Professional Documents

Culture Documents

Manual & Mechanical Checklist

Uploaded by

Martine OtienoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Manual & Mechanical Checklist

Uploaded by

Martine OtienoCopyright:

Available Formats

Date: 04/03/15 Revision No.

: 00

Issued by: VS Page No.: Page 1 of 7

Work Instruction Material Handling ( Manual & Mechanical ) Ref No.:

Work Instruction on

Material Handling ( Manual & Mechanical)

1.0 Purpose:

The purpose of this Work Instruction is to provide a safe process of manual and mechanical

material handling including the identifying and controlling of risk associated with these activities

at Construction Sites and associated offices, stores, etc. This work instruction will help to

ensure that all manual and mechanical material handling activities should be carried out in safe

manner to prevent any incident occurrence at site and to provide a safe & healthy work

environment at all time.

2.0 Scope:

The scope of this work instruction covers the guideline and requirement for manual and

mechanical material handling, includes safety tips / techniques for manual handling,

mechanical handling, storage of material and site housekeeping.

Before commencing this activity site execution team is recommended to evaluate the

foreseeable risk by conducting risk assessment of the particular activity so as to prevent any

harm to the engaged team

3.0 Roles & Responsibility:

GPL Project Manager is responsible for adherence to the work instructions through PMC &

responsible contractors. And the respective Contractor is responsible to transmit this work

instruction to their sub-contractors and ensure that the contents are clearly understood by them.

In case of not adherence to work instructions and non-performance by Contractor, the GPL

Project Manager has the right to get this done by other contractor and back charge the same to

defaulting contractors.

4.0 Definitions/Abbreviations:

Manual Handling: An activity requiring the use of force exerted by a person to lift, lower, push,

carry or otherwise move, hold or restrain an object.

Abbreviations:

BOCW: The Building & Other Construction Workers (Regulation of Emp & Conditions of

Service) Act, 1996 and Rules 1998.

HIRA: Hazard Identification & Risk Assessment

PMC: Project Management Consultant

PPE: Personal protective equipment

5.0 Legal:

The Building & Other Construction Workers (Regulation of Emp& Conditions of Service)

Act, 1996

The Building & Other Construction Workers (Regulation of Emp& Conditions of Service)

Central Rules, 1998.

Prepared by: RM Reviewed by: VS Approved by: JP

Date: 04/03/15 Revision No.: 00

Issued by: VS Page No.: Page 2 of 7

Work Instruction Material Handling ( Manual & Mechanical ) Ref No.:

6.0 Guideline for Manual and mechanical material handling: Manual materials handling

involves the handling, moving, lifting, and carrying of materials without the use of mechanical

equipment. Minimizing injuries that occur from materials handling requires planning about

these tasks. Following points must be taken into consideration while doing the manual and

mechanical material handling work,

i. Ensure that the workers engaged for manual material handling operation must be trained for

manual material handling techniques and should be carried out under experienced

supervision.

ii. Ensure that the lifting, carrying or moving of material, articles or things does not endanger

the safety of nearby and other workers.

iii. Before lifting or shifting, size up the load first. If it is too big in size, ask for help of others.

iv. Take a round, inspect and look of work / nearest area before lifting and check whether it is

slippery, has oil spillage, anything that can cause loss of balance.

v. Provide and ensure use of correct type of hand gloves (Scratch Proof Hand Gloves /

Leather Hand Gloves) as per requirement. Also ensure safety shoes, goggles (white glass)

and safety helmet with chin strip.

vi. Basic tips for manual material handling :

o Position the feet correctly while lifting the load. Space the legs apart from the hip with

one foot by the side of load & ahead of other foot in the direction of movement.

o The back needs to keep straight, not necessary vertical. It may at the same time be

inclined from hip as lifting posture may need.

o Arm should be closed to body. Grip the load correctly using roots of fingers & palm.

o Head should be slightly raised before lifting.

o Raise the body with leg muscles, the movement should not be jerky.

o While keeping load down, follow same procedure.

o While keeping load down, ensure that hand & fingers will not get pinched.

vii. Do not allow to stack material at high level, failure to this causes fatigue & serious strain.

Always use platform to stand on it to stack material at high level and ensure that material

should be stack only up to chest height.

viii. Do not carry load in such a manner that it obstruct the vision.

ix. Do not stand by holding heavy load in hand, if it is not avoidable, put down on the bench /

platform of suitable height. If bench is not / platform is not there, put it down on the ground

by using right method.

x. While moving load from one table / platform to other, do not twist the body but turn it

completely.

xi. While carry out material handling by using lifting machine, ensure that all banksman /

slingers should be trained.

xii. Check physical condition of all lifting tackles (chain sling, D shackles, nylon sling, and wire

rope sling) before use. All lifting tackles must be get tested by authorized competent person

in Form No. 11 once in a 6 month as per GPL guideline. Keep record of it.

xiii. All lifting machine whether it is own or hired from third party, shall be check for its physical

condition before use & ensure that testing of same shall be done by authorized competent

person. Test certificate must available in the lifting machine with operator.

Prepared by: RM Reviewed by: VS Approved by: JP

Date: 04/03/15 Revision No.: 00

Issued by: VS Page No.: Page 3 of 7

Work Instruction Material Handling ( Manual & Mechanical ) Ref No.:

xiv. Ensure that operator engaged for lifting operation must be trained, experienced and valid

licenses holder.

xv. Safe Working Load must be mark on the lifting tackles & lifting Machine with colour coding

as per the respective company standards.

xvi. Angle between two slings should be maintaining as per the length & weight of material to be

lifted.

xvii. While using nylon sling / chain sling, use packing material to protect from sharp points /

edges of material.

xviii. Load should be landed on the suitable sleepers (wooden boards / sleepers) to avoid

damage of lifting tackles.

xix. Never tie knot to chain sling or nylon sling to shorten them.

xx. Make sure that right pin is used in all D shackles & that they are properly screwed.

xxi. All hooks of lifting machine or lifting tackles should have safety hook latch lock to avoid

displacement of sling due to jerk or uneven movement of lifted material.

xxii. Always see that crane hook is centrally placed over the load (c. g. of the load) to prevent

swinging when load is being lifted.

xxiii. Take your hand away from chain, rope before lifting the load & stand clear to avoid pinch of

finger or hand between the sling & material.

xxiv. While giving signaling to the lifting machine, stand where you can see the load and operator

and vice - versa.

xxv. Ensure that only trained signal man shall be allowed for signaling and giving direction to the

operator.

xxvi. Use PPE like safety helmet, safety shoes, scratch proof hand gloves and safety harness.

xxvii. Hold the load after lifting by tag line (nylon rope) of sufficient length to avoid uneven

movement of material.

xxviii. When lifting machine is in operation, do not leave the area unless you have been relieved by

a trained signalman.

xxix. Do not ride on the load. Do not use lifting tackles for the other purpose like use of nylon sling

as a rope to hold the lifted material.

xxx. After completion of job, keep all lifting tackle in store with proper arrangement.

xxxi. If you found that some of the lifting tackles available at site are got damage or unsafe during

testing of it, immediately remove and make it as scrap permanently.

xxxii. Tool Box Talk must conduct before start the work

6.1 Manual Handling: Most of the operation in construction industry depends on manual material

handling, which involves lifting, shifting, or moving of material from one place to other.

Each handling task poses unique demands on the worker. However, workplaces can help

workers to perform these tasks safely and easily by implementing and adhering proper manual

handling techniques and procedures.

Following safety tips / techniques need to be considering for manual material handling.

i. As for as possible, mechanical lifting equipment shall be used in place of manual handling.

ii. No employee shall be asked to carry loads above his capacity and in any case no load shall

exceed 50kg.

Prepared by: RM Reviewed by: VS Approved by: JP

Date: 04/03/15 Revision No.: 00

Issued by: VS Page No.: Page 4 of 7

Work Instruction Material Handling ( Manual & Mechanical ) Ref No.:

iii. Lifting an object from the ground is more stressful than lifting the same object from several

inches off the ground. When possible, store objects on platforms (i.e., sleepers, shelves or

pallets) that raise them off the ground. Starting positions that are at a level between the knee and

waist are the least stressful to the back.

iv. Balance the load when possible. For example, if carrying handled containers (paint cans, etc.),

carry one in each hand. If carrying or lifting a box, try to distribute the weight of the items

evenly over the whole box (don’t allow one side to be noticeably heavier than the other). Avoid

carrying stacked items that can slip off and/or unbalance the load.

v. Ensure that the load does not obstruct your vision and that should be secure, so that it will not

shift during transport.

vi. Test the weight of the load by tipping or moving it slightly before you pick it up.

vii. Face the load squarely, keep back straight, and use legs to lift. Feet should be about shoulder

width apart to provide a stable stance. Avoid awkward body positions in picking

up/carrying/setting down items.

viii. Avoid stretching/bending while lifting.

ix. Never lift and twist. This action is hard on the back. Move your feet to reposition your direction.

x. Avoid awkward body positions in picking up/carrying/setting down items

xi. The load should be lifted and carried as close to the body as possible. When the load is not

carried closely, the body is positioned out of alignment and more strain is put on the lower back.

xii. Bring the object to the edge of the platform, shelf or pallet in preparation for the lift. Do not

reach over other objects.

xiii. If you become tired, put the load down and rest briefly. If the load begins to shift, put the load

down, reposition and secure contents, resume.

xiv. Plan the placement/delivery. Once the object reaches its final destination, be sure to set it down

in the same manner of lifting it: do not bend at the waist, keep the object close to body, and

maintain a wide posture.

xv. To prevent overemployment injuries, pay attention to pain, numbness and/or uncomfortable and

take action to prevent further strain or injury.

xvi. Change the routine: do not repeat the same activity over and over, but alternate it with other

activities. In some situations, equipment or tools are available that will reduce physical stress.

xvii. Material required to be lifted, carried or moved, shall be lifted, carried or moved in such a way

and with such precautions and safeguards that the lifting, carrying or moving of the material

does not endanger the safety of any worker and property.

xviii. Material shall be transported, placed or stored so that the material,:

a. will not tip, collapse or fall

b. can be removed or withdrawn without endangering the safety of any worker

xix. Material to be removed from a storage area, pile or rack, shall be removed in a manner that

will not endanger the safety of any worker

xx. Reduce the distance over which the load has to be moved by relocating workplace and

storage areas near to each other or vice-versa. Design work place or stations so that

workers:

a. can store and handle all material between ankle and shoulder height; waist height is

most desirable

b. can begin and end handling material at the same height

c. can face the load and handle materials as close to the body as possible

d. do not have to handle loads using awkward postures or an extended reach, and

e. do not handle loads in confined spaces that prevent them from using good body

mechanics

Prepared by: RM Reviewed by: VS Approved by: JP

Date: 04/03/15 Revision No.: 00

Issued by: VS Page No.: Page 5 of 7

Work Instruction Material Handling ( Manual & Mechanical ) Ref No.:

xxi. The best control measure is to eliminate the need for workers to perform manual handling

tasks. Since this is not always possible, design manual handling tasks so that they are

within the workers’ capabilities. Considerations include the load itself, the design of the

workstation and work practices. Providing mechanical handling devices or aids can often

eliminate the task itself or wellbeing the demands on the worker.

xxii. Reduce the weight of the load by

decreasing the size of the object (specify

size to suppliers), weight of the container

(e.g., plastic is lighter than steel), capacity

of containers, load in the container.

xxiii. Steps to follow:

Establish good footing;

Place feet about shoulder width apart;

Bend at the knees to grasp the weight;

Keep the back straight;

Get a firm hold;

Lift gradually by straightening the legs;

When the weight is too heavy or bulky to

lift comfortably, get help;

Take small steps, keeping the load close to

your body and no more than waist high;

Do not twist your body, move your feet to

turn; and

When putting down, reverse this

procedure.

6.2 Mechanical Handling: Mechanical lifting and handling equipment must be selected

considered with the size of material, weight of material, capacity of lifting accessories,

distance travel and topography of the area around the site.

I. Before carrying out heavy erections such as motors, panels, chillers, AHUs etc., a detailed

method statement is prepared and a risk assessment is carried out.

II. All lifting appliances like slings, chain pulley blocks etc. brought to the site will be provided

with a test certificate from approved third party (Competent Person).

III. Ensure that the hired crane deployed is suitable to the purpose of the job and is safe to use.

IV. While transporting materials in vehicles, it will be ensured that undue projections from the

vehicles will not be allowed. If there is any projection, the person responsible for the loading

operation shall ensure that either red flag or red lamp is tied to the projections to warn the

vehicles coming behind.

V. Keep the center of gravity of the load as low as possible. Place heavy objects on the bottom

of the load. Keep feet clear of the wheels.

VI. Load should be placed in such a way that so it will not slip, shift, or fall. Load only to a

height that will allow a clear view ahead.

VII. Trained and licensed operators/drivers will only be allowed to operate lifting machinery.

VIII. All technicians will be instructed on the correct and safe way to operate lifting machinery

6.3 Storage of Material.

i. All material stored in tiers shall be stacked, racked, blocked or otherwise secured to prevent

sliding, falling or collapse. Material will not be stored direct on the ground or on concrete floors.

Prepared by: RM Reviewed by: VS Approved by: JP

Date: 04/03/15 Revision No.: 00

Issued by: VS Page No.: Page 6 of 7

Work Instruction Material Handling ( Manual & Mechanical ) Ref No.:

ii. Material delivery and storage areas should have enough space and lighting to allow for the

safe movement of the materials.

iii. The ground conditions of storage and lay down areas should be even and compacted.

iv. Ensure the work area is flat level ground, i.e. make sure the slab area has a flat, compacted

graded area around it to accommodate materials such as brick packs.

v. Ensure the materials are stored in a manner that does not present hazards to other workers

or the publics.

vi. Keep all construction and associated materials out of reach of fall zone, at least two meter

away from the edges.

vii. Aisles and passageways shall be kept clear to provide for the free and safe movement of material

handling equipment or employees such areas shall be kept in good repair.

viii. Minimum required materials will only be supplied to site and it will be temporary.

ix. Method statement will be provided if materials are stocked at site for long duration.

x. The manufacturer’s recommendations will be followed with respect to temperature and humidity

requirements, and stacking.

xi. Material stored inside buildings under construction shall not be placed within 3 meters of an

exterior wall, which does not extend above the top of the material stores. Compressed gas

cylinders will be stored upright.

xii. Stacks of cylindrical objects such as pipes and cable drums will be stabilized using chocks or

wedges.

xiii. Material stack will be limited in height to ensure stability; heights of more than 2m will be

avoided unless specifically authorized by the project Manager.

xiv.Drums and containers will be marked clearly to indicate contents.

xv. Secure storage will be provided for all hazardous substances, to prevent access by unauthorized

persons.

xvi.Stockpiles and storage areas will be inspected regularly to ensure stability and to ensure that the

above physical precautions are in place. Verbal instructions and training will be given to

operatives as necessary to ensure good housekeeping standards are maintained on site.

6.4 Site Housekeeping: - Good housekeeping on a site has many positive effects including

increased harmony between different sub-contractors, decreased probability of accidents

and increased productivity. The site supervisor should ensure the work areas are free of

obstructions that may prevent the safe movement of materials and people. Well maintained

site makes the job easier and safe. Ensure the following

i. The site must be kept in as tidy a condition as possible.

ii. Remove the broken bricks form the place as it effects their own and others safety and also

have a tendency to tripping hazards on their own and others.

iii. Tidy up all construction waste with segregation of its type into one area (neat piles) at the

end of each day.

iv. Ensure all wind-blown material to be placed and secured in the designated area / bin

provided at site.

v. Routine, regular clean-ups, housekeeping should be scheduled as part of the workday.

vi. Fallow the HK WI and checklist.

7.0 Emergency Procedures and Details of Site Features:

A pre start job meeting shall be arranged for informing about proper communication method.

Arrangement of first aid facilities and emergency vehicles shall be ensured.

Contractor should inform to PMC/ GPL for commencement of work.

Prepared by: RM Reviewed by: VS Approved by: JP

Date: 04/03/15 Revision No.: 00

Issued by: VS Page No.: Page 7 of 7

Work Instruction Material Handling ( Manual & Mechanical ) Ref No.:

In condition as where work affecting by natural calamities like heavy rain, dusty

environment, thunderstorm, etc PMC/ GPL guidelines shall be followed.

8.0 Risk Assessment

Before commencing this activity the Safety Engineer of Contractor should evaluate the

foreseeable risk by conducting independent risk assessment in consultation with site execution

team as per site condition & topography to ensure that appropriate control measures are

established and incorporated. GPL /PMC Safety Engineer are responsible to review & approve

the same.

Use SOP on HIRA and standard HIRA record template available with HO-Safety

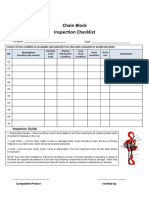

9.0 Checklist:

The site team is responsible to prepare a suitable checklist on “Manual & Mechanical Material

Handling” based on the above procedure and HIRA conducted at site and also keeping in view

the site location topography.

10.0 References:

i. Contract Document

ii. GPL HSE Guideline

iii. Site EHS Plan

iv. BOCW Act & Rules

Prepared by: RM Reviewed by: VS Approved by: JP

You might also like

- 16 Activities HIRADocument40 pages16 Activities HIRAAndini agnes Putri firdausNo ratings yet

- Chaliyama Steel Plant-Rungta Mines Limited Hazard Identification & Risk AssessmentDocument4 pagesChaliyama Steel Plant-Rungta Mines Limited Hazard Identification & Risk AssessmentCPP EI DSpNo ratings yet

- Risk Assesmennt For OutfallDocument9 pagesRisk Assesmennt For Outfallchinmay jagdeepNo ratings yet

- Ocp BatchingDocument1 pageOcp BatchingAarya Mishra TiwariNo ratings yet

- SOP For Drill PressDocument1 pageSOP For Drill Press5am. exeNo ratings yet

- 09.00AM to11.00PM Clear: TCE EffwaDocument3 pages09.00AM to11.00PM Clear: TCE EffwaAjayNo ratings yet

- Abrasive CutDocument1 pageAbrasive CutWahyu Haidar PratamaNo ratings yet

- Jsa 07 (G) # Steel Structure Erection & Miscellaneous Steel-Ptj - S-007Document30 pagesJsa 07 (G) # Steel Structure Erection & Miscellaneous Steel-Ptj - S-007elmsm14No ratings yet

- RA Every ActvityDocument38 pagesRA Every ActvityvijayNo ratings yet

- Hse Risk Register-RaDocument8 pagesHse Risk Register-RaNiraNo ratings yet

- Instructions For Using The Risk Assessment FormDocument9 pagesInstructions For Using The Risk Assessment FormMalik Khuram ShazadNo ratings yet

- Work Permit ProcedureDocument2 pagesWork Permit Procedureवात्सल्य कृतार्थNo ratings yet

- Alimak Hek 65 - 32Document5 pagesAlimak Hek 65 - 32Zhoro Boyssan LestaluhuNo ratings yet

- Job Safety Analysis: JSA Basic DataDocument5 pagesJob Safety Analysis: JSA Basic DataPrabhu DivakaranNo ratings yet

- 3 Hazard CommunicationDocument9 pages3 Hazard CommunicationAlaa AllamNo ratings yet

- MWR 135Document20 pagesMWR 135Philip Bautista TotanesNo ratings yet

- Procedure For OffloadingDocument10 pagesProcedure For OffloadingStansilous Tatenda Nyagomo100% (1)

- New SMP For Cable Tray WorkDocument9 pagesNew SMP For Cable Tray WorkGaurav KhandelwalNo ratings yet

- Lifting Plan Mobie Crane Unloading RebarDocument3 pagesLifting Plan Mobie Crane Unloading Rebarlutfi100% (1)

- Lifting Tools & Tackle RegisterDocument1 pageLifting Tools & Tackle RegisterDth InfraNo ratings yet

- SOP Endurequip HoistsDocument7 pagesSOP Endurequip HoistsMuhammad Zefrian SyahputraNo ratings yet

- 5.JSA of Batching Plant InstallationDocument4 pages5.JSA of Batching Plant InstallationNitesh kumar yadavNo ratings yet

- SOP For Use of Grinder Machines in WorkshopDocument8 pagesSOP For Use of Grinder Machines in WorkshopFaisal RajaNo ratings yet

- Scaff and Mewp and HeightDocument24 pagesScaff and Mewp and HeightRmr ReyesNo ratings yet

- Jacks and Vehicle Stands PDFDocument1 pageJacks and Vehicle Stands PDFcityofdarwingisNo ratings yet

- 5 SPS Hira RCCDocument13 pages5 SPS Hira RCCDwitikrushna RoutNo ratings yet

- Job Safety Analysis - Cone ErectionDocument6 pagesJob Safety Analysis - Cone ErectionEslam lotfy- Eslam elsadatNo ratings yet

- JHA SampleDocument1 pageJHA SampleJoseph PerezNo ratings yet

- Kaztec Fabrication Yard, Snake Island: Job Safety Analysis (JSA)Document3 pagesKaztec Fabrication Yard, Snake Island: Job Safety Analysis (JSA)Ogunwa EmmanuelNo ratings yet

- Roof Pipe Line Fire Safety Other: 1. Descrption and Location of Work: UteduaioDocument1 pageRoof Pipe Line Fire Safety Other: 1. Descrption and Location of Work: UteduaioTushar AgarwalNo ratings yet

- Activity Being Assessed: Risk Assessment For Skate Park ConstructionDocument9 pagesActivity Being Assessed: Risk Assessment For Skate Park ConstructionTerence Tsam0% (1)

- Thyssenkrupp Industrial Solutions (India) Job Safety Analysis 1 4Document6 pagesThyssenkrupp Industrial Solutions (India) Job Safety Analysis 1 4Nitesh KumarNo ratings yet

- Specicifc Risk AssessmentDocument5 pagesSpecicifc Risk AssessmentAejaz MujawarNo ratings yet

- ABC's of Fall Protection: Murray State University Susan MillerDocument24 pagesABC's of Fall Protection: Murray State University Susan MillerSam SalesNo ratings yet

- Skylift ChecklistDocument1 pageSkylift ChecklistSUKHVINDERNo ratings yet

- Risk Assessment - ExcavationDocument7 pagesRisk Assessment - Excavationmahmoud nadaNo ratings yet

- Scaffold Pre Use Daily Inspection ChecklistDocument2 pagesScaffold Pre Use Daily Inspection ChecklistmaramNo ratings yet

- 04, Use of Hand ToolsDocument2 pages04, Use of Hand ToolsFrancis K BonfulNo ratings yet

- Environmental, Health and Safety Risks AnalysisDocument2 pagesEnvironmental, Health and Safety Risks AnalysisKrishna Patil100% (1)

- Discharge Rod 11kv 3phaseDocument1 pageDischarge Rod 11kv 3phasewaytobhushan100% (1)

- Safe Lifting Procedure 2Document6 pagesSafe Lifting Procedure 2angelaNo ratings yet

- SBOI Chklist PDFDocument1 pageSBOI Chklist PDFRajanNo ratings yet

- HIRADocument7 pagesHIRAAkhilesh DubeyNo ratings yet

- Working at Height EbookDocument14 pagesWorking at Height EbookSubhi El Haj SalehNo ratings yet

- Risk Assessment For Erection of Steel GirderDocument11 pagesRisk Assessment For Erection of Steel GirderNirajan MarwaitNo ratings yet

- Genie Australia Operating Telescopic HandlerDocument10 pagesGenie Australia Operating Telescopic Handlerahmed ibNo ratings yet

- SHE-ECP-09-011 Good Stacking & Storage Procedure Rev02Document7 pagesSHE-ECP-09-011 Good Stacking & Storage Procedure Rev02grantNo ratings yet

- SOP 4 - Coal Bed Leveling in PGPDocument18 pagesSOP 4 - Coal Bed Leveling in PGPfaraz ahmedNo ratings yet

- 06 - Tata Power Mobile Crane Safety ProcedureDocument27 pages06 - Tata Power Mobile Crane Safety Procedurehse bsj100% (1)

- Compulsory Ppe As Needed Ppe: Safe Operating Procedures SOP 17 - Wool Press OperationDocument2 pagesCompulsory Ppe As Needed Ppe: Safe Operating Procedures SOP 17 - Wool Press OperationUlviyye ElesgerovaNo ratings yet

- Corporate Safety - Template: Job Safety & Environmental Analysis (JSEA) / Safe Work Method Statement (SWMS)Document6 pagesCorporate Safety - Template: Job Safety & Environmental Analysis (JSEA) / Safe Work Method Statement (SWMS)yyyyyuil100% (1)

- WAH - Working On Roofs - 0Document13 pagesWAH - Working On Roofs - 0Rizki DarmawanNo ratings yet

- Master Hira - 01Document4 pagesMaster Hira - 01Angw BasumataryNo ratings yet

- JHA-Mechanical Lifting1Document2 pagesJHA-Mechanical Lifting1john jaycoh veranoNo ratings yet

- JHA Lifting-Moving Heavy Objects - ROMODocument5 pagesJHA Lifting-Moving Heavy Objects - ROMOSAMUEL POBRENo ratings yet

- Rmdjv-pj74-Hiradc-subc 05 (Setting Out Piling Point)Document1 pageRmdjv-pj74-Hiradc-subc 05 (Setting Out Piling Point)myn maliQueNo ratings yet

- CR 8.8 Assistant Construction Supervisor TEMPLATEDocument1 pageCR 8.8 Assistant Construction Supervisor TEMPLATELiam Du PiesanieNo ratings yet

- Risk Assessment For ExcavationDocument3 pagesRisk Assessment For Excavationfibin haneefaNo ratings yet

- Check List For Welding Machine: Check Items Photos Y/N Check Items Photos Y/NDocument1 pageCheck List For Welding Machine: Check Items Photos Y/N Check Items Photos Y/NMartine OtienoNo ratings yet

- Check List For Main Distributor Board/Panel Board: Check Items Photos Y/N Check Items Photos Y/NDocument2 pagesCheck List For Main Distributor Board/Panel Board: Check Items Photos Y/N Check Items Photos Y/NMartine OtienoNo ratings yet

- Checklist Cherry PickerDocument2 pagesChecklist Cherry PickerMartine OtienoNo ratings yet

- COVID-19 - Office Set-Up ChecklistDocument5 pagesCOVID-19 - Office Set-Up ChecklistMartine OtienoNo ratings yet

- Check List For Main Distributor Board/Panel Board: Check Items Photos Y/N Check Items Photos Y/NDocument1 pageCheck List For Main Distributor Board/Panel Board: Check Items Photos Y/N Check Items Photos Y/NMartine OtienoNo ratings yet

- Check List For Industrial Generator: Contractor Name: Date Description Yes No RemarksDocument1 pageCheck List For Industrial Generator: Contractor Name: Date Description Yes No RemarksMartine OtienoNo ratings yet

- Checklist Drilling MachineDocument1 pageChecklist Drilling MachineMartine OtienoNo ratings yet

- Energy IsolationDocument1 pageEnergy IsolationMartine OtienoNo ratings yet

- Check List Metal Cutting Machine: Sr. No. Sr. NoDocument1 pageCheck List Metal Cutting Machine: Sr. No. Sr. NoMartine OtienoNo ratings yet

- Check List Metal Cutting Machine: Sr. No. Sr. NoDocument1 pageCheck List Metal Cutting Machine: Sr. No. Sr. NoMartine OtienoNo ratings yet

- Stockpiles and Surge Piles: Entry Restricted To Authorized Persons OnlyDocument1 pageStockpiles and Surge Piles: Entry Restricted To Authorized Persons OnlyMartine OtienoNo ratings yet

- Hazard Identification Methods: Qualitative QuantitativeDocument2 pagesHazard Identification Methods: Qualitative QuantitativeMartine OtienoNo ratings yet

- Safety Harness Inspection Checklist-1Document1 pageSafety Harness Inspection Checklist-1Martine OtienoNo ratings yet

- Hazard Identification Methods: Qualitative QuantitativeDocument2 pagesHazard Identification Methods: Qualitative QuantitativeMartine OtienoNo ratings yet

- Hazard Control-Risk Assessment Approach: Risk Probability Severity The Hierarchy of Controls AcceptableDocument1 pageHazard Control-Risk Assessment Approach: Risk Probability Severity The Hierarchy of Controls AcceptableMartine OtienoNo ratings yet

- Service Provision Tool Kit No Evaluation Kit Perfomance Indicator Accepted PerfomanceDocument4 pagesService Provision Tool Kit No Evaluation Kit Perfomance Indicator Accepted PerfomanceMartine OtienoNo ratings yet

- Chain Block Inspection Checklist: Location: DateDocument2 pagesChain Block Inspection Checklist: Location: DateMartine OtienoNo ratings yet

- Backhoe-Loader Daily Inspection ChecklistDocument1 pageBackhoe-Loader Daily Inspection ChecklistMartine OtienoNo ratings yet

- Gantry Crane Daily Inspection ChecklistDocument1 pageGantry Crane Daily Inspection ChecklistNajib MukodwaNo ratings yet

- Boom Truck Daily InspectionDocument1 pageBoom Truck Daily InspectionMartine OtienoNo ratings yet

- Bull Dozer Daily Inspection ChecklistDocument1 pageBull Dozer Daily Inspection ChecklistMartine Otieno100% (2)

- Phase Item No. Item Name OK NOT OK N/A DeficiencyDocument1 pagePhase Item No. Item Name OK NOT OK N/A DeficiencyMartine OtienoNo ratings yet

- Articulated Dump Truck Daily Inspection ChecklistDocument1 pageArticulated Dump Truck Daily Inspection ChecklistMartine OtienoNo ratings yet

- LH H&S Induction-New Employees & Contractors 2020Document1 pageLH H&S Induction-New Employees & Contractors 2020Martine OtienoNo ratings yet

- Portable Grinder-Pre Inspection ChecklistDocument2 pagesPortable Grinder-Pre Inspection ChecklistMartine Otieno100% (1)

- Suspended Scaffold Pre-Operation Inspection Checklist: Project InformationDocument4 pagesSuspended Scaffold Pre-Operation Inspection Checklist: Project InformationMartine OtienoNo ratings yet

- Safe Welding TrainingDocument13 pagesSafe Welding TrainingMartine OtienoNo ratings yet

- Safety TalkDocument1 pageSafety TalkMartine OtienoNo ratings yet

- Rokan Safety ProgramDocument157 pagesRokan Safety ProgramMartine OtienoNo ratings yet

- JSA Installation of Equipment For Electrical and InstrumentDocument3 pagesJSA Installation of Equipment For Electrical and InstrumentHong Hai Pham75% (4)

- Industrial Hygiene 2 PresentationDocument19 pagesIndustrial Hygiene 2 PresentationYashini DussoyeNo ratings yet

- Individual Support Work Skills Workshop Student Assessments BookletDocument68 pagesIndividual Support Work Skills Workshop Student Assessments BookletPranav Prajapati0% (2)

- Dissertation Topics On Oil and Gas Health and SafetyDocument8 pagesDissertation Topics On Oil and Gas Health and SafetyCollegePaperGhostWriterAkronNo ratings yet

- Msds Ammonium BicarbonateDocument5 pagesMsds Ammonium BicarbonateHayleyNo ratings yet

- Operating Instruction TE 3000 AVR 01 en Listsep en US Operating Instruction PUB 5364017 000Document26 pagesOperating Instruction TE 3000 AVR 01 en Listsep en US Operating Instruction PUB 5364017 000Muhammad Shakeel AttariNo ratings yet

- MSDS - Prima AutowashDocument10 pagesMSDS - Prima AutowashImran AzizNo ratings yet

- 3529-04 Basic Plumbing Qualification Handbook v1Document50 pages3529-04 Basic Plumbing Qualification Handbook v1LokuliyanaNNo ratings yet

- Construction Logistics Plan: Project: TolworthDocument28 pagesConstruction Logistics Plan: Project: TolworthSRIRAM D100% (1)

- Material Safety Data Sheet: #360F Liquid Flux 1. Product and Company IdentificationDocument5 pagesMaterial Safety Data Sheet: #360F Liquid Flux 1. Product and Company IdentificationteknoartistNo ratings yet

- Personal Protective Equipment (PPE)Document70 pagesPersonal Protective Equipment (PPE)shitNo ratings yet

- El-Cortsol 2Document3 pagesEl-Cortsol 2MaherNo ratings yet

- Uh Manual Perkins 800Document78 pagesUh Manual Perkins 800Birger ErikssonNo ratings yet

- Molten SulfurDocument13 pagesMolten SulfurAnonymous R23prjoKnoNo ratings yet

- K To 12 Smaw Welding Teacher's GuideDocument15 pagesK To 12 Smaw Welding Teacher's GuideHari Ng Sablay89% (47)

- Salicylic Acid CAS No 69-72-7: Material Safety Data Sheet Sds/MsdsDocument7 pagesSalicylic Acid CAS No 69-72-7: Material Safety Data Sheet Sds/MsdsSari RofiqohNo ratings yet

- SMAW Health Hazards of g12 Students During Laboratory ActivitiesDocument25 pagesSMAW Health Hazards of g12 Students During Laboratory ActivitiesPaul Patrick Guanzon100% (1)

- CNG Time Fill Post User GuideDocument18 pagesCNG Time Fill Post User Guidegiuseppe tropianoNo ratings yet

- Water-Block Seal S-20 en 1.0Document9 pagesWater-Block Seal S-20 en 1.0Youl SilvaNo ratings yet

- Fipronil SdsDocument5 pagesFipronil Sdsapi-387946507No ratings yet

- HSE Clasp GuidanceDocument11 pagesHSE Clasp GuidanceElliot MortonNo ratings yet

- Material Safety Data Sheet: Kvogell - L940Document5 pagesMaterial Safety Data Sheet: Kvogell - L940ravikunwar14No ratings yet

- One Direct Method Statement: Main Hazards Preventative MeasuresDocument5 pagesOne Direct Method Statement: Main Hazards Preventative MeasuresFaisal RazaNo ratings yet

- Deodorized Kerosene (DOK0) 12.26.18Document7 pagesDeodorized Kerosene (DOK0) 12.26.18Allel HamdacheNo ratings yet

- Oxonia Active.979252 04 EukDocument5 pagesOxonia Active.979252 04 EukghophalNo ratings yet

- Hazard Register ConstructionDocument15 pagesHazard Register ConstructionMohd ObaidullahNo ratings yet

- WMS - Pipe Civil Works-OCADocument6 pagesWMS - Pipe Civil Works-OCAKarthik babuNo ratings yet

- 3-0002-00054-1-d Iom in English - Packaged Rooftop Air Conditioners Precedent - Electric - Electric 3 - 10 Tons - 60 HZDocument64 pages3-0002-00054-1-d Iom in English - Packaged Rooftop Air Conditioners Precedent - Electric - Electric 3 - 10 Tons - 60 HZJose ReedNo ratings yet

- MSDS SodiumchloroasetatDocument10 pagesMSDS Sodiumchloroasetatanastasia natalisaNo ratings yet

- SSW Offshore Coaching - 10 SSW QuestionnaireDocument46 pagesSSW Offshore Coaching - 10 SSW QuestionnaireShahir HarunNo ratings yet