Professional Documents

Culture Documents

Air Compressor

Uploaded by

Lajapathi RaiCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Air Compressor

Uploaded by

Lajapathi RaiCopyright:

Available Formats

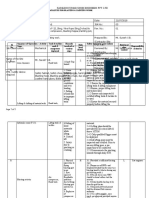

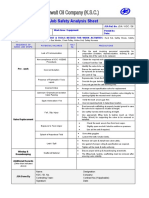

Job Safety Analysis

Doc.No.QG2/TR-5-SD-JSA-032

JSA Date: 27/07/2020

Rev-00

Short Description: JSA for Running Of Air Compressor

Asset: QG2 Permit No. (if applicable): Work Location: Train-5 SD 2020

Tools & Equipment Used: Air Compressor, Hand Tools

JSA Team Members: (e.g. Participant Team)

Name Staff No. Company

Aftab Waseer (Project Manager) 5345 DESCON

Syed Rehman Ali Shah (I/C HSE ) 70186 DESCON

Kaleem Ullah (Mech Team Leader) 81082 DESCON

Leakage Check hoses and connections prior toPage

start

1

PRT-PSF-FRM-013a –Running

Job Safetyof

Analysis Form 1 of the

Air Compressor 4 compressor.

Job Safety Analysis Worksheet

Section 2: Hazards and Controls

Hazard

Step No. Job Steps (Use Checklist as a Existing and Additional Controls

Guide to be Specific)

Daily inspection checklist to be filled in each shift by

performing party supervisor.

Drip Tray for Oil Leak to be provided.

Periodic checking by PP Area Coordinator

Release of pressure / Prior to disconnect the hose ensure no pressure in

handling of hose the hoses

Slips, trips and falls Maintain continuous housekeeping.

Hose management in the area

Noise Appropriate hearing protection to be used.

Restrict non essential personnel in the work area by

installing barrication with sign boards.

Manual handling during hose AwkwardImproper /poor body postures shall be

laying avoided such as stooping, twisting etc.

Hose must be TPI and inspected by QG approved

TPI.

Follow hose management procedure.

Maintain continuous housekeeping.

Electric shock Ensure equipment is earth and bounded.

2 Housekeeping and area Slips, trips and falls Good housekeeping to be maintained (a place for

cleaning everything and everything in its place always)

Manual handling Always follow the 6 Rules of manual handling.

Dust masks to be used by housekeeping crew.

Dust generation

PRT-PSF-FRM-013a – Job Safety Analysis Form Page 2 of

4

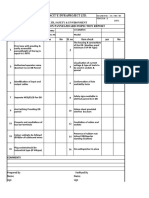

Job Safety Analysis Worksheet

Section 2: Hazards and Controls

Hazard

Step No. Job Steps (Use Checklist as a Existing and Additional Controls

Guide to be Specific)

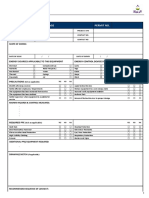

Notes: For Assets or Projects where e-PTW system is not rolled out, this JSA Form shall be used.

Section 3 Agreement

The Job had been analyzed for potential hazards, appropriate guidance had been obtained in identifying the hazards and the required controls were discussed and

agreed in the JSA Team Meeting

JSA Team Leader Name: Aftab Waseer/ Syed Rehman Ali Shah Date: Signature:

All controls stated in the JSA are in place and the hazards and controls indicated in the JSA have been cascaded to the crew

Job Supervisor Name: Date: Signature:

Endorsed by QG Host if the Job Supervisor is a contractor

QG Host Name: Date: Signature:

PRT-PSF-FRM-013a – Job Safety Analysis Form Page 3 of

4

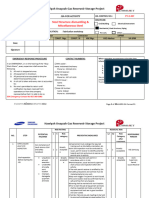

Job Safety Analysis Worksheet

Section 2: Hazards and Controls

Hazard

Step No. Job Steps (Use Checklist as a Existing and Additional Controls

Guide to be Specific)

Section 4 Hierarchy of Controls

Eliminati Removal of the hazard by eliminating the process will also eliminate the risks associated with the hazard. Example: Offsite Welding, No Working at Height etc

on

If the process cannot be eliminated, consider substituting the substance or hazardous process with one known to be less harmful to health or safety.

Substituti Example:Using Man Lift instead of Ladder or Scaffolding Structure.

on

Engineeri

Engineering type controls include changing processes, equipment or tools to reduce risk. For example: Reduction at source of noise or vibration through various

ng known engineering controls.Providing air-movers for ventilation.

Controls

Administr

Administrative controls involve introducing and maintaining work practices that reduce risk by limiting the exposure of an employee to the hazard.For

ative example:Reduce the time of exposure, Work Rest Cycle, Signages , Barriers, Procedures.

Controls

Additional / Special Personal Protective Equipment should be used when other measures have not been able to protect the employee against the hazard or risk of

exposure to the hazard. Where Additional PPE is used, the Job Supervisor should ensure that it fits the task force correctly, training is provided: Double Hearing

PPE Protectors, Respirators, Breathing Apparatus, Safety Harness etc.

PRT-PSF-FRM-013a – Job Safety Analysis Form Page 4 of

4

You might also like

- Copy (2) of Jsa For Mechanical Excavation at Brown Field Are Includes WeldingDocument4 pagesCopy (2) of Jsa For Mechanical Excavation at Brown Field Are Includes WeldingViron Baxhia100% (1)

- Abrasive CutDocument1 pageAbrasive CutWahyu Haidar PratamaNo ratings yet

- Work Shop TRA Grinding ActivitiesDocument13 pagesWork Shop TRA Grinding ActivitiesTarik MunafNo ratings yet

- Chaliyama Steel Plant-Rungta Mines Limited Hazard Identification & Risk AssessmentDocument4 pagesChaliyama Steel Plant-Rungta Mines Limited Hazard Identification & Risk AssessmentCPP EI DSpNo ratings yet

- Ocp BatchingDocument1 pageOcp BatchingAarya Mishra TiwariNo ratings yet

- Jobs Safety Analysis (JSA)Document4 pagesJobs Safety Analysis (JSA)uttam mishraNo ratings yet

- Question and Answer Ig1Document8 pagesQuestion and Answer Ig1RahulNo ratings yet

- JSA Formet New Blasting & PaintingDocument5 pagesJSA Formet New Blasting & Paintingsakthi venkatNo ratings yet

- Why Is Maintenance A High Risk ActivityDocument11 pagesWhy Is Maintenance A High Risk ActivityVũ GiangNo ratings yet

- Machine Shop SafetyDocument10 pagesMachine Shop SafetySreedhar Patnaik.MNo ratings yet

- 16.18 TBT - Gas Welding and CuttingDocument2 pages16.18 TBT - Gas Welding and Cuttinggrant100% (1)

- Manual & Mechanical ChecklistDocument7 pagesManual & Mechanical ChecklistMartine OtienoNo ratings yet

- Working at Height EbookDocument14 pagesWorking at Height EbookSubhi El Haj SalehNo ratings yet

- Safe Working at Heights Part 1 - KG - 310519Document15 pagesSafe Working at Heights Part 1 - KG - 310519eugene stevensNo ratings yet

- 1.tech Pneumatic Tool Safety 20180207Document2 pages1.tech Pneumatic Tool Safety 20180207Ku RatheeshNo ratings yet

- JHA For Installation 2 Inch Nozzle..Document6 pagesJHA For Installation 2 Inch Nozzle..arnolhari100% (1)

- Duhok Polytechnic University College of Technical Engineering Department of PetrochemicalDocument17 pagesDuhok Polytechnic University College of Technical Engineering Department of PetrochemicalDll ZarNo ratings yet

- Welding Safety: Lesson 1Document9 pagesWelding Safety: Lesson 1cyrelle rose jumentoNo ratings yet

- 020.abrasive Blasting Rev.0 PDFDocument12 pages020.abrasive Blasting Rev.0 PDFYounis KhanNo ratings yet

- Hydrostatic Pressure Testing Procedure1 PWLDocument6 pagesHydrostatic Pressure Testing Procedure1 PWLYavannaNo ratings yet

- Scaffold TowerDocument20 pagesScaffold TowerAndhika HerdiawanNo ratings yet

- Ladder Safety PDFDocument24 pagesLadder Safety PDFRusihan RehanNo ratings yet

- SAFETY NotesDocument95 pagesSAFETY NotesKaruna KaranNo ratings yet

- Air Compressor Air Compressor: (Small) (Small)Document1 pageAir Compressor Air Compressor: (Small) (Small)alcrosalitaNo ratings yet

- SHP Safety Walk Arounds For ManagersDocument2 pagesSHP Safety Walk Arounds For ManagersIoana UrsanNo ratings yet

- JSA - Bolt TensioningDocument5 pagesJSA - Bolt TensioningRaju KhalifaNo ratings yet

- Jobs Safety Analysis: Start DateDocument2 pagesJobs Safety Analysis: Start Dater afriantoNo ratings yet

- Scaffolding Hazard PreventionDocument2 pagesScaffolding Hazard PreventionRavikant PandeyNo ratings yet

- Isolation Permit/ High Voltage Permit NoDocument2 pagesIsolation Permit/ High Voltage Permit NoMohammed KadhimNo ratings yet

- Safety Audit MethodologyDocument5 pagesSafety Audit MethodologyLalit Kumar Das MohapatraNo ratings yet

- Toolbox Talk Trenching Safety PDFDocument1 pageToolbox Talk Trenching Safety PDFZeeshan BajwaNo ratings yet

- Instructions For Using The Risk Assessment FormDocument9 pagesInstructions For Using The Risk Assessment FormMalik Khuram ShazadNo ratings yet

- OB Afety NalysisDocument5 pagesOB Afety NalysisNaveed WarraichNo ratings yet

- Ocm1 Confined SpaceDocument2 pagesOcm1 Confined SpacerapidsicuminteNo ratings yet

- How Chin Engineering: Job Safety AnalysisDocument5 pagesHow Chin Engineering: Job Safety AnalysisHow Chin Engineering Sdn BhdNo ratings yet

- SOP For Use of Grinder Machines in WorkshopDocument8 pagesSOP For Use of Grinder Machines in WorkshopFaisal RajaNo ratings yet

- Safety Award ApplicationDocument7 pagesSafety Award ApplicationJason Smith100% (1)

- Design Criteria PDFDocument58 pagesDesign Criteria PDFsaculNo ratings yet

- Safe Usage of PPE Toolbox Talk Global EHS TBT 006Document4 pagesSafe Usage of PPE Toolbox Talk Global EHS TBT 006Global EHSNo ratings yet

- 4 Safe Use of Lifting GearsDocument2 pages4 Safe Use of Lifting GearsSiewkuan LeeNo ratings yet

- Jsa 07 (G) # Steel Structure Erection & Miscellaneous Steel-Ptj - S-007Document30 pagesJsa 07 (G) # Steel Structure Erection & Miscellaneous Steel-Ptj - S-007elmsm14No ratings yet

- Working at Heights: Dr.P.MuralidharDocument48 pagesWorking at Heights: Dr.P.MuralidharRituraj SinghNo ratings yet

- Job Safety Analysis (Jsa) : Fabrication Works, Welding Works Using Power Tools, Hand Tools, Welding Machine WapstechDocument3 pagesJob Safety Analysis (Jsa) : Fabrication Works, Welding Works Using Power Tools, Hand Tools, Welding Machine WapstechMohamedSaidNo ratings yet

- Hot Work Procedure 2021Document8 pagesHot Work Procedure 2021Wan Ahmad FaaizunNo ratings yet

- P111-Rsme-Tra-007 - Tra For Cold Tie inDocument5 pagesP111-Rsme-Tra-007 - Tra For Cold Tie inDarius DsouzaNo ratings yet

- Jha WTPDocument3 pagesJha WTPYer SonmoNo ratings yet

- Safety Topic 863 - Working Under Suspended LoadsDocument2 pagesSafety Topic 863 - Working Under Suspended LoadsAshishNo ratings yet

- JSA Safety Valve CertivicationDocument12 pagesJSA Safety Valve CertivicationelvandiNo ratings yet

- General Crane Operations and LiftingDocument2 pagesGeneral Crane Operations and LiftingAhmedAmer1No ratings yet

- Excavation ManuallyDocument1 pageExcavation ManuallyJack PNo ratings yet

- For Electrical PannelDocument2 pagesFor Electrical Panneljithin shankarNo ratings yet

- Library of PD&T QMS Project HSE Moments: Presented By: On DateDocument8 pagesLibrary of PD&T QMS Project HSE Moments: Presented By: On DateSyahril Aizal AhmadNo ratings yet

- JSA Format Erection of Column 901-C-01Document9 pagesJSA Format Erection of Column 901-C-01sakthi venkatNo ratings yet

- JSA Pressure TestingDocument1 pageJSA Pressure TestingScott Mills100% (1)

- Job Hazard Analysis: Generic Jha For Blasting & Painting WorksDocument7 pagesJob Hazard Analysis: Generic Jha For Blasting & Painting WorksReynaldo PesqueraNo ratings yet

- JSA #36-Valve ReplacementDocument1 pageJSA #36-Valve ReplacementVishal PrasadNo ratings yet

- Job Safety Analysis (Jsa) Job Safety Analysis (Jsa) (Erection Tower)Document1 pageJob Safety Analysis (Jsa) Job Safety Analysis (Jsa) (Erection Tower)Christo Stiocal DjNo ratings yet

- AEG - JSA - 107 - Oxygen Acetylene Torch PDFDocument2 pagesAEG - JSA - 107 - Oxygen Acetylene Torch PDFanon_421433640No ratings yet

- LSP - Work at Height ENGDocument1 pageLSP - Work at Height ENGYosuaNo ratings yet

- TSA-020 - Concrete Core DrillDocument3 pagesTSA-020 - Concrete Core DrillMusadiq HussainNo ratings yet

- Self Esteem and AdjustmentDocument22 pagesSelf Esteem and AdjustmentJan IrishNo ratings yet

- Ccii Proposal EssayDocument4 pagesCcii Proposal Essayapi-456307983No ratings yet

- Cognitive Behavioral Therapy - 7 Ways To Freedom From Anxiety, Depression, and Intrusive Thoughts (Happiness Is A Trainable, Attainable Skill! Book 1)Document105 pagesCognitive Behavioral Therapy - 7 Ways To Freedom From Anxiety, Depression, and Intrusive Thoughts (Happiness Is A Trainable, Attainable Skill! Book 1)SOUFIANE RACHID100% (8)

- QTR-2 2023 Meeting Format Nov.23Document45 pagesQTR-2 2023 Meeting Format Nov.23skumar31397No ratings yet

- Evolve Reach - Powered by HESIDocument7 pagesEvolve Reach - Powered by HESIangelsarerare14% (7)

- Accessing The Healing Power of The Vagus NerveDocument9 pagesAccessing The Healing Power of The Vagus NerveShubham Doshi33% (3)

- PFI Freediver ManualDocument69 pagesPFI Freediver ManualLuca MariniNo ratings yet

- Gastrointestinal Tract PDFDocument3 pagesGastrointestinal Tract PDFAlexandra Suan CatambingNo ratings yet

- v4n3 PDFDocument168 pagesv4n3 PDFJorge RodriguezNo ratings yet

- HY Endocrine UsmleDocument22 pagesHY Endocrine UsmleNakhal JararNo ratings yet

- Fawwaz Muhammad X-Ipa 1: 1. Who Is The Main Character of The Story? 2. When Did It Happen?Document3 pagesFawwaz Muhammad X-Ipa 1: 1. Who Is The Main Character of The Story? 2. When Did It Happen?Abbas AminuNo ratings yet

- 1103-1104 RepairDocument120 pages1103-1104 RepairCristobal Sanchez91% (23)

- Oedipus SummaryDocument1 pageOedipus SummaryReynold FrancoNo ratings yet

- 1000 Câu Word FormDocument36 pages1000 Câu Word FormThùy Linh LêNo ratings yet

- GudegDocument15 pagesGudegYenisNo ratings yet

- Tutorial SessionDocument5 pagesTutorial SessionKhánh LinhNo ratings yet

- Antiemetics - AMBOSSDocument4 pagesAntiemetics - AMBOSSOpio IsaacNo ratings yet

- 1501Document569 pages1501Ina Revenco33% (3)

- The Production of ParacetamolDocument4 pagesThe Production of ParacetamolBryan Tan100% (2)

- Invoice, packing list mẫuDocument2 pagesInvoice, packing list mẫuPHI BUI MINHNo ratings yet

- Book Review - Black Skin, White MasksDocument9 pagesBook Review - Black Skin, White MasksKaren A. LloydNo ratings yet

- MSDS TSHDocument8 pagesMSDS TSHdwiNo ratings yet

- Banana Disease 2 PDFDocument4 pagesBanana Disease 2 PDFAlimohammad YavariNo ratings yet

- Problems Associated With The Use of Compaction Grout For SinkholeDocument4 pagesProblems Associated With The Use of Compaction Grout For SinkholeVetriselvan ArumugamNo ratings yet

- Chapter 10 Fitness Training PrinciplesDocument80 pagesChapter 10 Fitness Training Principlesapi-115744109No ratings yet

- Operations Manual: Conical Burr Coffee GrinderDocument15 pagesOperations Manual: Conical Burr Coffee Grindercherrera73No ratings yet

- (Nikolaj Wolfson, Alexander Lerner, Leonid Roshal (B-Ok - CC)Document589 pages(Nikolaj Wolfson, Alexander Lerner, Leonid Roshal (B-Ok - CC)Andi sutandi100% (1)

- Calinescu2017 PDFDocument38 pagesCalinescu2017 PDFElizabeth UrrutiaNo ratings yet

- Bug Guide List of Bugs (Insects), Sell Prices, and Appearance Times ACNH - Animal Crossing New Horizons (Switch) Game8Document1 pageBug Guide List of Bugs (Insects), Sell Prices, and Appearance Times ACNH - Animal Crossing New Horizons (Switch) Game8botonlouietNo ratings yet