100% found this document useful (1 vote)

690 views6 pagesRammed Earth Technical Data 1

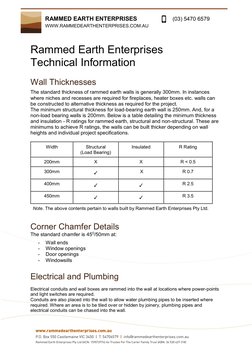

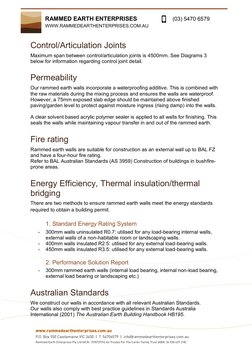

Rammed Earth Enterprises is a company that constructs rammed earth walls for homes and landscaping in Victoria. They provide information on wall thicknesses, openings, electrical and plumbing installation, roof tie-downs, control joints, permeability, fire ratings, and compliance with Australian standards. Walls can be built in standard thicknesses of 300mm or customized, with minimums of 250mm for structural and 200mm for non-structural.

Uploaded by

Amrit NarkarCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

100% found this document useful (1 vote)

690 views6 pagesRammed Earth Technical Data 1

Rammed Earth Enterprises is a company that constructs rammed earth walls for homes and landscaping in Victoria. They provide information on wall thicknesses, openings, electrical and plumbing installation, roof tie-downs, control joints, permeability, fire ratings, and compliance with Australian standards. Walls can be built in standard thicknesses of 300mm or customized, with minimums of 250mm for structural and 200mm for non-structural.

Uploaded by

Amrit NarkarCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd