Professional Documents

Culture Documents

Lubrificante Interno - Auxiliar de Processamento DataSheet1

Lubrificante Interno - Auxiliar de Processamento DataSheet1

Uploaded by

Kaique TozziCopyright:

Available Formats

You might also like

- Delivery Service Invoice: Rico'S Upholstery Consulting Rico'S Upholstery 1445 Virginia Ave BALDWIN PARK, CA 91706-5820Document2 pagesDelivery Service Invoice: Rico'S Upholstery Consulting Rico'S Upholstery 1445 Virginia Ave BALDWIN PARK, CA 91706-5820Rafael RicoNo ratings yet

- Albaflow: UNI Penetration AccelerantDocument5 pagesAlbaflow: UNI Penetration AccelerantsaskoNo ratings yet

- Pharmaceutics: A Practical Manual for PHARM & PHARM D CoursesFrom EverandPharmaceutics: A Practical Manual for PHARM & PHARM D CoursesRating: 5 out of 5 stars5/5 (2)

- AES Encryption and Decryption in Java - DevGlanDocument1 pageAES Encryption and Decryption in Java - DevGlanგენო მუმლაძეNo ratings yet

- Randstad2040 Structural VisionDocument41 pagesRandstad2040 Structural VisionAna Maria Fernandez MaldonadoNo ratings yet

- Prior Art PAPR Reduction 2012Document49 pagesPrior Art PAPR Reduction 2012Avik ModakNo ratings yet

- Lubrificante Interno - Auxiliar de Processamento DataSheet2Document1 pageLubrificante Interno - Auxiliar de Processamento DataSheet2Kaique TozziNo ratings yet

- PDS Pat Add Le 1019Document2 pagesPDS Pat Add Le 1019Graciele SantosNo ratings yet

- 5040 Plus PDFDocument3 pages5040 Plus PDFForeverNo ratings yet

- 3200258e - TDS - ALBATEX OADocument4 pages3200258e - TDS - ALBATEX OAeric tanudjajaNo ratings yet

- PDS Pat-Add Da 801Document2 pagesPDS Pat-Add Da 801deibi2No ratings yet

- TDS OF H-77 Agriculture Organosilicone AdjuvantDocument3 pagesTDS OF H-77 Agriculture Organosilicone AdjuvantAda FuNo ratings yet

- Cera Matizante Fa-110Document2 pagesCera Matizante Fa-110alfosoa5505No ratings yet

- White Mineral Oil (Textile Oils) Product Data SheetDocument1 pageWhite Mineral Oil (Textile Oils) Product Data SheetMajed DawaNo ratings yet

- Safety Data Sheet Toner - Black, Cyan, Magenta, Yellow: Trade NameDocument8 pagesSafety Data Sheet Toner - Black, Cyan, Magenta, Yellow: Trade NameДмитрий ЧумаковNo ratings yet

- Drew Plus TM 4507 A Foam Control DefoamerDocument2 pagesDrew Plus TM 4507 A Foam Control DefoamerDara PishtazNo ratings yet

- Acrysol Adt-100Document3 pagesAcrysol Adt-100wtwilightwNo ratings yet

- Albatex: AR Reduction InhibitorDocument4 pagesAlbatex: AR Reduction InhibitorsaskoNo ratings yet

- Evo Dot 61 EnglishDocument2 pagesEvo Dot 61 EnglishUtpalNo ratings yet

- Hydrosize® U7-01: Technical Data SheetDocument2 pagesHydrosize® U7-01: Technical Data Sheetcbanegas1983No ratings yet

- Ficha Tecnica NPT QUICK FLASH ADDITIVE M00009Document1 pageFicha Tecnica NPT QUICK FLASH ADDITIVE M00009Stéphanie BaltazarNo ratings yet

- 837 PDFDocument1 page837 PDFAndra PutraNo ratings yet

- TDS - Tergito HXDocument2 pagesTDS - Tergito HXmyunggooNo ratings yet

- LAWA007Document3 pagesLAWA007Fadilla AzhariNo ratings yet

- Albaflow: JET Penetration AccelerantDocument5 pagesAlbaflow: JET Penetration AccelerantGokhan RamiNo ratings yet

- N.T-Clear-DL100 (TDS)Document2 pagesN.T-Clear-DL100 (TDS)MahdiNo ratings yet

- Performance Coatings Product Data Sheet Lubrijet™ T340 Acrylic EmulsionDocument3 pagesPerformance Coatings Product Data Sheet Lubrijet™ T340 Acrylic EmulsionPedro Duplaa Soares FerreiraNo ratings yet

- Bioadimide 100 en RCRDocument2 pagesBioadimide 100 en RCRChanakyaNo ratings yet

- Rheofinish 302: High Performance Chemical and Physical Mould Release AgentsDocument1 pageRheofinish 302: High Performance Chemical and Physical Mould Release AgentsFrancois-No ratings yet

- Tai County Silicones CO., LTD. Ms-730Hv Softener: Description ApplicationsDocument1 pageTai County Silicones CO., LTD. Ms-730Hv Softener: Description ApplicationsMark WuNo ratings yet

- TDS - 57006 AddNox Anti Block MBDocument1 pageTDS - 57006 AddNox Anti Block MBRajiv DubeyNo ratings yet

- ELASTENE 1500 DCM-APR TDS en Final - 1501Document2 pagesELASTENE 1500 DCM-APR TDS en Final - 1501rogerkid17No ratings yet

- TD AGITAN 170 EN Ee22a56aabDocument1 pageTD AGITAN 170 EN Ee22a56aabMahmoud FlefilNo ratings yet

- Compound Ferric Green: Technical DataDocument1 pageCompound Ferric Green: Technical DatahuynhtrantriNo ratings yet

- Ultratex UHS Hydrophilic Softener: Technical Data SheetDocument5 pagesUltratex UHS Hydrophilic Softener: Technical Data SheetSon NguyenNo ratings yet

- 56food Superla White OilsDocument2 pages56food Superla White OilsDavid PomaNo ratings yet

- Attagel 50 January 2018 R5 ED2Document2 pagesAttagel 50 January 2018 R5 ED2APEX SONNo ratings yet

- Glucamate DOE-120 PDS PDFDocument4 pagesGlucamate DOE-120 PDS PDFRobyn BrownNo ratings yet

- Ceridust 5551 - For Lively Colors.: Exactly Your ChemistryDocument2 pagesCeridust 5551 - For Lively Colors.: Exactly Your ChemistryMaximiliano MackeviciusNo ratings yet

- Stepan Formulation 1220Document2 pagesStepan Formulation 1220Devesh KumarNo ratings yet

- Dowsil 51 AdditiveDocument5 pagesDowsil 51 AdditiveYến HoàngNo ratings yet

- Tinuvin 152 October 2019 R4 ICDocument3 pagesTinuvin 152 October 2019 R4 ICEmilio HipolaNo ratings yet

- 27 3520 01 Ecosense GL 60 HL SurfactantDocument3 pages27 3520 01 Ecosense GL 60 HL SurfactantKishore Gowda A SNo ratings yet

- White Vaseline Pds DK en 123027Document2 pagesWhite Vaseline Pds DK en 123027Julia TsoiNo ratings yet

- Stepan Formulation 995Document2 pagesStepan Formulation 995120984No ratings yet

- Stepan Formulation 1272Document2 pagesStepan Formulation 1272Mohamed AdelNo ratings yet

- Thaiol 1698 PDFDocument1 pageThaiol 1698 PDFJorge TorresNo ratings yet

- Epoxy Primer216Document2 pagesEpoxy Primer216kishortilekarNo ratings yet

- DOWSIL™ Q2-3238 Dispersible Silicone Additive: Features & BenefitsDocument2 pagesDOWSIL™ Q2-3238 Dispersible Silicone Additive: Features & BenefitsZhan FangNo ratings yet

- Technical Information: Wetting Agent For Aqueous SystemsDocument1 pageTechnical Information: Wetting Agent For Aqueous SystemsLong An ĐỗNo ratings yet

- Product Data Sheet: High Performance Cutting OilDocument1 pageProduct Data Sheet: High Performance Cutting OilSadid Shahzad100% (1)

- Wannate Mdi-100 en V5Document3 pagesWannate Mdi-100 en V5fuenmayor.lilibethNo ratings yet

- Tds Supermend Epoxy EnglishDocument4 pagesTds Supermend Epoxy EnglishNiklas LuwamNo ratings yet

- Bentone 38 - TDS - eDocument2 pagesBentone 38 - TDS - eDũng ĐỗNo ratings yet

- TDS Anti-Terra-204 enDocument4 pagesTDS Anti-Terra-204 enChemtools ChemtoolsNo ratings yet

- 3M™ Super 77™ Multipurpose Spray Adhesive (Aerosol) - 20221111Document4 pages3M™ Super 77™ Multipurpose Spray Adhesive (Aerosol) - 20221111HugoNo ratings yet

- Technical Information: Gecko Frontal UniDocument3 pagesTechnical Information: Gecko Frontal UniAtmaja SuryadiNo ratings yet

- Product Data Sheet: GeneralDocument1 pageProduct Data Sheet: Generalsriatul2006100% (1)

- PRIMAL™ AC-365 Acrylic Emulsion: Regional Product Availability DescriptionDocument3 pagesPRIMAL™ AC-365 Acrylic Emulsion: Regional Product Availability DescriptionLong An ĐỗNo ratings yet

- FILE - 20210525 - 094757 - Defom 5800F - TDS - EDocument2 pagesFILE - 20210525 - 094757 - Defom 5800F - TDS - Elee nguyenNo ratings yet

- Afe 2017 Xiameter-Afe-3168-Antifoam-EmulsDocument2 pagesAfe 2017 Xiameter-Afe-3168-Antifoam-EmulsZhan FangNo ratings yet

- Honeywell AC 316 TDSDocument1 pageHoneywell AC 316 TDSFine OrganicNo ratings yet

- Chemical Process Simplification: Improving Productivity and SustainabilityFrom EverandChemical Process Simplification: Improving Productivity and SustainabilityNo ratings yet

- Lubrificante Interno - Auxiliar de Processamento DataSheet2Document1 pageLubrificante Interno - Auxiliar de Processamento DataSheet2Kaique TozziNo ratings yet

- An Overview of Degradable and Biodegradable Polyolefins 2011Document35 pagesAn Overview of Degradable and Biodegradable Polyolefins 2011Kaique TozziNo ratings yet

- Eva ComsbrDocument9 pagesEva ComsbrKaique TozziNo ratings yet

- Mjalli 2017Document22 pagesMjalli 2017Kaique TozziNo ratings yet

- 10 1016@j Molliq 2018 04 113Document28 pages10 1016@j Molliq 2018 04 113Kaique TozziNo ratings yet

- 1 s2.0 S0167732217349449 MainDocument9 pages1 s2.0 S0167732217349449 MainKaique TozziNo ratings yet

- Barycki 2016Document9 pagesBarycki 2016Kaique TozziNo ratings yet

- Yang 2017Document39 pagesYang 2017Kaique TozziNo ratings yet

- 1 s2.0 S0009250918301787 MainDocument7 pages1 s2.0 S0009250918301787 MainKaique TozziNo ratings yet

- TCL Regular ExpressionsDocument5 pagesTCL Regular ExpressionsVeeranjaneyulu DhikondaNo ratings yet

- The Millennium Park Bus DepotDocument2 pagesThe Millennium Park Bus DepotSaiRajuNo ratings yet

- Topic 6 - Heating Cooling LoadsDocument66 pagesTopic 6 - Heating Cooling LoadsFahad ChaudharyNo ratings yet

- NOTES The Living World L4 - 2023-MinDocument2 pagesNOTES The Living World L4 - 2023-Minnandukr.8083No ratings yet

- The Cambridge Companion To Ancient Athens 9781108484558 1108484557 - CompressDocument504 pagesThe Cambridge Companion To Ancient Athens 9781108484558 1108484557 - Compresseffie lNo ratings yet

- Regal Christmas 2009Document118 pagesRegal Christmas 2009The Catalogue Stop100% (1)

- Live Soccer Scores and Sports Results - Opera - LiveScoreDocument12 pagesLive Soccer Scores and Sports Results - Opera - LiveScoreChumma Oru idNo ratings yet

- Pak Matiari-Lahore Transmission Company (Private) LimitedDocument4 pagesPak Matiari-Lahore Transmission Company (Private) LimitedAftab Ejaz QureshiNo ratings yet

- Fundamentals SyllabusDocument12 pagesFundamentals SyllabusRoy CabarlesNo ratings yet

- Sporlan Adlse-2Document12 pagesSporlan Adlse-2Serrefriair Garcia RefriNo ratings yet

- Effectiveness of Online Class To The Learning of The Bread and Pastry Production StudentsDocument30 pagesEffectiveness of Online Class To The Learning of The Bread and Pastry Production StudentsChristian Cj SamonteNo ratings yet

- Dfi PaperDocument11 pagesDfi PaperEswara PrasadNo ratings yet

- Red Bull-Case Study (CH 7)Document1 pageRed Bull-Case Study (CH 7)Tooba HussainNo ratings yet

- 2012 Business - Riverview Trial With SolutionsDocument31 pages2012 Business - Riverview Trial With SolutionsArpit KumarNo ratings yet

- Micro Focus Security Arcsight Logger: Configuration and Tuning Best PracticesDocument44 pagesMicro Focus Security Arcsight Logger: Configuration and Tuning Best PracticesBrice TOSSAVINo ratings yet

- BASF Concresive 2525Document3 pagesBASF Concresive 2525budhikurniawanNo ratings yet

- MN09 - Midnight - Fury of Shadow PDFDocument161 pagesMN09 - Midnight - Fury of Shadow PDFAlbert Marques100% (3)

- EngagementDocument7 pagesEngagementanne garciaNo ratings yet

- Is 1745 1978 PDFDocument13 pagesIs 1745 1978 PDFUpendra SubediNo ratings yet

- MDBTL Form 20190131220915 7000000081847160Document1 pageMDBTL Form 20190131220915 7000000081847160mohdwajid2009No ratings yet

- P.E 103 SyllabusDocument3 pagesP.E 103 SyllabusJenard H. AdorioNo ratings yet

- 9 Circuits EbookDocument60 pages9 Circuits EbookSaulius BanysNo ratings yet

- COD (Cystic Ovarian Degenration) PDFDocument6 pagesCOD (Cystic Ovarian Degenration) PDFAbhinav GuptaNo ratings yet

- BREADBOARDING - TinkercadDocument2 pagesBREADBOARDING - TinkercadJustin NievaNo ratings yet

- Atmel Library Components ListDocument6 pagesAtmel Library Components ListAmey KulkarniNo ratings yet

- Module Outline ExampleDocument2 pagesModule Outline ExampleNtibagirimpuhwe cassienNo ratings yet

Lubrificante Interno - Auxiliar de Processamento DataSheet1

Lubrificante Interno - Auxiliar de Processamento DataSheet1

Uploaded by

Kaique TozziOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Lubrificante Interno - Auxiliar de Processamento DataSheet1

Lubrificante Interno - Auxiliar de Processamento DataSheet1

Uploaded by

Kaique TozziCopyright:

Available Formats

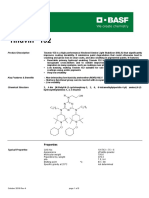

technical data

Mailing Address: Box 77 0855, Woodside, NY 11377

Shipping Address: 58-20 Broadway, Woodside, NY 11377

Tel: 718-672-8300 • Fax: 718-565-7447

E-mail: info@axelplastics.com

MOLD WIZ

INT-33LCA Powder or Pellet (100% Active)

General: A process aid with anti-static properties Use: Processing all Polyethylene, Polypropylene

which is incorporated directly into the resin. Improves including TPO, TPE, TPV & TPU.

resin flow/fill, improves dispersion of other resin additives Also for other resins where improved lubricity of the

(reinforcements, fillers, and pigments), shortens cycle molded part, or reduced coefficient of friction is

times, reduces temperatures and pressures of molding required.

machines, and reduces or eliminates weld/knit lines. Will not interfere with bonding, painting, printing or

Eliminates the need for an external mold release agent. An plating.

effective addition of process aid additive will not have any

adverse effect on physical properties or secondary Each component in this formulation has been

operations such as decorating, printing, bonding, or certified by our raw material suppliers as having

plating. direct USFDA approval for food contact.

Composition: Proprietary synergistic blend of

organic fatty acids, esters and amides.

TYPICAL PROPERTIES:

EFFECTIVE INGREDIENTS: 100%

SOLIDS: 100%

COLOR: Off White

DROPPING POINT: 170-210ºF / 76-99ºC

SHELF LIFE: Minimum of one year

AVAILABILITY: Powder or Pellet form

Application Instructions:

General: For best results, laboratory tests or pre-production trials should determine the optimum addition level.

MoldWiz process aid additives are effective within a range of 1 to 10 parts per 1000 resin excluding reinforcements,

pigments and fillers. A high amount of filler may require a higher percentage of process aid additive than the indicated

maximum. Always start an evaluation at 5 parts per 1000 (0.5%). The additive may increase the MFI. Reduce the level

of additive or reduce the process temperature to raise the resin viscosity and to eliminate screw slippage.

Mixing: Dry blend the process aid additive by tumbling or use an additive dispenser to meter directly into the resin

stream. Process aid additives may be compounded into the resin to make a master-batch.

All information given by us about our products is based upon our tests and experience. It is intended for use by persons having technical skill at their own

discretion and risk, and we assume no liability in connection with their use.

(060404)

You might also like

- Delivery Service Invoice: Rico'S Upholstery Consulting Rico'S Upholstery 1445 Virginia Ave BALDWIN PARK, CA 91706-5820Document2 pagesDelivery Service Invoice: Rico'S Upholstery Consulting Rico'S Upholstery 1445 Virginia Ave BALDWIN PARK, CA 91706-5820Rafael RicoNo ratings yet

- Albaflow: UNI Penetration AccelerantDocument5 pagesAlbaflow: UNI Penetration AccelerantsaskoNo ratings yet

- Pharmaceutics: A Practical Manual for PHARM & PHARM D CoursesFrom EverandPharmaceutics: A Practical Manual for PHARM & PHARM D CoursesRating: 5 out of 5 stars5/5 (2)

- AES Encryption and Decryption in Java - DevGlanDocument1 pageAES Encryption and Decryption in Java - DevGlanგენო მუმლაძეNo ratings yet

- Randstad2040 Structural VisionDocument41 pagesRandstad2040 Structural VisionAna Maria Fernandez MaldonadoNo ratings yet

- Prior Art PAPR Reduction 2012Document49 pagesPrior Art PAPR Reduction 2012Avik ModakNo ratings yet

- Lubrificante Interno - Auxiliar de Processamento DataSheet2Document1 pageLubrificante Interno - Auxiliar de Processamento DataSheet2Kaique TozziNo ratings yet

- PDS Pat Add Le 1019Document2 pagesPDS Pat Add Le 1019Graciele SantosNo ratings yet

- 5040 Plus PDFDocument3 pages5040 Plus PDFForeverNo ratings yet

- 3200258e - TDS - ALBATEX OADocument4 pages3200258e - TDS - ALBATEX OAeric tanudjajaNo ratings yet

- PDS Pat-Add Da 801Document2 pagesPDS Pat-Add Da 801deibi2No ratings yet

- TDS OF H-77 Agriculture Organosilicone AdjuvantDocument3 pagesTDS OF H-77 Agriculture Organosilicone AdjuvantAda FuNo ratings yet

- Cera Matizante Fa-110Document2 pagesCera Matizante Fa-110alfosoa5505No ratings yet

- White Mineral Oil (Textile Oils) Product Data SheetDocument1 pageWhite Mineral Oil (Textile Oils) Product Data SheetMajed DawaNo ratings yet

- Safety Data Sheet Toner - Black, Cyan, Magenta, Yellow: Trade NameDocument8 pagesSafety Data Sheet Toner - Black, Cyan, Magenta, Yellow: Trade NameДмитрий ЧумаковNo ratings yet

- Drew Plus TM 4507 A Foam Control DefoamerDocument2 pagesDrew Plus TM 4507 A Foam Control DefoamerDara PishtazNo ratings yet

- Acrysol Adt-100Document3 pagesAcrysol Adt-100wtwilightwNo ratings yet

- Albatex: AR Reduction InhibitorDocument4 pagesAlbatex: AR Reduction InhibitorsaskoNo ratings yet

- Evo Dot 61 EnglishDocument2 pagesEvo Dot 61 EnglishUtpalNo ratings yet

- Hydrosize® U7-01: Technical Data SheetDocument2 pagesHydrosize® U7-01: Technical Data Sheetcbanegas1983No ratings yet

- Ficha Tecnica NPT QUICK FLASH ADDITIVE M00009Document1 pageFicha Tecnica NPT QUICK FLASH ADDITIVE M00009Stéphanie BaltazarNo ratings yet

- 837 PDFDocument1 page837 PDFAndra PutraNo ratings yet

- TDS - Tergito HXDocument2 pagesTDS - Tergito HXmyunggooNo ratings yet

- LAWA007Document3 pagesLAWA007Fadilla AzhariNo ratings yet

- Albaflow: JET Penetration AccelerantDocument5 pagesAlbaflow: JET Penetration AccelerantGokhan RamiNo ratings yet

- N.T-Clear-DL100 (TDS)Document2 pagesN.T-Clear-DL100 (TDS)MahdiNo ratings yet

- Performance Coatings Product Data Sheet Lubrijet™ T340 Acrylic EmulsionDocument3 pagesPerformance Coatings Product Data Sheet Lubrijet™ T340 Acrylic EmulsionPedro Duplaa Soares FerreiraNo ratings yet

- Bioadimide 100 en RCRDocument2 pagesBioadimide 100 en RCRChanakyaNo ratings yet

- Rheofinish 302: High Performance Chemical and Physical Mould Release AgentsDocument1 pageRheofinish 302: High Performance Chemical and Physical Mould Release AgentsFrancois-No ratings yet

- Tai County Silicones CO., LTD. Ms-730Hv Softener: Description ApplicationsDocument1 pageTai County Silicones CO., LTD. Ms-730Hv Softener: Description ApplicationsMark WuNo ratings yet

- TDS - 57006 AddNox Anti Block MBDocument1 pageTDS - 57006 AddNox Anti Block MBRajiv DubeyNo ratings yet

- ELASTENE 1500 DCM-APR TDS en Final - 1501Document2 pagesELASTENE 1500 DCM-APR TDS en Final - 1501rogerkid17No ratings yet

- TD AGITAN 170 EN Ee22a56aabDocument1 pageTD AGITAN 170 EN Ee22a56aabMahmoud FlefilNo ratings yet

- Compound Ferric Green: Technical DataDocument1 pageCompound Ferric Green: Technical DatahuynhtrantriNo ratings yet

- Ultratex UHS Hydrophilic Softener: Technical Data SheetDocument5 pagesUltratex UHS Hydrophilic Softener: Technical Data SheetSon NguyenNo ratings yet

- 56food Superla White OilsDocument2 pages56food Superla White OilsDavid PomaNo ratings yet

- Attagel 50 January 2018 R5 ED2Document2 pagesAttagel 50 January 2018 R5 ED2APEX SONNo ratings yet

- Glucamate DOE-120 PDS PDFDocument4 pagesGlucamate DOE-120 PDS PDFRobyn BrownNo ratings yet

- Ceridust 5551 - For Lively Colors.: Exactly Your ChemistryDocument2 pagesCeridust 5551 - For Lively Colors.: Exactly Your ChemistryMaximiliano MackeviciusNo ratings yet

- Stepan Formulation 1220Document2 pagesStepan Formulation 1220Devesh KumarNo ratings yet

- Dowsil 51 AdditiveDocument5 pagesDowsil 51 AdditiveYến HoàngNo ratings yet

- Tinuvin 152 October 2019 R4 ICDocument3 pagesTinuvin 152 October 2019 R4 ICEmilio HipolaNo ratings yet

- 27 3520 01 Ecosense GL 60 HL SurfactantDocument3 pages27 3520 01 Ecosense GL 60 HL SurfactantKishore Gowda A SNo ratings yet

- White Vaseline Pds DK en 123027Document2 pagesWhite Vaseline Pds DK en 123027Julia TsoiNo ratings yet

- Stepan Formulation 995Document2 pagesStepan Formulation 995120984No ratings yet

- Stepan Formulation 1272Document2 pagesStepan Formulation 1272Mohamed AdelNo ratings yet

- Thaiol 1698 PDFDocument1 pageThaiol 1698 PDFJorge TorresNo ratings yet

- Epoxy Primer216Document2 pagesEpoxy Primer216kishortilekarNo ratings yet

- DOWSIL™ Q2-3238 Dispersible Silicone Additive: Features & BenefitsDocument2 pagesDOWSIL™ Q2-3238 Dispersible Silicone Additive: Features & BenefitsZhan FangNo ratings yet

- Technical Information: Wetting Agent For Aqueous SystemsDocument1 pageTechnical Information: Wetting Agent For Aqueous SystemsLong An ĐỗNo ratings yet

- Product Data Sheet: High Performance Cutting OilDocument1 pageProduct Data Sheet: High Performance Cutting OilSadid Shahzad100% (1)

- Wannate Mdi-100 en V5Document3 pagesWannate Mdi-100 en V5fuenmayor.lilibethNo ratings yet

- Tds Supermend Epoxy EnglishDocument4 pagesTds Supermend Epoxy EnglishNiklas LuwamNo ratings yet

- Bentone 38 - TDS - eDocument2 pagesBentone 38 - TDS - eDũng ĐỗNo ratings yet

- TDS Anti-Terra-204 enDocument4 pagesTDS Anti-Terra-204 enChemtools ChemtoolsNo ratings yet

- 3M™ Super 77™ Multipurpose Spray Adhesive (Aerosol) - 20221111Document4 pages3M™ Super 77™ Multipurpose Spray Adhesive (Aerosol) - 20221111HugoNo ratings yet

- Technical Information: Gecko Frontal UniDocument3 pagesTechnical Information: Gecko Frontal UniAtmaja SuryadiNo ratings yet

- Product Data Sheet: GeneralDocument1 pageProduct Data Sheet: Generalsriatul2006100% (1)

- PRIMAL™ AC-365 Acrylic Emulsion: Regional Product Availability DescriptionDocument3 pagesPRIMAL™ AC-365 Acrylic Emulsion: Regional Product Availability DescriptionLong An ĐỗNo ratings yet

- FILE - 20210525 - 094757 - Defom 5800F - TDS - EDocument2 pagesFILE - 20210525 - 094757 - Defom 5800F - TDS - Elee nguyenNo ratings yet

- Afe 2017 Xiameter-Afe-3168-Antifoam-EmulsDocument2 pagesAfe 2017 Xiameter-Afe-3168-Antifoam-EmulsZhan FangNo ratings yet

- Honeywell AC 316 TDSDocument1 pageHoneywell AC 316 TDSFine OrganicNo ratings yet

- Chemical Process Simplification: Improving Productivity and SustainabilityFrom EverandChemical Process Simplification: Improving Productivity and SustainabilityNo ratings yet

- Lubrificante Interno - Auxiliar de Processamento DataSheet2Document1 pageLubrificante Interno - Auxiliar de Processamento DataSheet2Kaique TozziNo ratings yet

- An Overview of Degradable and Biodegradable Polyolefins 2011Document35 pagesAn Overview of Degradable and Biodegradable Polyolefins 2011Kaique TozziNo ratings yet

- Eva ComsbrDocument9 pagesEva ComsbrKaique TozziNo ratings yet

- Mjalli 2017Document22 pagesMjalli 2017Kaique TozziNo ratings yet

- 10 1016@j Molliq 2018 04 113Document28 pages10 1016@j Molliq 2018 04 113Kaique TozziNo ratings yet

- 1 s2.0 S0167732217349449 MainDocument9 pages1 s2.0 S0167732217349449 MainKaique TozziNo ratings yet

- Barycki 2016Document9 pagesBarycki 2016Kaique TozziNo ratings yet

- Yang 2017Document39 pagesYang 2017Kaique TozziNo ratings yet

- 1 s2.0 S0009250918301787 MainDocument7 pages1 s2.0 S0009250918301787 MainKaique TozziNo ratings yet

- TCL Regular ExpressionsDocument5 pagesTCL Regular ExpressionsVeeranjaneyulu DhikondaNo ratings yet

- The Millennium Park Bus DepotDocument2 pagesThe Millennium Park Bus DepotSaiRajuNo ratings yet

- Topic 6 - Heating Cooling LoadsDocument66 pagesTopic 6 - Heating Cooling LoadsFahad ChaudharyNo ratings yet

- NOTES The Living World L4 - 2023-MinDocument2 pagesNOTES The Living World L4 - 2023-Minnandukr.8083No ratings yet

- The Cambridge Companion To Ancient Athens 9781108484558 1108484557 - CompressDocument504 pagesThe Cambridge Companion To Ancient Athens 9781108484558 1108484557 - Compresseffie lNo ratings yet

- Regal Christmas 2009Document118 pagesRegal Christmas 2009The Catalogue Stop100% (1)

- Live Soccer Scores and Sports Results - Opera - LiveScoreDocument12 pagesLive Soccer Scores and Sports Results - Opera - LiveScoreChumma Oru idNo ratings yet

- Pak Matiari-Lahore Transmission Company (Private) LimitedDocument4 pagesPak Matiari-Lahore Transmission Company (Private) LimitedAftab Ejaz QureshiNo ratings yet

- Fundamentals SyllabusDocument12 pagesFundamentals SyllabusRoy CabarlesNo ratings yet

- Sporlan Adlse-2Document12 pagesSporlan Adlse-2Serrefriair Garcia RefriNo ratings yet

- Effectiveness of Online Class To The Learning of The Bread and Pastry Production StudentsDocument30 pagesEffectiveness of Online Class To The Learning of The Bread and Pastry Production StudentsChristian Cj SamonteNo ratings yet

- Dfi PaperDocument11 pagesDfi PaperEswara PrasadNo ratings yet

- Red Bull-Case Study (CH 7)Document1 pageRed Bull-Case Study (CH 7)Tooba HussainNo ratings yet

- 2012 Business - Riverview Trial With SolutionsDocument31 pages2012 Business - Riverview Trial With SolutionsArpit KumarNo ratings yet

- Micro Focus Security Arcsight Logger: Configuration and Tuning Best PracticesDocument44 pagesMicro Focus Security Arcsight Logger: Configuration and Tuning Best PracticesBrice TOSSAVINo ratings yet

- BASF Concresive 2525Document3 pagesBASF Concresive 2525budhikurniawanNo ratings yet

- MN09 - Midnight - Fury of Shadow PDFDocument161 pagesMN09 - Midnight - Fury of Shadow PDFAlbert Marques100% (3)

- EngagementDocument7 pagesEngagementanne garciaNo ratings yet

- Is 1745 1978 PDFDocument13 pagesIs 1745 1978 PDFUpendra SubediNo ratings yet

- MDBTL Form 20190131220915 7000000081847160Document1 pageMDBTL Form 20190131220915 7000000081847160mohdwajid2009No ratings yet

- P.E 103 SyllabusDocument3 pagesP.E 103 SyllabusJenard H. AdorioNo ratings yet

- 9 Circuits EbookDocument60 pages9 Circuits EbookSaulius BanysNo ratings yet

- COD (Cystic Ovarian Degenration) PDFDocument6 pagesCOD (Cystic Ovarian Degenration) PDFAbhinav GuptaNo ratings yet

- BREADBOARDING - TinkercadDocument2 pagesBREADBOARDING - TinkercadJustin NievaNo ratings yet

- Atmel Library Components ListDocument6 pagesAtmel Library Components ListAmey KulkarniNo ratings yet

- Module Outline ExampleDocument2 pagesModule Outline ExampleNtibagirimpuhwe cassienNo ratings yet