah. 41455 Dilovası, Kocaeli, TÜRKİYE

info@zmakina.com.tr - +90 262 728 11 22

www.zmakina.com.tr

You might also like

- Fire Alarm Sys Nec 760Document10 pagesFire Alarm Sys Nec 760nadeem Uddin100% (1)

- Farm Machinery - Tractors - A Collection of Articles on the Operation, Mechanics and Maintenance of TractorsFrom EverandFarm Machinery - Tractors - A Collection of Articles on the Operation, Mechanics and Maintenance of TractorsNo ratings yet

- Abc of UccDocument28 pagesAbc of UccCount-Daniel John Fogarty100% (4)

- All Code ListsDocument3,292 pagesAll Code ListsshanzNo ratings yet

- Rate Analysis of PQCDocument6 pagesRate Analysis of PQCAmit Singh80% (5)

- 14 Design of Bolted JointsDocument13 pages14 Design of Bolted JointsPRASAD32675% (4)

- JS750 Concrete MixerDocument5 pagesJS750 Concrete MixerErikNo ratings yet

- 49 CFR 195Document3 pages49 CFR 195danigna77No ratings yet

- Jettty DesignDocument14 pagesJettty DesignNnamani ajNo ratings yet

- Mixing Systems For Every TaskDocument12 pagesMixing Systems For Every TaskNandhagopalan K100% (1)

- Artificial Ground Freezing PDFDocument24 pagesArtificial Ground Freezing PDFHannaFouadNo ratings yet

- Mobile Concrete Batching PlantDocument15 pagesMobile Concrete Batching PlantPaul Ticla PuenteNo ratings yet

- SchwingDocument8 pagesSchwingSanjay Baid100% (1)

- Compact Concrete Batching PlantDocument8 pagesCompact Concrete Batching PlantMunaNo ratings yet

- Mills - FLSMidthDocument11 pagesMills - FLSMidththach pha thien100% (1)

- Siva QADocument6 pagesSiva QAsivakanth mNo ratings yet

- Rate Analysis Report - Concrete Block MachineAMEX (Version 1)Document21 pagesRate Analysis Report - Concrete Block MachineAMEX (Version 1)Jayaraman KamarajNo ratings yet

- Iso 21969 2009 en PDFDocument8 pagesIso 21969 2009 en PDFAnonymous P7J7V4No ratings yet

- 30to60 CP30 CP45bro2016Document8 pages30to60 CP30 CP45bro2016Manoj RajNo ratings yet

- Vertical Roller Mills FLSMidthDocument11 pagesVertical Roller Mills FLSMidththach pha thienNo ratings yet

- Job Report WR Series enDocument20 pagesJob Report WR Series enproject listNo ratings yet

- Hot Mix Plant PDFDocument12 pagesHot Mix Plant PDFGautam Rai100% (2)

- 1) Compact Batching Plant CP30Document12 pages1) Compact Batching Plant CP30mohan kamkarNo ratings yet

- W Brochure Cold-Recyclers-Soil-Stabilizers 0316 EN PDFDocument44 pagesW Brochure Cold-Recyclers-Soil-Stabilizers 0316 EN PDFDao Phuc Lam100% (1)

- Assignment - 5 (RMC Plant)Document3 pagesAssignment - 5 (RMC Plant)Umesh HuleNo ratings yet

- CP30-CP45 May2023Document7 pagesCP30-CP45 May2023Amit YearnNo ratings yet

- 30to60 CP30 CP45bro2016Document8 pages30to60 CP30 CP45bro2016Muhammed shanNo ratings yet

- 30to60 CP30 CP45bro2016 PDFDocument8 pages30to60 CP30 CP45bro2016 PDFSukesh Kumar royNo ratings yet

- CP30-CP45 May2022Document8 pagesCP30-CP45 May2022Amit KumarNo ratings yet

- ZOOMLION 12JBH (Sinotruk N7 430 8×4)Document2 pagesZOOMLION 12JBH (Sinotruk N7 430 8×4)Mohammad AsimNo ratings yet

- CP30 CP45bro2013 PDFDocument8 pagesCP30 CP45bro2013 PDFDebasis Ghosh0% (1)

- Zoomlion K8JBW BetoneiraDocument2 pagesZoomlion K8JBW BetoneiraRonaldo FernandesNo ratings yet

- Papl Corp Cat 13-8-08Document35 pagesPapl Corp Cat 13-8-08Satyavan L RoundhalNo ratings yet

- Mobile Batching Plant: CP 18 C3 / CP 18 TM / CP 21Document4 pagesMobile Batching Plant: CP 18 C3 / CP 18 TM / CP 21saimun0% (1)

- Mobile Batching Plant: CP 18 C3 / CP 18 TM / CP 21Document4 pagesMobile Batching Plant: CP 18 C3 / CP 18 TM / CP 21niranjan lakraNo ratings yet

- Products, Services and SolutionsDocument40 pagesProducts, Services and SolutionsMohamad NasserNo ratings yet

- Truck Mixer Series - May - 2022Document10 pagesTruck Mixer Series - May - 2022Rahul SharmaNo ratings yet

- WCP036 ZSpec ZSheetDocument4 pagesWCP036 ZSpec ZSheetSHAILESH PATELNo ratings yet

- Delta Product BulletinDocument3 pagesDelta Product BulletinFikriNo ratings yet

- KWI DAF Minicell BrochureDocument4 pagesKWI DAF Minicell Brochurei.tultaevNo ratings yet

- Planetary Counterflow Mixer - 50HzDocument1 pagePlanetary Counterflow Mixer - 50Hzaagoyle1No ratings yet

- Cat Casseforme UKDocument12 pagesCat Casseforme UKMilan UljarevicNo ratings yet

- Brochure-Industrial Linings Z LTDDocument17 pagesBrochure-Industrial Linings Z LTDRAJNo ratings yet

- Amman Mixing SystemsDocument4 pagesAmman Mixing SystemsVirgil CenariuNo ratings yet

- ARS Hydrojet Services PVT LTD - Brochure - 2018Document4 pagesARS Hydrojet Services PVT LTD - Brochure - 2018R.SathyanarayananNo ratings yet

- Side Dump Loader 625e - SDLDocument2 pagesSide Dump Loader 625e - SDLSriram NambiNo ratings yet

- Bombas PVM Catálogo Técnico PDFDocument86 pagesBombas PVM Catálogo Técnico PDFMarvin Nta DgzNo ratings yet

- Widest Selection of Grouting Equipment in The WorldDocument6 pagesWidest Selection of Grouting Equipment in The Worldjet toledoNo ratings yet

- Robot Atlas MEYCO ME3Document8 pagesRobot Atlas MEYCO ME3Frank Prudencio ObregonNo ratings yet

- CP18 - CP21 - Bro - May - 2022 - 0Document4 pagesCP18 - CP21 - Bro - May - 2022 - 0Smart SankarNo ratings yet

- The Reliable Injection Pump For Extreme Conditions: AbcdefghiDocument4 pagesThe Reliable Injection Pump For Extreme Conditions: AbcdefghimerinofalNo ratings yet

- Sakuragawa - U Series - High Head PumpDocument2 pagesSakuragawa - U Series - High Head PumpDave WallaceNo ratings yet

- Schlosser-Pfeiffer Mischer EnglischDocument8 pagesSchlosser-Pfeiffer Mischer EnglischHESSGROUPNo ratings yet

- Vedpatashala Roads Quotation 23-Jan-2021Document3 pagesVedpatashala Roads Quotation 23-Jan-2021Tarun GuttaNo ratings yet

- AfsdDocument4 pagesAfsdweergfdfNo ratings yet

- Vup GBDocument12 pagesVup GBPatricio RojasNo ratings yet

- Asphalt Plant: Atlasindustries - inDocument10 pagesAsphalt Plant: Atlasindustries - inNisarg SutharNo ratings yet

- Unigrout Flex M - Technical Specification - EnglishDocument8 pagesUnigrout Flex M - Technical Specification - EnglishEmrah MertyürekNo ratings yet

- TR Cat Ramob STD Eng R04 1 4Document44 pagesTR Cat Ramob STD Eng R04 1 4CAT MINING SHOVELNo ratings yet

- TECHMATIK MIESZARKI A4 12 Stron ENDocument12 pagesTECHMATIK MIESZARKI A4 12 Stron ENAna NedeljkovicNo ratings yet

- 2017 CatalogDocument12 pages2017 CatalogJing JingNo ratings yet

- For Building Civil Engineering Works: Hagotech (U) LTDDocument3 pagesFor Building Civil Engineering Works: Hagotech (U) LTDAmpumuza AdrianNo ratings yet

- 2022-08-05 Boq Cbop Mir 500mw Rev2Document9 pages2022-08-05 Boq Cbop Mir 500mw Rev2анастNo ratings yet

- Mag. AgitatorDocument12 pagesMag. AgitatorGanesh.Mahendra100% (1)

- Rate Analysis For Roads Construction: SBP Commercial PVT LTDDocument13 pagesRate Analysis For Roads Construction: SBP Commercial PVT LTDSaurabh Kumar SharmaNo ratings yet

- Enquiry Gantry Crane (R K Control Instruments)Document3 pagesEnquiry Gantry Crane (R K Control Instruments)Jignesh TamkeNo ratings yet

- Агрегаты Насосные и Сварочные ПТМЗ (Eng)Document7 pagesАгрегаты Насосные и Сварочные ПТМЗ (Eng)Анатолий СалюкNo ratings yet

- Revised Estimate - Bhuki KhadiDocument1 pageRevised Estimate - Bhuki KhadiprabhusudhaNo ratings yet

- MEPC 1-Circ 723Document10 pagesMEPC 1-Circ 723Franco MitranoNo ratings yet

- GS-1930 GS-1530 Service Manual: Technical PublicationsDocument137 pagesGS-1930 GS-1530 Service Manual: Technical PublicationshabibullaNo ratings yet

- Brochure Otis Gen360 enDocument32 pagesBrochure Otis Gen360 enshimanshkNo ratings yet

- Comsol Acdc RF 42aDocument71 pagesComsol Acdc RF 42aneomindxNo ratings yet

- Multilateral Drilling and Completions - Applications in Practice D. ThemigDocument12 pagesMultilateral Drilling and Completions - Applications in Practice D. ThemigFaiz TalpurNo ratings yet

- 2.0 DCV-Brochure BV Valves (Pages) R01 PDFDocument12 pages2.0 DCV-Brochure BV Valves (Pages) R01 PDFAliZenatiNo ratings yet

- POLYMATH TutorialChemical Reaction Engineering PDFDocument8 pagesPOLYMATH TutorialChemical Reaction Engineering PDFAfifah SabriNo ratings yet

- Sunil Bhatia ResumeDocument5 pagesSunil Bhatia Resumepravin gamareNo ratings yet

- NS2 Simple Simulation ExampleDocument5 pagesNS2 Simple Simulation ExamplepradeepNo ratings yet

- Checklist of E/OHS Activities For Asbestos Management: Name of Publication DateDocument20 pagesChecklist of E/OHS Activities For Asbestos Management: Name of Publication DateidahssNo ratings yet

- Centrica, Scottish Gas Training AcademyDocument1 pageCentrica, Scottish Gas Training AcademyGary McAlpineNo ratings yet

- Afrimax Pricing Table Feb23 Rel BDocument1 pageAfrimax Pricing Table Feb23 Rel BPhadia ShavaNo ratings yet

- Datasheet 12NA60Document11 pagesDatasheet 12NA60ed pwtNo ratings yet

- Reverse LogisticsDocument18 pagesReverse Logisticsiazeem2401630No ratings yet

- 3 - Pitot-Static Inst, System & ADC - OcrDocument110 pages3 - Pitot-Static Inst, System & ADC - OcrtmhoangvnaNo ratings yet

- Report On The Heritage City ProjectDocument23 pagesReport On The Heritage City ProjectL'express Maurice100% (2)

- Pinhole Camera InformationDocument4 pagesPinhole Camera InformationD'ferti AnggraeniNo ratings yet

- Toyota's JIT Revolution 1Document6 pagesToyota's JIT Revolution 1Shambu PatilNo ratings yet

- Punjab ULBRFPVolume IAttachmentdate 21 Nov 2016Document214 pagesPunjab ULBRFPVolume IAttachmentdate 21 Nov 2016NishantvermaNo ratings yet

- Bus & Cycle Signs & MarkingsDocument5 pagesBus & Cycle Signs & MarkingsDaniel YitbarekNo ratings yet

- U441d - Brake - Rear (Air)Document6 pagesU441d - Brake - Rear (Air)bennieNo ratings yet

- SIL99-2C: Service Information LetterDocument22 pagesSIL99-2C: Service Information LettersandyNo ratings yet