Professional Documents

Culture Documents

JP Carbon Footprint Upload

Uploaded by

parf19710 ratings0% found this document useful (0 votes)

9 views1 pageRetreaded tires are just as safe as new tires and are manufactured to the same high standards required by law. Earthmoving tires can be retreaded up to 3 times, extending their life and reducing costs while benefiting the environment. Retreading tires helps reduce the number of tires produced by allowing reuse, saving natural resources and facilitating recycling.

Original Description:

huella de carbono

Original Title

100413__jp__carbon_footprint_upload

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentRetreaded tires are just as safe as new tires and are manufactured to the same high standards required by law. Earthmoving tires can be retreaded up to 3 times, extending their life and reducing costs while benefiting the environment. Retreading tires helps reduce the number of tires produced by allowing reuse, saving natural resources and facilitating recycling.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

9 views1 pageJP Carbon Footprint Upload

Uploaded by

parf1971Retreaded tires are just as safe as new tires and are manufactured to the same high standards required by law. Earthmoving tires can be retreaded up to 3 times, extending their life and reducing costs while benefiting the environment. Retreading tires helps reduce the number of tires produced by allowing reuse, saving natural resources and facilitating recycling.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

(Study conducted by Best Foot Forward - Commissioned by Centre for Remanufacturing & Reuse: 2013)

RETREADING TYRES

Contrary to popular belief, retreaded tyres are incredibly safe and are

manufactured to comply with the high standards of the European Standard as

required by law. This consists of being tested by the same load and speed criteria

carried out on new tyres.

Earthmoving tyres can be retreaded up to 3 times subject to hours used - not only

does this maximise tyre life and dramatically cut running costs, but it is also

immensely beneficial for the environment.

RETREADED TYRE MATERIALS Retreading does not

NEW TYRE MATERIALS

simply defer the

disposal of a tyre,

Material Input but helps to actively

Material Input

16.00R25 X-Straddle reduce the number 16.00R25 X-Straddle

of tyres in use,

300.0 kg 300.0 kg

hence saving natural

Metals resources and

Metals

helping to recycle.

250.0 kg 250.0 kg

Sulfur Every manufacturer Sulfur

produces tyres with 100.0 kg

the intention of

200.0 kg Vulcanising them having multiple

200.0 kg Vulcanising

Agents lives, resulting in 5.4 kg Agents

Oils cost savings for both 26.1 kg Oils

150.0 kg the customer and 150.0 kg 4.5 kg

environment. 36.0 kg

Carbon Black Carbon Black

3.3 kg 100.0 kg

100.0 kg 16.0 kg 32.4 kg

2.8 kg

22.0 kg SBR Rubber Schelkmann SBR Rubber

50.0 kg 19.8 kg precured retreading 50.0 kg

Natural system 75.6 kg Natural

46.2 kg Rubber guarantees 90% of Rubber

the new tyre 0.0 kg

0.0 kg

performance for all

its retreads.

Energy Input Their retreads have Energy Input

16.00R25 X-Straddle proven themselves 16.00R25 X-Straddle

worldwide in many

500 kWh varied mining 500 kWh

environments, and

400 kWh 400 kWh

due to growing

interest E P

300 kWh Electricity 300 kWh 63 kWh Electricity

Industries are able to

Natural Gas exclusively offer 200 kWh Natural Gas

200 kWh

39 kWh these retreads for

any size and quantity 252 kWh

100 kWh 100 kWh

154 kWh needed.

0 kWh 0 kWh

You might also like

- Plastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965From EverandPlastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965No ratings yet

- Indicator of Measurement: Table Xx. Basis For Mass Balance CalculationDocument11 pagesIndicator of Measurement: Table Xx. Basis For Mass Balance Calculationbookishnerd19No ratings yet

- Flyer Datenblaetter Sludge EN DRUCKDATENDocument2 pagesFlyer Datenblaetter Sludge EN DRUCKDATENarie2000No ratings yet

- Nova Polychem Products List 15-09-2022Document4 pagesNova Polychem Products List 15-09-2022CuriosityShopNo ratings yet

- BCA Green Mark 2021: Carbon CalculatorDocument12 pagesBCA Green Mark 2021: Carbon Calculatordevansh kakkarNo ratings yet

- National Pollution InventoryDocument1 pageNational Pollution InventoryRufus D SNo ratings yet

- ListDocument65 pagesListtuhin mollaNo ratings yet

- WIP SO Fitt May'23Document16 pagesWIP SO Fitt May'23Nur MukhayanNo ratings yet

- Filtrasorb 100 PDFDocument2 pagesFiltrasorb 100 PDFHerik AziziNo ratings yet

- Customer Price List STD 2011-04Document9 pagesCustomer Price List STD 2011-04SahrulNo ratings yet

- Calgon CarbonDocument2 pagesCalgon CarbonHerik AziziNo ratings yet

- Chapter - 6 Summary and ConclusionDocument5 pagesChapter - 6 Summary and Conclusionkingsen000No ratings yet

- 2K-Epoxy Industrial Flooring, Self-Leveling, With Good Pigment Stability (V 44422 - 2)Document3 pages2K-Epoxy Industrial Flooring, Self-Leveling, With Good Pigment Stability (V 44422 - 2)Ha ChienNo ratings yet

- New S750 and S770 Skid-Steer LoadersDocument2 pagesNew S750 and S770 Skid-Steer LoadersDiego Peñailillo ValladaresNo ratings yet

- Kaolite LI Monolithics Up To 2600°F (1427°C) : Datasheet Code US: 3-14-103 SDS: 103 / 153Document3 pagesKaolite LI Monolithics Up To 2600°F (1427°C) : Datasheet Code US: 3-14-103 SDS: 103 / 153luisNo ratings yet

- Session 19 v5Document16 pagesSession 19 v5Fabio RizzoNo ratings yet

- Activated Carbon Based TextilesDocument13 pagesActivated Carbon Based Textilesshobsundar1No ratings yet

- PC20OneSheet1 23 15Document2 pagesPC20OneSheet1 23 15brayan asprillaNo ratings yet

- Catalog - Carbon FilterDocument1 pageCatalog - Carbon FiltercarlomaderazoNo ratings yet

- Biomass BoilersDocument57 pagesBiomass BoilersBinh NgoNo ratings yet

- AMA450GBDocument4 pagesAMA450GBGesiel SoaresNo ratings yet

- Esco Waste InceneratorDocument4 pagesEsco Waste InceneratorRizki Try AtmantiNo ratings yet

- Force Sensors - 208 SeriesDocument1 pageForce Sensors - 208 SeriesSanthosh BalajiNo ratings yet

- Brochure en LRDocument24 pagesBrochure en LRMohit TyagiNo ratings yet

- Ramme - An Update On Combustion Products Utilization in Wisconsin 41916 PDFDocument68 pagesRamme - An Update On Combustion Products Utilization in Wisconsin 41916 PDFerosNo ratings yet

- DOMEX - The Transportation Steel Expert For TippersDocument6 pagesDOMEX - The Transportation Steel Expert For TippersMarcelo RodriguezNo ratings yet

- Cummins PEM ElectrolyzersDocument12 pagesCummins PEM ElectrolyzersSid KalraNo ratings yet

- Lant T Ypes: C (Mega/Ultra)Document3 pagesLant T Ypes: C (Mega/Ultra)Dksjnd UhefdnsmNo ratings yet

- En Aquacarb207c12x30Document2 pagesEn Aquacarb207c12x30fenda2No ratings yet

- Envirocarb 207C 4X8 AND 6X12: Coconut Based Granular Activated CarbonsDocument2 pagesEnvirocarb 207C 4X8 AND 6X12: Coconut Based Granular Activated CarbonsAlfonso BlancoNo ratings yet

- 820 Series TDSDocument2 pages820 Series TDSajaldaco100% (1)

- Puremaster V-300 Puremaster V-500 Puremaster V-700: Premium Whole House Water Filtration SystemsDocument5 pagesPuremaster V-300 Puremaster V-500 Puremaster V-700: Premium Whole House Water Filtration Systemspqr1No ratings yet

- 55 Zorflex WovenDocument2 pages55 Zorflex WovenHerik AziziNo ratings yet

- HRT VhamicalDocument10 pagesHRT VhamicalGPCNo ratings yet

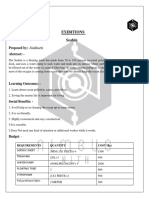

- Exibitions Seabin: Proposed By: - Siddharth AbstractDocument18 pagesExibitions Seabin: Proposed By: - Siddharth AbstractIshika SinghNo ratings yet

- Thermax Combloc Multi Fuel Compact 1500 6000 KG Steam BoilerDocument2 pagesThermax Combloc Multi Fuel Compact 1500 6000 KG Steam BoilerPRABA KARAN100% (1)

- Anaerobic Wastewater TreatmentDocument42 pagesAnaerobic Wastewater Treatmentmdb7gwq6hqNo ratings yet

- Material List 2022 Rev.4Document29 pagesMaterial List 2022 Rev.4lakshanNo ratings yet

- DOCS 500 - PCI GasesDocument4 pagesDOCS 500 - PCI Gaseszorgglub33% (3)

- Co2 Self Generating Plants Cbu Pentair Union Engineering Leaflet v2017 enDocument2 pagesCo2 Self Generating Plants Cbu Pentair Union Engineering Leaflet v2017 en88.diankurniaNo ratings yet

- Kaolite 2200-HS, 2200-HS Gun, 2500-HS, 2500-HS Gun, 2500 EXHS, Super HS GunDocument3 pagesKaolite 2200-HS, 2200-HS Gun, 2500-HS, 2500-HS Gun, 2500 EXHS, Super HS GunvladimirNo ratings yet

- Divalproex Tablets 250mg Process ParametersDocument3 pagesDivalproex Tablets 250mg Process ParameterssyedburhanuddinmoinNo ratings yet

- Big TireDocument12 pagesBig TireSatria HendraNo ratings yet

- EQUIPMENT LIST WITH WEIGHT (AutoRecovered)Document1 pageEQUIPMENT LIST WITH WEIGHT (AutoRecovered)Ann Mary EloiceNo ratings yet

- Improvement of Pulverized Coal Combustion Technology For Power GenerationDocument129 pagesImprovement of Pulverized Coal Combustion Technology For Power Generationsaliyarumesh2292100% (1)

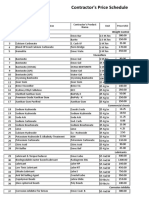

- 2020 Unit Cost Computation 01302020 PDFDocument202 pages2020 Unit Cost Computation 01302020 PDFFreddie Alba Ramos100% (1)

- CP Carbon Anode BackfillDocument1 pageCP Carbon Anode BackfillSoltani AliNo ratings yet

- Study On Strength Properties of Concrete Having Waste Plastic Granules As Fine AggregateDocument13 pagesStudy On Strength Properties of Concrete Having Waste Plastic Granules As Fine AggregateayyappagosuNo ratings yet

- Pyrocrete Series Brochure - 0115Document4 pagesPyrocrete Series Brochure - 0115Fadhana Anggara PutraNo ratings yet

- TDS of AxSorb DDocument1 pageTDS of AxSorb DJohan KhaeriNo ratings yet

- Water Well Drilling Rig ManufacturersDocument1 pageWater Well Drilling Rig ManufacturersKGR RigsNo ratings yet

- Installation-Manual Solimpeks TSM-200-300 Thermosiphon-Systems EU-Turkey 2021 ENGDocument29 pagesInstallation-Manual Solimpeks TSM-200-300 Thermosiphon-Systems EU-Turkey 2021 ENGDanilo JancicNo ratings yet

- ABC 140-240 Solidbatch: Asphalt-Mixing Plant ClassicDocument2 pagesABC 140-240 Solidbatch: Asphalt-Mixing Plant ClassicMuhamet KurtiNo ratings yet

- PBS INDIA Turbojet Engines 210315Document5 pagesPBS INDIA Turbojet Engines 210315AmarNo ratings yet

- CLC Plant PDFDocument14 pagesCLC Plant PDFkhgdhgdhNo ratings yet

- Hettich PDFDocument18 pagesHettich PDFEry PachecNo ratings yet

- Engineering Ropes 6x36 ClassDocument2 pagesEngineering Ropes 6x36 ClassSachin TiwariNo ratings yet

- Compresor 750 PCMDocument2 pagesCompresor 750 PCMarcobaxinNo ratings yet

- SGL8 X 30Document2 pagesSGL8 X 30DucVikingNo ratings yet

- GOLDEN DAWN 1 10 The Banishing Ritual of HexagramDocument4 pagesGOLDEN DAWN 1 10 The Banishing Ritual of HexagramF_RC86% (7)

- Installation Instructions: Harley-Davidson Softail Saddlebag Mount Bracket PART# 21946Document4 pagesInstallation Instructions: Harley-Davidson Softail Saddlebag Mount Bracket PART# 21946Justin StewartNo ratings yet

- Ketron 1000 PEEK PDS E 30032019 01Document1 pageKetron 1000 PEEK PDS E 30032019 01jorgepradaco1No ratings yet

- 1mrk508015-Ben B en Auxiliary Signalling and Trippning Relays Rxma 1 Rxma 2 Rxms 1 RXSF 1 Rxme 1 Rxme 18 RXMH 2 RXMDocument20 pages1mrk508015-Ben B en Auxiliary Signalling and Trippning Relays Rxma 1 Rxma 2 Rxms 1 RXSF 1 Rxme 1 Rxme 18 RXMH 2 RXMalaa6474794No ratings yet

- The Anaphylactic ShockDocument8 pagesThe Anaphylactic ShockRooby JeanpierreNo ratings yet

- ED1021 - I/O Expander With UART Interface & Analog Inputs: PreliminaryDocument9 pagesED1021 - I/O Expander With UART Interface & Analog Inputs: PreliminaryMilan NovakovićNo ratings yet

- Yes Bank FinalDocument107 pagesYes Bank FinalDrMehul JoshiNo ratings yet

- Vortex Based MathematicsDocument14 pagesVortex Based Mathematicssepsis19100% (2)

- MAPEH (P.E.) : Quarter 1 - Module 1: Physical Activity Pyramid For Young LearnersDocument11 pagesMAPEH (P.E.) : Quarter 1 - Module 1: Physical Activity Pyramid For Young LearnersAlbert Ian CasugaNo ratings yet

- International Standard Paper SizesDocument34 pagesInternational Standard Paper SizesAman KumarNo ratings yet

- DWS2510.02 - Auxiary Drive SpecificationDocument11 pagesDWS2510.02 - Auxiary Drive SpecificationCorneNo ratings yet

- Experiments: Mouthpiece, Which Is A Short Tube of Length About Equal To The Radius of The Orifice That Projects Into TheDocument4 pagesExperiments: Mouthpiece, Which Is A Short Tube of Length About Equal To The Radius of The Orifice That Projects Into Thefrancis dimakilingNo ratings yet

- Green Revolution: It's Acheivements and FailuresDocument24 pagesGreen Revolution: It's Acheivements and FailuresSingh HarmanNo ratings yet

- (Complete) BLC 201 Assignment Intro Logistics SCM Sep 2021 - McdonaldDocument12 pages(Complete) BLC 201 Assignment Intro Logistics SCM Sep 2021 - McdonaldHf CreationNo ratings yet

- ERIC Section4 Hadrian - C. AlbinusDocument83 pagesERIC Section4 Hadrian - C. AlbinusDarko SekulicNo ratings yet

- Subcontracting Process in Production - SAP BlogsDocument12 pagesSubcontracting Process in Production - SAP Blogsprasanna0788No ratings yet

- PC-FT 403: Lecture (1) byDocument21 pagesPC-FT 403: Lecture (1) byFT 19 Suparno DasNo ratings yet

- Midi Fighter Twister - User Guide 2016Document25 pagesMidi Fighter Twister - User Guide 2016moxmixNo ratings yet

- Prof Budi Wiweko - Protokol Dan Pemantauan Stimulasi Ovarium SederhanaDocument36 pagesProf Budi Wiweko - Protokol Dan Pemantauan Stimulasi Ovarium SederhanaAnisanang BanjarNo ratings yet

- Worktips 01 Priming of PavementsDocument2 pagesWorktips 01 Priming of PavementsDilhara WickramaarachchiNo ratings yet

- Evolution of Indian TolucaDocument28 pagesEvolution of Indian TolucaAlberto Duran IniestraNo ratings yet

- Figure Eight Island Homeowners' Association, Inc. Case StudyDocument16 pagesFigure Eight Island Homeowners' Association, Inc. Case StudyYoong YingNo ratings yet

- Trane 5 Ton HP Cond submittat4TWB3060-SUB-106 - 05.05 - 11012009Document2 pagesTrane 5 Ton HP Cond submittat4TWB3060-SUB-106 - 05.05 - 11012009nobleairNo ratings yet

- 24 - Al Nahda The Sheffeild Privat To International City, Greece K12 Dubai Bus Service TimetableDocument10 pages24 - Al Nahda The Sheffeild Privat To International City, Greece K12 Dubai Bus Service TimetableDubai Q&ANo ratings yet

- Bruker d8 XRD TutoriallDocument16 pagesBruker d8 XRD TutoriallravarNo ratings yet

- Introduction On Photogrammetry Paul R WolfDocument33 pagesIntroduction On Photogrammetry Paul R Wolfadnan yusufNo ratings yet

- Denel Dynamics Product Brochure PDFDocument36 pagesDenel Dynamics Product Brochure PDFeggboy196967% (3)

- Hopf 6870 - 1101Document58 pagesHopf 6870 - 1101macakafkaNo ratings yet

- Rajesh CVDocument3 pagesRajesh CVS R PramodNo ratings yet