Professional Documents

Culture Documents

Silo - Tips Concrete Swimming Pool Tanks Guidance On The Design of in Situ Concrete Water Retaining Structures

Silo - Tips Concrete Swimming Pool Tanks Guidance On The Design of in Situ Concrete Water Retaining Structures

Uploaded by

derichanzuOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Silo - Tips Concrete Swimming Pool Tanks Guidance On The Design of in Situ Concrete Water Retaining Structures

Silo - Tips Concrete Swimming Pool Tanks Guidance On The Design of in Situ Concrete Water Retaining Structures

Uploaded by

derichanzuCopyright:

Available Formats

08/10/2012

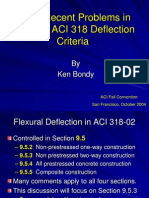

Outline

Scope

Concrete (swimming pool) Tanks

Guidance on the design of Structural Design

in-situ concrete water retaining structures • Eurocodes

SPATA Training • ULS design

• SLS design

4 Oct 2012

Materials

Charles Goodchild Specification

CEng., MCIOB, MIStructE AOB

Principal Structural Engineer

The Concrete Centre

Scope

Outline

Scope Concrete swimming pool tanks

These would normally be constructed from

Structural Design shuttered in-situ reinforced concrete to BS 8007.

• Eurocodes They can be formed with or without a screed /

render and normally have a ceramic tile finish.

• ULS design Waterproofing additives can be used to reduce

• SLS design the risk of leakage. The tank structure should be

thoroughly tested for water tightness, through a

Materials full depth tank test before finishes are applied.

Any faults should be remedied after allowing the

Specification pool tank to dry out thoroughly, and before tiling

or lining work is undertaken. Any repair is more

AOB effective from the wet side.

www.sportengland.org/facilities.../design _and.../idoc.ashx?...

Scope Scope

www.londonswi mmi ngpools.com/por tfoli o.ht ml#id_228

http://davidhallamltd.co.uk/pools/c ommer cial-pools

www.por tr aitpools.com/wp-content/br ochur e/ www.londonswi mmi ngpools.com/por tfoli o.ht ml#id_37

SPATA Training 4 Oct 2012 - Eurocode 2 Part

3 Tanks 1

08/10/2012

Scope

www.sportengland.org/facilities.../design _and.../idoc.ashx?. ..

http://www.londonswi mmi ngpools.com/

Scope

Outline

Planning: Design:

Scope

Location Architect

Type Structural engineer, Structural Design

Shape M & E consultant • Eurocodes

Dimensions Interior designer

• ULS design

Diving? Sub Aqua? Swimming pool specialist

• SLS design

Features

Roof structure Materials

Plant Hydraulic design criteria, AHU spec.,

ducts, pipes filters/pumps and water

treatment, plantroom, penetrations, Specification

Services lighting, moving floors

Changing facilities AOB

Spectator facilities

Other amenities

Eurocodes Eurocodes

What’s new in

water retaining structures)?

• Withdrawal of BS 8110, BS 8007 etc

• Eurocodes

• New information:

• CIRIA C660

• Revision to BS 8102

• Debate

• S Alexander, TSE Dec 06

• B Hughes, TSE Aug 08?

• ICE project 0706 on reinforcement to control

cracking (report Feb 2010)

BS 8007

SPATA Training 4 Oct 2012 - Eurocode 2 Part

3 Tanks 2

08/10/2012

Eurocodes Eurocodes

Eurocode 2: relationships – BS EN 1992-3

BS EN 1990

BS EN 1997 BASIS OF STRUCTURAL BS EN 1998

GEOTECHNICAL DESIGN SEISMIC DESIGN

DESIGN

BS EN 10138

BS EN 1991 Prestressing

ACTIONS ON STRUCTURES Steels

BS 8500 BS EN 206

Spe cifying BS EN 10080

Concrete Reinforcing

Concrete BS EN 1992

DESIGN OF CONCRETE Steels Pic of eurocodes incl pt 3

STRUCTURES

BS EN 13670

NSCS Part 1-1: General Rules for

Execution of BS 4449

Structures

Structures Reinforcing

DMRB? Part 1-2: Structural Fire Design

Steels

NBS?

Rail? BS EN 1994 BS EN 13369

BS EN 1992 BS EN 1992

CESWI? Design of Pre-cast

Part 2: Part 3: Liquid

Comp. Concrete

Bridges Ret. 13

Struct.

Structures

Eurocodes Eurocodes

Typical water-retaining structure

BS EN 1992-3 (cont)

Utility structures

- all about

minimising

material and

maintenance

cost

“A degree of

leakage may be

acceptable” -

discuss tightness

class with clients

… crack width?

0.05 to 0.2mm or

0.3?

BS EN 1992-3 (cont)

Eurocodes Eurocodes

Edge details

www.sportengland.org/facilities.../design _and.../idoc.ashx?...

www.londonswi mmi ngpools.com/por tfoli o.ht ml#id_38

SPATA Training 4 Oct 2012 - Eurocode 2 Part

3 Tanks 3

08/10/2012

Eurocodes

Outline

Concrete pool construction www.sportengland.org/facilities. ../design _and.../idoc.ashx?...

Structural Option 1:

• Monolithic design for whole of tank and pool surrounds when Scope

constructed from in-situ water retaining concrete to BS 8007/ BS

EN 1992 Part 3 gives a highly stable structure Structural Design

Option 2:

• Eurocodes

• Gunite sprayed reinforced concrete

• Reinforced concrete block work with waterproof renders /coatings • ULS design

An Integral transfer channel is the most common option

• SLS design

Fixtures and fittings need to be integrated into the tank design

Waterproofing • Inherent within well constructed in-situ reinforced concrete pools Materials

meeting BS 8007/ BS EN 1992 Part 3

• Can be augmented by waterproof liner and/or render Specification

Finishes Option 1

• Fully ceramic tiles on render backing is the preferred finish AOB

Option 2

• Specialist finish renders and paint finishes have been used where

long term durability is not so important

Structural design: loads cases Structural design - ULS

Design for Ultimate Limit State

Tank empty Tank full EQU – Equilibrium Limit State

(Tank in ground) (Tank in or above ground)

Actions for ULS STR & GEO – Structural and Geotechnical

Limit States

Soil loads Water loads • Partial factor for water actions:

Ground water loads • Normal level

• gQ for ‘silos and tanks’ BS EN 1991-4

Compaction loads • Accidental level

Maximum design liquid level during

Analysis

operations

Slab Walls Slab Walls gQ = 1.20

Equilibrium Flexure Flexure

Flexure Flexure Tension Tension • gF for Normal level ?

Soil structure Shear gF = 1.35?

interaction

Actions for SLS • Structural design

As above plus: As above plus: • As per ‘normal’ elements

• Early age thermal • Drying • 3D nature of design

• Autogenous • Differential temperature

Structural design - ULS Structural design - ULS

Analysis now often FEA

Was plate theory (via grillage).

Manifested by graphs or

tables

Horizontal moments in a

8 x 6 x 4 m deep tank

Courtesy HAC

SPATA Training 4 Oct 2012 - Eurocode 2 Part

3 Tanks 4

08/10/2012

Structural design - ULS Water Retaining :

N-M where tension exists

Design for tension:

Not only tensile forces from restraint but also tension from loading

Axial tension due

to water pressure

on Wall B

Axial tension due to

gFrwh water pressure on

Wall A

Section/Elevation Plan Section at corner

Not forgetting tension in base slabs!!

Structural design - ULS Structural design - ULS

Tanks in the ground:

Shear: BS EN 1997, Combination 1 and 2

VRdc is affected by tension Design for Ultimate Limit State

GEO – in the ground

• Combinations 1 and 2

• gF for ground water

o Normal gF = 1.35 (BS EN 1997)

o Most unfavourable gF = 1.20 (NA to BS EN 1991-4)

Structural design - Example Structural design below ground

Characteristic actions on basement wall and

adjacent slabs: LC1 water at ground level For empty Tanks in the ground

see– Concrete Basements

This guide covers the design and

construction of reinforced concrete

basements and is in accordance with

the Eurocodes.

The aim of the guide is to assist designers of

concrete basements of modest depth, i.e. not

exceeding 10 metres. It will also prove relevant

to designers of other underground structures. It

brings together in one publication the salient

features for the design and construction of such

water-resisting structures.

The guide has been written for generalist

Combination 1 Combination 2 structural engineers who have a basic

understanding of soil mechanics.

SPATA Training 4 Oct 2012 - Eurocode 2 Part

3 Tanks 5

08/10/2012

Structural design - SLS

Outline

Scope

Design for Serviceability Limit State

Structural Design

• Eurocodes

• ULS design ≡ Control of cracking

• SLS design

Materials

Specification

AOB

Structural design - SLS Structural design - SLS

Restraint factors

1. Test for restraint cracking

A section will crack if: Table 1 – Values of restraint factor R for a particular pour

BS EN 1992-3 Annex L

e r = Rax e free = K[([acT1 +e ca)] R1 + ([acT2 R2)] + e cd R3] > e ctu configuration

where CIRIA C660 Cl 3.2

K =

=

allowance for creep

0.65 when R is calculated using CIRIA C660

Pour configuration R

= 1.0 when R is calculated using BS EN 1992-3

ac

T1

=

=

coefficient of thermal expansion (See CIRIA C660 for values). See Table A6 for typical values

difference between the peak temperature of concrete during hydr ation and ambient

Thin wall cast on to massive concrete base 0,6 to 0,8 at base

e ca =

temperature °C (See CIRIA C660). Typical values are noted in Table A7

Autogenous shrinkage strain – value for early age (3 days: see Table A9)

0,1 to 0,2 at top

R 1, R 2, = restraint factors. See Section A5.6

usually 0.5

R3 For edge restraint from Figure L1 of BS EN 1992-3 for short- and long-term therm al and long- Massive pour cast onto blinding 0,1 to 0,2

term drying situations. For base-wall restraint they may be calculated in accordance with

CIRIA C660. Figure L1 may be used with CIRIA C660 methods providing an adjustment for Beware: effects

creep is made (See Figure A2 and note). Massive pour cast onto existing concrete 0,3 to 0,4 atofbase

creep

For end restraint, where the restraint is truly rigid 1.0 is most often used , for instance in infill

bays. This figure might be overly pessimistic for piled slabs. 0,1 to 0,2 atincluded

top

T2 = long-term drop in temperature after concreting, °C. T 2 depends on the ambient temperature

during concreting. The recommended values from CIRIA C660 for T 2 are 20°C for concrete cast Suspended slabs 0,2 to 0,4

in the summer and 10°C for concrete cast in winter. These figures are based on HA BD

28/87[60] based on monthly air temperatures for exposed bridges. Basements are likely to

follow soil temperatures so T 2 = 12°C may be considered appropriate at depth. Infill bays, i.e. rigid restraint 0,8 to 1,0

e cd = drying shrinkage strain, dependent on ambient RH, cement content and mem ber size (see BS

EN 1992-1-1 Exp. (3.9) or CIRIA C660 or Table A10). CIRIA C660 alludes to 45% RH for internal

conditions and 85% for external conditions.

e ctu = tensile strain capacity may be obtained from Eurocode 2 or CIRIA C660 for both short term and

long term values

Structural design - SLS Structural design - SLS

SLS Design vs time

Short term load strength

2. Minimum reinforcement

As,min = kc k Act (fct,eff /fyk) BS EN 1992-1-1 Exp (7.1)

where kc = A coefficient to account for stress distribution.

= 1.0 for pure tension.

Long term load strength When cracking first occurs the cause is usually early thermal effects and the whole section is likely

Stress due to to be in tension.

early thermal & k = A coefficient to account for self-equilibrating stresses

= 1.0 for thickness h < 300 mm and 0.65 for h > 800 mm (interpolation allowed for thicknesses

shrinkage & between 300 mm and 800 mm).

seasonal Act = area of concrete in the tension zone just prior to onset of cracking. Act is determined from section

Stress due to early properties but generally for basement slabs and walls is most often based on full thickness of the

section.

thermal & drying fct,eff == fctm

shrinkage mean tensile strength when cracking may be first expected to occur:

§ for early thermal effects 3 days

§ for long-term effects, 28 days (which considered to be a reasonable approximation)

Stress due to early thermal – See Table A5 for typical values.

allowing for creep fyk = characteristic yield strength of the reinforcement.

= 500 MPa

[1]CIRIA C660 Recent research[61] would suggest that a factor of 0.8 should be applied to fct,eff in the formula for crack

inducing strain due to end restraint. This factor accounts for long-term loading, in-situ strengths compared with laboratory

strengths and the fact that the concrete will crack at its weakest point. TR 59[62] concludes that the tensile strength of

concrete subjected to sustained tensile stress reduces with time to 60–70% of its instantaneous value.

Provision of minimum reinforcement does not guarantee any

CS TR 67 specific crack width. It is simply a necessary amount presumed by

models to control cracking; but not necessarily a sufficient amount

to limit actual crack widths.

SPATA Training 4 Oct 2012 - Eurocode 2 Part

3 Tanks 6

08/10/2012

Structural design - SLS Structural design - SLS

3. Crack widths and watertightness 3. Crack widths and watertightness

BS EN 1992-3 Cl 7.3 Tightness Classes - notes BS EN 1992-3 Cl 7.3

Tightness Classes

Lined

pools?

Tiled

pools

(most?)

Above

ground?

Special?

Structural design - SLS Structural design - SLS

4.2 e cr =(e cs - e cm )

4. Crack width calculations

Crack width, wk = sr,max ecr BS EN 1992-1-1 Exp (7.8) Consider a crack in a section:

where Debonding length

4.1 sr,max = Maximum crack spacing = 3.4c + 0.425 (k1k2f /rp,eff)

where S0 S0

c = nominal cover, cnom

Plan (or section)

k1 = 0.8

(CIRIA C660 suggests 1.14)

k2 = 1.0 for tension (e.g. from restraint) Strain in reinforcement

= 0.5 for bending εs

= (e 1 + e 2)/2e 1 for combinations of bending and tension ε εsm

Strain e sm - e cm

f = diameter of the bar in mm. εc ectu

rp,eff = As/Ac,eff ε εcm

Ac,eff for each face is based on {0.5h; 2.5(c + 0.5f); (h – x)/3} where h ε ε= 0

= thickness of section and x = depth to neutral axis. Sr,max

Strain in concrete

e cr = Crack-inducing strain

= Mean strain in steel – mean strain in concrete, over the

debonding length either side of the crack wk = sr,max ecr = sr,max (e sm - e cm) ecm ≈ ectu /2

= (e cs - e cm ) . . . . . .

Structural design - SLS Structural design - SLS

e cr = Crack-inducing strain = . . . . . . . . . . . . . . . Water Retaining : adding in tension

Wall 6 m high.

4.2a Early age crack-inducing strain CIRIA C660 Cl 3.2 Assumed H16 @ 100 bs

ecr = K[acT1 +eca] R1 – 0.5 e ctu The total load transferred may

be obtained by integration as

4.2b Long term crack-inducing strain CIRIA C660 Cl 3.2

T = 180 kN.

ecr = K[([ acT1 +eca )] R1 + ([ acT2 R2)] + ecd R3] – 0.5 e ctu

Total area of designed reinf’t

4.2c End restraint crack-inducing strain BS EN 1992-3 Exp (M.1) 6 ´ 2010 x 2 = 24120 mm2

ecr = 0.5ae kckfct,eff [1 + (1/ae r)] /Es Tension in pool wall Pressure

Corresponding stress ss = 7.46 MPa

4.2d Flexural (and applied tension) crack-inducing strain

leading to a strain es = 37.3 ´ 10–-6

ecr = (esm – ecm) = [ss – kt (fct,eff /rp,eff) (1 + ae rp,eff] /Es

This should be added to ecr

ecr ³ 0.6 (ss )/Es calculated previously to give the

BS EN 1992-1-1 Exp (7.9) modified crack width wk.

SPATA Training 4 Oct 2012 - Eurocode 2 Part

3 Tanks 7

08/10/2012

Structural design - SLS

Outline

Crack control without direct calculation Scope

don’t do it!

Structural Design

Deflection control

• Eurocodes

As ‘normal’ design

Minimising the risk of cracking • ULS design

Materials use cement replacements, aggregates with low a c, avoid high • SLS design

strength concretes

Materials

Construction construct at low temperatures, use GRP or steel formwork,

sequential pours

Specification

Detailing use small bars at close centres, avoid movement joints,

prestress? AOB

Selection of materials Selection of materials

Concrete: Admixtures

Porosity may be important but it’s the cracks that matter –

• Superstructure & Benign soils: not (usually) concrete!

RC30/37? Cement IIB-V (CEM I + 21%-35% fly ash) Concrete Society Working Group on Water Proofing

or IIIA (CEM I + 36% - 65% ggbs). admixtures:

cf C35A?: requirements: C28/35 (equiv) -- WCR 0.55 CC 325 CEM I,, IIB-V,) • no conclusive evidence to support their use (- from a

RC30/37: requirements : C30/37 S3 WCR 0.55 CC 300 CEM I, IIA, IIB-S, IIB-V, IIIA, IVB-V B) material scientist’s point of view).

• Aggressive soils: • from data there is some evidence to suggest that they may

reduce drying shrinkage (less permeability)and therefore

Advise producer of DC Class. reduce onset of cracking and reduce crack widths

For DC-2: FND-2? (C25/30)? Cost and risk:

More aggressive soils: Cement IIIB (CEM I + 66% - Traditional: Engineering, workmanship, supervision issues, risk & £££

80% ggbs) or IIVB-V (CEM I + 36%-55% fly ash) possible remedials and upheavals and contractual issues vs

vs

Admixtures: warranties, supervision & possible remedials and upheavals ££££ ?

Whatever the tank should still be designed properly!

Selection of materials Selection of materials

Water stops Waterbar

• Preformed strips – rubber, PVC, black steel

• Water-swellable water stops

• Cementitious crystalline water stops

• Miscellaneous post-construction techniques

• (Re) injectable water bars

• Rebate and sealant

Photo cr edits Water mans

SPATA Training 4 Oct 2012 - Eurocode 2 Part

3 Tanks 8

08/10/2012

Selection of materials Selection of materials

Hydrophilics Resin injection

Photo cr edit Max Fr ank

Photo cr edit Water mans

Selection of materials Selection of materials

Proprietary cementitious multi-coat

renders, toppings and coatings Proprietary cementitious multi-coat

renders, toppings and coatings

Specification

Outline

Specification:

Scope • BS EN 13670

• NSCS / NBS

Structural Design

Joints

• Eurocodes

• Construction joints

• ULS design • Water stops

• SLS design Miscellaneous

• Kickers

Materials • Formwork ties

• Membranes & coatings

Specification • Admixtures & additives

• Service penetrations

AOB

• Drainage

Inspection, remedials & maintenance

SPATA Training 4 Oct 2012 - Eurocode 2 Part

3 Tanks 9

08/10/2012

Specification

Materials

National

Structural Inspections

Concrete

Specification,

NSCS Waterstop

s

Ties

Specification

Additives

Kickers

Inspections Ties

Contractors’ Joints

choice of

materials

Guidance Waterstops

Performance

Spec

Specification Specification

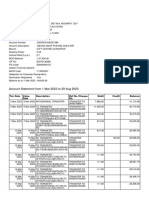

Table 1: AREAS AND DIMENSIONS FOR DIFFERENT

TYPES OF CONSTRUCTION. Testing:

Maximum Maximum

Construction Area (m )

2 Dimension (m ) No longer in BS EN 1992-3

Water – resisting walls 25 5

Suggest putting the testing to BS 8007 in project

Water – resisting slabs 100 10

specification

Slabs with major restraint at both ends 100 13

Slabs with major restraint at one end only 250 20

Slabs with little restraint in any direction 500 30

Walls 40 10

“Unless otherwise agreed”

and designed

NSCS Max pour sizes

SPATA Training 4 Oct 2012 - Eurocode 2 Part

3 Tanks 10

08/10/2012

AOB

Outline

BS8007 vs EC2

Scope

• No 0.7 bond factor in EC2

Structural Design (however detailing rules . . . )

• Eurocodes • Rebar cover and exposure:

• Pool water not ‘severe’ . . . XC2?, XC3/4? . 35 mm?

• ULS design

• Ground: determine Exposure class.

• SLS design • Nominal cover from EC2 & BS8500

Materials • SLS still dominates

• Min area of steel > 0.35%

Specification

• Avoid joints

AOB • %age of fly ash (35%) and ggbs (50%) no longer specifically

restricted

• Testing: nowhere. Suggest put in specification

• Different crack width formulae

AOB AOB

Cracking vs time

Restraint and loading 4.5

4.0 Loading

To determine whether a section cracks

STRENGTH or STRESS, MPa

3.5

Add e and Rax efree due to restraint and loading

3.0 Early ffctm

ctm

age

2.5

To determine crack widths thermalCuring

Restraint stage

Treat ecr due to restraint and loading separately 2.0

actfctm

1.5

sct

1.0

0.5

fctm

0.0

0 5 10 15 20 25 30 35 40

TIME, days 0.8fctm

AOB AOB

BS 8007 Restraint and loading : cracks don’t usually coincide

Surface cracks caused by flexure

3.2.2 The reinforcement provided to control cracking

arising from direct tension in the immature

concrete may be regarded as forming the whole or

a part of the reinforcement required to to control

cracking arising from direct and flexural tension in

the mature concrete

Through cracks Through cracks

caused by loading caused by restraint

Far side

Near side

SPATA Training 4 Oct 2012 - Eurocode 2 Part

3 Tanks 11

08/10/2012

AOB AOB

Possible revision to C660

2. Minimum reinforcement 2 Minimum reinforcement

As,min = kc k Act (fct,eff /fyk) BS EN 1992-1-1 Exp (7.1) As,min = k kc k Act (a ct fct,eff /fyk) BS EN 1992-1-1 Exp (7.1)

where kc = A coefficient to account for stress distribution. where kc = A coefficient to account for stress distribution.

= 1.0 for pure tension. = 1.0 for pure tension.

When cracking first occurs the cause is usually early thermal effects and the whole section is likely When cracking first occurs the cause is usually early thermal effects and the whole section is likely

to be in tension. to be in tension.

k = A coefficient to account for self-equilibrating stresses k = A coefficient to account for self-equilibrating stresses

= 1.0 for thickness h < 300 mm and 0.65 for h > 800 mm (interpolation allowed for thicknesses = 1.0 for thickness h < 300 mm and 0.65 for h > 800 mm (interpolation allowed for thicknesses

between 300 mm and 800 mm). between 300 mm and 800 mm).

Act = area of concrete in the tension zone just prior to onset of cracking. Act is determined from section Act = area of concrete in the tension zone just prior to onset of cracking. Act is determined from section

properties but generally for basement slabs and walls is most often based on full thickness of the properties but generally for basement slabs and walls is most often based on full thickness of the

section. section.

fct,eff == fctm fct,eff == fctm

mean tensile strength when cracking may be first expected to occur: mean tensile strength when cracking may be first expected to occur:

§ for early thermal effects 3 days § for early thermal effects 3 days

§ for long-term effects, 28 days (which considered to be a reasonable approximation) § for long-term effects, 28 days (which considered to be a reasonable approximation)

See Table A5 for typical values. See Table A5 for typical values.

fyk = characteristic yield strength of the reinforcement. fyk = characteristic yield strength of the reinforcement.

= 500 MPa = 500 MPa

[1]CIRIA C660 Recent research[61] would suggest that a factor of 0.8 should be applied to fct,eff in the formula for crack [1]CIRIA C660 Recent research[61] would suggest that a factor of 0.8 should be applied to fct,eff in the formula for crack

inducing strain due to end restraint. This factor accounts for long-term loading, in-situ strengths compared with laboratory inducing strain due to end restraint. This factor accounts for long-term loading, in-situ strengths compared with laboratory

strengths and the fact that the concrete will crack at its weakest point. TR 59[62] concludes that the tensile strength of

concrete subjected to sustained tensile stress reduces with time to 60–70% of its instantaneous value.

k = factor for stess relief, 0.8

strengths and the fact that the concrete will crack at its weakest point. TR 59[62] concludes that the tensile strength of

concrete subjected to sustained tensile stress reduces with time to 60–70% of its instantaneous value.

a ct = factor for sustained loading, 0.75

Provision of minimum reinforcement does not guarantee any Provision of minimum reinforcement does not guarantee any

specific crack width. It is simply a necessary amount presumed by specific crack width. It is simply a necessary amount presumed by

models to control cracking; but not necessarily a sufficient amount models to control cracking; but not necessarily a sufficient amount

to limit actual crack widths. to limit actual crack widths.

AOB AOB

Possible revision to C660

Crack widths and watertightness –recommendations for basements (TCC) Crack widths and watertightness

Construction Expected Crack width requirement Tight wk mm BS EN 1992-3 Cl 7.3

typea and water performance of -ness Flex-

Tightness Classes - notes

Restraint

table structure Class ural / axial

wk,max wk,1

A (membrane) Structure itself is not Design to Tightness class 0 of BS EN 1992-3. See

0 0.30 0.30e

considered watertight Table 9.2. Generally 0.3 mm for RC structure

B – high Structure is almost Design to Tightness class 1 of BS EN 1992-3. See

1 0.30b 0.05 to

watertight Table 9.2. Generally 0.3 mm for flexural cracks

permanently high but 0.2 mm to 0.05 mm for cracks that pass 0.20

water table through the section

(wrt

hd/h)

B – variable Structure is almost Design to Tightness class 1 of BS EN 1992-3. See

1c 0.30 b 0.20

watertight Table 9.2. Generally 0.3 mm for flexural cracks

fluctuating water but 0.2 mm for cracks that pass through the

table section

B – lowd Structure is watertight

under normal

Design to Tightness class 0 of BS EN 1992-3. See

Table 9.2. Generally 0.3 mm for RC structures

0c 0.30 0.30

water table conditions. Some risk

permanently below under exceptio nal

underside of slab conditions.

C (cavity) Structure itself is not Design to Tightness class 0 of BS EN 1992-3. See

0 0.30 0.30e

considered watertight Table 9.2. Generally 0.3 mm for RC structure.

Design to Tightness Class 1 may be helpful for

construction type C

(1)c (0.3) (0.05 to

0.20 or

0.20)

Key b Where the section is not fully cracked) the neutral axis depth at SLS should be at least xmin (where

xmin > max {50 mm or 0.2 × section thickness}) and variations in strain should < than 150 × 10–6.

AOB AOB

Possible revision to C660

Concrete pool tanks (cont)

Possible revisions to allowable crack widths wk1 Pre-cast concrete panels … and permanent shuttering ..Structural

movement joints should be avoided where possible. . . . . .If joints

are unavoidable, these must have an effective proprietary water

NB Dwk = Dwk bar system suitable for their application. . . . .Pool surrounds

= diurnal change in should be designed to the same standard as the pool tank.

crack width Other concrete pool construction forms include sprayed concrete

= possible new (gunite) and concrete blockwork formwork filled with reinforced

limits tied to concrete. These forms are primarily associated with private and

allowable time for hotel pools, and . . . Expert independent advice should be sought

cracks to heal before considering these forms of pool construction.

under full head The use of tanking membranes in the pool surrounds, as an

alternative to water retaining concrete should generally be

avoided. However if tanking is unavoidable great care must be

taken . . . . .

The risk of damage due to thermal shock when the pool is emptied

or filled with water and heated is a critical issue. This must be

taken into account. . . Max fill/empty rate 0.03m/hour

(0.75m/day) Max heating rate 0.25°C/hour (6°C/day)

Prefabricated sectional stainless steel tank structures . . Is. . an

www.sportengland.org/facilities.../design _and.../idoc.ashx?... emergent market. These are supported on a concrete slab . . . A

welded reinforced plastic liner may also be used for the walls

and/or floor of the tank.

SPATA Training 4 Oct 2012 - Eurocode 2 Part

3 Tanks 12

08/10/2012

AOB AOB

Sustainability: environmental Sustainability: social, economic www.sportengland.org/facilities.../design _and.../idoc.ashx?...

Robustness • Robust - minimal risk of damage from vandalism or pool hall activities.

Materials – should be selected with • Durable • Stable construction

regard to their environmental • Workmanship is critical to waterproofing and long term life of the pool

sustainability, whilst also ensuring Service life Proven long service life. Examples c 100 years

durability and lifecycle qualities:

Maintenance Minimal long term maintenance of pool tank structure. Re-grouting of ceramic

• Recyclable content tiles may be required c 20 year intervals. Life of finishes will depend upon

• BRE green guide rating quality of materials, maintenance of pool water

• Environmental profile. quality, wave action and chemicals Utilized

Concrete Industry

Construction • Long construction period for building the concrete shell

Sustainable Construction

• Wet trade of finishes require an extensive period for application and curing

May be OK for concretes Strategy. See

• Lack of a long term warranty. (Usually, the latent defects period will be 6/12

on large projects but: sustainableconcrete.org

years and the patent defects period will be12 months)

provenance, increased .uk

• Long overall construction program

cement content for 92% of concrete

angular aggregate. Quality • Resolution of severe defects and leakage can be complex requiring potential

surveyed is responsibly

26% of all aggregate is control drainage of pool and resulting in extended closure

sourced.

recycled. • Dimensional control dependant on quality of workmanship on site

45% improvement in

All recycled concrete is energy consuptyion in Costs • Tank construction: Normally used as benchmark

www.sportengland.org/facilities.../design _and.../idoc.ashx?... already being used. cement manufacture • Other associated costs: Dependant on the under-croft and basements

since 1990 plant room configurations and the contractors allowances for prelims.

AOB

Outline

Masonry design has changed too!

. . . . . BS EN 1996

Scope

Structural Design

• Eurocodes

• ULS design

• SLS design

Materials

Specification

AOB

www.londonswi mmi ngpools.com/swimming_pool_constr uction. html

To

The Editor of Concrete.

4 Meadows Business Park,

Blackwater, Camberley,

GU17 9AB

5th September 2012

Dear Sir,

‘Waterproof concrete’

Concrete (swimming pool) I note the recent space given to ‘waterproof concrete’. To suggest (Success with waterproof concrete,

Concrete, Aug 2012) that it can satisfy Types A, B and C construction is clearly fatuous. Type A relies on

a barrier or membranes and while admittedly a better outer wall will reduce water ingress, Type C

Tanks relies on the cavity. It is Type B, structurally integral protection, where the potential benefits lie.

The publicity is all very well but we engineers realise that besides joints, it is the cracks that cause leakage

Guidance on the design of and concern in Type B structures - not the concrete between. CIRIA C660 and the Eurocodes give us

in-situ concrete water retaining structures sound principles on which to base our assessment of the likelihood of cracking. Assuming cracks occur,

these documents may be used to give the appropriate amounts of reinforcement required to restrict

crack widths so that in time water ingress stops. Cracking and crack-width calculations are based on

fundamental properties of concrete (e.g. ac , T1, e ca, e cd, e ctu). Unfortunately the effects that

waterproofing admixtures have on these properties is largely unknown – despite the best efforts of a

recent Concrete Society Working Party to find out. So where these products are used, structural

designers often ignore effects or are reliant on warranties for the design.

Good workmanship is key and proponents’ efforts in this regard are to be applauded - as are the usual

warranties to seal any cracks that occur. However, the cost to our clients, the disruption caused by

making good, the lack of appropriate design information and the relinquishing of responsibility should

cause specifiers and designers some thought.

Yours sincerely

Charles Goodchild

Principal Structural Engineer The Concrete Centre

T 01276 606829 M 07870 179755 E cgoodchild@concretecentre.com

S 01276 606800 F 01276 606701 W www.concretecentre.com

4 M eadows Business Park, Blackwater, Camberley, GU17 9AB

The Concrete Centre is part of the Mineral Products Association, the trade association for the aggregates,

SPATA Training 4 Oct 2012 - Eurocode 2 Part

3 Tanks 13

08/10/2012

Structural design - SLS Structural design - SLS

Revision to C660 Revision to C660

Crack widths and watertightness e cr = Crack-inducing strain = . . . . . . . . . . . . . . .

Tightness Classes - notes BS EN 1992-3 Cl 7.3

9.7.2 Early age crack-inducing strain

CIRIA C660 Cl 3.2

e cr = K[a cT1 +e ca] R1 – 0.5 e ctu

9.7.3 Long term crack-inducing strain CIRIA C660 Cl 3.2

e cr = K[([a cT1 +e ca)] R1 + ([a cT2 R2)] + e cd R3] – 0.5 e ctu

9.7.4 End restraint crack-inducing strain BS EN 1992-3 Exp (M.1)

e cr = 0.5a e kckfct,eff [1 + (1/a e r)] /Es

9.7.5 Flexural (and applied tension) crack-inducing strain

e cr = (e sm – e cm) = [s s – kt (fct,eff /rp,eff) (1 + a e rp,eff] /Es

e cr ³ 0.6 (s s)/Es

BS EN 1992-1-1 Exp (7.9)

Basement (Tank) slab options

250 mm wall options

(300 mm thick)

NBG Excluding effects of

tension

Excluding

effects of

tension

End restraint rules Edge restraint rules

SPATA Training 4 Oct 2012 - Eurocode 2 Part

3 Tanks 14

You might also like

- XFLR5 Lab 1Document33 pagesXFLR5 Lab 1maryNo ratings yet

- Science Lesson Plan - Refraction LightDocument5 pagesScience Lesson Plan - Refraction Lightapi-45770214250% (2)

- Steel Angle Masonry SupportDocument2 pagesSteel Angle Masonry SupportYHK3001No ratings yet

- L8 Deflection CalculationsDocument10 pagesL8 Deflection CalculationsBogdan BuzaianuNo ratings yet

- Eb 8Document7 pagesEb 8SyedjamelNo ratings yet

- A Guide To Assessing Existing Roofs For The Addition of Solar PanelsDocument5 pagesA Guide To Assessing Existing Roofs For The Addition of Solar PanelsJames BrayNo ratings yet

- Column ShorteningDocument28 pagesColumn ShorteningKhaled Ali AladwarNo ratings yet

- PileDesignGuide PDFDocument46 pagesPileDesignGuide PDFRajinda BintangNo ratings yet

- 2.6 Losses: Eas458 Prestressed Concrete Design 2017/2018Document11 pages2.6 Losses: Eas458 Prestressed Concrete Design 2017/2018Chee Fong MakeNo ratings yet

- 19 - Design of Timber Floor JoistsDocument4 pages19 - Design of Timber Floor Joistsponsepoy100% (1)

- USER's Manual: Design of Structural Steelwork Elements According To Eurocode 3 EN 1993:2005Document60 pagesUSER's Manual: Design of Structural Steelwork Elements According To Eurocode 3 EN 1993:2005SergNo ratings yet

- Example Flat Slab Design - CarDocument31 pagesExample Flat Slab Design - CarRayGaintNo ratings yet

- Deflectionproblems in ACI-318Document42 pagesDeflectionproblems in ACI-318imzee25No ratings yet

- NBS - 001 Structure Sample Specification 2019-03-29Document23 pagesNBS - 001 Structure Sample Specification 2019-03-29Nay Win MaungNo ratings yet

- Rapt 550 ManualDocument16 pagesRapt 550 ManualbbwhaleNo ratings yet

- Sample Structural Use of Glass in Buildings Second EditionDocument3 pagesSample Structural Use of Glass in Buildings Second EditionNick BesterNo ratings yet

- HK Wind Code 2004Document60 pagesHK Wind Code 2004LeggotungleiNo ratings yet

- Introduction To Eurocode 2Document14 pagesIntroduction To Eurocode 2LUUVANDONG48XFNo ratings yet

- Design Example On A Pile Foundation - Seismic Design EurocodeDocument3 pagesDesign Example On A Pile Foundation - Seismic Design EurocodedenyfateNo ratings yet

- Slabs: Designing To Eurocode 2Document8 pagesSlabs: Designing To Eurocode 2way2saleemNo ratings yet

- What's New in ASCE 7-16?: The Big ChangesDocument17 pagesWhat's New in ASCE 7-16?: The Big ChangesduckeNo ratings yet

- GUIDE On Importing ETABS Thermal Model To SAFEDocument4 pagesGUIDE On Importing ETABS Thermal Model To SAFEMara Pearl Domingo-BonitaNo ratings yet

- Manual Composite Beam Design - ENUDocument56 pagesManual Composite Beam Design - ENUCezar PantelemonNo ratings yet

- Wind Tunnel Testing For Tall BuildingsDocument7 pagesWind Tunnel Testing For Tall BuildingsSilver Olguín CamachoNo ratings yet

- Limit State DesignDocument12 pagesLimit State DesignEzhil KumarNo ratings yet

- Wind Speed in Sri Lanka PDFDocument15 pagesWind Speed in Sri Lanka PDFsandrock92100% (1)

- Reinforced Concrete Slab Design Using The Empirical MethodDocument9 pagesReinforced Concrete Slab Design Using The Empirical MethodRezky MuliaNo ratings yet

- Structural,: PDF Compression, Ocr, Web-Optimization With Cvision'S PdfcompressorDocument174 pagesStructural,: PDF Compression, Ocr, Web-Optimization With Cvision'S PdfcompressorZuhal ZaeemNo ratings yet

- 4.1 Wind Pressure As Per ASCE 7-10Document9 pages4.1 Wind Pressure As Per ASCE 7-10khaja143No ratings yet

- Tekla Structural Designer 2016: Reference Guides (BS)Document98 pagesTekla Structural Designer 2016: Reference Guides (BS)akankwasaNo ratings yet

- Eurocode 8 and Other Seismic Design Codes PDFDocument23 pagesEurocode 8 and Other Seismic Design Codes PDFmarineugenNo ratings yet

- RC Desktop Toolkit v2Document27 pagesRC Desktop Toolkit v2pbharadwaj545No ratings yet

- Timber StructureDocument25 pagesTimber Structuremega100% (1)

- How2 Deflections FINALDocument8 pagesHow2 Deflections FINALDiep TuNo ratings yet

- Calculation of Wind Loads On Structures According To ASCE 7-10Document21 pagesCalculation of Wind Loads On Structures According To ASCE 7-10Chien ChieuNo ratings yet

- Wall Ties and Restraint FixingsDocument32 pagesWall Ties and Restraint FixingsErnest JuniorNo ratings yet

- Load Difference in NZ CodeDocument7 pagesLoad Difference in NZ CodeAslam KyonNo ratings yet

- Determining Wind Actions Using Eurocode 1-Part 2 Worked ExamplesDocument17 pagesDetermining Wind Actions Using Eurocode 1-Part 2 Worked Examplesval mejiaNo ratings yet

- Rules of ThumbDocument10 pagesRules of ThumbYazuraPoyoNo ratings yet

- Constructing The Building 2Document61 pagesConstructing The Building 2Ar Amit MehtaNo ratings yet

- Axial Shortening MendisDocument6 pagesAxial Shortening Mendisjoaobarbosa22No ratings yet

- Stephanos Dritsos - Seismic Assessment and Retrofitting of Structures - Eurocode8-Part3 and The Greek Code On Seismic Structural Interventions'Document98 pagesStephanos Dritsos - Seismic Assessment and Retrofitting of Structures - Eurocode8-Part3 and The Greek Code On Seismic Structural Interventions'moug_thNo ratings yet

- PCI Designer Notebook - Blast ConsiderationsDocument30 pagesPCI Designer Notebook - Blast ConsiderationsrshyamsNo ratings yet

- Ultimate Behaviour and Design of Post-TensionedDocument8 pagesUltimate Behaviour and Design of Post-TensionedManuel RochaNo ratings yet

- Arup - Ground MovementDocument4 pagesArup - Ground MovementJinsun JeongNo ratings yet

- Eurocode 6 Vertical Resistance 8-7-10Document8 pagesEurocode 6 Vertical Resistance 8-7-10Rodrigo Sánchez Ferreira100% (1)

- BS en 1992-1!2!2004 - Annex - UK - Design of Concrete StructuresPDocument6 pagesBS en 1992-1!2!2004 - Annex - UK - Design of Concrete StructuresPvaibhavNo ratings yet

- PDFDocument3 pagesPDF6BisnagaNo ratings yet

- Design of Planted Shear Walls of Tall BuldingDocument5 pagesDesign of Planted Shear Walls of Tall BuldingLuisito Sta. InesNo ratings yet

- Hollow CoreDocument6 pagesHollow CorershyamsNo ratings yet

- Steel Rev A PDFDocument34 pagesSteel Rev A PDFMario FeghaliNo ratings yet

- CIVL311 - CIVL911 - 2020 - Week1 - Student - 1 SlideDocument72 pagesCIVL311 - CIVL911 - 2020 - Week1 - Student - 1 SlideMohammad Touhidul HaqueNo ratings yet

- Comprehensive Step by Step Calculations For Retaining Wall Analysis Are Provided BelowDocument15 pagesComprehensive Step by Step Calculations For Retaining Wall Analysis Are Provided BelowLakshmiWijayasiriNo ratings yet

- Advanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionFrom EverandAdvanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionNo ratings yet

- Model Analysis of Plane Structures: The Commonwealth and International Library: Structures and Solid Body Mechanics DivisionFrom EverandModel Analysis of Plane Structures: The Commonwealth and International Library: Structures and Solid Body Mechanics DivisionNo ratings yet

- Finite Element Analysis of Structures through Unified FormulationFrom EverandFinite Element Analysis of Structures through Unified FormulationNo ratings yet

- Distinction Task 6.3 - Custom Program DesignDocument3 pagesDistinction Task 6.3 - Custom Program DesignĐức NguyễnNo ratings yet

- MIPS Reference Sheet For FIT1008 and FIT2085Document2 pagesMIPS Reference Sheet For FIT1008 and FIT2085Alireza KafaeiNo ratings yet

- DEC Schedule Maintenance Plan 2023Document2 pagesDEC Schedule Maintenance Plan 2023Michael MagdyNo ratings yet

- Sell Tourism Products and Services: Sitttsl005ADocument12 pagesSell Tourism Products and Services: Sitttsl005AZizu MohNo ratings yet

- Unit-1 2019Document261 pagesUnit-1 2019Mr. S. Paul JoshuaNo ratings yet

- 1st Quarter Classroom ObservationDocument4 pages1st Quarter Classroom ObservationJoriza NovioNo ratings yet

- Iecex Ine 11.0013XDocument5 pagesIecex Ine 11.0013XFrancesco_C100% (1)

- User Guide PDF To INDDDocument46 pagesUser Guide PDF To INDDManuel RVNo ratings yet

- MERCHANT OF VENUS Classic Game Solitaire AI (v1.2) : That It Can AffordDocument6 pagesMERCHANT OF VENUS Classic Game Solitaire AI (v1.2) : That It Can AffordNicola AlNo ratings yet

- Chapter 4 Quiz KeyDocument6 pagesChapter 4 Quiz Keyv9pratapNo ratings yet

- Stress Management2Document15 pagesStress Management2Mary Jo LegaspiNo ratings yet

- Eprs Stu (2019) 634414 enDocument60 pagesEprs Stu (2019) 634414 enGuilherme Ribeiro BarbosaNo ratings yet

- PuSm - Lecture 13 - Chapter 13 - Slides - OnlineDocument37 pagesPuSm - Lecture 13 - Chapter 13 - Slides - OnlineLaura FernandesNo ratings yet

- 50 - Ministerial Roll - Madras DioceseDocument6 pages50 - Ministerial Roll - Madras DioceseIsaac SamuelNo ratings yet

- Ground Atc TranscriptionDocument4 pagesGround Atc TranscriptionDesmond NgNo ratings yet

- Chapter 4 The Normal DistributionDocument12 pagesChapter 4 The Normal Distributionleonessa jorban cortesNo ratings yet

- CPO Transfemoral Prosthesis Above Knee PDFDocument2 pagesCPO Transfemoral Prosthesis Above Knee PDFkeerthiNo ratings yet

- Surveying Formulas (CESURVE)Document29 pagesSurveying Formulas (CESURVE)Chamberlaine LopezNo ratings yet

- 1MRK505383-UEN C en Application Manual Breaker Protection REQ650 Version 2.2Document292 pages1MRK505383-UEN C en Application Manual Breaker Protection REQ650 Version 2.2srinivasan balakrishnanNo ratings yet

- Vietnam 4matDocument10 pagesVietnam 4matDavid OgahNo ratings yet

- Boiler Installation Procedures With SamplesDocument67 pagesBoiler Installation Procedures With SamplesMalik RiazNo ratings yet

- DBU2 - GDEX - Jolyn Lee Jia YingDocument30 pagesDBU2 - GDEX - Jolyn Lee Jia YingTay Khai SernNo ratings yet

- Biotechnology Is The Use of Living Systems and Organisms To Develop orDocument2 pagesBiotechnology Is The Use of Living Systems and Organisms To Develop orLiezel-jheng Apostol LozadaNo ratings yet

- ZTWD ELt Ne USogw FDocument10 pagesZTWD ELt Ne USogw FSouravDeyNo ratings yet

- Three Logicians Walk Into A Bar (Or Why Logic Is Not So Scary)Document18 pagesThree Logicians Walk Into A Bar (Or Why Logic Is Not So Scary)Rytis JezukevičiusNo ratings yet

- This Is The Last Chance For 2016 Admission Candidates For Sixth Semester Examinations, As Per TheDocument2 pagesThis Is The Last Chance For 2016 Admission Candidates For Sixth Semester Examinations, As Per TheMetrecNo ratings yet

- Lomas de Omedo SismicaDocument12 pagesLomas de Omedo SismicaClaudia Prezzi PrezziNo ratings yet

- Breaking The Silence - Art TherapyDocument43 pagesBreaking The Silence - Art TherapyAdriana100% (1)