Professional Documents

Culture Documents

Brochure - SCHOTT - Pharma Services - 6 - State of The Art Analyses - ROW

Brochure - SCHOTT - Pharma Services - 6 - State of The Art Analyses - ROW

Uploaded by

Oleg ChernovOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Brochure - SCHOTT - Pharma Services - 6 - State of The Art Analyses - ROW

Brochure - SCHOTT - Pharma Services - 6 - State of The Art Analyses - ROW

Uploaded by

Oleg ChernovCopyright:

Available Formats

State-of-the-Art Analyses

Unique set of highly sophisticated and precise analyses methods performed

by SCHOTT pharma services experts on packaging analytics

Below you will find a selection of our analytical testing methods:

Chemical Durability Tests E&L and System Performance Tests

• ToF-SIMS Secondary Ion Mass Spectrometry and • GC-MS Gas Chromatography – Mass Spectrometry

Depth Profiling • GC-FID Gas Chromatography – Flame Ionisation Detection

• SEM Scanning Electron Microscopy • HS-GC Headspace – Gas Chromatography

• LiMi Stereo Microscopy • TD-GC Thermal desorption – Gas Chromatography

• EDS Energy-dispersive X-Ray Spectroscopy • LC-Q-Tof and LC-MS-IT-TOF Liquid Chromatography

• F-AAS, GF-AAS, HG-AAS Atomic high resolution Mass Spectrometry

Absorption Spectrometry • LC-DAD Liquid chromatography with UV/VIS detection

• HR ICP-MS High Resolution Inductive Coupled • IC Ion Chromatography

Plasma-Mass Spectrometry • ICP-OES Inductive Coupled Plasma – Optical Emission

• ICP-OES, Spark-OES Atomic Emission Spectrometry Spectrometry

• ICP-MS, Laser Ablation ICP-MS • ICP-MS Inductive Coupled Plasma – Mass Spectrometry

• FTIR- and Raman-Microscopy • HR ICP-MS High Resolution Inductive Coupled

• Wet Chemistry, Gravimetry, Titration Plasma – Mass Spectrometry

• Hydrolytic Resistance Tests • F-AAS, GF-AAS, HG-AAS Atomic Absorption Spectrometry

• Sample Preparation for Tests including Washing, • Hot Gas Extraction Methods for C, O, S, N Determination

Depyrogenation, Filling, and Sealing • Transmission, Reflection, Remission, Absorption in

UV-VIS-IR Range

• FTIR- and Raman-Microscopy

• X-ray fluorescence spectrometry

Mechanical Stability Tests Accredited according to DIN EN ISO/IEC 17025:

• Fractography, Crack Origin, Microscopic Fracture Patterns

• Stress-optical Measurements

• Statistical Analysis of Strength Data

• Fracture Toughness

• Crack Initiation Load, Elastic and Plastic Indentation

• Static Strength, Tension-compression (uniaxial)

• Bending, Bursting (hydrostatic)

• Dynamic Strength, Notch Test, DCDC (crack growth)

• Climate Testing

40103 ENGLISH-ROW 07/2019 ali/nino Printed in Germany

• FEA Finite Element Analysis

Recent Publications & Whitepapers

1. | Hladik, B., Buscke, F., Frost, R., Rothhaar, U. Comparative Leachable Study for Glass Vials to Demonstrate the Impact of Low Fill Volume,

J. Pharm. Sci. Technol. 2019, 73.

2. | Rothhaar, U., Klause, M., Hladik, B. Comparative Delamination Study to Demonstrate the Impact of Container Quality and Nature of Buffer System,

J. Pharm. Sci. Technol. 2016, 70, pgs 560 – 567.

3. | Haines, D., Maurer, F., Rothhaar, U. Why do Pharmaceutical Glass Containers Break: The Underestimated Power of Strength Testing and Fractography,

International Pharmaceutical Industry, 2016, Vol 8, Issue 1, pgs 88 – 92.

4. | Soegding, T., Canton, D.; Haines, D., Rothhaar, U. How Sterilization of Primary Packaging Influences the Results of E&L Studies, Contract Pharma,

2015, June, pgs 88 – 94.

5. | Haines, D.; Scheumann, V., Rothhaar, U. Glass Flakes: Pre-Testing Stops a Big Problem before it Even Starts, Contract Pharma 2013, June, pgs 92 – 98.

SCHOTT AG

Hattenbergstraße 10

55122 Mainz

Germany

Phone: +49 (0)6131/66-7339

Fax: +49 (0)3641/2888-9125

pharma.services@schott.com

www.schott.com/pharmaceutical_systems

You might also like

- Raman Spectroscopy of Carbon TetrachlorideDocument8 pagesRaman Spectroscopy of Carbon TetrachlorideNikoNo ratings yet

- The Simultaneous Determination of Caffeine and Acetylsalicylic Acid in An Analgesic by Ultraviolet SpectrophotometryDocument8 pagesThe Simultaneous Determination of Caffeine and Acetylsalicylic Acid in An Analgesic by Ultraviolet SpectrophotometryAthirah RaZi40% (5)

- G133 - A2LA Guide For Establishing Proficiency Testing Plans-23603-1Document9 pagesG133 - A2LA Guide For Establishing Proficiency Testing Plans-23603-1Alberto Garcia100% (1)

- Fisher Thermo Scientific Catalogue V DearDocument72 pagesFisher Thermo Scientific Catalogue V Dearmm0987654321100% (1)

- Principles of Metal Surface Treatment and Protection: Pergamon International Library of Science, Technology, Engineering and Social Studies: International Series on Materials Science and TechnologyFrom EverandPrinciples of Metal Surface Treatment and Protection: Pergamon International Library of Science, Technology, Engineering and Social Studies: International Series on Materials Science and TechnologyNo ratings yet

- CHEMISTRY 3080 4.0 Instrumental Methods of Chemical AnalysisDocument15 pagesCHEMISTRY 3080 4.0 Instrumental Methods of Chemical AnalysisFatma MaharaniNo ratings yet

- Bru Ker Almanac 2012Document208 pagesBru Ker Almanac 2012Alex FerdmanNo ratings yet

- Modern Instrumental Analysis in Chemical EnngineeringDocument93 pagesModern Instrumental Analysis in Chemical EnngineeringLakshman ReddyNo ratings yet

- What Is Analytical Chemistry?: Seeks ImprovedDocument52 pagesWhat Is Analytical Chemistry?: Seeks ImprovedFiqran Ratu WaraNo ratings yet

- Magryta2016 - Detection of Gaseous Compounds With Different TechniquesDocument20 pagesMagryta2016 - Detection of Gaseous Compounds With Different TechniquesHenriqueNo ratings yet

- MPCT2017 SyllabusDocument7 pagesMPCT2017 SyllabusMakumNo ratings yet

- GC Applications: Care + ResearchDocument4 pagesGC Applications: Care + ResearchUsman GhaniNo ratings yet

- Spectrochimica Acta Part B: Rafael F. Santos, Gabriel S. Carvalho, Fabio A. Duarte, Rodrigo C. Bolzan, Erico M.M. FloresDocument7 pagesSpectrochimica Acta Part B: Rafael F. Santos, Gabriel S. Carvalho, Fabio A. Duarte, Rodrigo C. Bolzan, Erico M.M. FloresSandi MahesaNo ratings yet

- Tandem Techniques (Separation Science Series) (R. P. W. Scott) PDFDocument569 pagesTandem Techniques (Separation Science Series) (R. P. W. Scott) PDFRaul CalderonNo ratings yet

- Nathan Scott Wednesday 21 May Technique Workshop: Protein-Ligand InteractionsDocument24 pagesNathan Scott Wednesday 21 May Technique Workshop: Protein-Ligand InteractionsrobsondoegitoNo ratings yet

- 90 1008 01 PDFDocument6 pages90 1008 01 PDFEmad EmadNo ratings yet

- AnalyticalDocument2 pagesAnalyticalRiya VishwakarmaNo ratings yet

- Certificate of Analysis: National Institute of Standards & TechnologyDocument4 pagesCertificate of Analysis: National Institute of Standards & TechnologySidneide Ferreira SantosNo ratings yet

- 1 Intro - Kimia Analis UIIDocument47 pages1 Intro - Kimia Analis UIIfitriNo ratings yet

- Lab - Materials and Nondestructive Evaluation LaboratoriesDocument31 pagesLab - Materials and Nondestructive Evaluation LaboratoriesHaco Chinedu ObasiNo ratings yet

- Farma QuimiDocument10 pagesFarma Quimiart95No ratings yet

- Level3 TopicsDocument2 pagesLevel3 TopicsBPHIRABUNo ratings yet

- Gas Chromatography-Mass Spectrometry (GC - MS)Document28 pagesGas Chromatography-Mass Spectrometry (GC - MS)Ankita Kashyap100% (2)

- Chemical SensorsDocument70 pagesChemical SensorsRenu SamuelNo ratings yet

- Characterisation of Polymer With GCDocument104 pagesCharacterisation of Polymer With GCAmit KumarNo ratings yet

- CH 607 Fundamentals of Analytical ChemistryDocument4 pagesCH 607 Fundamentals of Analytical ChemistrySreekanth IyerNo ratings yet

- Analytical InstrumentationDocument2 pagesAnalytical InstrumentationMahavirsinh Gohil75% (4)

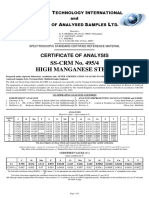

- SCRM No. 666/12 Ductile (Nodular) Iron: L Certificate of AnalysisDocument2 pagesSCRM No. 666/12 Ductile (Nodular) Iron: L Certificate of AnalysisPeterson SudlabNo ratings yet

- Manual XRD 6100Document28 pagesManual XRD 6100Valdecir MgáNo ratings yet

- C ThermMethodSelectionGuideO2020Document36 pagesC ThermMethodSelectionGuideO2020Ирина Игоревна ФадееваNo ratings yet

- Quality Assessment Herbal Drugs Review ArticleDocument18 pagesQuality Assessment Herbal Drugs Review ArticleDr Mohammed KamalNo ratings yet

- Performance: Unparalleled Micro-XrfDocument2 pagesPerformance: Unparalleled Micro-Xrftaufiq_hidayat_1982No ratings yet

- Ss CRM 495 - 4Document2 pagesSs CRM 495 - 4lehdruk7100No ratings yet

- Control, Analysis and TestingDocument44 pagesControl, Analysis and TestingJOSE ANGEL CARRASCONo ratings yet

- Physical Characterisation Pharma 2013Document2 pagesPhysical Characterisation Pharma 2013Prashansa ShresthaNo ratings yet

- Assignment Case Study (MEM661 8D8)Document8 pagesAssignment Case Study (MEM661 8D8)Amer LokhmanNo ratings yet

- CHEMISTRY 3080 4.0 Instrumental Methods of Chemical AnalysisDocument49 pagesCHEMISTRY 3080 4.0 Instrumental Methods of Chemical AnalysisFatma MokhtarNo ratings yet

- Am0sio2fste2015Document36 pagesAm0sio2fste2015LawrenceNo ratings yet

- Limestone Whitepaper PDFDocument5 pagesLimestone Whitepaper PDFras110477No ratings yet

- USP 1207 Guidance HerneticidadDocument44 pagesUSP 1207 Guidance HerneticidadEusebio Rodriguez BarraganNo ratings yet

- Technical Services BD Medical Pharmaceutical SystemsDocument13 pagesTechnical Services BD Medical Pharmaceutical SystemsChao Qiang KoNo ratings yet

- CH 20Document17 pagesCH 20Shonar KellaNo ratings yet

- Environmental Test EquipmentsDocument17 pagesEnvironmental Test EquipmentsJayu DarjiNo ratings yet

- Complete Material Testing SolutionsDocument1 pageComplete Material Testing Solutionspandey008No ratings yet

- M Tech in NDTDocument17 pagesM Tech in NDTjaimin100No ratings yet

- MetrologyDocument87 pagesMetrologyParabellum GamingNo ratings yet

- Monitoring Systems For MICDocument11 pagesMonitoring Systems For MICaseNo ratings yet

- Instrumental Methods of Analysis Lession NotesDocument82 pagesInstrumental Methods of Analysis Lession NotesK.Selvaraj86% (21)

- NDT Syllabus NIT TrichyDocument17 pagesNDT Syllabus NIT Trichykhizer mohamedNo ratings yet

- Syllabus For Fixed Term Associates-1Document7 pagesSyllabus For Fixed Term Associates-1Khan KhursheedNo ratings yet

- Ass AsDocument15 pagesAss AsMukesh BishtNo ratings yet

- What Is AAS/Atomic Absorption Spectroscopy?Document8 pagesWhat Is AAS/Atomic Absorption Spectroscopy?odunmoolorun dorcasNo ratings yet

- GC MS MSDocument12 pagesGC MS MSLý VươngNo ratings yet

- Abr Exams GuideDocument10 pagesAbr Exams GuideNelson Appiah-AgyeiNo ratings yet

- Instrumental Method Part 01Document18 pagesInstrumental Method Part 01TgemunuNo ratings yet

- JIP Meeting Western Australia UniversityDocument55 pagesJIP Meeting Western Australia UniversityViridiana SalazarNo ratings yet

- Kruss - Polarrimeter - BrochureDocument16 pagesKruss - Polarrimeter - BrochureMohammad Abu NuwarNo ratings yet

- JXST 26 1 2018Document29 pagesJXST 26 1 2018nasywa rahmatullailyNo ratings yet

- Analytical Chemistry: Hide MeDocument18 pagesAnalytical Chemistry: Hide MeArya ChowdhuryNo ratings yet

- API Manufacturing ProcessDocument37 pagesAPI Manufacturing ProcessAnonymous 75aETJ8ONo ratings yet

- Characterization of Composite MaterialsFrom EverandCharacterization of Composite MaterialsHatsuo IshidaNo ratings yet

- Sonderedition Techntubing 210x280 Row OnlineDocument52 pagesSonderedition Techntubing 210x280 Row OnlineOleg ChernovNo ratings yet

- Row Schott Technical Glasses View 2020-04-14Document80 pagesRow Schott Technical Glasses View 2020-04-14Oleg ChernovNo ratings yet

- SCH PDA GlassBreakage EN 20211202 AnsichtDocument2 pagesSCH PDA GlassBreakage EN 20211202 AnsichtOleg ChernovNo ratings yet

- SCH PDA Extractables EN 20211202 AnsichtDocument2 pagesSCH PDA Extractables EN 20211202 AnsichtOleg ChernovNo ratings yet

- SCHOTT PP Flyer Pharma Service Compendial Testing ROW RZ 2020 03 16Document3 pagesSCHOTT PP Flyer Pharma Service Compendial Testing ROW RZ 2020 03 16Oleg ChernovNo ratings yet

- History of Mass Spectrometry of Organic MoleculesDocument67 pagesHistory of Mass Spectrometry of Organic MoleculesEmir Gerardo Monterrey GutiérrezNo ratings yet

- Journal of Wood Chemistry and TechnologyDocument18 pagesJournal of Wood Chemistry and TechnologyGian Muhammad Ra'afiNo ratings yet

- Paper Chromatography PDFDocument8 pagesPaper Chromatography PDFAmit GhadeNo ratings yet

- Syllabus07 Molecular Spectroscopy2Document2 pagesSyllabus07 Molecular Spectroscopy2DrHamdy KhameesNo ratings yet

- UV-Vis Absorption Spectroscopy - TheoryDocument4 pagesUV-Vis Absorption Spectroscopy - TheoryAbdulhamid AbdulwaasiNo ratings yet

- 1.UV Spectro - IntroductionDocument49 pages1.UV Spectro - IntroductionRitika GuptaNo ratings yet

- UV Visible SpectrosDocument2 pagesUV Visible SpectrosM Hmza S MalikNo ratings yet

- UVSpectrosDocument22 pagesUVSpectrosAbu Tareq SarkerNo ratings yet

- Lesson 3 MBC 211 (Electrophoresis)Document9 pagesLesson 3 MBC 211 (Electrophoresis)ifioksunday52No ratings yet

- Lec 4B - Enviro Chem Anal2 - ModDocument14 pagesLec 4B - Enviro Chem Anal2 - ModBuTter ScoTch100% (1)

- Solid State NMRDocument11 pagesSolid State NMRscancian2000No ratings yet

- Unit4, Atomic&MolecularPhysics, InfraRed Spectros PDFDocument43 pagesUnit4, Atomic&MolecularPhysics, InfraRed Spectros PDFanujjuetNo ratings yet

- PermethrinDocument4 pagesPermethrinVenugopal GowdaNo ratings yet

- Agilent Application Note HILIC Column BetaineDocument2 pagesAgilent Application Note HILIC Column BetainePrashant GaurNo ratings yet

- Assignment-NMR WorkshopDocument2 pagesAssignment-NMR WorkshopSuman3 DuttaNo ratings yet

- Cleaning Reverse Phase ColumnDocument2 pagesCleaning Reverse Phase ColumnhbordasmNo ratings yet

- Report 5-FU 35 Days ENG 150115Document14 pagesReport 5-FU 35 Days ENG 150115Grace ValenciaNo ratings yet

- PAPER+CHROMATOGRAPHY PpsDocument35 pagesPAPER+CHROMATOGRAPHY PpsjasyeelelooNo ratings yet

- Ik EnglDocument14 pagesIk EnglIvesAntônioNo ratings yet

- Mass Spectros PDFDocument52 pagesMass Spectros PDFadelNo ratings yet

- Wavelength Selectors For IR SpectrophotometryDocument2 pagesWavelength Selectors For IR SpectrophotometrySean CollinsNo ratings yet

- Mass Spectrometry and Protein Analysis PDFDocument8 pagesMass Spectrometry and Protein Analysis PDFRubén Cuán RNo ratings yet

- ContentDocument4 pagesContentSheetal uikeyNo ratings yet

- HL Chemistry - Option A: Modern Analytical Chemistry: ChromatographyDocument83 pagesHL Chemistry - Option A: Modern Analytical Chemistry: ChromatographyDineshBabuNo ratings yet

- 2.12 Mass Spectra and IRDocument30 pages2.12 Mass Spectra and IRSandyDavidNo ratings yet

- 4.9 Spectroscopy and Chromatography-2Document45 pages4.9 Spectroscopy and Chromatography-2Michael Angelo FilomenoNo ratings yet

- 11.3 (2 Files Merged)Document28 pages11.3 (2 Files Merged)Tae Soo LeeNo ratings yet

- Ocr 33985 PP 09 Jan L Gce 2815 04Document12 pagesOcr 33985 PP 09 Jan L Gce 2815 04Philip_830No ratings yet