Professional Documents

Culture Documents

Work Design and Mesurment

Uploaded by

Duaa ElmanfiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Work Design and Mesurment

Uploaded by

Duaa ElmanfiCopyright:

Available Formats

IE363 : Work Design and

Measurement

By Lecturer /Duaa Awadh

IE Departmet - Faculty of Engineerig - Benghazi University -

IE363

Chapter One :Methods,

Standards, and Work Design:

Introduction

IE Departmet - Faculty of Engineerig - Benghazi University -

IE363

Productivity :

• the state or quality of being productive

• the effectiveness of productive effort, especially in industry, as measured in

terms of the rate of output per unit of input ( productivity = output/ input)

• in a factory, you can measure productivity by dividing the total output by

the number of workers. Imagine a table factory that employs 100 people

producing 2000 tables per day. The productivity of each employee is:

2000 (tables) ÷ 100 (workers) = 20 tables per worker per day

IE Departmet - Faculty of Engineerig - Benghazi University -

IE363

Productivity Importance

• The only way a business or enterprise can grow and increase its profitability is by

increasing its productivity.

• Productivity improvement refers to the increase in output per work-hour or time

expended.

IE Departmet - Faculty of Engineerig - Benghazi University -

IE363

Productivity Increasing

The fundamental tools that result in increased productivity include

• methods,

• time study standards (frequently referred to as work measurement),

• and work design

IE Departmet - Faculty of Engineerig - Benghazi University -

IE363

Figure 1.1 Typical organization chart showing the influence of methods,

standards, and work design on the operation of the enterprise

IE Departmet - Faculty of Engineerig - Benghazi University -

IE363

METHODS AND STANDARDS SCOPE

methods engineering includes designing, creating, and selecting the

best manufacturing methods, processes, tools, equipment, and skills to

manufacture a product based on the specifications that have been

developed by the product engineering section.

IE Departmet - Faculty of Engineerig - Benghazi University -

IE363

METHODS AND STANDARDS SCOPE

The overall procedure includes defining the problem; breaking the job

down into operations; analyzing each operation to determine the most

economical manufacturing procedures for the quantity involved, with

due regard for operator safety and job interest; applying proper time

values; and then following through to ensure that the prescribed

method is put into operation

IE Departmet - Faculty of Engineerig - Benghazi University -

IE363

METHODS ENGINEERING

1. Select the project.

2. Get and present the data.

3. Analyze the data.

4. Develop the ideal method

5. Present and install the method

6. Develop a job analysis

7. Establish time standards.

8. Follow up the method

IE Departmet - Faculty of Engineerig - Benghazi University -

IE363

WORK DESIGN

As part of developing or maintaining the new method, the principles of work design must

be used to fit the task and workstation ergonomically to the human operator.

Any productivity increases and reduced costs are more than offset by the increased

medical and workers’ compensation costs, especially considering today’s ever-escalating

health-care trends. Thus, it is necessary for the methods engineer to incorporate the

principles of work design into any new method, so that it not only will be more

productive but also will be safe and injury-free for the operator

IE Departmet - Faculty of Engineerig - Benghazi University -

IE363

STANDARDS

Standards are the end result of time study or work measurement.

The resulting standards are used to implement a wage payment scheme.

Production control, plant layout, purchasing, cost accounting and control, and process

and product design are additional areas closely related to both the methods and

standards functions

IE Departmet - Faculty of Engineerig - Benghazi University -

IE363

OBJECTIVES OF METHODS, STANDARDS,

AND WORK DESIGN

1. Minimize the time required to perform tasks.

2. Continually improve the quality and reliability of products and services.

3. Conserve resources and minimize cost by specifying the most appropriate direct and

indirect materials for the production of goods and services.

4. Consider the cost and availability of power.

5. Maximize the safety, health, and well-being of all employees.

6. Produce with an increasing concern for protecting the environment

IE Departmet - Faculty of Engineerig - Benghazi University -

IE363

MOTION STUDY AND THE WORK OF THE

GILBRETHS

Frank and Lilian Gilbreth were the founders of the modern motion-study technique,

which may be defined as the study of the body motions used in performing an operation,

to improve the operation by eliminating unnecessary motions, simplifying necessary

motions, and then establishing the most favorable motion sequence for maximum

efficiency

IE Departmet - Faculty of Engineerig - Benghazi University -

IE363

EMERGENCE OF WORK DESIGN

Work design is a relatively new science that deals with designing the task, workstation,

and working environment to fit the human operator better. In the United States, it is

more typically known as human factors, while internationally it is better known as

ergonomics, which is derived from the Greek words for work (erg) and laws (nomos).

IE Departmet - Faculty of Engineerig - Benghazi University -

IE363

The End

IE Departmet - Faculty of Engineerig - Benghazi University -

IE363

You might also like

- Increasing The Productivity by Using Work Study in A Manufacturing Industry-Literature ReviewDocument6 pagesIncreasing The Productivity by Using Work Study in A Manufacturing Industry-Literature ReviewTJPRC PublicationsNo ratings yet

- Practical Guide To Work Study [Revised Edition]From EverandPractical Guide To Work Study [Revised Edition]Rating: 4 out of 5 stars4/5 (1)

- 323 Chapter 1 Methods, Standards, and Work DesignDocument18 pages323 Chapter 1 Methods, Standards, and Work DesignCristi EteganNo ratings yet

- Industrial Engineering ManagementDocument92 pagesIndustrial Engineering ManagementCharles OndiekiNo ratings yet

- An Instructional Aid For Occupational Safety and Health in Mechanical Engineering Design: Enter asset subtitleFrom EverandAn Instructional Aid For Occupational Safety and Health in Mechanical Engineering Design: Enter asset subtitleNo ratings yet

- College of Engineering Andcomputer StudiesDocument43 pagesCollege of Engineering Andcomputer StudiesJego ElevadoNo ratings yet

- Safety and Ergonomics in It IndustryDocument18 pagesSafety and Ergonomics in It IndustryUdit chaudharyNo ratings yet

- Session IEDocument23 pagesSession IESWAPNIL KRISHNANo ratings yet

- Lecture 1 - Chapter 1 - Productivity and Quality of Life ....Document38 pagesLecture 1 - Chapter 1 - Productivity and Quality of Life ....Mahlatse100% (1)

- Industrial EngineerDocument3 pagesIndustrial EngineerpriyasubhaNo ratings yet

- Literature Review of Work Environment, Training and Health Safety Factors Analysis in Increasing ProductivityDocument4 pagesLiterature Review of Work Environment, Training and Health Safety Factors Analysis in Increasing ProductivityPipe GonzalezNo ratings yet

- Lesson 4 Methods and Standard ScopeDocument15 pagesLesson 4 Methods and Standard ScopeAllona Jean Pacquiao DayapNo ratings yet

- Giao Trình LeanDocument49 pagesGiao Trình LeanZen ĐặngNo ratings yet

- Time Study Approach For Productivity Improvement of Furniture IndustryDocument4 pagesTime Study Approach For Productivity Improvement of Furniture IndustryInternational Journal of Innovations in Engineering and ScienceNo ratings yet

- iNDUSTRIAL ENGINEERING UINTRODUCTIOMDocument49 pagesiNDUSTRIAL ENGINEERING UINTRODUCTIOMe tutorNo ratings yet

- Industrial Engineering & Ergonomics (Me 392)Document35 pagesIndustrial Engineering & Ergonomics (Me 392)Sampson DziwornuNo ratings yet

- Meb16043 - Concept of Work StudyDocument3 pagesMeb16043 - Concept of Work Studyolgambango60No ratings yet

- Case Study: Tanmay D Kulkarni (BE MECH B 68)Document5 pagesCase Study: Tanmay D Kulkarni (BE MECH B 68)SHUBHAM RAMNARAYAN AGRAHARINo ratings yet

- Lecture 01 - Merged PDFDocument69 pagesLecture 01 - Merged PDFNeo TarunNo ratings yet

- Garments ManufacturingDocument8 pagesGarments ManufacturingZeo LycanNo ratings yet

- Introduction To Industrial Engineering: o PeopleDocument6 pagesIntroduction To Industrial Engineering: o PeopleJohn David SalvadorNo ratings yet

- Week-1-Desain Sistem Kerja-CompressedDocument42 pagesWeek-1-Desain Sistem Kerja-CompressedArdy AnandaNo ratings yet

- Lecture-01 (IE)Document8 pagesLecture-01 (IE)2223401015No ratings yet

- Work Study (Method Study)Document87 pagesWork Study (Method Study)Preetam BezbaruaNo ratings yet

- What Are The Reports Made by IE Department in Garment Factories?Document10 pagesWhat Are The Reports Made by IE Department in Garment Factories?YousufNo ratings yet

- IndustrialDocument93 pagesIndustrialRahul PatelNo ratings yet

- Lecture 01 Work System Design-IntroductionDocument12 pagesLecture 01 Work System Design-IntroductionrbansalNo ratings yet

- WORK STUDY - Method Study & Time Study All in OneDocument96 pagesWORK STUDY - Method Study & Time Study All in Onemohammadmehrabi9640No ratings yet

- Introduction To Industrial Engineering PJJ-Taufik - D2496Document29 pagesIntroduction To Industrial Engineering PJJ-Taufik - D2496Farain FauziNo ratings yet

- Introduction To Industrial Engineering: Prepared By: Maria Socorro M. Bunda PIEDocument27 pagesIntroduction To Industrial Engineering: Prepared By: Maria Socorro M. Bunda PIEJM De LeonNo ratings yet

- Work Study-Method Study: Unit - Ii (Part I)Document20 pagesWork Study-Method Study: Unit - Ii (Part I)bagsNo ratings yet

- Pom NotesDocument91 pagesPom NotesEsha BafnaNo ratings yet

- Module No 2 of IEERP of MUMBAI UNIVERSITYDocument69 pagesModule No 2 of IEERP of MUMBAI UNIVERSITYVaibhav Vithoba Naik100% (1)

- 6 Improve The Productivity With Help of Industrial Engineering TechniquesDocument8 pages6 Improve The Productivity With Help of Industrial Engineering TechniquesSaif Assistant EngineerNo ratings yet

- Chapter 1 - 2 - 3 - 6 - 2019 - 2020Document101 pagesChapter 1 - 2 - 3 - 6 - 2019 - 2020Temesgen GashuNo ratings yet

- 7 Ie ToolsDocument13 pages7 Ie Toolscertifiq8213No ratings yet

- I.E - Chandan Kavlekar - Final JuryDocument17 pagesI.E - Chandan Kavlekar - Final JuryChandan SkNo ratings yet

- Time and Motion StudyDocument10 pagesTime and Motion StudyAvinash BarsaNo ratings yet

- Industrial and System EngineeringDocument213 pagesIndustrial and System EngineeringAjaikrishnaNo ratings yet

- PMM 12Document12 pagesPMM 12satexNo ratings yet

- MethodsDocument34 pagesMethodsjavarice653No ratings yet

- Productivity Improvement in Automobile Industry by Using Method StudyDocument3 pagesProductivity Improvement in Automobile Industry by Using Method Studyjay pNo ratings yet

- Notes - For CT-I - Industrial Engg - 16022018 PDFDocument54 pagesNotes - For CT-I - Industrial Engg - 16022018 PDFvijju ajjuNo ratings yet

- Industrial EngineeringDocument55 pagesIndustrial EngineeringKumar Ankur100% (2)

- Application of 7s MethodologyDocument16 pagesApplication of 7s MethodologyIsmail EkmekciNo ratings yet

- Theses On Application of IE in Garments Capacity Study and Line BalancingDocument40 pagesTheses On Application of IE in Garments Capacity Study and Line BalancingRoni khanNo ratings yet

- Introduction To Industrial Engineering-TAPECDocument28 pagesIntroduction To Industrial Engineering-TAPECrobinNo ratings yet

- Lecture (2) Productivity and Work StudyDocument37 pagesLecture (2) Productivity and Work StudyAbdulaziz almasoudiNo ratings yet

- OM Unit 3Document68 pagesOM Unit 3Dharaneesh VKNo ratings yet

- Work Study: BY R .C.BDocument32 pagesWork Study: BY R .C.BShailesh ShirguppikarNo ratings yet

- Module 1 - Objectives of Faciltity Layout and DesignDocument5 pagesModule 1 - Objectives of Faciltity Layout and DesignNECIE JOY LUNARIONo ratings yet

- Operations Managment Part-4Document20 pagesOperations Managment Part-4Sai Rock SaiNo ratings yet

- The Role of Productivity Improvement Tools and Techniques in The Textile Sector During ManufacturingDocument4 pagesThe Role of Productivity Improvement Tools and Techniques in The Textile Sector During ManufacturingDr NallusamyNo ratings yet

- Production Planning and Control: Kazi Mamunur RashidDocument22 pagesProduction Planning and Control: Kazi Mamunur RashidTaosif HassanNo ratings yet

- Aml Murc 2020Document4 pagesAml Murc 2020sunandar HlaingNo ratings yet

- Work Study: Engr. Lamia AnzumDocument34 pagesWork Study: Engr. Lamia Anzumইমরানুল শহীদ আলভীNo ratings yet

- WORK STUDY (WORK MEASUREMENT & METHOD STUDY) of PRODUCTION TECHNOLOGYDocument72 pagesWORK STUDY (WORK MEASUREMENT & METHOD STUDY) of PRODUCTION TECHNOLOGYvvns451988885% (133)

- KSP Solutibilty Practice ProblemsDocument22 pagesKSP Solutibilty Practice ProblemsRohan BhatiaNo ratings yet

- Slup 230Document24 pagesSlup 230Jelena TodorovicNo ratings yet

- OB Case Study Care by Volvo UK 2020Document1 pageOB Case Study Care by Volvo UK 2020Anima AgarwalNo ratings yet

- Ib Psychology - Perfect Saq Examination Answers PDFDocument2 pagesIb Psychology - Perfect Saq Examination Answers PDFzeelaf siraj0% (2)

- With You: Full-Line CatalogDocument68 pagesWith You: Full-Line CatalogCOMINo ratings yet

- I.A.-1 Question Bank EM-3 (Answers)Document11 pagesI.A.-1 Question Bank EM-3 (Answers)UmmNo ratings yet

- TransistorDocument3 pagesTransistorAndres Vejar Cerda0% (1)

- PH-01 (KD 3.1) Filling Out Forms (PG20) - GFormDocument4 pagesPH-01 (KD 3.1) Filling Out Forms (PG20) - GFormLahita AzizahNo ratings yet

- The Data Driven AuditDocument34 pagesThe Data Driven AuditMon compte Mon compteNo ratings yet

- HAFOMA Presentation 2022 ENGDocument9 pagesHAFOMA Presentation 2022 ENGVeljko MilicevicNo ratings yet

- Why We Need A Flying Amphibious Car 1. CarsDocument20 pagesWhy We Need A Flying Amphibious Car 1. CarsAsim AhmedNo ratings yet

- Managing Markets Strategically: Professor Noel CaponDocument49 pagesManaging Markets Strategically: Professor Noel CaponChristiandeuxNo ratings yet

- Human Development and Performance Throughout The Lifespan 2nd Edition Cronin Mandich Test BankDocument4 pagesHuman Development and Performance Throughout The Lifespan 2nd Edition Cronin Mandich Test Bankanne100% (28)

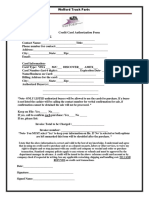

- Credit Card Authorization Form WoffordDocument1 pageCredit Card Authorization Form WoffordRaúl Enmanuel Capellan PeñaNo ratings yet

- Learning Plans in The Context of The 21 ST CenturyDocument29 pagesLearning Plans in The Context of The 21 ST CenturyHaidee F. PatalinghugNo ratings yet

- Libherr CraneDocument157 pagesLibherr Craneali67% (3)

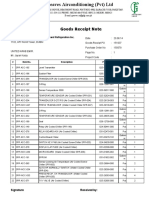

- Goods Receipt Note: Johnson Controls Air Conditioning and Refrigeration Inc. (YORK) DateDocument4 pagesGoods Receipt Note: Johnson Controls Air Conditioning and Refrigeration Inc. (YORK) DateSaad PathanNo ratings yet

- Electronic Parts Catalog - Option Detail Option Group Graphic Film Card DateDocument2 pagesElectronic Parts Catalog - Option Detail Option Group Graphic Film Card DatenurdinzaiNo ratings yet

- THE BASIC TYPES OF SPEECHES PPTDocument14 pagesTHE BASIC TYPES OF SPEECHES PPTKevin BanezNo ratings yet

- Chomsky's Universal GrammarDocument4 pagesChomsky's Universal GrammarFina Felisa L. AlcudiaNo ratings yet

- ResumeDocument3 pagesResumeAstig Kuging63% (8)

- Capacity Analysis of Kashmir Highway IslamabadDocument71 pagesCapacity Analysis of Kashmir Highway Islamabadm saadullah khanNo ratings yet

- MidsemDocument6 pagesMidsemAravind SomasundaramNo ratings yet

- Gates Crimp Data and Dies Manual BandasDocument138 pagesGates Crimp Data and Dies Manual BandasTOQUES00No ratings yet

- Hume 100 ReviewerDocument7 pagesHume 100 ReviewerShai GaviñoNo ratings yet

- FPGA Implementation For Humidity and Temperature Remote Sensing SystemDocument5 pagesFPGA Implementation For Humidity and Temperature Remote Sensing SystemteekamNo ratings yet

- 2011 Frequency AllocationsDocument1 page2011 Frequency Allocationsculeros1No ratings yet

- Concrete Casting - Pump Station ADocument13 pagesConcrete Casting - Pump Station ABright MuzaNo ratings yet

- Energy BodiesDocument1 pageEnergy BodiesannoyingsporeNo ratings yet

- Tecsun Pl310et PDFDocument30 pagesTecsun Pl310et PDFAxel BodemannNo ratings yet

![Practical Guide To Work Study [Revised Edition]](https://imgv2-2-f.scribdassets.com/img/word_document/245836753/149x198/e8597dfaef/1709916910?v=1)