Professional Documents

Culture Documents

27 3138 01 Supracare 780 Additive

Uploaded by

Ricardo BohorquezOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

27 3138 01 Supracare 780 Additive

Uploaded by

Ricardo BohorquezCopyright:

Available Formats

Technical Data Sheet

SUPRACARE™ 780 Additive

SUPRACARE™ 780 Additive is a multi-functional cellulosic derivative combining rheology

and structuring benefits

Features & High thickening efficiency (yield)

Benefits Highly tolerant to electrolytes

Non-ionic: compatible with majority of raw materials typically used in a formulation

Improved rate of foam generation in laundry and multifunctional bars

Improved binding and lower /mushiness in laundry/multifunctional/NSD bars

Controlled release in the toilet cistern blocks

Derived from natural raw materials

Inherently biodegradable as per OECD 302B

Composition Cellulosic derivative

Applications SUPRACARE™ 780 Additive is suitable for the following application:

Liquid laundry

Hand dishwash liquid

Hard surface cleaner

Laundry bars / multi-purpose bars / non-soap detergent (NSD) bars

Typical Properties

Specification Writers: These values are not intended for use in preparing specifications.

Property Unit Result

Appearance White to off white powder

Solubility

Viscosity (1% Solution) Haake Roto Visco RV 100 Shear Rate 2.55 S-1, 20°C cps 12000–16000

Solution pH (1%) 6.0–7.0

Moisture Content, % Max % 7 (max)

®™Trademark of The Dow Chemical Company (“Dow”) or an affiliated company of Dow

SUPRACARE™ 780 Additive

Page 1 of 6 © 2021 The Dow Chemical Company. All rights reserved. Form No. 27-3138-01-0521 S2D

Formulation Example 1:

Hand Dish Washing Liquid formulations

Comparing SupraCare™ 780 Additive to the market benchmark

Formulation 1 Formulation 2

Ingredients % w/w % w/w

Water 60% 60%

LABSA (90%) 7% 7%

NaOH (40%) 2%1 2%1

SLES (70%) 3% 3%

Cocamidopropyl betaine (40%) 0.3% 0.3%

ACUSOL™ 445 Detergent Polymer(48%) 1.2% 1.2%

NaOH (40%) ~0.5% QS pH ~8 ~0.5% QS pH ~8

MgSO4 0.8%2 0.8%2

SupraCare™ 780 Additive 0.30% 0

State of the art cellulosic rheology modifier 0 0.30%

Lemon Boost - Givaudan 0.1% 0.1%

Unicert Dye Yellow 8005 - solution at 0.1% 2% 2%

NaCl 0.97% 0.97%

Sodium Xylene Sulfonate (40%) 4% 4%

Water QS 100% formulation QS 100% formulation

Total 100% 100%

1. To partially neutralize LABSA.

2. Dispersed in below water prior addition.

Processing Instructions:

1. Take 60–70% of formulation water.

2. Add LABSA under stirring. Mix well and adjust pH using NaOH to ~6.

3. Add SLES, cocamidopropylbetaine and ACUSOL™ 445N Detergent Polymer under

stirring.

4. Add NaOH (40%) to reach pH ~8.

5. Add magnesium sulfate dispersed in remaining water.

6. Add the balance water.

7. Add SUPRACARE™ 780 Additive and mix for 1 hour under 160 rpm till full dispersion

and viscosity build up.

8. Add sodium xylene sulfonate, perfume, dyes and sodium chloride. Mix well till

homogeneous.

®™Trademark of The Dow Chemical Company (“Dow”) or an affiliated company of Dow

SUPRACARE™ 780 Additive

Page 2 of 6 © 2021 The Dow Chemical Company. All rights reserved. Form No. 27-3138-01-0521 S2D

Viscosity of the HDW Liquids as a function of

shear rate at 25°C

2500

Viscosity (cps)

2000

1500

1000

500

0

5RPM 10RPM 20RPM 50RPM

HDW formulation with 0.3% state of the art cellulosic rheology modifier

HDW formulation with 0.3% SupraCare™ 780

Rheology Profile of the HDW Liquid Formulations

SupraCare™ 780 Additive demonstrates higher yield

Figure 1: Comparative viscosity of hand dish wash liquids

Formulation Example 2:

Laundry Bars -affordable detergents

One of the desired cost-saving benefit is around Total Fatty Matter (TFM) reduction

Control Dow Formulation

Ingredient

% w/w % w/w

Soap noodles 80:20 (76% active) 85.25 69.25

Sodium Silicate (50%) 8 8

Titanium Dioxide 0.75 0.75

Fragrance and Dyes 1 1

SupraCare™ 780 Additive 0 0.5

Water 5 20.5

Total 100 100

Processing Instructions:

Option 1: Ready Made Soap Noodle Based Bars

Charge soap noodle in the sigma mixer and crush them uniformly by mixing them for 15–20

min. Add SUPRACARE™ 780 Additive and mix it for 5 min. Add glycerin mix it for 2–3 min.

Add sodium silicate mix it for 10 min. Add microfine talc mix it for 2–3 min. Add TiO2 and mix

it for 2–3 min. Add water if and when required under mixing. Add color mix it for 3–4 min (till

the color develops in the dough). Add perfume and mix it for 1–2 min and then discharge it

from the sigma mixer. Take the dough from the sigma mixer to the triple roll and then the

mix from the triple roll mill to the extruder for plodding the bars.

®™Trademark of The Dow Chemical Company (“Dow”) or an affiliated company of Dow

SUPRACARE™ 780 Additive

Page 3 of 6 © 2021 The Dow Chemical Company. All rights reserved. Form No. 27-3138-01-0521 S2D

Formulation Processing Instructions (Cont.):

Example 2 (Cont.) Option 2: In-situ Saponification Plant

The SUPRACARE™ 780 Additive can be mixed with the fatty acids and then saponified. In

this case the soap noodles will have built in SUPRACARE™ 780 Additive. Rest of the unit

operations remains same.

Total water content in soap bars

% Water content

35

30

25

20

15

10

5

0

Control Dow formulation

Water Content of Laundry Bars

SupraCare™ 780 Additive enables high water structuring

Figure 2: Comparative water content in laundry bars

% Rate of wear of soap bars

Dow formulation

-35%

Control

0 2 4 6 8 10 12

Rate of Wear Assessment:

SupraCare™ 780 Additive enables longer lasting bars

Figure 3: Comparative rate of wear profile for laundry bars

®™Trademark of The Dow Chemical Company (“Dow”) or an affiliated company of Dow

SUPRACARE™ 780 Additive

Page 4 of 6 © 2021 The Dow Chemical Company. All rights reserved. Form No. 27-3138-01-0521 S2D

Foam profile

175

170

Foam height (mm)

165

160

155

150

145

140

Control Dow formulation

Improving Foam Profile

SupraCare™ 780 Additive boosts foam height

Figure 4: Comparative foam profile of laundry bars

How to Use SUPRACARE™ 780 Additive should be gradually added into aqueous solutions under

continuous stirring to prevent lump formation. The typical use varies from 0.25–0.5% by

weight.

Handling PRODUCT SAFETY INFORMATION REQUIRED FOR SAFE USE IS NOT INCLUDED IN

Precautions THIS DOCUMENT. BEFORE HANDLING, READ PRODUCT AND SAFETY DATA SHEETS

AND CONTAINER LABELS FOR SAFE USE, PHYSICAL AND HEALTH HAZARD

INFORMATION. THE SAFETY DATA SHEET IS AVAILABLE ON THE DOW WEBSITE AT

DOW.COM, OR FROM YOUR DOW SALES APPLICATION ENGINEER, OR

DISTRIBUTOR, OR BY CALLING DOW CUSTOMER SERVICE.

Usable Life and Store product in tightly closed original container at temperatures recommended on the

Storage product label.

Packaging 25 kg bags.

Information

Limitations This product is neither tested nor represented as suitable for medical or pharmaceutical

uses.

Health and To support customers in their product safety needs, Dow has an extensive Product

Environmental Stewardship organization and a team of product safety and regulatory compliance

specialists available in each area.

Information

For further information, please see our website, dow.com or consult your local Dow

representative.

®™Trademark of The Dow Chemical Company (“Dow”) or an affiliated company of Dow

SUPRACARE™ 780 Additive

Page 5 of 6 © 2021 The Dow Chemical Company. All rights reserved. Form No. 27-3138-01-0521 S2D

Disposal Dispose in accordance with all local, state (provincial) and federal regulations. Empty

Considerations containers may contain hazardous residues. This material and its container must be

disposed in a safe and legal manner.

It is the user’s responsibility to verify that treatment and disposal procedures comply with

local, state (provincial) and federal regulations. Contact your Dow Technical Representative

for more information.

Product Dow has a fundamental concern for all who make, distribute, and use its products, and for

Stewardship the environment in which we live. This concern is the basis for our product stewardship

philosophy by which we assess the safety, health, and environmental information on our

products and then take appropriate steps to protect employee and public health and our

environment. The success of our product stewardship program rests with each and every

individual involved with Dow products - from the initial concept and research, to manufacture,

use, sale, disposal, and recycle of each product.

Customer Notice Dow strongly encourages its customers to review both their manufacturing processes and

their applications of Dow products from the standpoint of human health and environmental

quality to ensure that Dow products are not used in ways for which they are not intended or

tested. Dow personnel are available to answer your questions and to provide reasonable

technical support. Dow product literature, including safety data sheets, should be consulted

prior to use of Dow products. Current safety data sheets are available from Dow.

dow.com NOTICE: No freedom from infringement of any patent owned by Dow or others is to be inferred. Because use conditions and

applicable laws may differ from one location to another and may change with time, Customer is responsible for determining

whether products and the information in this document are appropriate for Customer's use and for ensuring that Customer's

workplace and disposal practices are in compliance with applicable laws and other government enactments. The product shown

in this literature may not be available for sale and/or available in all geographies where Dow is represented. The claims made

may not have been approved for use in all countries. Dow assumes no obligation or liability for the information in this document.

References to "Dow" or the "Company" mean the Dow legal entity selling the products to Customer unless otherwise expressly

noted. NO WARRANTIES ARE GIVEN; ALL IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A

PARTICULAR PURPOSE ARE EXPRESSLY EXCLUDED.

Page 6 of 6 ®Trademark of The Dow Chemical Company Form No. 27-3138-01-0521 S2D

You might also like

- Huntsman TericDocument2 pagesHuntsman Tericpmarteene100% (1)

- Natural Based Solubilizers Evonik Pp8Document8 pagesNatural Based Solubilizers Evonik Pp8Zoltán KirályNo ratings yet

- Datasheet Exodrill 5000Document1 pageDatasheet Exodrill 5000Federico ArqueroNo ratings yet

- SpecialitySilicas Proof 5Document2 pagesSpecialitySilicas Proof 5tmlNo ratings yet

- Homework #4 MEMS6460: (30 Points)Document7 pagesHomework #4 MEMS6460: (30 Points)vidhukiran100% (1)

- Module 4 Learning and DevelopmentDocument10 pagesModule 4 Learning and DevelopmentMelg VieNo ratings yet

- TDS Gum Rosin Perhutani Rev December 2021Document1 pageTDS Gum Rosin Perhutani Rev December 2021faisalNo ratings yet

- H 005 E Hordaphos For Household CleaningDocument19 pagesH 005 E Hordaphos For Household Cleaningrosswell2312100% (3)

- DA7200E 0304 BR HordaphosDocument12 pagesDA7200E 0304 BR HordaphoshomayounalaeiNo ratings yet

- ACUMER™ 1510: Polyacrylic Acid HomopolymerDocument3 pagesACUMER™ 1510: Polyacrylic Acid HomopolymerdaniNo ratings yet

- Honeywell Performance Additives Water Based Emulsions Brochure PDFDocument12 pagesHoneywell Performance Additives Water Based Emulsions Brochure PDFyogi4yogesh100% (1)

- Kinetik Technologies Green GuideDocument12 pagesKinetik Technologies Green GuidegowestcreativeNo ratings yet

- Hostapur Sas 60Document8 pagesHostapur Sas 60betun2011No ratings yet

- Poly Dad MacDocument4 pagesPoly Dad Macjummakhan jummakhanNo ratings yet

- Presentation Hans Ridderikhoff - BPM Symposium 15-06-2011 SecuredDocument0 pagesPresentation Hans Ridderikhoff - BPM Symposium 15-06-2011 SecuredHugo WizenbergNo ratings yet

- Amp95 TDSDocument4 pagesAmp95 TDSImran AhmadNo ratings yet

- Stepan Formulation 1203Document2 pagesStepan Formulation 1203ali shahrouzianNo ratings yet

- Brij CS20Document8 pagesBrij CS20Yovani Huaquisaca CoaquiraNo ratings yet

- Liquid Laundry StandardDocument2 pagesLiquid Laundry StandardChemist TechnologistNo ratings yet

- NanoemulsionesDocument28 pagesNanoemulsionesGranLobo Zaytsev100% (1)

- Wax Emulsion Curing CompoundDocument2 pagesWax Emulsion Curing CompoundSanjay KambleNo ratings yet

- IndustrialAndPreparativeResin CatalogueDocument26 pagesIndustrialAndPreparativeResin CatalogueI. Murali KrishnaNo ratings yet

- FICHA TECNICA CARBOMERO Acrypol 956Document2 pagesFICHA TECNICA CARBOMERO Acrypol 956Carlos SiuNo ratings yet

- PEG Esters Table PDFDocument1 pagePEG Esters Table PDFJhon SandovalNo ratings yet

- 27 1147 01Document8 pages27 1147 01ketchitoNo ratings yet

- Luwax and Poligen - Application Guide BAFSDocument9 pagesLuwax and Poligen - Application Guide BAFSHiếu Mai ĐứcNo ratings yet

- Carnauba Wax T3 L - TDS (04-12)Document1 pageCarnauba Wax T3 L - TDS (04-12)vzimak2355No ratings yet

- Stepan Formulation 1212Document2 pagesStepan Formulation 1212Mohamed AdelNo ratings yet

- Coa Fb-50 Plus Textile AntifoamDocument4 pagesCoa Fb-50 Plus Textile AntifoamShandy Yudha Nugraha100% (1)

- 2017 - Formulation & Adjuvant Technology 33Document1 page2017 - Formulation & Adjuvant Technology 33Catherine TangNo ratings yet

- Taski Spiral HDDocument2 pagesTaski Spiral HDVasanthakumar VenkatesanNo ratings yet

- 2018 - EMEA - Brochure - Miranol UltraDocument4 pages2018 - EMEA - Brochure - Miranol UltraEnrico MolinoNo ratings yet

- Formulation and Evaluation of Ow Emulsions UsingDocument7 pagesFormulation and Evaluation of Ow Emulsions UsingalinerhcNo ratings yet

- Solvay Paint AdditivesDocument106 pagesSolvay Paint AdditivesMohamed HalemNo ratings yet

- BioGenic Sallic 210Document2 pagesBioGenic Sallic 210Long Man100% (1)

- Cremophor® RH 40 Product Details: Soluble in Essential OilsDocument2 pagesCremophor® RH 40 Product Details: Soluble in Essential OilsJai MurugeshNo ratings yet

- SF 1214Document4 pagesSF 1214liniaxcitoNo ratings yet

- Leaflet GBDocument4 pagesLeaflet GBdokterasadNo ratings yet

- TDS - KemFoamX 2550 - ENDocument2 pagesTDS - KemFoamX 2550 - ENSteven CoultonNo ratings yet

- GA-013 Functional Coatings BrochureDocument6 pagesGA-013 Functional Coatings Brochuregopinath87No ratings yet

- Shellac Wax 7302 L: ApplicationDocument1 pageShellac Wax 7302 L: Application333cubi333No ratings yet

- Emulsifier For Base Cutting OilsDocument3 pagesEmulsifier For Base Cutting Oilscm_chemical810% (1)

- Clariant Brochure Home Care 2017 enDocument42 pagesClariant Brochure Home Care 2017 ensrushtiNo ratings yet

- Crills and CrilletsDocument6 pagesCrills and CrilletsLukmanWibowo100% (1)

- Propylene Carbonate at Dow ChemicalsDocument6 pagesPropylene Carbonate at Dow Chemicalsjangri1098No ratings yet

- Stepan Formulation 1202Document2 pagesStepan Formulation 1202Mohamed AdelNo ratings yet

- Textile Auxiliaries Non Surfactant Auxiliaries 01Document82 pagesTextile Auxiliaries Non Surfactant Auxiliaries 01Vimal GirnaraNo ratings yet

- Hostapur SAS A Traditional SpecialityDocument44 pagesHostapur SAS A Traditional SpecialityMehmet AydinNo ratings yet

- Ciba - Salcare Conditioning PolymersDocument16 pagesCiba - Salcare Conditioning PolymersMartin Velez Lozano100% (3)

- Application Guide For Water TreatmentDocument5 pagesApplication Guide For Water TreatmentNovara RahmatNo ratings yet

- 1DS REWOPOL SB CS 50 K e 0211Document2 pages1DS REWOPOL SB CS 50 K e 0211Florentina OlaruNo ratings yet

- Stepan Formulation 1220Document2 pagesStepan Formulation 1220Devesh KumarNo ratings yet

- Wax-Based Emulsifiers For Wax Emulsions For Use in Engineered WooDocument118 pagesWax-Based Emulsifiers For Wax Emulsions For Use in Engineered WooyamakunNo ratings yet

- Brochure FT Wax enDocument3 pagesBrochure FT Wax enkishanptlNo ratings yet

- Carnauba-Super-Micropowder 2442 P 5: ApplicationDocument1 pageCarnauba-Super-Micropowder 2442 P 5: Application333cubi333No ratings yet

- Textile Softeners SiliconeDocument4 pagesTextile Softeners SiliconeNilesh DaradeNo ratings yet

- HLB - The Easiest Way To Create An Emulsion: Cosmetic EmulsionsDocument24 pagesHLB - The Easiest Way To Create An Emulsion: Cosmetic EmulsionsVeliYunusKavalciNo ratings yet

- Growth Story of Biopesticides in Tamil NaduDocument26 pagesGrowth Story of Biopesticides in Tamil NaduBalaji RajendranNo ratings yet

- Ethylene Glycol MonostearateDocument4 pagesEthylene Glycol MonostearateVaibhav NikharNo ratings yet

- Antiespumante Xiameter Afe-2210 EmulsionDocument4 pagesAntiespumante Xiameter Afe-2210 EmulsionOnesany TecnologiasNo ratings yet

- Multiple Emulsion NewDocument39 pagesMultiple Emulsion NewRohit Verma100% (2)

- B - Laundry-Folder - HC - 08 - 100806a - 05.2011 - Laundry Brochure - All Combine PDFDocument14 pagesB - Laundry-Folder - HC - 08 - 100806a - 05.2011 - Laundry Brochure - All Combine PDFtml100% (1)

- Alkest LV 1400 - FinalDocument6 pagesAlkest LV 1400 - FinalRicardo BohorquezNo ratings yet

- Tomadol 900Document2 pagesTomadol 900Ricardo BohorquezNo ratings yet

- Aceite Mineral - Ficha Tecnica - Kaifeng Chemical - Ingles PDFDocument1 pageAceite Mineral - Ficha Tecnica - Kaifeng Chemical - Ingles PDFRicardo BohorquezNo ratings yet

- Aceite Mineral 70 NF - Acuerdo de Calidad - Lubline - Ingles PDFDocument3 pagesAceite Mineral 70 NF - Acuerdo de Calidad - Lubline - Ingles PDFRicardo BohorquezNo ratings yet

- Aceite Mineral 50 NF - Ficha Tecnica - Lubline - Ingles PDFDocument1 pageAceite Mineral 50 NF - Ficha Tecnica - Lubline - Ingles PDFRicardo BohorquezNo ratings yet

- Aceite Mineral 70 A - Ficha Tecnica - Lubline - Ingles PDFDocument1 pageAceite Mineral 70 A - Ficha Tecnica - Lubline - Ingles PDFRicardo BohorquezNo ratings yet

- Aceite Mineral 70 NF - Certificado de BSE TSE - Lubline - Ingles PDFDocument1 pageAceite Mineral 70 NF - Certificado de BSE TSE - Lubline - Ingles PDFRicardo BohorquezNo ratings yet

- Aceite Mineral - Hoja de Seguridad - Kaifeng Chemical - Ingles PDFDocument5 pagesAceite Mineral - Hoja de Seguridad - Kaifeng Chemical - Ingles PDFRicardo BohorquezNo ratings yet

- Aceite Mineral 70 NF - Acuerdo de Calidad - Lubline - Ingles PDFDocument3 pagesAceite Mineral 70 NF - Acuerdo de Calidad - Lubline - Ingles PDFRicardo BohorquezNo ratings yet

- Aceite Mineral 70 A - Ficha Tecnica - Lubline - Ingles PDFDocument1 pageAceite Mineral 70 A - Ficha Tecnica - Lubline - Ingles PDFRicardo BohorquezNo ratings yet

- Aceite Mineral - Hoja de Seguridad - Kaifeng Chemical - Ingles PDFDocument5 pagesAceite Mineral - Hoja de Seguridad - Kaifeng Chemical - Ingles PDFRicardo BohorquezNo ratings yet

- Aceite Mineral 70 NF - Carta Sobre NSF Registro - Lubline - Ingles PDFDocument2 pagesAceite Mineral 70 NF - Carta Sobre NSF Registro - Lubline - Ingles PDFRicardo BohorquezNo ratings yet

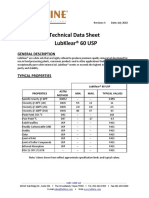

- Aceite Mineral 60 USP - Ficha Tecnica - Lubline - Ingles PDFDocument1 pageAceite Mineral 60 USP - Ficha Tecnica - Lubline - Ingles PDFRicardo BohorquezNo ratings yet

- MKT - Versenex 80 - H&LDocument1 pageMKT - Versenex 80 - H&LRicardo BohorquezNo ratings yet

- Aceite Mineral - Hoja de Seguridad - Gandhar - Ingles PDFDocument5 pagesAceite Mineral - Hoja de Seguridad - Gandhar - Ingles PDFRicardo Bohorquez100% (1)

- MKT - Opulyn 301-2 - H&L PDFDocument1 pageMKT - Opulyn 301-2 - H&L PDFRicardo BohorquezNo ratings yet

- TDS - Versene 220 Crystal - H&L PDFDocument2 pagesTDS - Versene 220 Crystal - H&L PDFRicardo BohorquezNo ratings yet

- TDS - Versene 220 Crystal - H&L PDFDocument2 pagesTDS - Versene 220 Crystal - H&L PDFRicardo BohorquezNo ratings yet

- TDS - Opulyn 301 - Ingles - H&LDocument3 pagesTDS - Opulyn 301 - Ingles - H&LRicardo BohorquezNo ratings yet

- Formulating Manual Dishwash DetergentsDocument4 pagesFormulating Manual Dishwash DetergentsSuresh_Rawal_2794100% (1)

- Formulating Manual Dishwash DetergentsDocument4 pagesFormulating Manual Dishwash DetergentsSuresh_Rawal_2794100% (1)

- Heavy Duty Hand Cleaner Cream HCSC20Document1 pageHeavy Duty Hand Cleaner Cream HCSC20Ricardo BohorquezNo ratings yet

- Anti Fog Anti Static Glass Cleaner W Crodasinic Ls30 Hi-590-1Document1 pageAnti Fog Anti Static Glass Cleaner W Crodasinic Ls30 Hi-590-1Ricardo BohorquezNo ratings yet

- Mathematical Argument, Language and Proof: AS/A LEVEL 2017Document4 pagesMathematical Argument, Language and Proof: AS/A LEVEL 2017Florita LagramaNo ratings yet

- Design and Analysis of Composite Propeller ShaftDocument6 pagesDesign and Analysis of Composite Propeller ShaftVinod Bawane100% (1)

- Chap 3 and 5Document156 pagesChap 3 and 5Richell Mark MiguelNo ratings yet

- Mechanism and Mechanical Vibration (Lab Work) Teaching PlanDocument8 pagesMechanism and Mechanical Vibration (Lab Work) Teaching PlanBelia NomeNo ratings yet

- 5 - One - Hot - Encoding - Ipynb - ColaboratoryDocument8 pages5 - One - Hot - Encoding - Ipynb - Colaboratoryduryodhan sahooNo ratings yet

- Class 6 Term 1 Curriculum Break Up and MYE SyallabiDocument3 pagesClass 6 Term 1 Curriculum Break Up and MYE SyallabiSyed Nasir AbbasNo ratings yet

- FEM - Solid - Mechanics - 2022-2023Document52 pagesFEM - Solid - Mechanics - 2022-2023houda houbanNo ratings yet

- The Cure For BoredomDocument3 pagesThe Cure For BoredomNarette SolanoyNo ratings yet

- Checklist For Evaluating SimDocument26 pagesChecklist For Evaluating SimNickole Ordiales100% (1)

- Marking Scheme According To AIDocument2 pagesMarking Scheme According To AIAbdul RehmanNo ratings yet

- How To Retire Happy Wild and FreeDocument3 pagesHow To Retire Happy Wild and Freeruth.aduncan2014No ratings yet

- Cambridge International AS and A Level Global Perspectives and ResearchDocument35 pagesCambridge International AS and A Level Global Perspectives and ResearchSwati RaiNo ratings yet

- Single Motherhood in India - Problems and ChallengesDocument2 pagesSingle Motherhood in India - Problems and ChallengesS. BhaaratNo ratings yet

- Long Persistent Luminescence and Blue Photochrımism in Eu Dy Co-Doped Barium Silicate Glass Ceramic PhosphorDocument21 pagesLong Persistent Luminescence and Blue Photochrımism in Eu Dy Co-Doped Barium Silicate Glass Ceramic Phosphorabdi soyluNo ratings yet

- 0450 - Volume V.4Document47 pages0450 - Volume V.4Billy MakoyNo ratings yet

- EE4533 Tutorial 11 Solutions PDFDocument6 pagesEE4533 Tutorial 11 Solutions PDFcheeling1530No ratings yet

- How To Write Case Comment - Simple GuideDocument3 pagesHow To Write Case Comment - Simple GuidepranjalNo ratings yet

- Standards-Based Cylinders DSBC, To ISO 15552: Look For The Star!Document61 pagesStandards-Based Cylinders DSBC, To ISO 15552: Look For The Star!Shriniwas SharmaNo ratings yet

- Homolgy ModelingDocument19 pagesHomolgy ModelingJainendra JainNo ratings yet

- Causal Essay OutlineDocument7 pagesCausal Essay Outlinemiwaj0pabuk2100% (2)

- Science FinalDocument3 pagesScience Finalapi-577230763No ratings yet

- Applied Behavior Analysis Cooper 2nd Edition Test BankDocument5 pagesApplied Behavior Analysis Cooper 2nd Edition Test Bankzacharygonzalezqwjsambgny100% (43)

- Practical Issues and Its Solution Note For Energy Metering System Among Power Players An Experience Sharing Case StudyDocument6 pagesPractical Issues and Its Solution Note For Energy Metering System Among Power Players An Experience Sharing Case StudyGuru MishraNo ratings yet

- Simon - Science Seeks Parsimony, Not SimplicityDocument66 pagesSimon - Science Seeks Parsimony, Not SimplicityAnima Sola100% (1)

- Electric PotentialDocument92 pagesElectric PotentialBanani BhattacharyaNo ratings yet

- Lab Grown MeatDocument17 pagesLab Grown MeatSaya SufiaNo ratings yet

- EQUATIONSDocument34 pagesEQUATIONSveer pratap mauryaNo ratings yet

- RRT and RRT - Star Using Vehicle DynamicsDocument5 pagesRRT and RRT - Star Using Vehicle DynamicsMinh Truyền ĐỗNo ratings yet