Professional Documents

Culture Documents

Rotating Equipment Strategy for Performance Optimization

Uploaded by

Lot SalasOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Rotating Equipment Strategy for Performance Optimization

Uploaded by

Lot SalasCopyright:

Available Formats

R

I N S T I T U T E

www.lubrication-institute.com

Solutions Unlimited

Rotating Assets Strategy

Performance

Visit : www.lubrication-institute.com Call : +91-9431117604

R

I N S T I T U T E

www.lubrication-institute.com

Solutions Unlimited

Rotating Equipment Overview

Rotating Equipments is a very critical for process chain. Every year hundreds of thousands of dollars are lost due to

downtime brought on by machinery failure attributing mainly to rotating equipment, the unavailability of suitable

spare components and the failure to accurately diagnose the real underlying problem.

This course is designed for an insight into rotating equipment reliability program, its implementation, performance

factors, efficiency and uptime. The course is aimed at learning the management of rotating equipment with proactive

strategy.

LEARNING OBJECTIVES WHO SHOULD ATTEND

Rotating equipment Basic Maintenance Management

Classifications of different rotating equipment Managers

details about pumps, compressors, turbine etc Engineers

Auxiliary systems like lubrication system ,bearings ,seals Chief Engineers

Rotating Equipment Reliability Improvement Strategy Vice Presidents

Condition Monitoring Methods For Rotating Equipment Maintenance Staff

Best Practices Maintenance Planning Managers

Advance Maintenance Management in Process Chain. Maintenance Program Engineers

Effective reliability program to optimize the performance Reliability Engineers / Managers

of critical Rotating Equipment Finance and procurement people

Visit : www.lubrication-institute.com Call : +91-9431117604

R

I N S T I T U T E

www.lubrication-institute.com

Solutions Unlimited

Pump Performance

1. Pump terminology, types, classification &

application

2. Pump performance parameters, curves &

application

3. Pump specification, catalogue, head, discharge,

NPSH, cavitation

Pump Maintenance For Reliability Turbines - Strategies For Operations &

4. Operations of Rotodynamic pumps Maintenance

5. Operations of PD pumps - differences in

17. Introduction to steam & gas turbines, types &

strategy

application

Pump Standards, Design & Selection: 18. Maintenance of steam turbines for reliability

6. Introduction to pump standards 19. Maintenance of gas turbines for reliability

7. Basics of pumps design

Condition Monitoring of Rotating Assets,

8. Selection of a pump for an application

RCA & Care For Optimum Performance:

20. Condition monitoring of rotating machinery

21. Root cause analysis for machinery failure

22. Installation and alignment, care of rotating

machinery

Best Practices & Developing Reliability

Strategies

Compressors Strategies For Operations & 23. Best practices - pumps & compressors

Maintenance 24. Preventive & Predictive care of rotating

9. Compressor types, application, terminology assets

10. Surge & choke, importance, performance curves 25. Best practices - Turbines

11. Mechanical design of compressors 26. Modern developments in maintenance,

inspection & application for reliability

12. Maintenance, PM of compressors

Manage Seals, Bearings, Compressor

Selection Strategies :

13. Dry gas seals, mechanical seals, bearings

overview of strategy for reliability

14. Turbo compressors - operations, performance

15. PD compressors - operations and performance

16. Selection of compressors, specifications

Visit : www.lubrication-institute.com Call : +91-9431117604

R

I N S T I T U T E

www.lubrication-institute.com

Live & Interactive Online Training

2022 Calendar

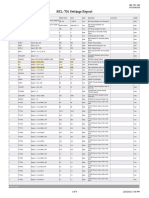

NAME OF TRAINING / CERTIFICATION

Skill Training Skill Training

Machinery Lubrication Level - I Oil Analysis Level - II (MLA II)

(MLA I / MLT I) Ferrography and Interpretation

JANUARY MAY OCTOBER FEBRUARY JUNE DECEMBER

18-20th 17-19th 18-20th 22-24th 14-16th 13-15th

Rotating Assets Strategy Lubricant Blending & Quality

for performance Assurance

MARCH APRIL

29-31st 25-28th

Skill Training

API 653 Maintenance, Repairs & Machinery Lubrication Level - II

Upkeep of Storage Tanks API 653 (MLT II)

MAY JULY

24-27th 26-28th

Skill Training Skill Training

Machinery Lubrication Engineer Oil Analysis Level - I (MLA III)

(MLE)

AUGUST SEPTEMBER

22-26th 20-23th

Reliability Centered Maintenance

NOVEMBER

22-25th

+91 9431117604

You might also like

- Final Cits TractorDocument22 pagesFinal Cits Tractorparveenrathee123No ratings yet

- Steam Turbine Oil Eyeopening ArticleDocument15 pagesSteam Turbine Oil Eyeopening ArticleRajeswaran NatarajanNo ratings yet

- Curriculam Vitae Objective Engineer .: Yyyyy 3. Indian 4. 5. 6Document3 pagesCurriculam Vitae Objective Engineer .: Yyyyy 3. Indian 4. 5. 6Arshad Rashid ShahNo ratings yet

- Machinery Lubrication Level IIDocument6 pagesMachinery Lubrication Level IILot SalasNo ratings yet

- LJ 50 QTDocument54 pagesLJ 50 QTverkacktNo ratings yet

- 7-9 April 2014, Al Khobar, Kingdom of Saudi Arabia: Featured Presentation byDocument11 pages7-9 April 2014, Al Khobar, Kingdom of Saudi Arabia: Featured Presentation byshivarachappaNo ratings yet

- Labour Market Intelligence Study For Oil & Gas SectorDocument19 pagesLabour Market Intelligence Study For Oil & Gas SectorHussein BoffuNo ratings yet

- RP 205 Crane Operation Maintenance and Testing PDFDocument30 pagesRP 205 Crane Operation Maintenance and Testing PDFDeepak SugathanNo ratings yet

- Intro NomenclatureDocument14 pagesIntro NomenclaturepmcisissengueNo ratings yet

- Steam Turbine With Registration FormDocument5 pagesSteam Turbine With Registration FormmydewamailidNo ratings yet

- Mech ForemanDocument4 pagesMech ForemanSiva SabarishNo ratings yet

- OISD Standard for Inspection of PumpsDocument18 pagesOISD Standard for Inspection of PumpsNanu Patel100% (1)

- 200120-NSH AMC CONTRACT ConceptDocument22 pages200120-NSH AMC CONTRACT ConceptSaurabh YadavNo ratings yet

- 09 Rotating Equipment - InddDocument12 pages09 Rotating Equipment - InddAnonymous q9eCZHMuSNo ratings yet

- Tilting Pad Journal BearingDocument87 pagesTilting Pad Journal BearingMohamed GomaaNo ratings yet

- Brochure 031017 English Print ICML-web PDFDocument4 pagesBrochure 031017 English Print ICML-web PDFEmerson 2140No ratings yet

- TEF - Awareness - Mining ForumDocument18 pagesTEF - Awareness - Mining ForumTC BengalonNo ratings yet

- Rotating Equipment TrainingDocument4 pagesRotating Equipment TrainingHatem HusseinNo ratings yet

- Steps To Optimize Lubricants Use PDFDocument113 pagesSteps To Optimize Lubricants Use PDFPrabhu LohakareNo ratings yet

- Machinery Lubrication MagazineDocument82 pagesMachinery Lubrication Magazined_ansari26No ratings yet

- CV Riyas Ali M KDocument2 pagesCV Riyas Ali M Kkaran patelNo ratings yet

- Lubrication Audits - P21E43Document6 pagesLubrication Audits - P21E43Cesar Augusto Morales CasanovaNo ratings yet

- Inbi Gtbi 2018Document5 pagesInbi Gtbi 2018SyedNadeemAhmedNo ratings yet

- Revision of Grease Specification for Rail BearingsDocument17 pagesRevision of Grease Specification for Rail Bearingsarbind kumarNo ratings yet

- WP1606 Machinery Lubrication WhitepaperDocument6 pagesWP1606 Machinery Lubrication WhitepaperDELIO SÁNCHEZNo ratings yet

- Handbook of Mechanical In-Service InspectionDocument704 pagesHandbook of Mechanical In-Service InspectionJojolasNo ratings yet

- Your Machine Tool and Give A To Your: Retrofit Boost Bottom Line!Document4 pagesYour Machine Tool and Give A To Your: Retrofit Boost Bottom Line!Ashok MalkudNo ratings yet

- Solutions For Predictive Equipment Maintenance: The Science of Fluid AnalysisDocument16 pagesSolutions For Predictive Equipment Maintenance: The Science of Fluid Analysishouston machacaNo ratings yet

- Piston Rings For Combustion Engines - 53094Document80 pagesPiston Rings For Combustion Engines - 53094Dario Rojas A100% (1)

- Mechanical SupervisorDocument2 pagesMechanical Supervisorsinghyuvraj373No ratings yet

- MGMT BriefDocument52 pagesMGMT BriefGustavo Fajardo PulidoNo ratings yet

- Operation & Maintenance Manual: P158LE / - 1 / - 2 / - S / - III P180LE / - 1 / - S / - II P222LE / - 1 / - S / - IIDocument165 pagesOperation & Maintenance Manual: P158LE / - 1 / - 2 / - S / - III P180LE / - 1 / - S / - II P222LE / - 1 / - S / - IIMuhammad EmamNo ratings yet

- SKF Reliability MaintenanceInstitute Courses PDFDocument26 pagesSKF Reliability MaintenanceInstitute Courses PDFelbusharieltaher1261No ratings yet

- Multiple Disc Brakes: Posi-Torque Winch Brakes, Pressure Override Brakes, Wheel Mount Brakes, and Driveline BrakesDocument52 pagesMultiple Disc Brakes: Posi-Torque Winch Brakes, Pressure Override Brakes, Wheel Mount Brakes, and Driveline BrakesLucas BritoNo ratings yet

- Bearing and Equipment Lubrication Strategies - Getting It RightDocument64 pagesBearing and Equipment Lubrication Strategies - Getting It Rightsrikanth siddhardhaNo ratings yet

- 1int. To CompDocument6 pages1int. To CompDiyaNegiNo ratings yet

- Maintenance and Operator'S Manual T. F. C. 45 QSM11Document299 pagesMaintenance and Operator'S Manual T. F. C. 45 QSM11Văn Đạt100% (6)

- Saravanan.T.D: Personal Details Profile SummaryDocument4 pagesSaravanan.T.D: Personal Details Profile Summarypalla mounicaNo ratings yet

- Lubrication and seal oil systems overviewDocument26 pagesLubrication and seal oil systems overviewpietroNo ratings yet

- Intro Nom Sebd0350Document16 pagesIntro Nom Sebd0350pmcisissengueNo ratings yet

- Overhaul Basics ModuleDocument18 pagesOverhaul Basics Moduleঅজানা রশ্মি Ajana rashmiNo ratings yet

- Milat Profile - Final VersionDocument24 pagesMilat Profile - Final VersionE BNo ratings yet

- In House Programs 2015 EngineeringDocument6 pagesIn House Programs 2015 EngineeringKURNIAWANNo ratings yet

- Signum Oil Analysis Condition Monitoring Fundamentals English UkDocument20 pagesSignum Oil Analysis Condition Monitoring Fundamentals English UkHim SatiNo ratings yet

- GCC Shutdowns, Turnarounds and Outages Conference 2023Document14 pagesGCC Shutdowns, Turnarounds and Outages Conference 2023NadeemNo ratings yet

- 28 Manual de Servicio ToritoDocument133 pages28 Manual de Servicio ToritoJulian Uribe HerreraNo ratings yet

- OVERVIEW Engine N45 - N67 MNADocument30 pagesOVERVIEW Engine N45 - N67 MNAJoin DigitaNo ratings yet

- Handbook of Mechanical In-Service Inspection-Pressure Systems and Mechanical Plant-Clifford Matthews PDFDocument705 pagesHandbook of Mechanical In-Service Inspection-Pressure Systems and Mechanical Plant-Clifford Matthews PDFVICTOR SEGOVIA100% (5)

- 7fbcu15 Operator ManualDocument89 pages7fbcu15 Operator ManualInfoNo ratings yet

- Presentation - Triveni Turbines-RefurbishingDocument29 pagesPresentation - Triveni Turbines-RefurbishingManoj Singh100% (1)

- Triveni Turbine's Lifecycle Solutions for Aftermarket Steam TurbinesDocument29 pagesTriveni Turbine's Lifecycle Solutions for Aftermarket Steam TurbinesManoj Singh100% (1)

- Maintenance Course For Engineers.Document270 pagesMaintenance Course For Engineers.Gaurav100% (3)

- OISD-GDN-206 First Edition, September, 2001Document49 pagesOISD-GDN-206 First Edition, September, 2001ShivprasadNo ratings yet

- Chery SQR7080R Engine Service ManualDocument57 pagesChery SQR7080R Engine Service ManualUmar ShamsudinNo ratings yet

- Maintenanceof DG OISD STD 127 PDFDocument20 pagesMaintenanceof DG OISD STD 127 PDFSanath KumarNo ratings yet

- macpAR 2017 2018Document114 pagesmacpAR 2017 2018wqhnhwomNo ratings yet

- Machinery LubricationDocument90 pagesMachinery Lubricationgilen30No ratings yet

- Gearbox Monitoring by Vibration AnalysisDocument18 pagesGearbox Monitoring by Vibration AnalysisJavadAminpourNo ratings yet

- Future of Maintenance - AI Making An Impact - Dr. Sami El-SayedDocument16 pagesFuture of Maintenance - AI Making An Impact - Dr. Sami El-SayedPeterW.BertyNo ratings yet

- Technical SubjectDocument94 pagesTechnical SubjectJulius Alano91% (23)

- DUAL NATURE - PHOTOELECTRIC EFFECTDocument6 pagesDUAL NATURE - PHOTOELECTRIC EFFECTjagatdhatriNo ratings yet

- Effect of Quenching Temperature On The Mechanical Properties of Cast Ti 6al 4V AlloyDocument7 pagesEffect of Quenching Temperature On The Mechanical Properties of Cast Ti 6al 4V AlloySEP-PublisherNo ratings yet

- Skid Vibration ProblemsDocument16 pagesSkid Vibration ProblemsarturomNo ratings yet

- Kriyashakti in ShortDocument1 pageKriyashakti in ShortMorganNo ratings yet

- Indian Economy Lecture Notes Unit IIDocument11 pagesIndian Economy Lecture Notes Unit IIAmit Kumar50% (2)

- Process Design QuestionnaireDocument30 pagesProcess Design QuestionnaireNguyen Anh TungNo ratings yet

- Unit - Iv Urban Conservation: Principles and ObjectivesDocument4 pagesUnit - Iv Urban Conservation: Principles and ObjectivesManiMannan100% (1)

- RRB ALP Syllabus 2017 - Subjects & TopicsDocument5 pagesRRB ALP Syllabus 2017 - Subjects & TopicsABHILASHNo ratings yet

- Smarter Washing Solutions: Modular Wash RangeDocument5 pagesSmarter Washing Solutions: Modular Wash RangeSujesh AnNo ratings yet

- David 2105 PrelimExamsDocument10 pagesDavid 2105 PrelimExamsJAZPER DAVIDNo ratings yet

- Plastics SolutionsDocument20 pagesPlastics SolutionsGavazzi JuarezNo ratings yet

- Checklist of C&i For Full Load OperationDocument9 pagesChecklist of C&i For Full Load Operationrohit_me083No ratings yet

- EC8252 Electronic DevicesDocument9 pagesEC8252 Electronic DevicesSiva ÑärêshNo ratings yet

- AssignmentDocument9 pagesAssignmentAhmad KhanNo ratings yet

- Solis 1P (1 5K) 4G - V1Document24 pagesSolis 1P (1 5K) 4G - V1Jhasper ManagyoNo ratings yet

- 7TH LPDocument8 pages7TH LPSeema MotagiNo ratings yet

- Makerere University 72 Graduation List For May 2022Document160 pagesMakerere University 72 Graduation List For May 2022The Campus Times100% (2)

- ShoeBox Compressor ManualDocument7 pagesShoeBox Compressor ManualSteveZ59100% (1)

- Pay utility bills for power, gas and water onlineDocument13 pagesPay utility bills for power, gas and water onlineshahid2opuNo ratings yet

- FormDocument2 pagesFormBhargav VekariaNo ratings yet

- SEL-701 Settings ReportDocument9 pagesSEL-701 Settings ReportJosé AntonioNo ratings yet

- 5 - 18b - Mineral ResourcesDocument90 pages5 - 18b - Mineral ResourcesDa Apollyon100% (4)

- Work, Energy and Forces ExplainedDocument26 pagesWork, Energy and Forces ExplainednyumnamNo ratings yet

- What Is The Difference Between Graft and CorruptionDocument3 pagesWhat Is The Difference Between Graft and CorruptionPrince Khalid67% (3)

- Colloid Chemistry in Mineral ProcessingDocument429 pagesColloid Chemistry in Mineral ProcessingNataniel Linares100% (1)

- Puente Grua EquipoDocument28 pagesPuente Grua EquipoGalo AyalaNo ratings yet

- Control Valve: CPE501 Chemical Process ControlDocument4 pagesControl Valve: CPE501 Chemical Process ControlnazirulNo ratings yet

- Roxtec Cable Seals: For Power Transmission and Distribution ApplicationsDocument24 pagesRoxtec Cable Seals: For Power Transmission and Distribution ApplicationsarifNo ratings yet

- OTCQB Company ListDocument119 pagesOTCQB Company ListtbconantNo ratings yet