Professional Documents

Culture Documents

APP008 - Hitachi Screw Point List and Startup Sequence

Uploaded by

marcyel Oliveira WoliveiraCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

APP008 - Hitachi Screw Point List and Startup Sequence

Uploaded by

marcyel Oliveira WoliveiraCopyright:

Available Formats

APP-008 Hitachi Screw Compressor

Micro Control Systems

APPLICATION NOTE

APP-008

Hitachi Screw Point List and Startup

Sequence

Revision History

Date Author Description

1/16/98 RCT Initial App note (draft copy)

3/12/98 RCT Released

3/13/98 RCT Update corrections

APP-008 Hitachi Screw Compressor

This Application Note outlines the point set up when building the configuration

file and the start up sequence for Hitachi screw compressors.

Theory

The MCS-8 algorithm has a predefined sequence of relay outputs by

refrigeration circuit. These sequences can start at any relay output, assuming

enough relay outputs follow to handle the sequence.

Relay Output points list

Hitachi Screw Compressor

1. Compressor

2. Slide Load Solenoid

3. Slide Unload Solenoid

4. Start Unload Solenoid

5. Liquid Line Solenoid

Example of Hitachi Screw Compressor Sequence

The following Information Screens would be required for the above relay outputs.

• Hitachi Screw Compressor Type has been selected

• The continuous pump down option has not been selected. Pump down

will occur when the compressor is to be turned off and started.

• The auto rotation option has been selected. If two or more circuits

exist, auto rotation will occur.

APP008 Hitachi Screw Point List and Startup Sequence.doc 12/04/01 2

APP-008 Hitachi Screw Compressor

• 5 has been entered for Num Comp stages (number of relay outputs)

• COMP1 has been selected as the Starting Compressor

Start up sequence

When the Hitachi screw compressor is to be started, the system first

ensures that the compressor is in a completely unloaded state. The circuit

state will move from the OFF to a ST UNLD, start unload, state. After 60

seconds the system will move to an UNLOADED state and then

determine the proper setting of the slide valve.

RO OFF STATE ST UNLD UNLOADED

Compressor OFF ON ON

Slide Load Solenoid OFF OFF OFF

Slide Unload Solenoid OFF ON OFF

Fast Unload Solenoid OFF ON OFF

Liquid Line Solenoid OFF ON ON

The system will now determine the appropriate action to take based upon the

controlling temperature.

The following is a list of circuit control states that can exist for a Hitachi screw

compressor:

OFF

This state is entered when no cooling capacity is required from this circuit or the

prior state was ANTICYC, LOST IO or DISABLE. After 60 seconds in this state

the circuit is ready to provide cooling capacity if needed.

ST UNLD

For screw compressors, this state is entered when the compressor is turned on.

The system will remain in this state for 60 seconds while the “start unloader” and

the regular unload points are on. This is to ensure that the screw is unloaded.

APP008 Hitachi Screw Point List and Startup Sequence.doc 12/04/01 3

APP-008 Hitachi Screw Compressor

LOADING

For screw compressors, this state is when the screw load solenoid is being

pulsed to increase the cooling capacity of the circuit. The duration of the pulse is

specified in the set point (LOAD PULSE).

HOLDING

In this state, the required refrigeration capacity of system is being met; no

movement of the slide valve is required.

UNLDING

The screw unload solenoid is being pulsed to reduce the cooling capacity of the

circuit by moving the slide valve. The duration of the pulse is specified in set

point (UNLOAD PULSE).

DIS HLD

The screw slide valve is being held, will not load due to a high discharge

pressure or high discharge temperature. The system will allow the slide valve to

be unloaded if required.

DIS UNL

The screw slide valve is being unloaded due to a high discharge pressure or high

discharge temperature.

SUC UNL

In this state the screw compressor is being unloaded turned off due to low

suction pressure.

UNLDED

In this state is when the Hitachi screw’s slide is fully unloaded (indicated after

pulsing 30 seconds with no change in the compressors amp draw). When in this

state, every five minutes the unload solenoid is turned on for 30 seconds to

insure that the slide is fully unloaded. If the hot gas bypass (HGB) is provided, it

can be turned on only in this state. The HGB is controlled on either suction

pressure or leaving liquid temperature set points.

APP008 Hitachi Screw Point List and Startup Sequence.doc 12/04/01 4

APP-008 Hitachi Screw Compressor

SUC HLD

This state is entered when a screw slide position is not allowed to load due to

low suction pressure. The screw slide position will remain constant or be allowed

to unload if required.

LOADED

This state is when the compressor is fully loaded (indicated after pulsing 30

seconds with no increase in the compressor amp draw). In this state, the circuit

is providing the maximum amount of cooling capacity. When in this state, every

five minutes the load solenoid is turned on for 30 seconds to insure that the slide

remains fully loaded.

PMP DWN

This state is entered whenever the pump down switch has been turned on or if

this circuit is no longer wanted on. The compressor is on and the liquid line

solenoid is closed. This state is active until the suction pressure reaches the

value in the set point (PMP DN PSI) or the time has exceeded the value in the

set point (PMP DN DELAY). The circuit will then move to the ANTICYC State.

ANTICYC

This state is entered when the PMP DWN State has been successfully

completed. The circuit will stay in this state with all circuit points off for the period

of time contained in set point (CYCLE DELAY). The circuit will then move to the

OFF State.

DISABLE

This state is entered after the circuit has been pumped down due to the pump

down switch being on. In this state the compressor, and all related points, plus

the liquid line are off. The circuit will not leave this state unless the pump down

switch is turned off. If the pump down switch is turned off, the Circuit State will be

changed to OFF State.

SAFETY

This state is entered when a safety trips but a lockout is not to be generated. An

alarm is generated and the system will restart after a five minute delay. If the

same safety occurs within ½ hour, the circuit goes to the LOCK OUT State which

will require a manual reset.

APP008 Hitachi Screw Point List and Startup Sequence.doc 12/04/01 5

APP-008 Hitachi Screw Compressor

LOCK OUT

This state is entered when the CAPACITY CONTROL STATE is LOCK OUT or a

safety set point for this circuit has indicated that a critical situation has been

encountered. Set points such as (LOW SUCTION) or (HI DISCH PSI) are

examples of safety set points. Lockouts can be reset without authorization from

the keypad or PConn program; however if the lockout condition has not been

corrected, the circuit will again be forced into the LOCKOUT State.

APP008 Hitachi Screw Point List and Startup Sequence.doc 12/04/01 6

You might also like

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGFrom EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- AC001 Carrier 30HWC035 Chiller Wiring-30HWADocument12 pagesAC001 Carrier 30HWC035 Chiller Wiring-30HWACelso OtalNo ratings yet

- Hd785-3 Electric OptionalDocument13 pagesHd785-3 Electric OptionalBima Dwi UtomoNo ratings yet

- 6l80 IntroductionDocument28 pages6l80 IntroductionLojan Coronel José Humberto100% (3)

- McQuay Controller HandbookDocument70 pagesMcQuay Controller HandbookAna Gil Pinto Brás100% (2)

- Manual Del QuantaDocument7 pagesManual Del QuantaAntonio RenteríaNo ratings yet

- Curtis AirPLUSDocument37 pagesCurtis AirPLUSpekawwNo ratings yet

- Descritivo de Manutenção - Guindaste Appleton Marine - SWL 30 TonsDocument9 pagesDescritivo de Manutenção - Guindaste Appleton Marine - SWL 30 TonsSérgio Meneses VieiraNo ratings yet

- Check The OLTC Position For Startup Condition On 9 Step Position. Closed 10BBA10GS001, 10BBA10GS010, 10BBA30GS001Document5 pagesCheck The OLTC Position For Startup Condition On 9 Step Position. Closed 10BBA10GS001, 10BBA10GS010, 10BBA30GS001jose Alberto uribe Minier100% (1)

- Bobcat EduDocument21 pagesBobcat EduJuan VergelNo ratings yet

- Profile Warranty and Service Information for GE WasherDocument12 pagesProfile Warranty and Service Information for GE WasherJim HarmkeNo ratings yet

- 09-Soft Clutch-System DescriptionDocument3 pages09-Soft Clutch-System DescriptionGrisha Mari KosoyanNo ratings yet

- Idle Valve Options: 2 Wired Valves (Ms1, 2 and 3 Fidle Wire - Ms3X Setup Use Ms3X Idle Wire)Document14 pagesIdle Valve Options: 2 Wired Valves (Ms1, 2 and 3 Fidle Wire - Ms3X Setup Use Ms3X Idle Wire)m_tOmNo ratings yet

- Diesel Pump of The Desmi GroupDocument10 pagesDiesel Pump of The Desmi Groupngocdhxd92No ratings yet

- Automatic Flocculant Plant Control PhilosophyDocument8 pagesAutomatic Flocculant Plant Control PhilosophyBebel VillarNo ratings yet

- Iom Ylae-2Document32 pagesIom Ylae-2lam100% (1)

- TORNATECH JP Manual EnglishDocument14 pagesTORNATECH JP Manual EnglishWalid AHMED MOUNIR MORSYNo ratings yet

- Absorption Liquid Chillers: Millennium Control Center Operations ManualDocument118 pagesAbsorption Liquid Chillers: Millennium Control Center Operations ManualYOLY_91No ratings yet

- 18speed FullerDocument100 pages18speed FullerPieter Coetzer100% (4)

- Suzuki SwiftDocument7 pagesSuzuki SwiftAsher GinsbergNo ratings yet

- Desarmado y Armado Hidrau 416CDocument99 pagesDesarmado y Armado Hidrau 416CedhuamNo ratings yet

- Chapter 4 Part C:: Fuel and Exhaust Systems - K-Jetronic Fuel Injection - 16 Valve EnginesDocument6 pagesChapter 4 Part C:: Fuel and Exhaust Systems - K-Jetronic Fuel Injection - 16 Valve EnginesmohhizbarNo ratings yet

- Dometic Royale RM3862Document37 pagesDometic Royale RM3862SWNo ratings yet

- Comp (1) RepaireDocument14 pagesComp (1) RepaireKalimulla Shaik100% (8)

- Chiller Plant Manager Control SequenceDocument5 pagesChiller Plant Manager Control SequenceBhagyaraj NPNo ratings yet

- Akira Ac S5cgaDocument17 pagesAkira Ac S5cgaHapsoro On GmailNo ratings yet

- Service Letter Z26-1: ZEE Systems, IncDocument6 pagesService Letter Z26-1: ZEE Systems, IncProvincial AirwaysNo ratings yet

- Pruebas Yu AjustesDocument15 pagesPruebas Yu AjustesFbrzo Di GvargasNo ratings yet

- Hydraulic Pump - Test and Adjust: Pantalla AnteriorDocument14 pagesHydraulic Pump - Test and Adjust: Pantalla Anterioriver_millan100% (1)

- Control Box For Boiler & BurnerDocument10 pagesControl Box For Boiler & BurnerSergeyNo ratings yet

- Atrs 2Document28 pagesAtrs 2harisankarNo ratings yet

- R134A Digital Manifold: Includes Automotive Refrigerant and Oil Capacity ReadingsDocument4 pagesR134A Digital Manifold: Includes Automotive Refrigerant and Oil Capacity ReadingsJoe NoboNo ratings yet

- Turbine Interlocks and ProtectionDocument31 pagesTurbine Interlocks and ProtectionShambhu Mehta100% (1)

- Nueva Lavadora GEDocument65 pagesNueva Lavadora GEEdison EspinalNo ratings yet

- Deh Governing-LancoDocument35 pagesDeh Governing-LancoPRAMOD KUMAR NANDANo ratings yet

- Pump Control Model FPC 30010Document4 pagesPump Control Model FPC 30010vstojnicNo ratings yet

- Rtaa Svd01a en - 01012004Document10 pagesRtaa Svd01a en - 01012004alcomech100% (3)

- Millennium: R134A Refrigerant Cooling Capacities 336 KW To 1090 KWDocument26 pagesMillennium: R134A Refrigerant Cooling Capacities 336 KW To 1090 KWttt449No ratings yet

- Warning Chiller PDFDocument64 pagesWarning Chiller PDFnurcahyo febriNo ratings yet

- AttTesting and AdjustingDocument8 pagesAttTesting and Adjustingchanlin100% (1)

- Calibration ChokeDocument11 pagesCalibration ChokeAmar BadradineNo ratings yet

- Hyundai Excel X2 1989-1998 Air ConditioningDocument53 pagesHyundai Excel X2 1989-1998 Air ConditioningaurbinaeNo ratings yet

- ALFA LAVAL Service Manual PA605Document12 pagesALFA LAVAL Service Manual PA605Mery A. Dominguez100% (1)

- Ioties Document No:-Mccpl-Pctl-Acc-Doc-M-0001 - Rev. P3Document23 pagesIoties Document No:-Mccpl-Pctl-Acc-Doc-M-0001 - Rev. P3pramodtryNo ratings yet

- Dometic RM 2612 RV Ref Ridge Rat orDocument20 pagesDometic RM 2612 RV Ref Ridge Rat orgoldminer4No ratings yet

- 3022Document2 pages3022markjparrNo ratings yet

- TAKTIS-KAU2060 ManualDocument16 pagesTAKTIS-KAU2060 ManualDavid BrooksNo ratings yet

- 3 Control PeripheryDocument3 pages3 Control PeripheryccqyugaoNo ratings yet

- T631 CDDocument3 pagesT631 CDAnonymous 9Yv6n5qvSNo ratings yet

- York - Trouble Shooting Centrifugal Chiller PDFDocument6 pagesYork - Trouble Shooting Centrifugal Chiller PDFdanhtranHVAC67% (9)

- CN - Rev 03 Control Narrative Logic Pump Item PAX60122B - OMHDocument12 pagesCN - Rev 03 Control Narrative Logic Pump Item PAX60122B - OMHnjennsNo ratings yet

- SIG Motorized ValveDocument6 pagesSIG Motorized ValveAlexandre FerreiraNo ratings yet

- Simonazzi Motorized ValveDocument6 pagesSimonazzi Motorized Valveronal553No ratings yet

- Service & Maintenance TrainingDocument85 pagesService & Maintenance TrainingERWIN SAPUTRANo ratings yet

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementFrom EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo ratings yet

- Diesel Engine Care and Repair: A Captain's Quick GuideFrom EverandDiesel Engine Care and Repair: A Captain's Quick GuideRating: 5 out of 5 stars5/5 (1)

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- EDRIVE MA860H Stepper Motor Driver Datasheet SummaryDocument7 pagesEDRIVE MA860H Stepper Motor Driver Datasheet Summarymarcyel Oliveira WoliveiraNo ratings yet

- Ult R 1222121Document56 pagesUlt R 1222121IvicaNo ratings yet

- Leo Acm Manual InsturctionDocument13 pagesLeo Acm Manual Insturctionmarcyel Oliveira WoliveiraNo ratings yet

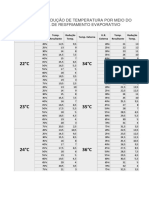

- TABLE OF TEMPERATURE REDUCTION THROUGH EVAPORATIVE COOLING SYSTEMDocument4 pagesTABLE OF TEMPERATURE REDUCTION THROUGH EVAPORATIVE COOLING SYSTEMmarcyel Oliveira WoliveiraNo ratings yet

- Growatt PV Inverter Modbus RS485 ProtocolDocument15 pagesGrowatt PV Inverter Modbus RS485 Protocolmarcyel Oliveira WoliveiraNo ratings yet

- TYF Oxit: Ready-to-Use, High-Performance Ultra Low Viscous Secondary Refrigerants For Applications Down To - 50 °CDocument9 pagesTYF Oxit: Ready-to-Use, High-Performance Ultra Low Viscous Secondary Refrigerants For Applications Down To - 50 °Cmarcyel Oliveira WoliveiraNo ratings yet

- Growatt OffGrid SPF5000 Modbus RS485 RTU ProtocolDocument22 pagesGrowatt OffGrid SPF5000 Modbus RS485 RTU ProtocolMiguel BernardoNo ratings yet

- TrackSo Connection Manual GrowattDocument6 pagesTrackSo Connection Manual Growattmarcyel Oliveira WoliveiraNo ratings yet

- 997 060160 1Document2 pages997 060160 1vitor4santos_6No ratings yet

- Change Parts Capacity Control Hitachi Screw CompressorsDocument2 pagesChange Parts Capacity Control Hitachi Screw Compressorsmarcyel Oliveira WoliveiraNo ratings yet

- Bacnet/Modbus Carrier Translator Installation InstructionsDocument3 pagesBacnet/Modbus Carrier Translator Installation Instructionsmarcyel Oliveira WoliveiraNo ratings yet

- SHELL Guide OfficialDocument1,092 pagesSHELL Guide Officialmarcyel Oliveira WoliveiraNo ratings yet

- Carrier Comfort Network (CCN)Document6 pagesCarrier Comfort Network (CCN)Bhargav VallabhaneniNo ratings yet

- DELTA IA-IES C EN 20191230 WebDocument108 pagesDELTA IA-IES C EN 20191230 Webmarcyel Oliveira WoliveiraNo ratings yet

- 33CN-5SI Installation Manual-1Document4 pages33CN-5SI Installation Manual-1Modussar IlyasNo ratings yet

- On Your Operating System?: Applies ToDocument2 pagesOn Your Operating System?: Applies Tomarcyel Oliveira WoliveiraNo ratings yet

- 33CN-5SI Installation Manual-1Document4 pages33CN-5SI Installation Manual-1Modussar IlyasNo ratings yet

- ACoolDataset - Total Active Businesses in City of Los Angeles Council District 11Document2,205 pagesACoolDataset - Total Active Businesses in City of Los Angeles Council District 11marcyel Oliveira WoliveiraNo ratings yet

- HVAC-Guide-manual-v37.indd 1 3/13/2009 12:56:18 PMDocument37 pagesHVAC-Guide-manual-v37.indd 1 3/13/2009 12:56:18 PMmarcyel Oliveira WoliveiraNo ratings yet

- TGW-700 User ManualDocument87 pagesTGW-700 User Manualmarcyel Oliveira WoliveiraNo ratings yet

- TYF Oxit: ConcentrateDocument8 pagesTYF Oxit: Concentratemarcyel Oliveira WoliveiraNo ratings yet

- TGW-700 User ManualDocument87 pagesTGW-700 User Manualmarcyel Oliveira WoliveiraNo ratings yet

- Service ManualDocument82 pagesService ManualRadu_IS100% (1)

- SHELL Guide OfficialDocument1,092 pagesSHELL Guide Officialmarcyel Oliveira WoliveiraNo ratings yet

- Danfoss Cooling &: Refrigerant PerspectiveDocument26 pagesDanfoss Cooling &: Refrigerant Perspectivemarcyel Oliveira WoliveiraNo ratings yet

- Manual DOPSOFT PDFDocument1,803 pagesManual DOPSOFT PDFMario Tapia100% (1)

- Production Chemistry and Flow Assurance SimulationDocument21 pagesProduction Chemistry and Flow Assurance SimulationWael Badri100% (1)

- Pathology AIIMSDocument26 pagesPathology AIIMSvkNo ratings yet

- STM - Merck Case AnswersDocument2 pagesSTM - Merck Case AnswersreetayanNo ratings yet

- Top 50 Most Delicious Taco Reci - Julie HatfieldDocument267 pagesTop 50 Most Delicious Taco Reci - Julie HatfieldMazhar Aslam100% (2)

- Earth First! Climbers Guild Vol. 2Document16 pagesEarth First! Climbers Guild Vol. 2CascadiaDefenders100% (2)

- Understanding the Relationship Between Place and HealthDocument14 pagesUnderstanding the Relationship Between Place and HealtheNo ratings yet

- Development Team: Analytical Chemistry PolarographyDocument18 pagesDevelopment Team: Analytical Chemistry PolarographyKanchanNo ratings yet

- IED Recognition GuideDocument28 pagesIED Recognition GuideLeafs61100% (5)

- General Psychology Mid Term ExamDocument2 pagesGeneral Psychology Mid Term Examapi-534780597No ratings yet

- Berca Engineering SUBMITTEDDocument20 pagesBerca Engineering SUBMITTEDJohandika FerbiantokoNo ratings yet

- Physics Investigatory Project Class 12Document12 pagesPhysics Investigatory Project Class 12shivanginirai7No ratings yet

- Cerberus PRO Product Catalog: Fire Safety Products and AccessoriesDocument253 pagesCerberus PRO Product Catalog: Fire Safety Products and AccessoriesleonardoleitealertaNo ratings yet

- 6-Step Guide to Crushing Imposter SyndromeDocument10 pages6-Step Guide to Crushing Imposter SyndromeMark KestNo ratings yet

- Impact of Excessive Mobile Phone Usage On Human JCSB 1000235Document5 pagesImpact of Excessive Mobile Phone Usage On Human JCSB 1000235nidNo ratings yet

- LC Used in ProteimicsDocument15 pagesLC Used in ProteimicsMandu ManNo ratings yet

- Acp 22 9349 2022Document20 pagesAcp 22 9349 2022merlinakisNo ratings yet

- PMBOK - Chapter 9: Project Human Resource ManagementDocument16 pagesPMBOK - Chapter 9: Project Human Resource Management7565006No ratings yet

- Flashcards - CP4 Preparation of A Standard Solution and Titration - Edexcel IAL Chemistry A-LevelDocument37 pagesFlashcards - CP4 Preparation of A Standard Solution and Titration - Edexcel IAL Chemistry A-LevelTravel UnlimitedNo ratings yet

- Master Key Bonus - The Healing CodeDocument8 pagesMaster Key Bonus - The Healing CodeChanterelle Vasto100% (12)

- Pharmaceutical Microbiology - B.pharmDocument383 pagesPharmaceutical Microbiology - B.pharmkeyurNo ratings yet

- Plane Bearings: Material Indicator Shape or SeriesDocument4 pagesPlane Bearings: Material Indicator Shape or SeriesJuan LoaizaNo ratings yet

- Concrete's enormous role in world's longest sea bridgeDocument3 pagesConcrete's enormous role in world's longest sea bridgeRafiath SiraNo ratings yet

- How Game-Based Teaching Strategy Affect The Student's Learning in MathematicsDocument13 pagesHow Game-Based Teaching Strategy Affect The Student's Learning in MathematicsAaron Jay BulataoNo ratings yet

- Early Years and Childcare Safeguarding AuditDocument4 pagesEarly Years and Childcare Safeguarding AuditEarly Years Careers100% (1)

- Land Tenure SystemsDocument140 pagesLand Tenure SystemsjoeclintNo ratings yet

- Literature Review On Procrastination Impact On Academic PerformanceDocument2 pagesLiterature Review On Procrastination Impact On Academic Performancemomi100% (1)

- Concrete Epoxy HV PDFDocument2 pagesConcrete Epoxy HV PDFGeovanni Mabiscay0% (1)

- Fermentation Technology for Food Preservation and ProcessingDocument47 pagesFermentation Technology for Food Preservation and ProcessingAhmad Syamil Muhamad ZinNo ratings yet

- Alpine Valley Liability ReleaseDocument1 pageAlpine Valley Liability ReleaseChristina Nakazaki0% (1)

- Proper Application of Duff Phelps ERP Adjustment PDFDocument4 pagesProper Application of Duff Phelps ERP Adjustment PDFramsiva354No ratings yet