Professional Documents

Culture Documents

TS 15100

Uploaded by

Giveaway0 ratings0% found this document useful (0 votes)

21 views1 pageThis document provides test data for the HEMPADUR 15100 product, including:

1) Adhesion/cohesion was measured at 5 MPa using ISO 4624/ASTM D 4541 tests.

2) Hardness was measured at 84 using DIN 53505 tests on a 200 μm coating.

3) Water absorption was measured at 0.4% after 1 day and 2.24% after 60 days using ASTM D 570 tests on a 200 μm coating.

4) Flexibility and abrasion resistance tests were also performed according to various standards.

Original Description:

Hempel

Original Title

TS_15100

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document provides test data for the HEMPADUR 15100 product, including:

1) Adhesion/cohesion was measured at 5 MPa using ISO 4624/ASTM D 4541 tests.

2) Hardness was measured at 84 using DIN 53505 tests on a 200 μm coating.

3) Water absorption was measured at 0.4% after 1 day and 2.24% after 60 days using ASTM D 570 tests on a 200 μm coating.

4) Flexibility and abrasion resistance tests were also performed according to various standards.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

21 views1 pageTS 15100

Uploaded by

GiveawayThis document provides test data for the HEMPADUR 15100 product, including:

1) Adhesion/cohesion was measured at 5 MPa using ISO 4624/ASTM D 4541 tests.

2) Hardness was measured at 84 using DIN 53505 tests on a 200 μm coating.

3) Water absorption was measured at 0.4% after 1 day and 2.24% after 60 days using ASTM D 570 tests on a 200 μm coating.

4) Flexibility and abrasion resistance tests were also performed according to various standards.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

TECHNICAL STATEMENT

In addition to the Technical Product Data Sheet and the Safety Data Sheet the following additional test data

are listed for the product:

HEMPADUR 15100

Please note that the measurements given below have been obtained under very controlled laboratory

conditions. On-site measurements may give different results depending on circumstances.

ADHESION/COHESION: (ISO 4624/ASTM D 4541, Saeberg - Pneumatic adhesion tester):

Pull Off Value: 5 MPa (51 kgf/cm2 )

HARDNESS: (DIN 53505, Shore D):

84 (average of 10 measurements)

2 X 200 µm HEMPADUR 15100

WATER ABSORPTION: (ASTM D 570):

2 X 200 µm HEMPADUR 15100.

Weight increase after

1 day: 0.4%. and after 60 days: 2.24%

FLEXIBILITY: (ASTM D 2370):

2 X 200 µm HEMPADUR 15100

Tensile Strength 13.4 +/- 0.9 MPa.

Elongation 4.5 %

(ISO 1519/ASTM D522, Mandrel bend test):

No cracking with mandrel diameters higher than 32 mm at dry film

thickness of 500 µm.

ABRASION RESISTANCE: (ASTM D 4060, Taber Abraser):

Wheel CS-17:

Approx. 65 mg/1000 rotations, load 500 grams (Corresponding to a

DFT loss of 15 µm/1000 rotations).

RESISTANCE TO AGEING: Coating system:

2 X 250 µm HEMPADUR 15100

(ISO 6270/ASTM D4585, Condensation chamber):

No rust or blistering and good adhesion after 3 months.

RESISTANCE TO CATHODIC (ISO 15711 - Cathodic Protection - modified):

PROTECTION: No blisters and perfect adhesion after 12 months exposure

(-1050 mV) (3 x 125 µm HEMPADUR 15100)

HEMPEL A/S

Products Solutions & Performance

Søren Nyborg Rasmussen

12 January 2005

HEMPEL

You might also like

- Geotextiles and Geomembranes HandbookFrom EverandGeotextiles and Geomembranes HandbookT.S. IngoldRating: 5 out of 5 stars5/5 (1)

- TS 15130Document1 pageTS 15130GiveawayNo ratings yet

- TS 15300Document1 pageTS 15300GiveawayNo ratings yet

- TS 15360Document1 pageTS 15360GiveawayNo ratings yet

- TS 15280Document1 pageTS 15280GiveawayNo ratings yet

- Fluteck P7500 CA v01.19Document2 pagesFluteck P7500 CA v01.19fprovitaliNo ratings yet

- Tds Deckdrain 1200s nw8 GCD A01 Deck1200s 0518 001Document1 pageTds Deckdrain 1200s nw8 GCD A01 Deck1200s 0518 001AladinNo ratings yet

- Rowad HDSDocument1 pageRowad HDSsellami walidNo ratings yet

- Sikadur-42 MP Normal HCDocument6 pagesSikadur-42 MP Normal HCDidiet PuteraNo ratings yet

- HDPE Double Side TextureDocument1 pageHDPE Double Side TextureArun Chandra BabuNo ratings yet

- PF7000Aliphatic PolyurethaneDocument2 pagesPF7000Aliphatic PolyurethaneLuis ArciaNo ratings yet

- Silicone Foam: Phucat Co.,Ltd - Moonphin Adhesive TapeDocument2 pagesSilicone Foam: Phucat Co.,Ltd - Moonphin Adhesive TapeTran Tuan anhNo ratings yet

- Lldpe Ll0209Aa Linear Low Density Polyethylene: 3) Typical Data Test Method Typical Value Unit Property PhysicalDocument2 pagesLldpe Ll0209Aa Linear Low Density Polyethylene: 3) Typical Data Test Method Typical Value Unit Property PhysicalĐỗ Ngọc TúNo ratings yet

- Protective & Marine Coatings: DTM Acrylic Primer/FinishDocument4 pagesProtective & Marine Coatings: DTM Acrylic Primer/FinishAna CabreraNo ratings yet

- Mobil DTE 10 Excel SeriesDocument3 pagesMobil DTE 10 Excel SeriesSuprastowo Bin SarinoNo ratings yet

- ASTM FL7100U Eng 240223Document1 pageASTM FL7100U Eng 240223MERVENo ratings yet

- Fibre-Reinforced Geosynthetic Clay Liner (GBR-C) Bentofix® NSP 4000Document1 pageFibre-Reinforced Geosynthetic Clay Liner (GBR-C) Bentofix® NSP 4000Luis Alberto GutiérrezNo ratings yet

- Product Data SheetDocument2 pagesProduct Data SheetshahneillNo ratings yet

- RX 102 BLACK GREY 9141: Linear Low Density Polyethylene: ColourDocument1 pageRX 102 BLACK GREY 9141: Linear Low Density Polyethylene: ColourEetu SatosalmiNo ratings yet

- 01 Al Munaif UPVC High Pressure FittingsDocument36 pages01 Al Munaif UPVC High Pressure FittingsmohammedNo ratings yet

- TDS B0155DDocument1 pageTDS B0155DtechnopackishvarlalNo ratings yet

- Sikadur®-42 MP Slow HC: Product Data SheetDocument4 pagesSikadur®-42 MP Slow HC: Product Data SheetCbeztNo ratings yet

- Technical Data Sheet Polycarbonate: Benefits ApplicationsDocument2 pagesTechnical Data Sheet Polycarbonate: Benefits ApplicationsjackNo ratings yet

- Phucat Co.,Ltd - Moonphin Adhesive Tape: Silicone FoamDocument2 pagesPhucat Co.,Ltd - Moonphin Adhesive Tape: Silicone FoamTran Tuan anhNo ratings yet

- Bakelite PF 31Document3 pagesBakelite PF 31dioguitomsolhaNo ratings yet

- FDM Nylon FamilyDocument6 pagesFDM Nylon FamilykaledioskoppNo ratings yet

- Scotch Heavy Duty Mining Tape 31: Data Sheet June 2013Document2 pagesScotch Heavy Duty Mining Tape 31: Data Sheet June 2013Kishan MohtaNo ratings yet

- Deckdrain S1200NW8 Data SheetDocument1 pageDeckdrain S1200NW8 Data SheetsdvsdvdsaNo ratings yet

- Technical Data Sheet For Hdpe Pe 100, 315.0 MM X 28.6 MM DuctDocument1 pageTechnical Data Sheet For Hdpe Pe 100, 315.0 MM X 28.6 MM DuctJohn BenzNo ratings yet

- tds12 19 2019 - 10 49 12Document1 pagetds12 19 2019 - 10 49 12Camilo DazaNo ratings yet

- Viscowrap-Ht: Product Data SheetDocument2 pagesViscowrap-Ht: Product Data SheetFarid HarisNo ratings yet

- Technical Brief Galal Make SleevesDocument1 pageTechnical Brief Galal Make SleevesSELVAGANAPATHINo ratings yet

- Sikadur®-42 MP Slow HC: Product Data SheetDocument4 pagesSikadur®-42 MP Slow HC: Product Data SheetAmnart KhampanitNo ratings yet

- PolycarbonateDocument2 pagesPolycarbonatepuvitta sudeshilaNo ratings yet

- PolycarbonateDocument2 pagesPolycarbonateROHIT SHARMANo ratings yet

- PolycarbonateDocument2 pagesPolycarbonateAdnan KhanNo ratings yet

- Revetment Use Geotextile - MC TS70Document1 pageRevetment Use Geotextile - MC TS70jurieskNo ratings yet

- SABIC® HDPE - M200056 - Global - Technical - Data - SheetDocument2 pagesSABIC® HDPE - M200056 - Global - Technical - Data - SheetAhmed Elgazar100% (1)

- TS 13624Document1 pageTS 13624GiveawayNo ratings yet

- Sikadur - 42 MP SlowhcDocument4 pagesSikadur - 42 MP Slowhcaritamay3456No ratings yet

- DTM Acrylic Pimer Finish B66W1Document4 pagesDTM Acrylic Pimer Finish B66W1Vernon Jiménez FonsecaNo ratings yet

- Exalite-10 GB PDFDocument2 pagesExalite-10 GB PDFvijayNo ratings yet

- DTM Bonding Primer: Protective & Marine CoatingsDocument4 pagesDTM Bonding Primer: Protective & Marine CoatingsAna CabreraNo ratings yet

- Infino Pc-Abs Hp1000xa (Natural)Document1 pageInfino Pc-Abs Hp1000xa (Natural)Rhekron PlasticsNo ratings yet

- Polyken 930: Product Data SheetDocument2 pagesPolyken 930: Product Data SheetEdwin Bustamante Cabrera100% (1)

- 3M Heavy Wall Heat Shrink Tubing ITCSNDocument4 pages3M Heavy Wall Heat Shrink Tubing ITCSNmuahdibNo ratings yet

- TECNOLEN 25 Bs1d0 - 42234 - 42344 - V5 - ENDocument2 pagesTECNOLEN 25 Bs1d0 - 42234 - 42344 - V5 - ENKarima ABOUALINo ratings yet

- PLA Filament: Physical Conditions Test Method Typical Value MechanicalDocument2 pagesPLA Filament: Physical Conditions Test Method Typical Value MechanicalRui MatiasNo ratings yet

- HD M5306 PDFDocument2 pagesHD M5306 PDFmohamed1303No ratings yet

- Linear Low Density Polyethylene: Blown Film GradeDocument1 pageLinear Low Density Polyethylene: Blown Film GradeChetan BholeNo ratings yet

- PA6EDocument1 pagePA6EDiego ReggianiniNo ratings yet

- Um180821 TDS Tpu 95a RB V11Document3 pagesUm180821 TDS Tpu 95a RB V11Steven DonosoNo ratings yet

- Lotte - M7100 - 2016.11월) -Document1 pageLotte - M7100 - 2016.11월) -Ronald LeonNo ratings yet

- Sikadur - 42 MP Normal HC: 3-Part, Multi Purpose Epoxy Grouting SystemDocument5 pagesSikadur - 42 MP Normal HC: 3-Part, Multi Purpose Epoxy Grouting SystemJay PadamaNo ratings yet

- Elite NG 5401BDocument3 pagesElite NG 5401BAbdo WalidNo ratings yet

- TDS ASIA MACLINE TMH Rev7 Mar 2015Document1 pageTDS ASIA MACLINE TMH Rev7 Mar 2015Andrew Zapanta Jr.No ratings yet

- Test Report FBE 2Document1 pageTest Report FBE 2Anderson VelandiaNo ratings yet

- Low Density Polyethylene: DescriptionDocument2 pagesLow Density Polyethylene: DescriptionlyesNo ratings yet

- Wire Rope End SocketsDocument8 pagesWire Rope End SocketsGiveawayNo ratings yet

- STCW.7 Circ.15 - Data Required To Be Included in Documentary Evidence of Training Leading To The Award of A Certificate of Competency.Document4 pagesSTCW.7 Circ.15 - Data Required To Be Included in Documentary Evidence of Training Leading To The Award of A Certificate of Competency.GiveawayNo ratings yet

- IMO Guidance - Near-Misses - MSC-MEPC.7Document6 pagesIMO Guidance - Near-Misses - MSC-MEPC.7Rajesh BaranNo ratings yet

- TS 13624Document1 pageTS 13624GiveawayNo ratings yet

- TS 13140Document1 pageTS 13140GiveawayNo ratings yet

- 4 Albert Embankment London Se1 7Sr Telephone: 020 7735 7611 Fax: 020 7587 3210 Telex: 23588 IMOLDN GDocument23 pages4 Albert Embankment London Se1 7Sr Telephone: 020 7735 7611 Fax: 020 7587 3210 Telex: 23588 IMOLDN GGiveawayNo ratings yet

- 46 CFR Part 172 Subpart B (Up To Date As of 6-16-2022)Document3 pages46 CFR Part 172 Subpart B (Up To Date As of 6-16-2022)GiveawayNo ratings yet

- Guidance For Shippers Declaration 508Document10 pagesGuidance For Shippers Declaration 508GiveawayNo ratings yet

- Interim Guidance On Training and Assessment in The Operational Use of The Electronic Chart Display and Information System (Ecdis) SimulatorsDocument14 pagesInterim Guidance On Training and Assessment in The Operational Use of The Electronic Chart Display and Information System (Ecdis) SimulatorsGiveawayNo ratings yet

- 4 Albert Embankment London Se1 7Sr Telephone: 020-7735 7611 Fax: 020-7587 3210 Telex: 23588 IMOLDN GDocument1 page4 Albert Embankment London Se1 7Sr Telephone: 020-7735 7611 Fax: 020-7587 3210 Telex: 23588 IMOLDN GGiveawayNo ratings yet

- LPC - Liquid Bulk Cargo Sampling Collecting Evidence RevDocument2 pagesLPC - Liquid Bulk Cargo Sampling Collecting Evidence RevGiveawayNo ratings yet

- MSC 1-Circ 1164-Rev 21Document6 pagesMSC 1-Circ 1164-Rev 21GiveawayNo ratings yet

- MSCCirc.918 - Guidance For Port State Control Officers in Respect of Certificates of Competency Issued Under The Provisions of The STCW ConventionDocument1 pageMSCCirc.918 - Guidance For Port State Control Officers in Respect of Certificates of Competency Issued Under The Provisions of The STCW ConventionGiveawayNo ratings yet

- FAL 2-Circ 50-Rev 3Document2 pagesFAL 2-Circ 50-Rev 3GiveawayNo ratings yet

- Ladder Safety GuideDocument20 pagesLadder Safety GuideGiveawayNo ratings yet

- FAL 6-Circ 17Document2 pagesFAL 6-Circ 17GiveawayNo ratings yet

- Hempel's Galvosil 15789 Base en-USDocument13 pagesHempel's Galvosil 15789 Base en-USGiveawayNo ratings yet

- IPC-D121H (-M) 2 MP IR Fixed Network Dome Camera: Key FeaturesDocument4 pagesIPC-D121H (-M) 2 MP IR Fixed Network Dome Camera: Key FeaturesGiveawayNo ratings yet

- Port Facilities BangladeshDocument45 pagesPort Facilities BangladeshGiveawayNo ratings yet

- Safety Summary 2012: Alan Deans QA ISM ManagerDocument22 pagesSafety Summary 2012: Alan Deans QA ISM ManagerGiveawayNo ratings yet

- BV Systemicfailures 11x16 03112019 PapDocument24 pagesBV Systemicfailures 11x16 03112019 PapGiveawayNo ratings yet

- S-Center UserGuide UBX-16012261Document26 pagesS-Center UserGuide UBX-16012261GiveawayNo ratings yet

- Ellis Lived ExperiencesDocument31 pagesEllis Lived ExperiencesJeanny Mae PesebreNo ratings yet

- Debug and AssemblerDocument9 pagesDebug and AssemblerManoj GurralaNo ratings yet

- PE 12 Q3 WK1-2 Understanding On Health Related FitnessDocument8 pagesPE 12 Q3 WK1-2 Understanding On Health Related FitnessEmarkzkie Mosra OrecrebNo ratings yet

- Evelyn Arizpe - Teresa Colomer - Carmen Martínez-Roldán - Visual Journeys Through Wordless Narratives - An International Inquiry With Immigrant Children and The Arrival-Bloomsbury Academic (2014)Document290 pagesEvelyn Arizpe - Teresa Colomer - Carmen Martínez-Roldán - Visual Journeys Through Wordless Narratives - An International Inquiry With Immigrant Children and The Arrival-Bloomsbury Academic (2014)Lucia QuirogaNo ratings yet

- Minolta Spotmeter f-1 PDFDocument50 pagesMinolta Spotmeter f-1 PDFmacpator100% (1)

- Shaheed Suhrawardy Medical College HospitalDocument3 pagesShaheed Suhrawardy Medical College HospitalDr. Mohammad Nazrul IslamNo ratings yet

- Electric Heater Datasheet: Duty Bundle (@nom Voltage) Duty Heater (@nom Voltage)Document3 pagesElectric Heater Datasheet: Duty Bundle (@nom Voltage) Duty Heater (@nom Voltage)SonNguyenNo ratings yet

- Preparatory Newsletter No 3 2013Document22 pagesPreparatory Newsletter No 3 2013SJC AdminNo ratings yet

- 1 Raven's™ Standard Progressive Matrices Plus (SPM Plus) - PSI OnlineDocument1 page1 Raven's™ Standard Progressive Matrices Plus (SPM Plus) - PSI OnlineVINEET GAIROLANo ratings yet

- Cosmology Questions and Answers - SanfoundryDocument9 pagesCosmology Questions and Answers - SanfoundryGopinathan MNo ratings yet

- Apspdcl PDFDocument21 pagesApspdcl PDFK.sanjeev KumarNo ratings yet

- Dispersion Relation of Electromagnetic WavesDocument2 pagesDispersion Relation of Electromagnetic WavesFidel SouzaNo ratings yet

- Global Governance and Interstate SystemDocument25 pagesGlobal Governance and Interstate SystemRay Stephen SantosNo ratings yet

- Paper 19 AugustDocument552 pagesPaper 19 AugustUma Sankar Pradhan100% (1)

- Tasha Giles: WebsiteDocument1 pageTasha Giles: Websiteapi-395325861No ratings yet

- Operating Instructions: Vacuum Drying Oven Pump ModuleDocument56 pagesOperating Instructions: Vacuum Drying Oven Pump ModuleSarah NeoSkyrerNo ratings yet

- Some Sunsickday - Kitchenro11Document356 pagesSome Sunsickday - Kitchenro11Spencer HNo ratings yet

- Rights of An Accused Under Custodial InvestigationDocument17 pagesRights of An Accused Under Custodial Investigationadrianfrancis9100% (1)

- Amlodipine Besylate Drug StudyDocument2 pagesAmlodipine Besylate Drug StudyJonieP84No ratings yet

- HC-97G FactsheetDocument1 pageHC-97G FactsheettylerturpinNo ratings yet

- Infoblatt Skischulen Trends Port eDocument18 pagesInfoblatt Skischulen Trends Port eAustrian National Tourism BoardNo ratings yet

- 0 - Danica Joy v. RallecaDocument2 pages0 - Danica Joy v. RallecaRandy Jake Calizo BaluscangNo ratings yet

- Foreign Affairs May June 2021 IssueDocument216 pagesForeign Affairs May June 2021 IssueSohail BhattiNo ratings yet

- 1) About The Pandemic COVID-19Document2 pages1) About The Pandemic COVID-19محسين اشيكNo ratings yet

- Bio-Lubricant Production From Vegetable Oil and Animal Fat: International UniversityDocument52 pagesBio-Lubricant Production From Vegetable Oil and Animal Fat: International UniversityKiệtNguyễnNo ratings yet

- 1973 Essays On The Sources For Chinese History CanberraDocument392 pages1973 Essays On The Sources For Chinese History CanberraChanna LiNo ratings yet

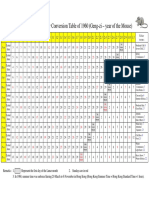

- Gregorian-Lunar Calendar Conversion Table of 1960 (Geng-Zi - Year of The Mouse)Document1 pageGregorian-Lunar Calendar Conversion Table of 1960 (Geng-Zi - Year of The Mouse)Anomali SahamNo ratings yet

- Wec14 01 Rms 20230112Document23 pagesWec14 01 Rms 20230112Shafay SheikhNo ratings yet

- Memo For Completed RubricDocument3 pagesMemo For Completed Rubricnisev2003No ratings yet

- Azure Arc DoccumentDocument143 pagesAzure Arc Doccumentg.jithendarNo ratings yet