Professional Documents

Culture Documents

T00043 Prox Operation Workshop

Uploaded by

HAMZA BENOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

T00043 Prox Operation Workshop

Uploaded by

HAMZA BENCopyright:

Available Formats

Proximity Transducer System Workshop

Proximity Transducer System

Workshop

Workshop Rerequisites

• Digital Multimeter

• TK-3 Proximity probe test kit

• Tool kit

• Excel spreadsheets “proximitor curve” and “Linear Analysis Spreadsheet”. If these

spreadsheets are not on the computer desktop, consult with your instructor about how

to access these files.

List of tasks:

1. Measure the resistance of the probe and probe cable

2. Acquire data, create a probe curve with a matched transducer system, and find the

transducer system average scale factor

3. Analyze the probe data for linear integrity

4. Acquire data, create a probe curve with an unmatched transducer system, and observe

the results

Task 1: Measure the resistance of the probe and

probe cable.

1. Assemble a matched transducer system.

2. Measure the resistance of the extension cable and probe between the center conductor

and the connector casing as shown below.

Rev 1, Dec08 1 T00043

Copyright (C) 2008 General Electric Company. All rights reserved.

Proximity Transducer System Workshop

3. Verify that the resistance is within specifications as listed below.

Probe Length Resistance from the Center Conductor to the Outer Conductor (RPROBE) (ohms)

0.5 7.45 ± 0.50

1.0 7.59 ± 0.50

1.5 7.73 ± 0.50

2.0 7.88 ± 0.50

5.0 8.73 ± 0.70

9.0 9.87 ± 0.90

Length of Extension Resistance from Center Resistance from Outer

Cable Conductor to Center Conductor to Outer Conductor

Conductor (RCORE) (ohms) (RJACKET) (ohms)

3.0 0.66 ± 0.10 0.20 ± 0.04

3.5 0.77 ± 0.12 0.23 ± 0.05

4.0 0.88 ± 0.13 0.26 ± 0.05

4.5 0.99 ± 0.15 0.30 ± 0.06

7.0 1.54 ± 0.23 0.46 ± 0.09

7.5 1.65 ± 0.25 0.49 ± 0.10

8.0 1.76 ± 0.26 0.53 ± 0.11

8.5 1.87 ± 0.28 0.56 ± 0.11

Rev 1, Dec08 2 T00043

Copyright (C) 2008 General Electric Company. All rights reserved.

Proximity Transducer System Workshop

Task 2: Acquire data, create a probe curve

with a matched transducer system, and find

the transducer system average scale factor

This exercise will familiarize you with the proximity probe verification process.

A. You will be using the spindle micrometer to check the voltage versus distance

characteristics of the probe and Proximitors.

1. Secure the probe in position using the correct probe sleeve. With the spindle

micrometer set to zero, position the probe into the spindle micrometer so that the probe

tip lightly contacts the observed sample.

Adjust the spindle micrometer so that the target moves away from the probe tip. Then

return it to zero to ensure the probe is positioned properly.

2. Connect the probe to the Proximitor using the appropriate extension cable.

3. Connect the DMM between the Proximitor OUTPUT and COM connectors. For this

workshop you are using the monitor as a load. If a monitor were not attached, you would

attach a 10K Ohm resistor across the DMM input terminal to simulate monitor input

impedance.

4. Starting at zero, adjust the spindle micrometer out in 5 mil increments. Log the

voltage values at each increment in the data sheet. Be sure to also document transducer

part and serial numbers. Using a transducer system that generates 200mV/mil will give us

approximately one-volt change for each five mils. Calculate the average scale factor

(ASF).

Notice that you can either log the data in the table on page 5 of this workshop or you can

log the data into the spreadsheet called “proximitor curve”.

5. Using the data collected and logged, go to the page following the data log sheet, and

plot the voltage vs gap graph until the response starts to become non-linear. Notice that

if you use the spreadsheet, the data will be plotted for you.

NOTE

The first and last 10 mils of the curve cannot be used due to non-linearity. A sharp

change in the slope of the curve will occur at a probe to target gap of about 10 to 20 mils.

This change will depend upon the type of probe and Proximitor used and the type of

material being observed. The response curve should be linear starting at approximately

10 mils and remain so through 90 mils or more.

Rev 1, Dec08 3 T00043

Copyright (C) 2008 General Electric Company. All rights reserved.

Proximity Transducer System Workshop

Task 3: Analyze the probe data for linear

integrity

A. This next process will demonstrate the incremental linearity of the transducer system

response.

1. Open the spreadsheet labeled “Linear Analysis Spreadsheet”. If it is not on your

computer’s desktop, your Instructor will give you instructions for finding it.

2. Enter the values from the 10 mil level to the 90 mil level in your data log to the

appropriate locations in your spreadsheet. Confirm this matches your hand calculated

value.

Task 4: Acquire data, create a probe curve

with an unmatched transducer system, and

observe the results

A. For the last exercise, you will repeat the process in Laboratory Activity 1, using an

unmatched transducer system.

1. Connect either a longer or shorter extension cable as specified by the Instructor to

your proximity transducer system.

2. Use the data log sheet on the next page to collect your measured values.

3. Use the graph page following the data log sheet to plot the response curve of your

transducer system.

Rev 1, Dec08 4 T00043

Copyright (C) 2008 General Electric Company. All rights reserved.

Proximity Transducer System Workshop

Log Sheet for Voltage vs Distance Data

Probe Model No. Probe Model No.

Probe Serial No. Probe Serial No.

Prox Model No. Prox Model No.

Prox Serial No. Prox Serial No.

Ext. Cable Model No. Ext. Cable Model No.

Ext. Cable Serial No. Ext. Cable Serial No.

Data Table

Mils Volts DC Mils Volts DC

0 0

5 5

10 10

15 15

20 20

25 25

30 30

35 35

40 40

45 45

50 50

55 55

60 60

65 65

70 70

75 75

80 80

85 85

90 90

95 95

100 100

Average Scale Factor Average Scale Factor

Circle One Matched / Mis-matched Circle One Matched / Mis-matched

Rev 1, Dec08 5 T00043

Copyright (C) 2008 General Electric Company. All rights reserved.

Proximity Transducer System Workshop

Voltage (-Vdc) vs Distance (mils) Graph

160

90 100 110 120 130 140 150

80

70

60

50

40

30

20

10

24

22

20

18

16

14

12

10

Rev 1, Dec08 6 T00043

Copyright (C) 2008 General Electric Company. All rights reserved.

Proximity Transducer System Workshop

Task Completion Checklist

This checklist can be used to collect the instructor’s initials or signature for each task that

is completed successfully. Note to instructor: If the student cannot perform a task

satisfactorily, perform appropriate remediation. Ensure that the student is able to perform

the task satisfactorily before signing the evaluation as being complete.

Student:

Date:

Task Description Completed Notes

Task 1: Measure the resistance of

the probe and probe cable

Task 2: Acquire data, create a

probe curve with a matched

transducer system, and find the

transducer system average scale

factor

Task 3: Analyze the probe data for

linear integrity

Task 4: Acquire data, create a

probe curve with an unmatched

transducer system, and observe

the results

Rev 1, Dec08 7 T00043

Copyright (C) 2008 General Electric Company. All rights reserved.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5796)

- T00062 Data Acquisition DDE Server WorkshopDocument4 pagesT00062 Data Acquisition DDE Server WorkshopHAMZA BENNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Oil & Gas Industry ApplicationsDocument240 pagesOil & Gas Industry ApplicationsHAMZA BEN100% (1)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- 02.centum VP InstallationDocument541 pages02.centum VP InstallationHAMZA BENNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- SPEEDTRONIC MARK V - Maintenance: Raining Manual - Vol IiDocument306 pagesSPEEDTRONIC MARK V - Maintenance: Raining Manual - Vol IiHAMZA BEN100% (1)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Toolboxst Basics: After Completing This Training, You Will Be Able ToDocument12 pagesToolboxst Basics: After Completing This Training, You Will Be Able ToHAMZA BENNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- 09 FinderDocument11 pages09 FinderHAMZA BENNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Anti SurgeDocument57 pagesAnti SurgeHAMZA BENNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Bacnetmanual0808a 1736662790Document24 pagesBacnetmanual0808a 1736662790jonatan toledoNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (589)

- Product Update 2010 - Smmsi Outdoor UnitsDocument3 pagesProduct Update 2010 - Smmsi Outdoor UnitssnowwooNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Photovoltaics: Technology Overview: M.A. GreenDocument10 pagesPhotovoltaics: Technology Overview: M.A. GreenMatheus Rodrigues CannabravaNo ratings yet

- Z Dezmembrari LCD PDPDocument4 pagesZ Dezmembrari LCD PDPIonel ColamischiNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Hetero Dy Ne Detection PDFDocument14 pagesHetero Dy Ne Detection PDFVidula PalekarNo ratings yet

- Service Manual 32LJ500VDocument48 pagesService Manual 32LJ500VNicu Liviu33% (6)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Datasheet S4-WiFi-ST GBR V2.5 2023 06Document2 pagesDatasheet S4-WiFi-ST GBR V2.5 2023 06Bianca OlaruNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Home Assignment No-1 (CLO-1) : School of Electrical Engineering and Computer ScienceDocument2 pagesHome Assignment No-1 (CLO-1) : School of Electrical Engineering and Computer ScienceRamish SaeedNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- EXPERIMENT 6:observation of The V-I Characteristic of A DiodeDocument5 pagesEXPERIMENT 6:observation of The V-I Characteristic of A DiodeShubham waghmareNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Service Manual VideoJet 1210, 1220 и 1510Document380 pagesService Manual VideoJet 1210, 1220 и 1510yemoleg88No ratings yet

- SWM 1984 06Document52 pagesSWM 1984 06paulNo ratings yet

- Manual Varispeed f7Document476 pagesManual Varispeed f7Samir PirelaNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- mcp4725 Use CodeDocument10 pagesmcp4725 Use CodeShakirullah KhanNo ratings yet

- DS0961006-0171070 Camera FAMOS 170 PAL - NTSC EN A03Document2 pagesDS0961006-0171070 Camera FAMOS 170 PAL - NTSC EN A03rankee iloNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Module 19 - Main Transformer Step Down Transformer and GCBDocument67 pagesModule 19 - Main Transformer Step Down Transformer and GCBDipayan DasNo ratings yet

- 4500B InstructionManual PDFDocument372 pages4500B InstructionManual PDFpaquirri999No ratings yet

- Electronic Devices, 9th Edition by Tom Floyd: 1. OverviewDocument4 pagesElectronic Devices, 9th Edition by Tom Floyd: 1. OverviewWahid ullahNo ratings yet

- Manual Transmisor Tex 100Document44 pagesManual Transmisor Tex 100José Hugo Sosa SalasNo ratings yet

- Ape4518r14v06 1887 DatasheetDocument3 pagesApe4518r14v06 1887 DatasheetdavideNo ratings yet

- Analog Device Admv1014-Evalz-Ug-1420Document19 pagesAnalog Device Admv1014-Evalz-Ug-1420Ib MotoNo ratings yet

- To Determine The V Curve of A Synchronous MotorDocument3 pagesTo Determine The V Curve of A Synchronous MotorAthay khanNo ratings yet

- Utilization of Electrical Energy: Chapter 2: Electric Drives L-2-1Document23 pagesUtilization of Electrical Energy: Chapter 2: Electric Drives L-2-1Frozen BoyNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- Electrical and Electronics EngineeringDocument26 pagesElectrical and Electronics EngineeringAli SabahNo ratings yet

- Imel7002 L3Document115 pagesImel7002 L3就爱吃饭团No ratings yet

- 4-Bit Universal ShifterDocument3 pages4-Bit Universal ShifteraeunNo ratings yet

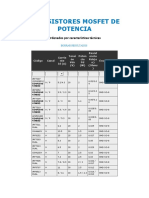

- Transistores Mosfet de PotenciaDocument15 pagesTransistores Mosfet de PotenciaLuis SanchezNo ratings yet

- ADV200 Catalog System & AccessoriesDocument18 pagesADV200 Catalog System & AccessoriesMr. Tung PTCVietNamNo ratings yet

- P/N 1029718A Problue Melter Main Circuit Board Service Kit - P/N 1028322Document1 pageP/N 1029718A Problue Melter Main Circuit Board Service Kit - P/N 1028322aaaaa kkkkNo ratings yet

- Sensors: Comparison of Filtering Methods For Enhanced Reliability of A Train Axle Counter SystemDocument18 pagesSensors: Comparison of Filtering Methods For Enhanced Reliability of A Train Axle Counter SystemDeni Agustina JNo ratings yet

- Speed Control IM (Edited)Document37 pagesSpeed Control IM (Edited)مصطفى حمدىNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)