Professional Documents

Culture Documents

FM-I Lab Manual-Final

Uploaded by

SHINDE MAYUR TU7F2122004Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

FM-I Lab Manual-Final

Uploaded by

SHINDE MAYUR TU7F2122004Copyright:

Available Formats

TEC, Nerul Fluid Mechanics-I

TPCT’s

TERNA ENGINEERING COLLEGE, NERUL

Department of Civil Engineering

Fluid Mechanics-I

LABORATORY MANUAL

AY- 2021-22

Class: S.E Civil

Subject Incharge: Prof. Abhijeet Keskar.

Department of Civil Engineering Page 1

TEC, Nerul Fluid Mechanics-I

LIST OF EXPERIMENTS

Sr. Experiments Page

no. no.

1. Determination of the Metacentric height of

a floating body.

2. Investigating the validity of the Bernoulli

equation applied to a steady

Flow of water through a tapered duct.

3. Determination of coefficient of discharge

of Venturimeter.

4. Determination of coefficient of discharge

of Orifice meter.

5. Determination of coefficient of discharge

of Notches (Rectangular and

Triangular notch).

6. To determine the value of coefficient of

contraction, coefficient of Velocity and

coefficient of discharge for the given

orifice.

Department of Civil Engineering Page 2

TEC, Nerul Fluid Mechanics-I

Experiment no.1

METACENTRIC HEIGHT OF A

SHIP

Name:

Class:

Date of performance:

Date of submission:

Sign:

Grade:

Department of Civil Engineering Page 3

TEC, Nerul Fluid Mechanics-I

Experiment no.1

METACENTRIC HEIGHT OF A SHIP

AIM:

To determine the meta- centric height of a ship.

SPECIFICATIONS:

1. M.S. tank of size 0.5*0.5*0.4m with drain plug as storage.

2. A hollow ship model with balancing weight.

3. Tilting weights 2 numbers for balancing.

4. A pendulum and graduated scale for measuring tilt angle.

THEORY: A ship model (with known C.G.) is floated in still water. A known

weight (W1) is moved across the deck of the ship through a certain distance (z)

measured from O, consequently the ship gets tilted through a certain angle (θ)

which is measured on the scale. The Meta-centric Height (MG) is found

(equating tilting and restoring moments) from the following relation.

𝑾𝟏 ∗𝒙

𝑮𝑴 =

𝑾 𝐭𝐚𝐧 𝜽

Fig. Meta-centric Height

Department of Civil Engineering Page 4

TEC, Nerul Fluid Mechanics-I

PROCEDURE:

1. Find the weight ‘W’ of the model of the ship outside water.

2. Place the ship model in water with a movable weight (W1) at any position,

adjust the screws S to zero reading on the scale.

3. Move the weight W1 across the deck through a certain distance (z); it will

result in tilting of the ship model.

4. Note down the angle of tilt ‘(θ)’.

5. Note down more readings, by either varying the load W1 and keeping the

distance ‘z’ constant or Keeping the load W1 constant and varying the

distance ‘z’.

OBSERVATION:

Length of the tank =

Width of the tank =

Area of the tank =

OBERVATION TABLE

Trial 1

𝑮𝑴 Mean Mean

X

Sr. No. W (kg) W1 (kg)

(mm)

θ 𝑾𝟏 ∗ 𝒙 value of

= MG

𝑾 𝐭𝐚𝐧 𝜽

1

Department of Civil Engineering Page 5

TEC, Nerul Fluid Mechanics-I

4

Trial 2

𝑮𝑴 Mean Mean

X

Sr. No. W (kg) W1 (kg)

(mm)

θ 𝑾𝟏 ∗ 𝒙 value of

= MG

𝑾 𝐭𝐚𝐧 𝜽

1

Department of Civil Engineering Page 6

TEC, Nerul Fluid Mechanics-I

SAMPLE CALCULATION

Department of Civil Engineering Page 7

TEC, Nerul Fluid Mechanics-I

RESULT

The meta- centric height of a ship is ....................

CONCLUSION:

PRECAUTIONS:

1. Free movement of pendulum must be ensured.

2. Readings to be noted down only when the water in the tank becomes standstill.

3. Note down the reading of the tilt angle only when the pendulum becomes

steady.

Department of Civil Engineering Page 8

TEC, Nerul Fluid Mechanics-I

QUESTIONS:-

1. Define Buoyancy?

2. Define Meta-centre?

3. Define Meta- centric height?

4. With respect to the position of metacenter, state the condition of equilibrium for

a floating body?

5. Why to find Meta-Centric Height?

6. What is the equation for Meta-Centric height in analytical method?

Department of Civil Engineering Page 9

TEC, Nerul Fluid Mechanics-I

Experiment no.2

BERNOULLI’S THEOREM

Name:

Class:

Date of performance:

Date of submission:

Sign:

Grade:

Department of Civil Engineering Page 10

TEC, Nerul Fluid Mechanics-I

Experiment no.2

BERNOULLI’S THEOREM

AIM:

To Verify the Bernoulli’s theorem .

APPARATUS:

1. A tapered inclined pipe (piezometer

tubes fitted at different points/sections).

2. A supply tank of water.

3. A measuring tank.

4. A stopwatch.

5. A scale.

THEORY:

Bernoulli’s theorem states that in a steady

flow of an ideal fluid the total energy per

unit mass of fluid (at any section) remains

constant along a streamline flow.

Neglecting losses, the total energy at

sections 1 and 2 will have the following

relation:

Pressure head (P1/ W) + Velocity head

(V12/2g) + Elevation (Z1) = a Constant

ρ = Density of the fluid (kg/m3)

V = Velocity of flow (m/s)

P + v2 + z = constant

ρg 2g

Where, P/ρg = pressure head.

V2/2g = velocity head

Z = potential head from datum.

Department of Civil Engineering Page 11

PHCET, Rasayani Fluid Mechanics-I

PROCEDURE:

1. By slowly opening the inlet valve allow the water to flow from the supply tank.

2. Adjust the flow in such a manner that a constant head of water is available in the supply tank (i.e.

inflow= outflow).

3. Note down the quantity of water collected (Q) in the measuring tank for a given interval of time

using a stop watch.

4. Compute the areas of cross-section (A1 and A2) under the piezometer tubes.

5. Use the continuity equation to get V1 and V2 as follows:

Q = A1V1 = A2V2

V1 = Q/ A1

V2 = Q/ A2

6. Read the pressure head (P/W) directly from the piezometer tubes at the concerned sections.

7. Note down the datum head (z) at different sections (for horizontal pipe line z will be constant).

8. Tabulate the various values as shown in table.

OBSERVATION TABLE:

Pressure

head Measuring

Sr. Velocity Velocity

P/w tank Time Discharge Datum Total

no Area V= Q/ A head

readings t(sec) Q(m3/sec) head head

. V2/2g

(Vol) m3

1. 5.04x10-4

2. 4.06x10-4

3. 3.91x10-4

4. 2.60x10-4

5. 3.45x10-4

6. 3.68x10-4

7. 3.91x10-4

8. 4.14x10-4

9. 4.6x10-4

Department of Civil Engineering Page 12

TEC, Nerul Fluid Mechanics-I

SAMPLE CALCULATION:-

1. Discharge Q = q / t = ......... . cm3 /sec

2. Velocity V= Q/ A= ..............= ............ cm/sec

Where A is the cross sectional area of the fluid flow

3. Velocity head V 2 /2g = ......... . cm

4. Pressure head (actual measurement or piezometer tube reading) P/w=

............. cm

5. Total Head H = Pressure head + Velocity Head = .................... . cm

GRAPHS:

1. Plot (P/γ) + Z Vs distance of piezometer tubes for some reference (on x-axis). Join the points by a

smooth curve. This is known as the hydraulic line.

2. E = (P/γ) + Z + (V2/2g) Vs distance of piezometer tubes. Join the points smoothly. This is the total

energy line

RESULT:

CONCLUSION:

Department of Civil Engineering Page 13

TEC, Nerul Fluid Mechanics-I

Experiment no.3

COEFFICIENT OF DISCHARGE

OF VENTURIMETER

Name:

Class:

Date of performance:

Date of submission:

Sign:

Grade

Department of Civil Engineering Page 14

TEC, Nerul Fluid Mechanics-I

Experiment no: 3

COEFFICIENT OF DISCHARGE OF VENTURIMETER

AIM:

To determine the coefficient of discharge through Venturimeter.

APPARATUS:

Venturimeter installed on different diameter pipes, arrangement of varying flow

rate, U- tube manometer, collecting tube tank.

THEORY:

Venturimeter are depending on Bernoulli’s equation. Venturimeter is a device

used for measuring the rate of fluid flowing through a pipe. The consist of three part

in short

1. Converging area part

2. Throat

3. Diverging part

Theoretical discharge can be calculated by

𝑄 = 𝑎 1 * 𝑎 2 √2𝑔h

√𝑎1 - 𝑎2

2 2

Where, a1 = Cross sectional area of a pipe

a2 = Cross sectional area at the throat of venturimeter

h = Differential pressure head between entrance & throat of venturimeter

g = Gravitational acceleration

The actual discharge is determined by collecting water over a known period of time.

Coefficient of discharge for Venturimeter (Cd) = Actual Discharge

Theoretical Discharge

Coefficient of discharge for Venturimeter is closer to 1

Department of Civil Engineering Page 15

TEC, Nerul Fluid Mechanics-I

Fig. Venturimeter

PROCEDURE:

1. Set the manometer pressure to the atmospheric pressure by opening the upper

valve.

2. Now start the supply at water controlled by the stop valve.

3. One of the valves of any one of the pipe open and close all other of three.

4. Take the discharge reading for the particular flow.

5. Take the reading for the pressure head on from the u-tube manometer for

corresponding reading of discharge.

6. Now take three readings for this pipe and calculate the Cd for that instrument

using formula.

7. Now close the valve and open valve of other diameter pipe and take the three

reading for this.

8. Similarly take the reading for all other diameter pipe and calculate Cd for each .

Department of Civil Engineering Page 16

TEC, Nerul Fluid Mechanics-I

OBSERVATIONS & CALCULATIONS:

1. Diameter of venturimeter, d1 = .......................cm

2. Diameter of venturimeter at throat, d2 =........................ cm

3. Diameter of collecting tank, D = ...................... . cm

4. Specific gravity of manometric fluid S = ...................

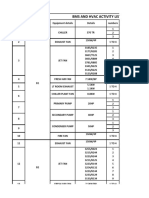

Sr. Manometer reading Rise of Time for Area of Volume Actual Theoretical Coefficient of

No water collecting collectin of water discharge discharge discharge

. R cm rise g tank A Qt

𝑉

level in collected (Qa) = for

h1 h2 h= (h1- of water t cm2 Vt= A x R venturimeter

=

𝑡

the Cm3/ sec

h2) (S- collecting sec. cm2 𝑄 𝑎

1) (𝑎1𝑎2 ∗√ Cd =

tank R cm 2√𝑎

𝑔 h1 −𝑎 2 𝑄 𝑡

cm of 2 2

water

SAMPLE CALCULATIONS:

Department of Civil Engineering Page 17

TEC, Nerul Fluid Mechanics-I

RESULT:

Hence the coefficient of discharge of Venturimeter is .

CONCLUSION:

Hence, Coefficient of discharge through Venturimeter is determined.

Department of Civil Engineering Page 18

TEC, Nerul Fluid Mechanics-I

QUESTIONS:

1. What is Venturimeter? And what is its use?

2. Define coefficient of discharge?

3. Where separation of flow occurs?

4. Define converging & diverging area part?

5. Define throat?

6. Where pressure is low in Venturimeter?

Department of Civil Engineering Page 19

TEC, Nerul Fluid Mechanics-I

Experiment no.4

COEFFICIENT OF DISCHARGE

OF ORIFICEMETER

Name:

Class:

Date of performance:

Date of submission:

Sign:

Grade:

Department of Civil Engineering Page 20

TEC, Nerul Fluid Mechanics-I

Experiment no: 4

COEFFICIENT OF DISCHARGE OF ORIFICEMETER

AIM: To determine the coefficient of discharge through Orifice meter.

APPARATUS:

1. Orifice meter

2. Installed on different pipes

3. Arrangement of varying flow rate

4. U-tube manometer

5. Collecting tank.

THEORY:

Orifice meter is used to measure the discharge in any closed surface. Orifice meter

works on the principle that by reducing the cross section area of the flow passage, a

pressure difference between the two sections is developed and this difference

enables the determination of the discharge through the pipe. In a water distribution

system and in processing industries it is necessary to measure the volume of liquid

flowing through a pipe line. The orifice meter is introduced in the pipeline to achieve

this. Hence knowledge of the value of the coefficient of discharge of the orifice meter

is a must. Orifice meter consists of a flat circular plate with a circular hole called

orifice, which is concentric with the pipe axis pressure tapings are connected to pipe

wall on the both sides of the plate. So that the difference in the fluid pressure on both

sides of the orifice plate are measured. As the fluid passes through the orifice meter,

a lot of eddies are formed and there is a loss of energy due to which the actual

discharge Qa , is far less than Qth and is given by

Actual Discharge

Coefficient of discharge for orifice meter Cd = _______________________

Theoretical Discharge

Actual Discharge (Qa) = V/t (cm3/ sec)

Theoretical discharge, Q t = 𝑎1 𝑎2 ∗√2𝑔h

√𝑎1 −𝑎2 2 2(cm 3 / sec)

Department of Civil Engineering Page 21

TEC, Nerul Fluid Mechanics-I

Equivalent pressure head in meters of flowing liquid, ∆ℎ = (ℎ2 − ℎ1 )[(𝑠𝑚 ⁄𝑠𝑓 ) − 1]

Fig. Orifice meter

PROCEDURE:

1. Set the manometer pressure to the atmospheric pressure by opening the upper

valve.

2. Now start the supply at water controlled by the stop valve.

3. One of the valves of any one of the pipe open and close all other of three.

4. Take the discharge reading for the particular flow.

5. Take the reading for the pressure head on from the u-tube manometer for

corresponding reading of discharge.

6. Now take three readings for this pipe and calculate the Cd for that instrument

using formula.

7. Now close the valve and open valve of other diameter pipe and take the three

reading for this.

8. Similarly take the reading for all other diameter pipe and calculate Cd for each.

Department of Civil Engineering Page 22

TEC, Nerul Fluid Mechanics-I

OBSERVATIONS & CALCULATIONS:

1. Diameter of the pipe to which orifice meter fitted d 1 = ..................

2. Diameter of the orifice, d2 = ....................................... (Note: d2/d1 = 0.60)

3. Size of the collecting tank = l x b x h = ..................

4. Area of cross section = ........................

5. Area of collecting tank = ......................... .

Sr. Manometer Reading Rise of Area of Volume Actual Theoretical

No. water level collecting of water Discharge discharge, Cd=

in the tank A collected (Qa) = V/t, Q act

Δh= collecting cm2 Vt= Lx A cm3/ sec Q th

h1 h2-h1 (S-1) tank L cm cm3 cm3/ sec

cm h2 (cm)

cm

SAMPLE CALCULATION:

∆h=h2 - h1

Qa= A × h / t

Qt = a1a2 ×√2 g h

√𝑎12 − 𝑎22

Cd= Actual Discharge

Theoretical Discharge

Sm = Specific gravity of manometric fluid = 13.6 for mercury

Sf = Specific gravity of fluid flowing in pipe = 1 for water

Department of Civil Engineering Page 23

TEC, Nerul Fluid Mechanics-I

MODEL GRAPHS:

A graph is drawn between Qa and Qth and the value of Cd is determined.

Department of Civil Engineering Page 24

TEC, Nerul Fluid Mechanics-I

RESULT:

Hence the coefficient of discharge of Orifice meter is .

CONCLUSION:

Department of Civil Engineering Page 25

TEC, Nerul Fluid Mechanics-I

QUESTIONS:

1. Define Orifice?

2. Define Mouth piece?

3. Define vena contracta?

4. Where the velocity of flow is maximum and pressure is minimum?

5. What is the reason for smaller value of Cd?

6. What is the principle of Orifice mete

Department of Civil Engineering Page 26

TEC, Nerul Fluid Mechanics-I

Experiment no.5

COEFFICIENT OF DISCHARGE

OF NOTCH

Name:

Class:

Date of performance:

Date of submission:

Sign:

Grade:

Department of Civil Engineering Page 27

TEC, Nerul Fluid Mechanics-I

Experiment no: 5

COEFFICIENT OF DISCHARGE OF NOTCH

AIM: To determine coefficient of discharge of rectangular notch and V-notch

APPARATUS:

Arrangement for finding the coefficient of discharge inclusive of supply tank,

collecting tank, pointer, scale & different type of notches

THEORY:

A notch is an opening in the side of a measuring tank or reservoir extending above

the free surface. These notches are used to measure discharge of open channel

flows, by passing them across the stream. Notches are generally used for

measuring discharge in small open channels or laboratory flumes.

Notches can be of different shapes such as triangular, rectangular, trapezoidal,

stepped notch, etc. the bottom of the notch over which the water flows is known as

crest or sill and the thin sheet of water flowing through the notch is known as

nappe or vein. The edges of the notch are bevelled on the downstream side so as to

have a sharp-edged sides and crest resulting in minimum contact with the flowing

fluid.

The discharge over notch is measured by measuring the head acting over the notch.

As water approaches the notch, its surface becomes curved. Therefore, the head

over the notch is to be measured at the upstream of the notch where the effect of

curvature is minimum. Also, it should be close to the notch so that the loss of

energy between head measuring section and notch is neglegible. In practical, the

head over notch is measured at a distance of 3 to 4 times the maximum head from

the notch.

Fig. Longitudinal Section of Experimental Setup for Notches

Department of Civil Engineering Page 28

TEC, Nerul Fluid Mechanics-I

PROCEDURE:

1. The notch under test is positioned at the end of tank with vertical sharp edge on

the upstream side.

2. Open the inlet valve and fill water until the crest of notch.

3. Note down the height of crest level by pointer gauge.

4. Change the inlet supply and note the height of this level in the tank.

5. Note the volume of water collected in collecting tank for a particular time and

find out the discharge.

6. Height and discharge readings for different flow rate are noted.

OBSERVATIONS AND OBSERVATION TABLE:

Breath of tank =

Length of tank =

Height of water to crest level for rectangular notch is

= Height of water to crest level for V notch =

Angle of V notch =

Width of Rectangular notch =

Discharge

Type Of Initial Final Q Final height Head above Cd

Difference Time

notch height height Volume reading above crest level

In height taken (t)

of tank of tank width

cm cm cm (sec) cm3 cm3/sec

Department of Civil Engineering Page 29

TEC, Nerul Fluid Mechanics-I

CALCULATIONS:

Department of Civil Engineering Page 30

TEC, Nerul Fluid Mechanics-I

RESULT:

The coefficient of discharge of V Notch is .

The coefficient of discharge of Rectangular Notch is _____________ .

CONCLUSION:

Department of Civil Engineering Page 31

TEC, Nerul Fluid Mechanics-I

QUESTIONS:

1. What is a Notch?

2. What is the use of notch?

3. What are the types of notches according to shape of opening?

4. What are the types of notches according to the effect of sides on the nappe

emerging from a notch?

5. What is theoretical discharge for Rectangular notch?

6. What is crest height?

Department of Civil Engineering Page 32

TEC, Nerul Fluid Mechanics-I

Experiment no. 6

HYDRAULIC COEFFICIENTS OF

ORIFICE

Name:

Class:

Date of performance:

Date of submission:

Sign:

Grade:

Department of Civil Engineering Page 33

TEC, Nerul Fluid Mechanics-I

Experiment no. 6

HYDRAULIC COEFFICIENTS OF ORIFICE

AIM :

To determine the coefficients of discharge, coefficient of contraction and the

coefficient of velocity for the given orifice by constant head method.

TOOLS REQUIRED:

Orifice tank, Point gauge for measuring jet trajectory, Calibrated collecting tank,

Stop watch and measuring scale etc.

THEORY:

An orifice is an opening made in the side or bottom of tank having a closing

perimeter. Through which the fluid may be discharged orifice are used to

measure the rate of flow of liquid, apparatus is designed to measure the

coefficient of discharge of orifice.

The apparatus consist of a supply tank of the side of which a universal fixture for

mounting orifices is attached a centrifuge pump supplies the water to supply

tank. Head over the orifice is controlled by a bypass valve provided of pump

discharge which is used to calculate number of orifice.

Water is allowed to flow through the orifice keeping the head constant by

adjusting the inlet valve. The actual discharge Qa is determined using the

measuring tank.

Co-efficient of discharge

Actual discharge

Where, a – Area of measuring tank in cm2

h – Height differences in piezometer in cm.

t – Time to collect water for a height difference of h cm, measured in sec

Department of Civil Engineering Page 34

TEC, Nerul Fluid Mechanics-I

Theoretical discharge

Fig. Orifice meter

OBSERVATIONS:

Area of cross section of collecting tank = .......................... m2

Diameter of orifice, d = ............................... cm

X correction = ......................... cm

Y correction = .............................cm

Area of orifice, a= (it/4) d2 =........................... m2

Department of Civil Engineering Page 35

TEC, Nerul Fluid Mechanics-I

OBSERVATION TABLE:

SAMPLE CALCULATIONS:

Where, Qa – Actual discharge = A x h / t

a – Area of the measuring tank.

H – Rise of water level (say 10cm) in meters.

T – Time in seconds for raise of water level.

D – Diameter of the orifice A – Area of the Orifice (or Mouthpiece) =

(π / 4) d2

H – Height of liquid above the centre of the Orifice (or Mouthpiece).

Coefficient of discharge

Co-efficient of Velocity

X = Horizontal co-ordinate of the jet at the measuring point

Y = Vertical co-ordinate of the jet at the measuring point

H = Height of liquid above the centre of the Orifices.

Department of Civil Engineering Page 36

TEC, Nerul Fluid Mechanics-I

Co-efficient of Contraction Cc = Cd / Cv

RESULT:

Coefficient of discharge of the given orifice = _

Coefficient of velocity of the given orifice = __

Coefficient of contraction of the given orifice =

CONCLUSION:

Department of Civil Engineering Page 37

TEC, Nerul Fluid Mechanics-I

QUESTIONS:

1. What do you mean by Vena- Contracta?

2. What is coefficient of velocity?

3. Define orifice?

4. Define mouthpiece?

5. Define coefficient of contraction?

Department of Civil Engineering Page 38

You might also like

- Seneca Seismic Design Handbook - First Edition PDFDocument94 pagesSeneca Seismic Design Handbook - First Edition PDFBeenayShahi100% (1)

- Rate Analysis For Block Work& PlasteringDocument20 pagesRate Analysis For Block Work& PlasteringNaveen Tibba88% (8)

- Fluid Mechanics I Lab ManualDocument30 pagesFluid Mechanics I Lab ManualVivek Thakur SujanianNo ratings yet

- One Degree of Freedom Resonance Wave Energy ConvertorDocument11 pagesOne Degree of Freedom Resonance Wave Energy ConvertorMr PolashNo ratings yet

- Fluid Mechanics Lab Manual NewDocument69 pagesFluid Mechanics Lab Manual NewAnonymous liOlZbdoNo ratings yet

- NPTEL-Fire-set 2 KeyDocument10 pagesNPTEL-Fire-set 2 KeyPiyush KumarNo ratings yet

- Lab Mannual OF Fluid Mechanics: Deptt. of Mechanical EngineeringDocument39 pagesLab Mannual OF Fluid Mechanics: Deptt. of Mechanical EngineeringSumit Kumar PandeyNo ratings yet

- Final FMHM LAB MANUAL Manual of 1Document67 pagesFinal FMHM LAB MANUAL Manual of 1Motee SinghNo ratings yet

- Fluid Mechanics & Hydraulic Machines LabDocument46 pagesFluid Mechanics & Hydraulic Machines LabLuli LolNo ratings yet

- 2 FMHM Lab ManualDocument46 pages2 FMHM Lab ManualKishoreNo ratings yet

- Comparing The Economic Feasibility of of PDFDocument15 pagesComparing The Economic Feasibility of of PDFNarayanan JayachandranNo ratings yet

- KhemakhemDocument7 pagesKhemakhemaekockautNo ratings yet

- Chavez, Valencia, Jaramillo, Coronado, Rodriguez - Failure Analysis of A Pelton ImpellerDocument11 pagesChavez, Valencia, Jaramillo, Coronado, Rodriguez - Failure Analysis of A Pelton ImpellerHidan WLNo ratings yet

- Dynamic Buckling of Cylindrical Storage PDFDocument14 pagesDynamic Buckling of Cylindrical Storage PDFamar alicheNo ratings yet

- Measurements of Hydrodynamic Forces - Surface Pressure - and Wake For Obliquely Towed Tanker Model and Uncertainty Analysis For CFD ValidationDocument11 pagesMeasurements of Hydrodynamic Forces - Surface Pressure - and Wake For Obliquely Towed Tanker Model and Uncertainty Analysis For CFD ValidationelmasykurNo ratings yet

- Ce 8381 - Strength of Materials and Fluid Mechanics and Machinery Laboratory ManualDocument38 pagesCe 8381 - Strength of Materials and Fluid Mechanics and Machinery Laboratory ManualManivannan JeevaNo ratings yet

- Dielectric Constant CO ModifiedDocument7 pagesDielectric Constant CO ModifiedZSxdcdNo ratings yet

- Fluid Mechanics Lab ManualDocument22 pagesFluid Mechanics Lab ManualStructure Engineering /946No ratings yet

- Circulation Rate Modelling of Mill ChargDocument8 pagesCirculation Rate Modelling of Mill ChargrodrigoNo ratings yet

- 2015 - Numerical Method Trimaran Wave ResistanceDocument15 pages2015 - Numerical Method Trimaran Wave Resistancenauval.archNo ratings yet

- Engineering Dynamics Lab ReportDocument36 pagesEngineering Dynamics Lab Reportabdul rehmanNo ratings yet

- METU Chem. Eng. Dept. Ch.E. 410 Chem. Eng. Lab II Experiment 1.2. Tubular Viscometry (Visc)Document5 pagesMETU Chem. Eng. Dept. Ch.E. 410 Chem. Eng. Lab II Experiment 1.2. Tubular Viscometry (Visc)newtonNo ratings yet

- Fluid Mechanics Sessional CE 262Document28 pagesFluid Mechanics Sessional CE 262মোঃমেহেদী হাসান শরীফNo ratings yet

- Jeme 2020Document8 pagesJeme 2020Carlene ToaNo ratings yet

- Static Stability of Floating Structures PDFDocument84 pagesStatic Stability of Floating Structures PDFparamarthasom1974No ratings yet

- Chhoeung 2019 J. Phys. Conf. Ser. 1357 012028Document10 pagesChhoeung 2019 J. Phys. Conf. Ser. 1357 012028Dinh Nguyen DaoNo ratings yet

- Lab Manual: Muzaffarpur Institute of Technology MuzaffarpurDocument22 pagesLab Manual: Muzaffarpur Institute of Technology MuzaffarpurGautam GunjanNo ratings yet

- Fluid Mechanics ModuleDocument72 pagesFluid Mechanics Moduleeric labordo100% (1)

- HM Manuals With Calculation 090618Document50 pagesHM Manuals With Calculation 090618Zaky MuzaffarNo ratings yet

- Study of Seismic Analysis of Non-Conventional Shapes of Elevated Water TankDocument13 pagesStudy of Seismic Analysis of Non-Conventional Shapes of Elevated Water TankIJRASETPublications100% (2)

- Lab Manual 3.3 - LEVEL 1 - Measurement of Flow Over Broad Crestedsharp Crested Weir.Document4 pagesLab Manual 3.3 - LEVEL 1 - Measurement of Flow Over Broad Crestedsharp Crested Weir.Muhamad IzzanNo ratings yet

- Fluid Mechanics Sessional CE 262Document28 pagesFluid Mechanics Sessional CE 262মোঃমেহেদী হাসান শরীফNo ratings yet

- Fluid Mechanics 1 Lab ManualDocument36 pagesFluid Mechanics 1 Lab ManualMr. Danish SaeedNo ratings yet

- AD Lab Manual 3 c2Document3 pagesAD Lab Manual 3 c2catiav5123No ratings yet

- Presentation 2Document36 pagesPresentation 2parnitejuNo ratings yet

- PDFDocument19 pagesPDFHAFIZ ARSALAN ALINo ratings yet

- Fluid Mechanics I I Lab ManualDocument30 pagesFluid Mechanics I I Lab ManualVivek Thakur SujanianNo ratings yet

- Vibration Lab Experiment 01Document2 pagesVibration Lab Experiment 01Mohammad DaniyalNo ratings yet

- Sloshing in Rectangular Tanks and Interaction With Ship MotionsDocument180 pagesSloshing in Rectangular Tanks and Interaction With Ship MotionsPrince MishraNo ratings yet

- An Innovative Electric Ship Steering Systems: Analysis and ImplementationDocument10 pagesAn Innovative Electric Ship Steering Systems: Analysis and ImplementationTJPRC PublicationsNo ratings yet

- Structure Analysis - I I Lab Manual: Prepared By: Parveen Berwal Approved By: Dr. Arabinda SharmaDocument31 pagesStructure Analysis - I I Lab Manual: Prepared By: Parveen Berwal Approved By: Dr. Arabinda Sharmapiu dasNo ratings yet

- USBR - Hydrodynamic PressuresDocument20 pagesUSBR - Hydrodynamic PressuresguNo ratings yet

- Scale Effects On Hydrodynamic Manoeuvring Force PredictionDocument6 pagesScale Effects On Hydrodynamic Manoeuvring Force PredictionMaciej ReichelNo ratings yet

- AsdasDocument8 pagesAsdasRaul Dejolde JrNo ratings yet

- Mechanical Vibrrations Lab Manual: Name Dua SaboorDocument5 pagesMechanical Vibrrations Lab Manual: Name Dua SaboorUmbreen TariqNo ratings yet

- Mesh ShipDocument7 pagesMesh ShipPranshu MalikNo ratings yet

- Fishing Vessel Hull Design and Towing Resistance Calculation by The CFD MethodsDocument4 pagesFishing Vessel Hull Design and Towing Resistance Calculation by The CFD MethodsshahjadaNo ratings yet

- Renewable Energy: D. Us Ar, S . BalDocument11 pagesRenewable Energy: D. Us Ar, S . BalNorman IskandarNo ratings yet

- MTS 226 Materials and Manufacturing Processes: Instructor: Dr. Hamid Jabbar Hamid - Jabbar@ceme - Nust.edu - PKDocument44 pagesMTS 226 Materials and Manufacturing Processes: Instructor: Dr. Hamid Jabbar Hamid - Jabbar@ceme - Nust.edu - PKARSLAN FALAKNo ratings yet

- Laboratory Manual: Gujarat Technological University Bachelor of EngineeringDocument48 pagesLaboratory Manual: Gujarat Technological University Bachelor of EngineeringDipika GuptaNo ratings yet

- 4 - Impact of Jet PDFDocument7 pages4 - Impact of Jet PDFromasokyNo ratings yet

- Report Sem 7 PDFDocument37 pagesReport Sem 7 PDFSudhanshu TanochNo ratings yet

- Computational Study of Sloshing Behavior in 3-D Rectangular Tank With and Without Baffle Under Seismic ExcitationDocument61 pagesComputational Study of Sloshing Behavior in 3-D Rectangular Tank With and Without Baffle Under Seismic ExcitationNicolas PironnetNo ratings yet

- Final Lab Manual App. PhysicsDocument50 pagesFinal Lab Manual App. PhysicsGdotNo ratings yet

- Dynamics Lab MANUAL New PrintDocument56 pagesDynamics Lab MANUAL New PrintMartin De Boras PragashNo ratings yet

- Experiment Computation of Manning's N - EP1Document5 pagesExperiment Computation of Manning's N - EP1Md. FizNo ratings yet

- 2.mathematical Model For The Manoeuvring Ship in Shalow WaterDocument12 pages2.mathematical Model For The Manoeuvring Ship in Shalow WaterЮра ОксамытныйNo ratings yet

- 20-ME-9 Uzair Akram FM Lab 3Document5 pages20-ME-9 Uzair Akram FM Lab 3uzair akramNo ratings yet

- Mechanics: Problems in Undergraduate PhysicsFrom EverandMechanics: Problems in Undergraduate PhysicsRating: 3.5 out of 5 stars3.5/5 (2)

- IPN ProfilesDocument2 pagesIPN ProfilesAntonio CavicchioniNo ratings yet

- Tubular, Core, and Outrigger StructuresDocument15 pagesTubular, Core, and Outrigger StructuresUmer FarooqNo ratings yet

- Buderus Manuel Ductile PDFDocument133 pagesBuderus Manuel Ductile PDFjjjNo ratings yet

- PRC Quiz1Document1 pagePRC Quiz1Umair AshrafNo ratings yet

- False CeilingDocument70 pagesFalse CeilingpravallikakvNo ratings yet

- Analysis of Timber Joints With Punched Metal Plate FastenersDocument4 pagesAnalysis of Timber Joints With Punched Metal Plate FastenersBatuhan DerNo ratings yet

- Moltistoreyed Building - DT 15.09.17Document14 pagesMoltistoreyed Building - DT 15.09.17V.m. RajanNo ratings yet

- Thermoplastic Thermosetting Structural Composites: School Chemical Engineering Georgia Institute Technology Atlanta, andDocument4 pagesThermoplastic Thermosetting Structural Composites: School Chemical Engineering Georgia Institute Technology Atlanta, andAbd BaghadNo ratings yet

- IIDT (Wall Slab Connection)Document1 pageIIDT (Wall Slab Connection)Ashaari Cha-eNo ratings yet

- Astm - c172 c172m 17Document1 pageAstm - c172 c172m 17jaafar abdullahNo ratings yet

- Jgeot 15 P 112Document13 pagesJgeot 15 P 112Andrei NardelliNo ratings yet

- January 20, 2021 CE 401 - CE31S6 Geotechnical Engineering 1 (Soil Mechanics) GROUP - (5 Members)Document5 pagesJanuary 20, 2021 CE 401 - CE31S6 Geotechnical Engineering 1 (Soil Mechanics) GROUP - (5 Members)Katy PerryNo ratings yet

- Typical Cross SectionDocument8 pagesTypical Cross SectionAmit PhadatareNo ratings yet

- Module 6: Stresses Around Underground Openings: 6.6 Excavation Shape and Boundary StressDocument10 pagesModule 6: Stresses Around Underground Openings: 6.6 Excavation Shape and Boundary Stressفردوس سليمانNo ratings yet

- Material List: Produced On 13/11/2020 With Xpress Selection V9.0.1 - Database DIL 16.0.2Document11 pagesMaterial List: Produced On 13/11/2020 With Xpress Selection V9.0.1 - Database DIL 16.0.2Sicologo CimeNo ratings yet

- Fatigue in Plain ConcreteDocument109 pagesFatigue in Plain ConcreteSergeyGalkinNo ratings yet

- Defroster Multi OutletsDocument2 pagesDefroster Multi OutletsAyhan ÇalışkanNo ratings yet

- Glulam - Service Class 1Document3 pagesGlulam - Service Class 1ikanyu79No ratings yet

- Super Health Cntr-Model-01Document1 pageSuper Health Cntr-Model-01Jennylou DingalNo ratings yet

- 2 Steel Used in BridgesDocument2 pages2 Steel Used in BridgesJay PatelNo ratings yet

- Quick Inspection Manual of Damaged Reinforced Concrete Buildings Due To Earthquakes (Govt. of Japan)Document52 pagesQuick Inspection Manual of Damaged Reinforced Concrete Buildings Due To Earthquakes (Govt. of Japan)TuanQuachNo ratings yet

- Axis Bank - HVAC Equipments ListDocument8 pagesAxis Bank - HVAC Equipments Listmohamad chaudhariNo ratings yet

- Engineering Plastics Polybutylene Terephthalate Technical DataDocument2 pagesEngineering Plastics Polybutylene Terephthalate Technical Dataavinashchauhan2695No ratings yet

- REPORT01Document110 pagesREPORT01kennysawegNo ratings yet

- Admixture Technical Sheet - ATS 4 Accelerating AdmixturesDocument4 pagesAdmixture Technical Sheet - ATS 4 Accelerating Admixturesmehrdad_so1981No ratings yet

- Cadangan Tambahan Dan Pindaan Sebuah Rumah Teres Dua Tingkat Di No.14 Lorong SG - Soi Jaya 3, Perumahan SG - Soi Jaya 2 26060 Kuantan, Pahang D.MDocument9 pagesCadangan Tambahan Dan Pindaan Sebuah Rumah Teres Dua Tingkat Di No.14 Lorong SG - Soi Jaya 3, Perumahan SG - Soi Jaya 2 26060 Kuantan, Pahang D.MAkram ShamsulNo ratings yet

- 111111Document1 page111111Je Espenida100% (1)

- Ebcs 4 PDFDocument140 pagesEbcs 4 PDFAbera Mulugeta100% (4)