Professional Documents

Culture Documents

Unconventional Machining Processes Question Bank

Uploaded by

chellakutti t0 ratings0% found this document useful (0 votes)

15 views4 pagesThis document contains a question bank with answers about unconventional machining processes such as electrical discharge machining (EDM), ultrasonic machining (USM), and abrasive water jet machining (AWJM). It defines conventional vs unconventional machining, lists the key parameters for AWJM and USM, and discusses principles such as how AWJM works by eroding material with an abrasive water jet and how USM uses vibrations and abrasives to remove material. It also covers topics like EDM operating parameters, common tool and dielectric materials, and applications for these non-traditional machining techniques.

Original Description:

Original Title

UCMP 1 Question bank

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document contains a question bank with answers about unconventional machining processes such as electrical discharge machining (EDM), ultrasonic machining (USM), and abrasive water jet machining (AWJM). It defines conventional vs unconventional machining, lists the key parameters for AWJM and USM, and discusses principles such as how AWJM works by eroding material with an abrasive water jet and how USM uses vibrations and abrasives to remove material. It also covers topics like EDM operating parameters, common tool and dielectric materials, and applications for these non-traditional machining techniques.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

15 views4 pagesUnconventional Machining Processes Question Bank

Uploaded by

chellakutti tThis document contains a question bank with answers about unconventional machining processes such as electrical discharge machining (EDM), ultrasonic machining (USM), and abrasive water jet machining (AWJM). It defines conventional vs unconventional machining, lists the key parameters for AWJM and USM, and discusses principles such as how AWJM works by eroding material with an abrasive water jet and how USM uses vibrations and abrasives to remove material. It also covers topics like EDM operating parameters, common tool and dielectric materials, and applications for these non-traditional machining techniques.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 4

Unconventional machining process

Question bank with answer

1. Which of the following is un-conventional machining process?

a) Grinding b) Milling c) Drilling d) EDM

2. Which of the following is mechanical energy based nontraditional machining process?

a) Grinding b) Milling c) AWJM d) USM

3. Which of the following is nontraditional machining process?

a) Grinding b) Milling c) Drilling d) USM

4. Non-Traditional machining can also be called as?

a) Contact Machining b) Non-Contact Machining c) Half contact machining

d) Partial contact machining

5. The sound wave less than audible range is called as

a) Ultrasonic b) Infrasonic c) Sonic d) None of these

6. The sound wave above than audible range is called as

a) Ultrasonic b) Infrasonic c) Sonic d) None of these

7. When the metal is removed by erosion caused by rapidly recurring spark discharges

between the tool and work, the process is known as

a) ECM b) EDM c) USM d) None of these

8. Nozzle material in AWJM

a) Silica b) Gelatin c) Tungsten carbide d) All the above

9. Abrasive used in USM

a) Diamond b) Gelatin c) Tungsten carbide d) All the above

10. Wire cut EDM process wire made up of

a) Brass b) Silica c) Tungsten d) None of these

1. What is meant by Conventional Machining Processes?

In conventional machining processes, metal is removed by using some sort of the tools

which is harder than the work piece and is subjected to wear. In this process, tool and

work piece being in direct contact with each other.

2. What is meant by Unconventional Machining Processes?

The Unconventional machining processes do not employ a conventional or traditional

tool for metal removal; instead, they directly utilize some form of energy for metal

machining. In this process, there is no direct physical contact between the tool and the

work piece.

3. Classify the different types of unconventional machining processes based on the

mechanical energy.

1. Abrasive Jet Machining (AJM)

2. Water Jet Machining (WJM)

3. Ultrasonic Machining (USM)

4. Abrasive Water Jet Machining (AWJM)

4. Classify the different types of non-traditional processes

Mechanical Processes

Abrasive Jet Machining (AJM)

Water Jet Machining (WJM)

Ultrasonic Machining (USM)

Abrasive Water Jet Machining (AWJM)

Thermal Processes

Electron Beam Machining (EBM)

Laser Beam Machining (LBM)

Plasma Arc Machining (PAM)

Electric Discharge Machining (EDM)

Wire cut Electric Discharge Machining (WEDM)

5. Explain about the principle of AWJM, USM, EDM

AWJM:

The abrasive water jet machining process works on the principle that when a high-

velocity jet of water with abrasive particle strikes the work piece, machining of the

work piece takes place by erosion of the work piece material.

USM:

In USM, aslurry of small abrasive particles are force against the work piece by means

of a vibrating too and it causes the removal of metal from the work piece.

EDM:

In EDM metal is removed by producing powerful electric spark discharge between the

tool( cathode) and the work material (anode).

6. Define standoff distance

The distance between the nozzle tip and the work piece, it has great influence on the

diameter of cut, shape and also metal removal rate.

7. Define transducer and its type

Transducer is a device which converts one form of energy into another form of energy.

Type : 1. Piezoelectric, 2. Magnetrostriction

8. List the process parameter of AWJM

1. Tool

2. Pressure of water

3. Abrasive material

4. Mass flow rate

5. Metal removal rate

6. Nozzle material

7. Standoff distance

9. List the process parameter of USM

1. Metal removal rate

2. Tool material

3. Tool wear rate

4. Surface finish

5. Work Material

6. Abrasive material and abrasive slurry

10. List the application of USM

1. Holes as 0.1mm can be drilled

2. Machine glass, ceramics, tungsten

3. Several machining operations like

a. Drilling

b. Grinding

c. Turning

d. Threading on of all both conducting and non-conducting material

11. List the process parameter of EDM

1. Operating parameter

2. Taper

3. Surface finish

4. Current density

12. List the common tool materials used in EDM

1. Copper

2. Graphite

3. Copper – tungsten

13. What are the application of EDM

1. Thread cutting in jobs

2. Drilling of micro holes

3. Helical profile drilling

4. Curved hole drilling

14. Name the common dielectric fluid used in EDM

Petroleum base

1. Hydrocarbon fluids

2. Paraffin

3. White spirit

4. Transformer oil

5. Kerosene

6. Mineral oil

You might also like

- Ucmp 2 Mark With AnswerDocument17 pagesUcmp 2 Mark With AnsweranithayesurajNo ratings yet

- UMP BookDocument135 pagesUMP BookSurendran MahalingamNo ratings yet

- Measuring Surface Roughness Using EDMDocument19 pagesMeasuring Surface Roughness Using EDMAli RazaNo ratings yet

- Mech Vi Non Traditional Machining (10me665) NotesDocument45 pagesMech Vi Non Traditional Machining (10me665) Notesnikhil0% (1)

- 6UMPQB Two MarksDocument19 pages6UMPQB Two MarksRajakumar SundaramNo ratings yet

- 9 Non Conventional MachiningDocument36 pages9 Non Conventional MachiningPrashant KuwarNo ratings yet

- HW 8 Non Traditional Machining Ch26Document2 pagesHW 8 Non Traditional Machining Ch26BobNo ratings yet

- Department of Mechanical Engineering Question Bank 15ume911 Unconventional Machining Processes Unit - I Part ADocument6 pagesDepartment of Mechanical Engineering Question Bank 15ume911 Unconventional Machining Processes Unit - I Part ANagarajNo ratings yet

- Ch-12 Unconventional MachiningDocument188 pagesCh-12 Unconventional MachiningAbhishek AroraNo ratings yet

- BMMP3533 - Labsheet - EDM Die Sinker 20192020Document5 pagesBMMP3533 - Labsheet - EDM Die Sinker 20192020Amilin HatiaraNo ratings yet

- Ucmt PDFDocument17 pagesUcmt PDFSaurabh ManralNo ratings yet

- Ump e MaterialDocument93 pagesUmp e MaterialDushyanthkumar DasariNo ratings yet

- ME1001-UNCONVENTIONAL MACHINING PROCESSESDocument27 pagesME1001-UNCONVENTIONAL MACHINING PROCESSESashoku24007No ratings yet

- Seminar On Non Conventional MachiningDocument34 pagesSeminar On Non Conventional MachiningMohit Gulati60% (5)

- Introduction to Non-Traditional Machining ProcessesDocument57 pagesIntroduction to Non-Traditional Machining ProcessesramadanNo ratings yet

- Unconventional Machining ProcessesDocument8 pagesUnconventional Machining ProcessesEugene BoadoNo ratings yet

- PT Unit 6Document41 pagesPT Unit 6Sanjay RiderNo ratings yet

- Ucmp QuestionsDocument6 pagesUcmp QuestionsKalai ArasanNo ratings yet

- Unconventional Machining ProcessesDocument64 pagesUnconventional Machining Processesdeepak kantipudiNo ratings yet

- Non-Traditional Machining Processes ExplainedDocument33 pagesNon-Traditional Machining Processes ExplainedRavichandran GNo ratings yet

- Non Conventional Machining ProcessesDocument143 pagesNon Conventional Machining Processesmahesh100% (2)

- Non-Traditional Machining TechniquesDocument33 pagesNon-Traditional Machining TechniquesVikrant BhardwajNo ratings yet

- Non-Traditional Machining ProcessesDocument64 pagesNon-Traditional Machining ProcessespardhuduNo ratings yet

- Non Traditional MachiningDocument71 pagesNon Traditional MachiningShamanth SHNo ratings yet

- Machining ProcessesDocument6 pagesMachining ProcessesUsama AnsariNo ratings yet

- Non Traditional MachiningDocument77 pagesNon Traditional MachiningAnirudhNo ratings yet

- Unconventional Machining Processes GuideDocument59 pagesUnconventional Machining Processes GuideAkilesh SNo ratings yet

- Ch-12 Unconventional MachiningDocument135 pagesCh-12 Unconventional MachiningSaumil ShahNo ratings yet

- Unconventional Machining ProcessDocument15 pagesUnconventional Machining ProcessShashwatAgNo ratings yet

- For Minor ProjectDocument19 pagesFor Minor ProjectSABBAH NEYAZI (RA1911002010148)No ratings yet

- EDM Process Parameters and ApplicationsDocument2 pagesEDM Process Parameters and ApplicationsMahmoud EldesoukiNo ratings yet

- Unit 1Document37 pagesUnit 1Dare DevilNo ratings yet

- EDM and ECM NotesDocument25 pagesEDM and ECM NotesFRANCIS THOMASNo ratings yet

- 9 - Nontraditional Machining (2hr-33 Slides)Document33 pages9 - Nontraditional Machining (2hr-33 Slides)Rahul SharmaNo ratings yet

- Nontraditional Machining ProcessDocument86 pagesNontraditional Machining ProcessVarad DateNo ratings yet

- Unconventional Machining ProcessDocument36 pagesUnconventional Machining ProcessInderpal SinghNo ratings yet

- Advanced Manufacturing Question SampleDocument2 pagesAdvanced Manufacturing Question SampleBakul RoyNo ratings yet

- Amm Model Test Paper Q1. (A) State The Characteristics and Function of Dielectric Fluid Used in EDMDocument12 pagesAmm Model Test Paper Q1. (A) State The Characteristics and Function of Dielectric Fluid Used in EDMErin BarryNo ratings yet

- KCG College unconventional machining processes question bankDocument20 pagesKCG College unconventional machining processes question bankBalaNo ratings yet

- Usm, Ecm, EdmDocument24 pagesUsm, Ecm, EdmFRANCIS THOMASNo ratings yet

- 10 NontraditionalDocument8 pages10 NontraditionalShashank KasliwalNo ratings yet

- Non-Traditional Machining Processes: A) Primary Manufacturing Processes: B) Secondary Manufacturing ProcessesDocument36 pagesNon-Traditional Machining Processes: A) Primary Manufacturing Processes: B) Secondary Manufacturing ProcessesGbm RajNo ratings yet

- Modern ManufacturingDocument8 pagesModern Manufacturingমুকসেতিন আল রাজী রিফাতNo ratings yet

- A Review On Recent Developments in Machining Methods Based On Electrical Discharge PhenomenaDocument18 pagesA Review On Recent Developments in Machining Methods Based On Electrical Discharge PhenomenachristianNo ratings yet

- Unit 4: Micro Machining and Nano Fabrication TechniquesDocument21 pagesUnit 4: Micro Machining and Nano Fabrication TechniquesSachin SBNo ratings yet

- Electrical Discharge Machining (Edm) : Process PrinciplesDocument11 pagesElectrical Discharge Machining (Edm) : Process PrinciplesPrasad ChikkamNo ratings yet

- Non-conventional machining processesDocument6 pagesNon-conventional machining processesPANKWORLDNo ratings yet

- Nalanda College of Engineering: Non-Conventional MachiningDocument28 pagesNalanda College of Engineering: Non-Conventional Machiningraj aryanNo ratings yet

- Over All Concept of This ChapterDocument57 pagesOver All Concept of This ChapterberhaneNo ratings yet

- MP-II MCQ Unit IVDocument6 pagesMP-II MCQ Unit IVMagnus CarlsenNo ratings yet

- Ch-3 Tool Life, Tool Wear, Economics and MachinabilityDocument91 pagesCh-3 Tool Life, Tool Wear, Economics and MachinabilityManish Kumar Mehta100% (1)

- Nontraditional Machining Processes LectureDocument34 pagesNontraditional Machining Processes LecturetnchsgNo ratings yet

- IIT Roorkee Advanced Manufacturing ProcessesDocument92 pagesIIT Roorkee Advanced Manufacturing Processesvishal guptaNo ratings yet

- D) Wood: Unconventional Machining Process 2 Class TestDocument3 pagesD) Wood: Unconventional Machining Process 2 Class TestajitsssNo ratings yet

- Abrasive NewDocument13 pagesAbrasive NewShanmuganathanNo ratings yet

- Non Traditional Method IntroductionDocument7 pagesNon Traditional Method IntroductionAjay KumarNo ratings yet

- Non-Destructive Evaluation of Corrosion and Corrosion-assisted CrackingFrom EverandNon-Destructive Evaluation of Corrosion and Corrosion-assisted CrackingRaman SinghNo ratings yet

- UCMP 3 Question BankDocument2 pagesUCMP 3 Question Bankchellakutti tNo ratings yet

- Quiz on kinematic pairs, mechanisms and degrees of freedomDocument5 pagesQuiz on kinematic pairs, mechanisms and degrees of freedomchellakutti tNo ratings yet

- Quiz KomDocument5 pagesQuiz Komchellakutti tNo ratings yet

- Charlotte's Web: Pictures by Garth WilliamsDocument31 pagesCharlotte's Web: Pictures by Garth WilliamsMadhan RajNo ratings yet

- Maze of Bones Storia Teaching GuideDocument8 pagesMaze of Bones Storia Teaching Guidechellakutti t100% (2)

- A.O. Smith Del 6 Den 52 O&m ManualDocument24 pagesA.O. Smith Del 6 Den 52 O&m ManualJonalou ArominNo ratings yet

- e Doctor Charge 130Document2 pagese Doctor Charge 130sorinsoareNo ratings yet

- Estimating Revenue from Energy Storage in Market AreasDocument30 pagesEstimating Revenue from Energy Storage in Market AreasNeethu Elizabeth MichaelNo ratings yet

- GSM Module Based Integrative Detection of Open Drainage Over Flow and CurrentDocument91 pagesGSM Module Based Integrative Detection of Open Drainage Over Flow and Currentvijay4vlrNo ratings yet

- 3) DB11 Detector BaseDocument2 pages3) DB11 Detector BaseMosin Bin MahammedNo ratings yet

- LaserSaber Joule Ringer Matches Dons Adjusting DeviceDocument2 pagesLaserSaber Joule Ringer Matches Dons Adjusting DeviceTony GaryNo ratings yet

- LM 3405Document22 pagesLM 3405yakkovNo ratings yet

- Multiplex Data Transmitter: ModelDocument189 pagesMultiplex Data Transmitter: ModelPeter Jordan100% (1)

- Method Statement For Installation of Access Control SystemDocument115 pagesMethod Statement For Installation of Access Control SystemRahul Sharma100% (2)

- Mission Loudspeaker System Mission NXT Satellites: FS2-AV FS2Document4 pagesMission Loudspeaker System Mission NXT Satellites: FS2-AV FS2klaus allowsNo ratings yet

- 07a70206 HighvoltageengineeringDocument4 pages07a70206 HighvoltageengineeringSamiullah MohammedNo ratings yet

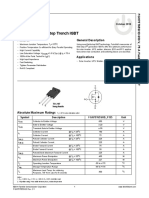

- FGH75T65SHD: 650 V, 75 A Field Stop Trench IGBTDocument9 pagesFGH75T65SHD: 650 V, 75 A Field Stop Trench IGBTРоман АлександровичNo ratings yet

- 3.at Final Draw For P0089Document60 pages3.at Final Draw For P0089FILIN VLADIMIR100% (1)

- Anixter Thermocouple and RTD Wire Wire Wisdom enDocument2 pagesAnixter Thermocouple and RTD Wire Wire Wisdom enFelipe GustavoNo ratings yet

- T885 Receiver ManualDocument72 pagesT885 Receiver Manualbilou57No ratings yet

- Year 12 Physics Cathode Rays Wave-Particle DebateDocument8 pagesYear 12 Physics Cathode Rays Wave-Particle DebateAaron HongNo ratings yet

- Digital Transformation Lab: by B.Nagasuman K.NarasimhaDocument10 pagesDigital Transformation Lab: by B.Nagasuman K.NarasimhaNarasimha KopparthiNo ratings yet

- r17 M.tech Eee Model PapersDocument28 pagesr17 M.tech Eee Model PaperslvijayanandNo ratings yet

- Ec6403-Emf-Iv-Even SemDocument4 pagesEc6403-Emf-Iv-Even SemaddssdfaNo ratings yet

- 341340b C4xe Datasheet WebDocument2 pages341340b C4xe Datasheet WebPrashantNo ratings yet

- Distance Basics PDFDocument39 pagesDistance Basics PDFsurya892No ratings yet

- Sla Fiamm Vrla BatteriesDocument4 pagesSla Fiamm Vrla BatteriesSyed FaisalNo ratings yet

- HE24 NoDocument1 pageHE24 NoIlir DalipiNo ratings yet

- Ut60e ManualDocument5 pagesUt60e Manualfacu0014No ratings yet

- LMV358 PDFDocument30 pagesLMV358 PDFYann GarciaNo ratings yet

- EAA CPL 010 Aircraft TechnicalDocument211 pagesEAA CPL 010 Aircraft TechnicalFrederico Ribeiro100% (1)

- KX 9010Document1 pageKX 9010Muhammad JamilNo ratings yet

- Introduction to Generators, Protection Schemes, Relays and MaintenanceDocument44 pagesIntroduction to Generators, Protection Schemes, Relays and MaintenancerahulNrana100% (1)

- Manual SX460Document5 pagesManual SX460Emilio Sosa100% (8)

- 23-Page PLDocument20 pages23-Page PLmaharshahzadNo ratings yet