Professional Documents

Culture Documents

LG 140

Uploaded by

ĆerimovićDooOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

LG 140

Uploaded by

ĆerimovićDooCopyright:

Available Formats

Forward and Reversing Vibrating Plate

LG140/160/200

Operation & Maintenance

ILG140EN4, June 2002

Petrol Engine:

Honda GX160

Honda GX200

Diesel Engine:

Hatz 1B20

These instructions apply from:

LG140 PIN (S/N) *31400001* Honda/Hatz

LG160 PIN (S/N) *31600001* Honda/Hatz

LG200 PIN (S/N) *32000001* Honda

LG200 PIN (S/N) *32001123* Hatz

R A L

SE O U

U F N

E E A

R BL S M

TU ILA HI

FU A P T

AV EE

K

The Dynapac LG140/160/200 are compact Forward/Reverse Vibratory Plates with excellent com-

paction data. Speed and compaction depth are regulated steplessly via hydraulic servo control of

the eccentric element. This gives the plate smooth motion and makes it very easy to operate.

All-round plates for compaction work close to piles and concrete bases. Also for floor filling and

foundations as well as backfill in pipe trenches. The LG160 is ideal for compaction on block paving

and patching work. The LG200 is an ideal plate for compacting sand and gravel in cable and pipe

trenches, foundation work, road repairs, etc.

The handle is suspended on special shock absorbers to keep it free from vibrations. A protection

frame with single-point lifting lug is covering all vital parts of the machine. The LG plates are desig-

ned for operation in well ventilated spaces, as all combustion engine machines.

We reserve the right to change specifications without notice.

Printed in Sweden (safety instructions included).

Downloaded from www.Manualslib.com manuals search engine

CONTENTS

Page

Machine plate ................................................................... 3

General ............................................................................. 3

Safety instructions (For all Light products) .................... 4-6

Safety when driving .......................................................... 7

Safety decals, Location/Description ............................. 8, 9

Fuel and lubricants ......................................................... 10

Technical data........................................................... 11, 12

Technical data – Dimensions .......................................... 13

Operation – Honda GX160/GX200 ........................... 14, 15

Operation – Hatz 1B20 ............................................. 16, 17

Operation – All engine types .......................................... 18

Lifting, transportation and towing .................................. 19

Maintenance – service points ................................... 20, 21

Maintenance – Every 10 hours of operation ................... 22

Maintenance – Every 100 hours of operation ................. 23

Maintenance – Every 500 hours of operation ........... 24, 25

WARNING SYMBOLS

WARNING Indicates danger or hazardous

procedure that could result in serious or fatal

personal injury if the warning is ignored.

CAUTION Indicates danger or hazardous proce-

dure that could result in damage to machine or

property if the warning is ignored.

SAFETY INSTRUCTIONS

The safety instructions are included in this

manual and must be studied by the operator.

Always follow the safety rules and keep the CALIFORNIA

manual available for future use.

Proposition 65 Warning

Read through the entire manual before Diesel engine exhaust and some

starting any maintenance operations. of its constituents are known to the

State of California to cause cancer,

birth defects, and other reproductive

harm.

Ensure good ventilation (air extraction) if the

engine is run indoors.

2 LG140/160/200 ILG140EN4

Downloaded from www.Manualslib.com manuals search engine

GENERAL

It is important that the machine is maintained correctly to

ensure proper function. It should be kept clean so that any

leakage, loose bolts and loose connections can be discov-

ered in time.

Make a habit of inspecting the machine every day before

starting up by checking all round it to detect any sign of

leakage or other faults.

SPARE A THOUGHT FOR THE ENVIRONMENT!

Do not let oil, fuel and other environmentally ha-

zardous substances contaminate the environment.

Always dispose of used filters, drained oil and any

remaining fuel properly.

This manual contains instructions for periodic attention

which should normally be carried out by the operator.

There are additional instructions relating to the

engine, for which the manufacturer’s instructions are

detailed in the engine manual.

MACHINE PLATE

Fill in all data below, when delivering and

commissioning the machine.

L000500A

....................................... .......................................

Engine Model Engine Number

LG140/160/200 ILG140EN4 3

Downloaded from www.Manualslib.com manuals search engine

SAFETY INSTRUCTIONS (FOR ALL LIGHT PRODUCTS)

Symbols Safety equipment

The signal words WARNING and CAUTION

used in the safety instructions have the follow- Long exposure to loud noise without

ing meanings: ear protectors can cause permanent

damage to hearing.

WARNING: Indicates danger or haz-

ardous procedure that could lead to Long exposure to vibrations can dam-

serious or mortal injury if the warn- age the hands, fingers and wrists. Do

ing is neglected. not use the machine if you experience

discomfort, cramp or pain. Consult a

CAUTION: Indicates danger or haz- doctor before resuming work with

ardous procedure that could lead to the machine.

machine or property damage if the

warning is neglected.

Always use approved safety equipment. The

operator, and people in the immediate vicinity

Important rules for your safety of the working area, must wear:

• Safety helmet

The machine must not be modified • Safety goggles

without the prior consent of the manu- • Ear protectors

facturer. Use only original parts. Use • Dust mask in dusty environments

only the accessories recommended • High-visibility clothing

by Dynapac. If modifications not ap- • Protective gloves

proved by Dynapac are carried out, • Protective shoes

these could result in serious injury Avoid wearing loosely fitting clothing that might

to yourself or other personnel. get caught in the machine. If you have long hair,

cover it with a hair net. Vibrations from hand-held

• These recommendations are based on machines are transmitted into the hands via the

international safety standards. You must also handles of the machine. Dynapac’s machines

observe any local safety regulations which are equipped with vibration-relieved handles.

may be in force. Read all instructions care- Depending on operation, the course and dura-

fully before operating the machine. Keep the tion of exposure, the recommended limit values

instructions in a safe place. for hand and arm vibration can be exceeded.

• Signs and stickers giving important infor- Take suitable measures as required, eg, wear

mation about safety and maintenance are protective gloves, and do not vibrate already

supplied with every machine. Make sure compacted material.

that they are always legible. The ordering Be alert to acoustic signals from other ma-

numbers for new stickers can be found in the chines in the working area.

spare parts list.

• Use of the machine and its accessories is

restricted to the applications specified in the Working area

Do not use the machine near flammable material or

product literature.

in explosive environments. Sparks can be emitted

• For reasons of product safety, the machine from the exhaust pipe, and these can ignite flam-

must not be modified in any way. mable material. When you take a pause or have

• Replace damaged parts immediately. finished working with the machine, do not park it

Replace all wear parts in good time. on or near flammable materials. The exhaust pipe

can get very hot during operation, and can cause

Be alert certain material to ignite. Make sure that there

Always pay attention to what you are doing, and are no other personnel inside the working area

use your common sense. Do not use the machine while the machine is in use. Keep the worksite

if you are tired or under the influence of drugs, clean and free of extraneous objects. Store the

alcohol or other substances which can effect your machine in a safe place, out of unauthorized’s

vision, reaction ability or judgement. reach, preferably in a locked container.

4 LG140/160/200 ILG140EN4

Downloaded from www.Manualslib.com manuals search engine

SAFETY INSTRUCTIONS (FOR ALL LIGHT PRODUCTS)

Filling with fuel (Gasoline/diesel)

Always take extreme care when driv-

Petrol has an extremely low flash- ing the machine on slopes. Always

point and can be explosive in certain drive straight up and down on slopes.

situations. Do not smoke. Make sure Do not exceed the maximum grad-

that worksite ventilation is good. ability of the machine according to

the instruction book. Stay clear of

Keep away from all hot or spark-generating ob- machine when operating on a slope

jects when handling fuel. Wait until the machine or in a trench.

has cooled before filling the tank. Fill the tank

at least 3 metres away from where you intend Do not touch the engine, the exhaust pipe or

to use the machine. Avoid spilling petrol, diesel the eccentric element of the machine. They

or oil on the ground. Protect your hands from gets very hot during operation and can cause

contact with petrol, diesel and oil. burn injuries.

Open the tank cap slowly to release any over- Do not touch V-belts or rotating parts during

pressure that might exist in the tank. Do not operation.

overfill the tank. Inspect the machine for fuel

leakage regularly. Parking

Park the machine on ground as level and firm

Do not use a machine that is leaking fuel. as possible. Before leaving machine:

• Apply the parking brake.

Starting the machine • Shut off the engine and pull the ignition key

out.

Before starting read instruction

book and make your self familiar Loading/Unloading

with the machine and make sure

that: Never remain under or in the immediate

vicinity of the machine when it is lifted

• All handles are free from grease, oil and dirt. by a crane. Only use marked lifting

• The machine does not show any obvious points. Always make sure that all

faults. lifting devices are dimensioned for

• All protective devices are securely fastened in the weight of the products.

their places.

• All control levers in ”neutral” position. Maintenance

Maintenance work must only be carried out by

Start the machine according to the instruction- skilled personnel. Keep unauthorized persons

book. away from the machine. Do not carry out main-

tenance work while the machine is moving or the

Operation engine is running.

Keep your feet well clear of the

machine.

Do not operate the machine in

poorly ventilated spaces. There is a

risk of carbon monoxide poisoning.

Use the machine only for the purpose for which

it is intended. Make sure you know how to stop

the machine quickly in the event of an emergency

situation.

LG140/160/200 ILG140EN4 5

Downloaded from www.Manualslib.com manuals search engine

SAFETY INSTRUCTIONS (FOR ALL LIGHT PRODUCTS)

Working with the hydraulic system

Regular maintenance of the hydraulic system

is important. Minor damage or a split hose or

coupling can have devastating consequences.

Bear in mind that the hydraulic hoses are made

of rubber and can deteriorate with age, which can

result in splitting. In all cases of uncertainty with

regard to durability or wear, replace the hoses

with new original hoses from Dynapac.

Working with battery

The battery contains poisonous and corrosive

sulphuric acid. Wear protective glasses and

avoid getting acid on your skin, clothes or on the

machines. If you get sulphuric acid on yourself,

rinse the skin with water. If you get acid in your

eyes, rinse them with water for at least 15 minutes

and seek immediate medical treatment. The gas

that is emitted by the battery is explosive. When

fitting or replacing a battery, always take care so

that you do not short- circuit the battery poles.

Repair

Never use a machine that is damaged. Qualified

repair work requires trained personnel, please

contact your nearest authorized workshop.

Extinguishing fires

If there is a fire in or on the machine, it is best

to use an ABE-class fire extinguisher. Howe-

ver, a BE-class CO2 extinguisher is also suita-

ble.

6 LG140/160/200 ILG140EN4

Downloaded from www.Manualslib.com manuals search engine

SAFETY WHEN DRIVING

Driving near an edge

When driving near an edge, at least two thirds of the

plate must be on firm solid ground.

If the machine tips over, switch off the en-

gine before attempting to lift.

At least

2/3

L000503A

Machine location when operating

on edges

Tilting

Make sure that the work site is safe. Wet and loose

earth reduces manoeuvrability especially on sloping

ground. Always observe particular caution on sloping

and uneven terrain.

Where possible, avoid all driving across a

slope. Instead, drive up and down on sloping

ground.

Never work on slopes that are greater than the capa-

Max 20° bility of the machine. Maximum slope of the machine

or 36% in operation is 20° (depending on condition of the

ground).

L000504A

Tipping angle on side slopes The tilting angle is measured on a hard, level surface

with the machine stationary. Vibration switched OFF

and all tanks full. Remember that loose ground, vibra-

tion switched ON, and driving speed can all cause the

machine to topple even on a smaller slope than speci-

fied here.

Never leave the machine unattended with the

engine running.

Max 20°

or 36%

L000505A

Driving on slopes

LG140/160/200 ILG140EN4 7

Downloaded from www.Manualslib.com manuals search engine

SAFETY DECALS, LOCATION/DESCRIPTION

6 7 1 2 5 4 3

L000278A

8 LG140/160/200 ILG140EN4

Downloaded from www.Manualslib.com manuals search engine

SAFETY DECALS, LOCATION/DESCRIPTION

1. 4. 6. 791297

109

The operator must read Petrol Guaranteed

the safety manual, and the (Honda) Sound Power

operation and maintenance level

instructions before using the

machine.

2. 4. 7.

283743

Warning - hot surfaces in Diesel Use ear

the engine compartment. (Hatz) protectors

Do not touch.

3. 5.

Warning, hand and arm Lifting

entanglement. Never reach point

into the hazardous area.

LG140/160/200 ILG140EN4 9

Downloaded from www.Manualslib.com manuals search engine

FUEL AND LUBRICANTS

ENGINE OIL Use SAE 15W / 40:

Honda GX160 0,6 l (0.65 qts)

Honda GX200 0,6 l (0.65 qts)

Hatz 1B20 0,9 l (0.95 qts)

HYDRAULIC FLUID Hydraulic fluid, recommendations:

LG 140 1,0 lit. Shell TX32

LG 160 1,0 lit. Shell TX32

LG 200 1,0 lit. Shell TX32

FUEL Honda

Use ordinary grade petrol (unleaded)

Volume: 3,6 l (3.8 qts)

FUEL Hatz

Use diesel oil which satisfy EN 590 or DIN 51601

Volume: 3,6 l (3.8 qts)

Stop the engine before refilling the fuel tank.

Never refuel near a naked flame or sparks

which could start a fire. Don’t smoke. Use

only pure fuel and clean filling equipment.

Take care not to spill fuel.

Service parts P/N

Honda GX160 Honda GX200 Hatz 1B20

Engine air filter element 23 93 23 23 93 23 93 70 13

Engine oil filter - - 93 70 01

Engine fuel filter - - 93 69 64

V-belt LG140 28 12 53 - -

LG160 28 12 53 - -

LG200 - 28 13 45 28 12 49

Accessories

Polyurethane plate cpl. LG160 P/N 280894 LG200 P/N 280895

Transport wheel cpl. LG140/160/200 P/N 281886

10 LG140/160/200 ILG140EN4

Downloaded from www.Manualslib.com manuals search engine

TECHNICAL DATA

LG140 LG140 LG160 LG160

Honda Hatz Honda Hatz

Weight

Net weight, kg (lbs) 152 (335) 164 (362) 156 (344) 169 (373)

Operating weight, kg (lbs) 154 (339) 166 (366) 158 (348) 171 (377)

Compaction data

Vibr.frequency, Hz (vpm) 65 (3900) 65 (3900) 82 (4920) 82 (4920)

Centrifugalforce, kN (lbf) 22 (4945.8) 22 (4945.8) 35 (7868.31) 35 (7868.31)

Amplitude, mm (in) 2,0 (0.08) 2,0 (0.08) 1,7 (0.07) 1,7 (0.07)

Operating data

Speed of travel, m/min (ft/min) 0-25 (0-82) 0-25 (0-82) 0-25 (0-82) 0-25 (0-82)

Max. tilt, ° 20 20 20 20

Volumes

Fuel tank, lit. (qts) 3,6 (3.8) 3,6 (3.8) 3,6 (3.8) 3,6 (3.8)

Crank case, lit. (qts)

SAE 15W/40 0,6 (0.63) 0,9 (0.95) 0,6 (0.63) 0,9 (0.95)

Hydraulic fluid, lit. (qts)

Shell TX32 1,0 (1.0) 1,0 (1.0) 1,0 (1.0) 1,0 (1.0)

Eccentricelement, lit. (qts)

SAE 10W/30 0,4 (0.42) 0,5 (0.53) 0,4 (0.42) 0,5 (0.53)

Engine

Model Honda Hatz Honda Hatz

GX160 1B20 GX160 1B20

Recoil start Recoil start Recoil start Recoil start

Output, kW (hp) 4,1 (5.5) 2,8 (3.8) 4,1 (5.5) 2,8 (3.8)

Engine speed, rpm 3600 2600 3600 2600

Noise and Vibrations

Noise level Sound pressure level at the operator's ear according to ISO 6394:

LpA dB (A) = 90 90 92 90

Sound power level according to ISO 3744:

LwA dB (A) = 110 104 107 104

Vibration values The hand - arm vibration values according to ISO 5349:

a m/s2 = 0,6 1,9 1,4 3,1

The above noise level and vibration values were determined at normal speed of the engine with

vibration on. The machine was placed on an elastic base.

During operation these values may differ because of the actual operational conditions.

LG140/160/200 ILG140EN4 11

Downloaded from www.Manualslib.com manuals search engine

TECHNICAL DATA

LG200 LG200 LG200

Honda Hatz Hatz El.

Weight

Net weight, kg (lbs) 220 (485) 231 (509) 248 (547)

Operating weight, kg (lbs) 222 (489) 233 (514) 250 (551)

Compaction data

Vibr.frequency, Hz (vpm) 65 (3900) 65 (3900) 65 (3900)

Centrifugal force, kN (lbf) 36 (8093.12) 36 (8093.12) 36 (8093.12)

Amplitude, mm (in) 1,9 (0.08) 1,9 (0.08) 1,9 (0.08)

Operating data

Speed of travel, m/min (ft/min) 0-25 (0-82) 0-25 (0-82) 0-25 (0-82)

Max. tilt, ° 20 20 20

Volumes

Fuel tank, lit. (qts) 3,6 (3.8) 3,6 (3.8) 3,6 (3.8)

Crank case, lit. (qts)

SAE 15W/40 0,6 (0.65) 0,9 (0.95) 0,9 (0.95)

Hydraulic fluid, lit. (qts)

Shell TX32 1,0 (1.0) 1,0 (1.0) 1,0 (1.0)

Eccentricelement, lit. (qts)

SAE 10W/30 0,4 (0.42) 0,5 (0.53) 0,5 (0.53)

Engine

Model Honda Hatz Hatz

GX200 1B20 1B20

Recoil start Recoil start El.start

Output, kW (hp) 4,8 (6.4) 3,1 (4.2)§ 3,1 (4.2)

Engine speed, rpm 3600 3000 3000

Noise and Vibrations

Noise level Sound pressure level at the operator's ear according to ISO 6394:

LpA dB (A) = 90 90 90

Sound power level according to ISO 3744:

LwA dB (A) = 105 106 106

Vibration values The hand - arm vibration values according to ISO 5349:

a m/s2 = 0,6 0,8 0,8

The above noise level and vibration values were determined at normal speed of the engine with

vibration on. The machine was placed on an elastic base.

During operation these values may differ because of the actual operational conditions.

12 LG140/160/200 ILG140EN4

Downloaded from www.Manualslib.com manuals search engine

TECHNICAL DATA – DIMENSIONS

D E C

L000501A L000502A

CONTACT

AREA B

G

F

A

LG140 LG160 LG200

A mm (in) 1265 (49.8) 1265 (49.8) 1315 (51.8)

B mm (in) 330 *) (13.0) 450 (17.7) 500 (19.7)

C mm (in) 1115 (43.9) 1115 (43.9) 1065 (41.9)

D mm (in) 1000 (39.4) 1000 (39.4) 1000 (39.4)

E mm (in) 800 (31.5) 800 (31.5) 780 (30.1)

F mm (in) 765 (30.1) 765 (30.1) 800 (31.5)

G mm (in) 650 (25.6) 650 (25.6) 700 (27.6)

Contact area

m2 (in2) 0,09834 (152.4) 0,1341 (207.9) 0,1735

(268.9)

Accessories Transport device Transport device Transport device

- Polyurethane plate Polyurethane plate

*

)Total width LG140 = 385 mm (15.2 in)

LG140/160/200 ILG140EN4 13

Downloaded from www.Manualslib.com manuals search engine

OPERATION – HONDA GX160/GX200

Before start

1. Fill fuel tank.

Tank volume 3,6 lit. (3.8 qts)

1 2

2. Check oil level in engine crank case.

Oil volume 0,6 lit. (0.65 qts)

Max.

Min.

OK

L000039A L000077A

Starting the engine

3. Open the fuel cock and open the throttle fully.

L000509A

4. Open throttle fully. Move the choke valve to the close

position. Do not use the choke if the engine is warm

or the air temperature is high.

L000512A

5. Turn the start button to position I.

L000064A

14 LG140/160/200 ILG140EN4

Downloaded from www.Manualslib.com manuals search engine

OPERATION – HONDA GX160/GX200

6. Pull out the handle to the point where you feel

strong resistance and then return it to the initial

position, then pull briskly. As the engine warms up,

gradually move the choke valve to the open position.

7

7. After the engine starts,set the speed lever to the low

speed position and warm it up without load for a few

6 minutes.

L000513A

Stopping the engine

1. Throttle in neutral position. Let engine run a few

minutes.

1

L000510A

2. Turn the start button to position O.

L000065A

3. Close the fuel cock.

3

L000041A

LG140/160/200 ILG140EN4 15

Downloaded from www.Manualslib.com manuals search engine

OPERATION – HATZ 1B20

Before start

1. Fill fuel tank.

Tank volume: 3,6 lit. (3.8 qts)

1 2

2. Check oil level in engine crank case.

Oil volume: 1,0 lit. (1.06 qts)

Max.

Min.

OK

L000514A L000077A

Starting the engine

3. Set speed control lever either 1/2 START or max.

START position, as desired or necessary. Starting at

3

a lower speed will help to prevent exhaust smoke.

L000509A

4 Manual start

5 4. Pull the starting cable out by the handle until you

6 feel a slight resistance. Let the cable run back; in

this way the entire length of the starting cable can

be used to start the engine.

5. Grip the handle with both hands.

L000452A 6. Commence pulling the starting cable vigorously and

at an increasing speed (do not jerk it violently) until

the engine starts.

If after several attempts of starting the exhaust

begins to emit white smoke, move the speed

control lever to the stop position and pull the

starting cable out slowly 5 times. Repeat the

starting procedure.

O El. start

4. Insert the starter key and turn it to position I. Char-

ging and oil pressure indicators light up.

I 4

5. Turn the starter key through position II to III. Re

lease the key as soon as the engine runs.

II 5 Make sure that the key remains at position II so

III L000457A

that the battery is charged.

16 LG140/160/200 ILG140EN4

Downloaded from www.Manualslib.com manuals search engine

OPERATION – HATZ 1B20

Stopping the engine

1. Throttle in neutral position. Let the engine idle a few

minutes.

L000510A

2. Push the engine switch to OFF.

L000515A

El. start

O

3

2. Turn the starter key to position O and remove it. All

indicator lights must go out.

The ignition key must be turned to O, or else the

machine will consume electric power.

Always remove the key when you leave the

L000510A

machine, and keep it in a safe place. This will

make it difficult for any unauthorized person

to start and drive the machine.

LG140/160/200 ILG140EN4 17

Downloaded from www.Manualslib.com manuals search engine

OPERATION – ALL ENGINE TYPES

Operating

1. Open throttle fully.

During compaction work the engine must always

run at full throttle.

1

L000509A

Drive direction and speed are infinetely variable with

the hydraulic lever.

3 1

1. Forward (the hydraulic lever is pushed forward with

small movements).

2 2. Reverse (the hydraulic lever is pushed backwards

with small movements).

3. Stationary (the hydraulic lever is moved with small

movements in the opposite direction until the machi-

ne is stationary).

L000511A

18 LG140/160/200 ILG140EN4

Downloaded from www.Manualslib.com manuals search engine

LIFTING, TRANSPORTATION AND TOWING

Lifting/Towing

Never walk or stand underneath a hoisted

machine

1

Use only the frame lifting hook (1) for lifting the

machine.

All lifting devices must be dimensioned in order

to fullfil all regulations. Before lifting check that

shock absorbers (2) and protecting frame are

2 correctly attached and not damaged.

L000290A

Transportation

Always secure the machine firmly during

all transportation. Place lashing band in a U

shape around the bottom plate and secure

both front and rear

L000291A

Machine ready for transportation

1. Lashing strap

LG140/160/200 ILG140EN4 19

Downloaded from www.Manualslib.com manuals search engine

MAINTENANCE – SERVICE POINTS

Honda GX160, GX200 – Petrol Engine Hatz 1B20 – Diesel Engine

1

1

8

3

4, 6

4, 6

5

2

L000253A L000252A

Fig. 1 Honda GX160, GX200 – Hatz 1B20

1. Fuel tank

2. Fuel filter

3. Air filter

4. Engine oil

5. Engine oil filter

6. Oil dipstick 3 1

7. Oil drain plug

8. Engine cooling system

11

10

7

9

L000292A

Fig. 2

1. Fuel tank

3. Air filter

7. Oil drain plug

9. Eccentric element,

level/drain plug

10. Hydraulic reservoir

11. V-belt

Every 10 hours of operation (daily)

Item in fig. Maintenance see page Comments

1 Check and replenish fuel

4 Check and replenish lube oil 22

Check for oil leakage

Check and tighten engine parts 22

3 Clean / replace air cleaner elements

20 LG140/160/200 ILG140EN4

Downloaded from www.Manualslib.com manuals search engine

MAINTENANCE – SERVICE POINTS

The first 20 hours of operation

Item in fig. Maintenance see page Comments

Change lube oil 23

5 Clean / replace oil filter See engine manual.

3 Clean / replace air cleaner elements See engine manual.

Check and adjust the engine valve clearance See engine manual.

Monthly

Item in fig. Maintenance see page Comments

10 Check oil level in hydraulic reservoir 23

11 Check V-belt 23

Every 100 hours of operation

Item in fig. Maintenance see page Comments

7 Change lube oil 23

3 Clean / replace air cleaner elements See engine manual.

Every 500 hours of operation

Item in fig. 1 Maintenance see page Comments

7 Change engine oil 23

9 Change eccentric element oil 25

10 Change hydraulic fluid 25

5 Clean / replace oil filter See engine manual.

3 Clean / replace air cleaner elements See engine manual.

Check fuel injection pump See engine manual.

Check fuel injection nozzle See engine manual.

Adjust valve head clearance for intake

and exhaust valves See engine manual.

Every 1000 hours of operation

Item in fig. Maintenance see page Comments

Lap intake and exhaust valves See engine manual.

Replace pistong rings See engine manual.

LG140/160/200 ILG140EN4 21

Downloaded from www.Manualslib.com manuals search engine

MAINTENANCE – EVERY 10 HOURS OF OPERATION

1. Check oil level (1) engine's crankcase.

1

L000253A

1. Oil dipstick

2. Air cleaner

2. Check air cleaner (2).

3. Check the battery (Hatz electric starter).

We recommend reading the detailed motor instructions

2 supplied with the machine.

1

L000252A

1. Oil dipstick

2. Air cleaner

4. Check and, where necessary, tighten screws and

nuts.

L000028A

5. Keep machine clean.

L000508A

22 LG140/160/200 ILG140EN4

Downloaded from www.Manualslib.com manuals search engine

MAINTENANCE – MONTHLY

1. Check oil level in hydraulic tank.

Check oil level on the dipstick.

L000517A

Dipstick

2. Check the V-belt.

L000297A

MAINTENANCE – EVERY 100 HOURS OF OPERATION

1. Change oil (first change after 20 hours, together

2

with engine filter).

L000516A

1. Oil dipstick

2. Fuel filter

3. Oil filter

4. Oil drain plug/drain hose

2. Lubricate controls.

1

4

L000253A

1. Oil dipstick

4. Oil drain plug

LG140/160/200 ILG140EN4 23

Downloaded from www.Manualslib.com manuals search engine

MAINTENANCE – EVERY 500 HOURS OF OPERATION

1. Replace fuel filter. (See engine manual)

2. Change oil. (See engine manual)

3. Replace oil filter. (See engine manual)

4. Replace air cleaner element. (See engine manual)

L000253A

L000252A

24 LG140/160/200 ILG140EN4

Downloaded from www.Manualslib.com manuals search engine

MAINTENANCE – EVERY 500 HOURS OF OPERATION

Changing oil in eccentric element

Recommended oil: SAE 10W/30.

LG140 0,4 lit.

LG160 0,4 lit.

LG200 0,5 lit.

1

L000518A

1. Oil level plug

1. Slant the machine and drain oil from eccentric.

2. Clean sealing surfaces.

3. Fill with oil.

4. Tighten oil plug.

L000401A

L000402A

Changing oil in hydraulic system

Recommended oil:

LG140 1,0 lit. Shell TX32

LG160 1,0 lit. Shell TX32

LG200 1,0 lit. Shell TX32

L000517A

Lubricating of controls and 1. Remove old grease.

2. Lubricate all parts. Apply grease generously.

Recommended lubricant: Shell Alvania EP2.

LG140/160/200 ILG140EN4 25

Downloaded from www.Manualslib.com manuals search engine

Box 504, SE-371 23 Karlskrona, Sweden

Phone: +46 455 30 60 00

Fax: +46 455 30 60 30

www.dynapac.com

26 LG140/160/200 ILG140EN4

Downloaded from www.Manualslib.com manuals search engine

You might also like

- OMKV11661 POD UnlockedDocument80 pagesOMKV11661 POD Unlockedeliminar348No ratings yet

- 2015 Seadoo 4-Tec Service ManualDocument1,453 pages2015 Seadoo 4-Tec Service ManualZack BurichNo ratings yet

- Scotts S1642 S1742 S2046Document68 pagesScotts S1642 S1742 S2046robert mceldoonNo ratings yet

- ZW 3106Document506 pagesZW 3106Yotor besuNo ratings yet

- Operating Instructions: Rota - DiscDocument53 pagesOperating Instructions: Rota - DiscArmorNo ratings yet

- Rota Disc OPERATORS MANUALDocument53 pagesRota Disc OPERATORS MANUALCoco BangoNo ratings yet

- Thank You For Purchasing A John Deere Product: OMLVU14661 Issue K2 Compact Utility TractorDocument164 pagesThank You For Purchasing A John Deere Product: OMLVU14661 Issue K2 Compact Utility TractorTerry BagwellNo ratings yet

- P130 P175 P185WJDU JUL02 CPN22478358 GBDocument49 pagesP130 P175 P185WJDU JUL02 CPN22478358 GBAgeng A. PooNo ratings yet

- Vibratory Trench Compactor LP 852: Diesel Engine: Hatz 2G40 These Instructions Apply From: LP 852 PIN (S/N) 48600052Document34 pagesVibratory Trench Compactor LP 852: Diesel Engine: Hatz 2G40 These Instructions Apply From: LP 852 PIN (S/N) 48600052Nicolae HincuNo ratings yet

- Operation & Maintenance Manual Flail CutterDocument108 pagesOperation & Maintenance Manual Flail CutterHenry HuayhuaNo ratings yet

- Operation ManualDocument312 pagesOperation Manualuuganaa ugi100% (1)

- Indexer Cam Gear Kurvengetriebe HSG BWV - HEINZDocument20 pagesIndexer Cam Gear Kurvengetriebe HSG BWV - HEINZluiz cláudioNo ratings yet

- New Holland Kobelco E265 E305 Excavators Operation Maintenance Instruction Manual 6043548400Document251 pagesNew Holland Kobelco E265 E305 Excavators Operation Maintenance Instruction Manual 6043548400VALENTIN ILETECHAGRI100% (1)

- G10 / G20 Series: Scara RobotDocument252 pagesG10 / G20 Series: Scara RobotMARTIN LOPEZNo ratings yet

- Werkstatthandbuch Honda BF130 PDFDocument486 pagesWerkstatthandbuch Honda BF130 PDFRajkoRapo100% (3)

- ABG 225 EPM Operators ManualDocument370 pagesABG 225 EPM Operators Manualvitor santos100% (1)

- DX200 Safety BoardDocument164 pagesDX200 Safety Boardautomacao2No ratings yet

- 6C50ZC5600P1 Fe15-37a (H) - Instruction ManualDocument82 pages6C50ZC5600P1 Fe15-37a (H) - Instruction ManualThanh BarcaNo ratings yet

- Manual Motosierra T425 HusqvarnaDocument340 pagesManual Motosierra T425 HusqvarnaJuanNo ratings yet

- Dum Truck Komatsu hd465-7hd605-7 PDFDocument395 pagesDum Truck Komatsu hd465-7hd605-7 PDFamin100% (1)

- Jungheinrich DFG 660 Service ManualDocument194 pagesJungheinrich DFG 660 Service ManualNhàn Nguyễn ThanhNo ratings yet

- 10-20181031134746 Pts 184 PDFDocument475 pages10-20181031134746 Pts 184 PDFSuryana IskandarNo ratings yet

- E20 7255008 enUS SM PDFDocument671 pagesE20 7255008 enUS SM PDFLacatusu Mircea100% (3)

- D21P-8 (JPN) - Interim Tier4 Ten00269-03 O&mDocument197 pagesD21P-8 (JPN) - Interim Tier4 Ten00269-03 O&mhaimay118No ratings yet

- 225 6720347 enUS SMDocument318 pages225 6720347 enUS SMGuillermo Guardia GuzmanNo ratings yet

- MC3 Sullair PartsListManual 185 KubotaDocument60 pagesMC3 Sullair PartsListManual 185 Kubotaivan castillonNo ratings yet

- ALISSON HT 700 Hydr Service ManualDocument328 pagesALISSON HT 700 Hydr Service ManualAnonymous eExWojLxNo ratings yet

- DG1000 User's GuideDocument150 pagesDG1000 User's GuideBrehui Traian-ViorelNo ratings yet

- Epson g10 g20 Robot Manual (r19)Document252 pagesEpson g10 g20 Robot Manual (r19)FlorinNo ratings yet

- D37EX-22 O&M ManualDocument303 pagesD37EX-22 O&M Manualmohyuddinuetian100% (1)

- Komatsu PC210LC 11 Operation Maintenance ManualDocument497 pagesKomatsu PC210LC 11 Operation Maintenance ManualTharindu ManamperyNo ratings yet

- Hino Wo6dti ServicemanualDocument10 pagesHino Wo6dti Servicemanualiva100% (55)

- Ten00695 00Document491 pagesTen00695 00xuan50% (2)

- 220 6722345 enUS SMDocument299 pages220 6722345 enUS SMGuillermo Guardia GuzmanNo ratings yet

- D65ex 18Document483 pagesD65ex 18djonsenNo ratings yet

- Manual Operation Maintenance Komatsu pc300lc pc350lc Hydraulic Excavators PDFDocument343 pagesManual Operation Maintenance Komatsu pc300lc pc350lc Hydraulic Excavators PDFGanapati Hegde100% (1)

- 1102v-4g EuropaDocument75 pages1102v-4g EuropaΜερκουρηςκαπαNo ratings yet

- Rigol: User's GuideDocument151 pagesRigol: User's GuideFabrizio GiordanoNo ratings yet

- ByD F3 Service ManualDocument193 pagesByD F3 Service ManualMARTIN VILAR100% (2)

- EX1200 7B - ENMKAB 1 1 Operators ManualDocument454 pagesEX1200 7B - ENMKAB 1 1 Operators ManualJardel Fernandes de MoraesNo ratings yet

- Serial Number 0G960500 and Above EFI Models 0G960500 Thru 0T408999Document654 pagesSerial Number 0G960500 and Above EFI Models 0G960500 Thru 0T408999Ingo BorchersNo ratings yet

- K04 Gebruikshandleiding EngelsDocument476 pagesK04 Gebruikshandleiding Engelslouis.cauliezNo ratings yet

- L20 Series: Service and Repair ManualDocument28 pagesL20 Series: Service and Repair ManualJoe CorreaNo ratings yet

- L4GCDocument6 pagesL4GCjohanNo ratings yet

- Komatsu Super D155ax3Document240 pagesKomatsu Super D155ax3Jako MishyNo ratings yet

- Excavator Service Manual: 325 (S/N 514013001 & Above) 328 (S/N 516611001 & Above)Document463 pagesExcavator Service Manual: 325 (S/N 514013001 & Above) 328 (S/N 516611001 & Above)MariahaNo ratings yet

- Dl420a Om en (#10001 - 2012)Document236 pagesDl420a Om en (#10001 - 2012)Abdelrahman100% (3)

- Operating Instructions: BetriebsanleitungDocument34 pagesOperating Instructions: BetriebsanleitungAndrey LyutikNo ratings yet

- eng-GB20036078B HDocument340 pageseng-GB20036078B Hvictor villarroelNo ratings yet

- Komatsu Hydraulic Excavator Pc340lc 340nlc 7k Operation Maintenance ManualDocument20 pagesKomatsu Hydraulic Excavator Pc340lc 340nlc 7k Operation Maintenance Manualedward100% (51)

- GR 1600 EuDocument285 pagesGR 1600 EuMac KrisNo ratings yet

- Jungheinrich DFG - TFG 660-690 Service Manual PDFDocument221 pagesJungheinrich DFG - TFG 660-690 Service Manual PDFAdrian Ferreyra100% (2)

- Omm PC200-8Document393 pagesOmm PC200-8Mulyadi TarchaniNo ratings yet

- Operator Manuals English Version 5.1Document40 pagesOperator Manuals English Version 5.1Alberto Garcia OliverNo ratings yet

- VW Transporter T4 (Petrol and Diesel - 1990-1995) Workshop Manual: Owners Edition (Owners' Workshop Manuals)From EverandVW Transporter T4 (Petrol and Diesel - 1990-1995) Workshop Manual: Owners Edition (Owners' Workshop Manuals)No ratings yet

- Mercedes - Benz Vito & V-Class Petrol & Diesel Models: Workshop Manual - 2000 - 2003From EverandMercedes - Benz Vito & V-Class Petrol & Diesel Models: Workshop Manual - 2000 - 2003Rating: 5 out of 5 stars5/5 (1)

- Mercedes Benz & Dodge Sprinter CDI 2000-2006 Owners Workshop ManualFrom EverandMercedes Benz & Dodge Sprinter CDI 2000-2006 Owners Workshop ManualNo ratings yet

- Mercedes Benz & Dodge Sprinter CDI 2000-2006 Owners Workshop ManualFrom EverandMercedes Benz & Dodge Sprinter CDI 2000-2006 Owners Workshop ManualRating: 2.5 out of 5 stars2.5/5 (2)

- Allison Transmissions: How to Rebuild & Modify: How to Rebuild & ModifyFrom EverandAllison Transmissions: How to Rebuild & Modify: How to Rebuild & ModifyRating: 5 out of 5 stars5/5 (1)

- CR 1Document24 pagesCR 1ĆerimovićDooNo ratings yet

- Top Speed 4T Sae 10W40 Jaso Ma2 - enDocument1 pageTop Speed 4T Sae 10W40 Jaso Ma2 - enĆerimovićDooNo ratings yet

- Formula 4T 20W50 HD Jaso Ma2 - enDocument1 pageFormula 4T 20W50 HD Jaso Ma2 - enĆerimovićDooNo ratings yet

- Formula 4T 10W40 Jaso Ma2 - enDocument1 pageFormula 4T 10W40 Jaso Ma2 - enĆerimovićDooNo ratings yet

- FJR Model HistoryDocument12 pagesFJR Model HistoryĆerimovićDooNo ratings yet

- 300 V 4T Factory Line 10W-40: Racing Lubricant For Race Bikes 100% Synthetic - Double EsterDocument1 page300 V 4T Factory Line 10W-40: Racing Lubricant For Race Bikes 100% Synthetic - Double EsterĆerimovićDooNo ratings yet

- Ficha Compactacao Bomag Bpr30Document2 pagesFicha Compactacao Bomag Bpr30ĆerimovićDooNo ratings yet

- Cijene Motocikala 2019Document4 pagesCijene Motocikala 2019ĆerimovićDooNo ratings yet

- Nucl - Phys.B v.743 PDFDocument355 pagesNucl - Phys.B v.743 PDFbuddy72No ratings yet

- Rab Task Template Cinta JayaDocument3 pagesRab Task Template Cinta JayalukmanNo ratings yet

- What Is Coulomb's Electricity?Document4 pagesWhat Is Coulomb's Electricity?George Mpantes mathematics teacherNo ratings yet

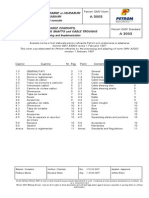

- Petrom OMV - Norm - A - 3003 - Rom - Eng - Rev.1 - 2006-04-10Document13 pagesPetrom OMV - Norm - A - 3003 - Rom - Eng - Rev.1 - 2006-04-10lucianduNo ratings yet

- Polycab Solar PDFDocument6 pagesPolycab Solar PDFVivek RamachandranNo ratings yet

- Why Does A Delta - Wye Transformer Make 30 Degrees Phase Shift - Electrical Engineering Stack ExchangeDocument3 pagesWhy Does A Delta - Wye Transformer Make 30 Degrees Phase Shift - Electrical Engineering Stack ExchangeCorey PorterNo ratings yet

- Max Born PaperDocument22 pagesMax Born PaperChukwunonso ArinzeNo ratings yet

- Six Month Industrial Training At: Pioneer Industries Limited Pathankot, PunjabDocument25 pagesSix Month Industrial Training At: Pioneer Industries Limited Pathankot, Punjabmanna726No ratings yet

- TCXDVN 356-2005 Design of Concrete and RC Structures PDFDocument231 pagesTCXDVN 356-2005 Design of Concrete and RC Structures PDFphamducquangNo ratings yet

- Cambridge IGCSE: Co-Ordinated Sciences 0654/43Document28 pagesCambridge IGCSE: Co-Ordinated Sciences 0654/43Muhammad Luthfansyah PrabowoNo ratings yet

- Voltage RegulationDocument90 pagesVoltage RegulationelhaffarNo ratings yet

- General Physics 2Document15 pagesGeneral Physics 2Shendy AcostaNo ratings yet

- About Arcelormittal Burns HarborDocument3 pagesAbout Arcelormittal Burns HarborMalcolm DiamondNo ratings yet

- Characteristic of Shunt Wound DC GeneratorDocument10 pagesCharacteristic of Shunt Wound DC GeneratorGideon MoyoNo ratings yet

- Image Sp100Document99 pagesImage Sp100Almacen SertecNo ratings yet

- ZA6VSD RysDocument1 pageZA6VSD RysDanielNo ratings yet

- 02 Unit-09 (Physics Student Copy)Document5 pages02 Unit-09 (Physics Student Copy)Saad ArsalanNo ratings yet

- TKIS Relay Setting NewDocument34 pagesTKIS Relay Setting NewsalmanNo ratings yet

- BS 476-7-1997Document24 pagesBS 476-7-1997Ivan ChanNo ratings yet

- 304E2 Main Pump DisassemblyDocument6 pages304E2 Main Pump Disassemblyevan50% (2)

- Aiwa Tv-Se2130 PDFDocument33 pagesAiwa Tv-Se2130 PDFSekoNo ratings yet

- Group 15 P Block Important QuestionsDocument8 pagesGroup 15 P Block Important Questionsanujtyagi100% (1)

- Text 2Document5 pagesText 2Olatunde OpeyemiNo ratings yet

- Storage TankDocument21 pagesStorage Tanknazar750100% (1)

- Heritage of Bown Coal Industry Saxony - Prof. Dr. Phil. Habil. Helmuth AlbrechtDocument32 pagesHeritage of Bown Coal Industry Saxony - Prof. Dr. Phil. Habil. Helmuth AlbrechtDimitrios Mavromatidis100% (1)

- Holtek Semicon HT7750SA C192571Document17 pagesHoltek Semicon HT7750SA C192571a637888No ratings yet

- Wiring Diagram LH SFI Fuel Injection System ENGINE 104 As of 1.6.92 Up To 31.5.93 in MODEL 140 PDFDocument6 pagesWiring Diagram LH SFI Fuel Injection System ENGINE 104 As of 1.6.92 Up To 31.5.93 in MODEL 140 PDFAlex NewskyNo ratings yet

- Dc4812vrf Installation Manual 166203Document28 pagesDc4812vrf Installation Manual 166203Carlos LehmanNo ratings yet

- User Manual: RefrigeratorDocument21 pagesUser Manual: Refrigeratormynko85No ratings yet

- Dry Quenched Coke - Enabler To Enhance BF PerformanceDocument26 pagesDry Quenched Coke - Enabler To Enhance BF PerformanceSatyamKumarNo ratings yet