Professional Documents

Culture Documents

MN Blending 2020 Final

Uploaded by

Mihaly JOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MN Blending 2020 Final

Uploaded by

Mihaly JCopyright:

Available Formats

MicroNIR®

Learning Series

MicroNIR for tumble blending

monitoring

Emiliano Genorini and Cristina Malegori

GoToWebinar - April, 30th 2020

viavisolutions.com © 2020 VIAVI Solutions Inc. 1

MicroNIR Learning Series

Schedule of Events

16-Apr-2020 4PM-5PM CET Pharma raw material identification

23-Apr-2020 4PM-5PM CET Granulation and drying monitoring

30-Apr-2020 4PM-5PM CET Tumble blender monitoring

07-May-2020 4PM-5PM CET Tablet compression monitoring

14-May-2020 4PM-5PM CET PAT-Ux and PAT-Wx for hazardous locations

viavisolutions.com © 2020 VIAVI Solutions Inc. 2

MicroNIR Learning Series

Today’s Agenda

Welcome and company profile Emiliano Genorini and Cristina Malegori

LVF technology Emiliano Genorini

MicroNIR product line Emiliano Genorini

Tumble Blender Monitoring Emiliano Genorini

MBSD (Moving Block Standard

Cristina Malegori

Deviation)

Hands on Cristina Malegori

Q&A Emiliano Genorini and Cristina Malegori

viavisolutions.com © 2020 VIAVI Solutions Inc. 3

MicroNIR Learning Series

Today’s presenters

Emiliano Genorini Cristina Malegori

MicroNIR account manager MicroNIR field application specialist

EMEA and LATAM cristina.malegori@viavisolutions.com

emiliano.genorini@viavisolutions.com

viavisolutions.com © 2020 VIAVI Solutions Inc. 4

VIAVI Solutions

Company Profile

viavisolutions.com © 2020 VIAVI Solutions Inc. 5

VIAVI Solutions

Company Profile

viavisolutions.com © 2020 VIAVI Solutions Inc. 6

VIAVI Solutions

Company Profile, OSP Business Unit Timeline

viavisolutions.com © 2020 VIAVI Solutions Inc. 7

VIAVI Solutions

Company Profile, OSP Market Segments

Consumer Electronics Government & Aerospace Anti-Counterfeiting

Automotive Spectral Sensing

viavisolutions.com © 2020 VIAVI Solutions Inc. 8

VIAVI Solutions

Company Profile, OSP Santa Rosa

Operations and Leadership

Research and Development Teams

Sales and Marketing Teams

viavisolutions.com © 2020 VIAVI Solutions Inc. 9

MicroNIR Vision

viavisolutions.com © 2020 VIAVI Solutions Inc. 10

MicroNIR Vision

Evolution

viavisolutions.com © 2020 VIAVI Solutions Inc. 11

MicroNIR Vision

Smarter World

Miniaturization

Connectivity

Affordability

Enabling

a Smarter

World

Performance

viavisolutions.com © 2020 VIAVI Solutions Inc. 12

MicroNIR

Technology

viavisolutions.com © 2020 VIAVI Solutions Inc. 13

MicroNIR Technology

LVF (Linear Variable Filter)

• LVF is one dimensional continuously varying bandpass filter

• Filter is fabricated on glass using hard, dense, and stable

inorganic materials for long life and environmental stability

• Enables a spectrometer that is compact, lightweight, robust,

and has no moving parts or free space optics

• VIAVI LVF was developed for

NASA → OSIRIS-REx mission

to Bennu flies a VIAVI LVF-based

spectrometer

viavisolutions.com © 2020 VIAVI Solutions Inc. 14

MicroNIR LVF Technology

Advantages

• Small size enables unique applications

• Lamps rated for >40,000 hr lifetime @ < 1 W

• No need of laser

• No moving parts or free-space optics:

- No misalignment

- Long-term stability

- 100% transferability between units

• No fiber optics:

- Nothing to damage or wear out

- Insensitive to temperature variation

viavisolutions.com © 2020 VIAVI Solutions Inc. 15

MicroNIR

Product Line

viavisolutions.com © 2020 VIAVI Solutions Inc. 16

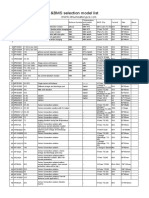

MicroNIR Product Line

Overview

Instruments Accessories Software

• Compact & lightweight • Wide variety of accessories to • Full chemometric package

− Miniature but full function support diverse applications − Everything needed to build a

• Robust, reliable, repeatable • Enable NIRS analysis of all complete solution with MicroNIR

types of media instruments and accessories

− Minimal unit-to-unit variation

− Powders, liquids, bulk solids, − Expandable with plug-ins to

simplifies scale-up

live plants, produce, grains, Unscrambler, SIMCA and SOLO

− All instruments share optical polymers, etc. • Fully GMX compliant for

engines for model transfer

• Support rigorous sampling regulated environments

• Models and accessories for methods − 21CFRPart11

diverse applications

− high-performance and − USP 1119 or EP 2.2.40

• OEM versions available repeatable models

viavisolutions.com © 2020 VIAVI Solutions Inc. 17

MicroNIR Product Line

Products, 1700ES

• Compact spectrometer engine for

universities, or OEM customers

• USB connection for power and data

• Functionally similar to all other MicroNIR

instruments

viavisolutions.com © 2020 VIAVI Solutions Inc. 18

MicroNIR Product Line

Products, IP65 and IP67

OnSite-W PAT-U and PAT-W

• Handheld, wireless model for field, at- • Rugged process monitoring

line, and material identification instruments for factory applications

applications • IP65 and IP67 rated

• Bluetooth or USB connectivity to tablet • PAT-W:

or PC or mobile − Wireless and Ethernet connection

• Internal, rechargeable battery with − Rechargeable Li-ion battery with > 8 hours

continuous run time > than 10 hours of continuous run time

− Multi-axis sensor for positional triggering

• IP65 and IP67 rated for use in wet and in tumble blender

dusty environments − Multiple trigger options

viavisolutions.com © 2020 VIAVI Solutions Inc. 19

MicroNIR Product Line

Products, HazLoc

PAT-Ux

PAT-Wx

viavisolutions.com © 2020 VIAVI Solutions Inc. 20

Process Analytical

Technology

viavisolutions.com © 2020 VIAVI Solutions Inc. 21

Process Analytical Technology

Introduction

“…a system for designing, analyzing, and controlling manufacturing through

timely measurements (i.e., during processing) of critical quality and

performance attributes of raw and in-process materials and processes, with

the goal of ensuring final product quality…”

Process Analytical Technology (PAT) in Pharmaceutical Development:

http://www.americanpharmaceuticalreview.com/Featured-Articles/115453-Process-Analytical-Technology-

PAT-in-Pharmaceutical-Development

“Quality cannot be tested into products; it should be built-in or should be by

design”

Process Analytical Technology (PAT):

https://www.fda.gov/aboutfda/centersoffices/officeofmedicalproductsandtobacco/cder/ucm088828.htm

viavisolutions.com © 2020 VIAVI Solutions Inc. 22

Process Analytical Technology

Introduction

viavisolutions.com © 2020 VIAVI Solutions Inc. 23

Process Analytical Technology

Introduction

Traditional Approach PAT Approach

• The process is developed, frozen and • Real time On-Line and In-Line

validated using 3 commercial batches analysis

• Process safeguarding with SOPs, • Process understanding and

training, etc continuous process verification

• Subsequent quality control via off- • Process control and regulation based on

line investigation in the laboratory statistics

• Multivariate analysis for understanding

complex relationships

Process is understood and

Process is a black box continuously managed

viavisolutions.com © 2020 VIAVI Solutions Inc. 24

Process Analytical Technology

QbT (Quality by Test) vs Quality by Design (QbD), Cost of Quality

viavisolutions.com © 2020 VIAVI Solutions Inc. 25

Process Analytical Technology

Where does NIR fit in pharma process?

viavisolutions.com © 2020 VIAVI Solutions Inc. 26

Tumble Blender

Monitoring

viavisolutions.com © 2020 VIAVI Solutions Inc. 27

Tumble Blender

Why is it important?

• The tablet development and manufacturing process

and focus on the critical role that blending plays

in making a quality tablet

• The blending phase it is critical for the distribute

homogenously the APIs and excipients

• A tablet might need to be quick to dissolve in your

body, but it also must not break up in its packaging

viavisolutions.com © 2020 VIAVI Solutions Inc. 28

Tumble Blender

Status of Art, Sampling

• Blend uniformity testing in the pharmaceutical industry is

traditionally carried out by stopping the blender after a

given time, commonly defined by existing procedures

• The operator then withdraws 10 samples at predefined

locations specified by the current ICH guidelines.

• Samples are then analyzed offline in the QC/QA laboratory

by means of HPLC, UV-Vis, etc

viavisolutions.com © 2020 VIAVI Solutions Inc. 29

Tumble Blender

Status of Art, Sampling

• Continuous monitoring is not thereby possible

• Laboratory characterization is labor intensive and

time-consuming

• Operator exposure to API and solvents may require

extra safety measures

• The blend is exposed to the environment

viavisolutions.com © 2020 VIAVI Solutions Inc. 30

Tumble Blender

Status of Art, Sampling

• Sampling errors 10-50 times Sample thieves de-mix

powder beds resulting in

greater than analytical errors! heterogeneity increase

• Non-reproducible, therefore cannot

be corrected for statistically

• QbD requires isolation of the greatest

source of variability (sample thief)

viavisolutions.com © 2020 VIAVI Solutions Inc. 31

Tumble Blender

PAT-W in action

viavisolutions.com © 2020 VIAVI Solutions Inc. 32

Tumble Blender

Experiment Set Up

• Delay time sets the waiting time after

the accelerometer has reached an

active scanning position

• G1-G3 Parameters are settings of the

gravity switch and are usually kept at

the default settings for most applications

viavisolutions.com © 2020 VIAVI Solutions Inc. 33

Tumble Blender

Where and why it is important?

Formulation Lab Production

• No sampling required • No sampling required

• Real time feedback • Real time feedback

• Optimize blending time • Continous manufacturing

• Reduce QC laboratory effort • Process validation (only 3 batches

plus 1 at a predefined time) vs.

• QbD vs QbT continous process verification (all

• Define process experimental domain batches)

• See batch to batch reproducibility

• Scale up from R&D to production

• Completely integrated in blending HMI

• Reduce QC laboratory effort

viavisolutions.com © 2020 VIAVI Solutions Inc. 34

Tumble Blender

Which critical attributes coudl influence the blending?

• Rotation Time

• API concentration

• Excipients

• Particle Size

• Blender Capacity

• Rotation Rate

• Fill level

• Loading Method

viavisolutions.com © 2020 VIAVI Solutions Inc. 35

Tumble Blender

Effects of Critical Attributes on Blending Profile

0.1 0.1

0.09 0.09

0.08 0.08

0.07 0.07

0.06 0.06

0.05 0.05 60% Filll

0.04 5 Liter Bin 0.04 75% Filll

10 Liter Bin 90% Filll

0.03 0.03

40 Liter Bin

0.02 0.02

0.01 0.01

0 0

0 5 10 15 20 25 30 35 40 0 10 20 30 40 50 60 70 80

0.1

Rotation Number

0.1 0.09

0.09 0.08

0.08 0.07

0.07

0.06

0.06

0.05

0.05 15 rpm

0.04 Active Layered - Centered

0.04 25 rpm

32 rpm 0.03 Active Spot - Off Center

0.03

0.02

0.02

0.01

0.01

0 0

0 5 10 15 20 25 30 35 40 0 5 10 15 20 25 30 35 40

Rotation Number Rotation Number

viavisolutions.com © 2020 VIAVI Solutions Inc. 36

Tumble Blender

How validate NIR results?

• Taking a sample from the blender is not recommended (Esbensen)

• NIR is a measurement of API and excipient, HPLC a measurement of API

- Therefore, comparing HPLC and NIR is not a good approach

• MBSD (Moving Block Standard Deviation) and PCA (Principal Component Analysis)

are unsupervised methods and require validation method to define threshold:

- Option A → compare multiple blending profiles and observe the coherence

- Option B → measure tablets and check homogeneity

• Option B → QC must take 10 tablets every hour during compression:

- Assess the first three by reference method; these are 100% statistically representative

- If the first three meet potency and variance criteria, the process is validated

- Otherwise, further testing must be done.

viavisolutions.com © 2020 VIAVI Solutions Inc. 37

Tumble Blender

API+Lactose, Orginal Spectra

viavisolutions.com © 2020 VIAVI Solutions Inc. 38

Tumble Blender

API+Lactose, Pretreated Spctra (1der+SNV)

viavisolutions.com © 2020 VIAVI Solutions Inc. 39

Tumble Blender

API+Lactose, MBSD (Moving Block Standard Deviation)

%RSD

Mixing phase End Point

Block (Rotations + 20)

viavisolutions.com © 2020 VIAVI Solutions Inc. 40

Tumble Blender

API+Lactose, MBSD (Moving Block Standard Deviation)

After 300 rotations all the three

%RSD

All the three blendings are

showing a frist minumum blndeings are showing better

around 200 rotation stable %RSD

viavisolutions.com © 2020 VIAVI Solutions Inc. 41

Tumble Blender

API+Lactose, PCA Loadings

• In this plot are shown the PC1 and PC2 of the first blending

normalized vs the 1 derivative spectra of Lactose and API

• Lactose has a profile similarto PC1 (indipendently from sign)

• API has profile simialr to PC2 (indipendently from sign)

• Similar consideration can be taken using blending 2 and 3

▪ PC1

▪ PC2

▪ Lactose

▪ API

viavisolutions.com © 2020 VIAVI Solutions Inc. 42

Tumble Blender

API+Lactose, PCA (Principal Component Analysis)

API effect on blending

Lactose effect on blending

End point

viavisolutions.com © 2020 VIAVI Solutions Inc. 43

Tumble Blender

API 0.1%, Pretreated Spectra + Spiked PLS

Region where API changes is related to the

linearity of the model

viavisolutions.com © 2020 VIAVI Solutions Inc. 44

Tumble Blender

API 0.1%, PCA Score Plot

Placebo blending

direction

Active batch blending direction

Active blending direction

specific to absorbance at

1131 nm

Absorbance specific to active

in PC2 direction

viavisolutions.com © 2020 VIAVI Solutions Inc. 45

Tumble Blender

API 0.1%, PCA Projections

viavisolutions.com © 2020 VIAVI Solutions Inc. 46

Experiment Set Up

viavisolutions.com © 2020 VIAVI Solutions Inc. 47

MicroNIR PAT-W

Experiment Set Up

MicroNIR Pro Software 3.1

version

viavisolutions.com © 2020 VIAVI Solutions Inc. 48

Case Study

Blending monitoring

AIM of the WORK =

API following of the

blending process

Lactose

1. ON-LINE MONITORING

The process can be followed with both the MB approach and the PCA projection

→ Today we will focus on the MB approach

2. END POINT DETERMINATION

The end-point, the moment in which the mixture is as more homogeneous as possible, can

be defined and set as process threshold for further blendings.

viavisolutions.com © 2020 VIAVI Solutions Inc. 49

MBM - Moving Block Method

The approach

• Moving Block Standard Deviation (MBSD): it is a sensible assessment of uniformity

(less heterogeneity); it is the suitable approach for detect small variations along the

process.

• Moving Block Mean (MBM): it is a robust assessment of uniformity (less

heterogeneity); it is the suitable approach for complex mixtures (number of

ingredients/particle size)

• % Relative Standard Deviation (%RSD): it is the percentage ratio of MBSD/MBM for

a single block. It allows the relative variability of the block to its mean. Can be used to

detect process faults.

→ The progression of the blending leads to MB charts showing a plateau when the

endpoint has been reached.

This endpoint must be validated using external information!

viavisolutions.com © 2020 VIAVI Solutions Inc. 50

MBM - Moving Block Method

The algorithm

• The number of spectra to be included in the

block must be predefined by the analyst to

provide enough information about both macro

and micro changes within the evolving

process.

• The block is moving, like a boxcar, along the

profile, discharging the first spectrum in the

block after the acquisition of a new one.

• For each acquisition, a new block is defined,

and the statistical parameters are calculated.

viavisolutions.com © 2020 VIAVI Solutions Inc. 51

MBM – The F test

The help of statistics in defining the threshold

• The end-point detection is based

𝑣𝑎𝑟𝑖𝑎𝑛𝑐𝑒 (𝐵1) on Fischer F-Test

𝐹𝑐𝑎𝑙 =

𝑣𝑎𝑟𝑖𝑎𝑛𝑐𝑒 (𝐵2)

• The calculation is performed on

independent block of spectra

• Also in this case, a validation of

the limit is required; the F test is

intended to be a help and not a

rule.

viavisolutions.com © 2020 VIAVI Solutions Inc. 52

MBM – Moving Block method

Advanced strategies

• The MB method (MBSD, MBM and RSD%)

can be performed on one or multiple

selected regions of the spectra, with the aim

of focusing on the absorption band of specific

ingredients.

• The MB method (MBSD, MBM and RSD%)

can be performed on PC profiles, after

using PCA as compression method.

viavisolutions.com © 2020 VIAVI Solutions Inc. 53

Hands On

viavisolutions.com © 2020 VIAVI Solutions Inc. 54

Q&A

viavisolutions.com © 2020 VIAVI Solutions Inc. 55

Q&A

MicroNIR Team for you

Visit VIAVI MicroNIR Spectrometer website

Feel free to contact us at MicroNIR@viavisolutions.com

Thank you for attending MicroNIR Webinar

Presentation and recording will be sent tomorrow

viavisolutions.com © 2020 VIAVI Solutions Inc. 56

viavisolutions.com

You might also like

- SmartCare Strategy Roadmap PDFDocument31 pagesSmartCare Strategy Roadmap PDFuxunNo ratings yet

- ATS Offline Offline - Q-Doc - PCT - EGIS - R&D - S100008500Document9 pagesATS Offline Offline - Q-Doc - PCT - EGIS - R&D - S100008500Mihaly JNo ratings yet

- KritiLabs Intro PDFDocument10 pagesKritiLabs Intro PDFVelur Ranganathan GanapathyNo ratings yet

- LLT PCB Model List ADocument2 pagesLLT PCB Model List AÁlvaro Satué Crespo100% (1)

- Ip 501 PDFDocument10 pagesIp 501 PDFAmir HamzahNo ratings yet

- MN - RMID - 2020 FinalDocument39 pagesMN - RMID - 2020 FinalMihaly JNo ratings yet

- UBNT Overview - v2Document11 pagesUBNT Overview - v2Ravindra Sagar SugoorNo ratings yet

- UC Product Catalog Y2024Document52 pagesUC Product Catalog Y2024Takumina ServicesNo ratings yet

- Siemens Simatic WinccDocument8 pagesSiemens Simatic WincchennrynsNo ratings yet

- Simatic Wincc: Answers For IndustryDocument8 pagesSimatic Wincc: Answers For IndustryAlina MirelaNo ratings yet

- Simatic Wincc: The Scalable and Open SCADA System For Maximum Plant Transparency and ProductivityDocument8 pagesSimatic Wincc: The Scalable and Open SCADA System For Maximum Plant Transparency and ProductivityDrakeNo ratings yet

- Industry 4.0 - Class 5 & 6 - Group 7Document8 pagesIndustry 4.0 - Class 5 & 6 - Group 7SWETHA LAGISETTINo ratings yet

- Ivideon Bridge: A Device For Transforming Traditional Video Surveillance Systems Into Cloud SystemsDocument15 pagesIvideon Bridge: A Device For Transforming Traditional Video Surveillance Systems Into Cloud SystemsJohn SmithNo ratings yet

- Huawei Cyber Security Strategy and ApproachDocument20 pagesHuawei Cyber Security Strategy and ApproachValcoNo ratings yet

- Affordable Automation For MSME Sector - WiproDocument19 pagesAffordable Automation For MSME Sector - WiprovenkateshNo ratings yet

- Sensors For Wearable Electronics & Mobile Healthcare: June © 2015Document43 pagesSensors For Wearable Electronics & Mobile Healthcare: June © 2015jesus llumpoNo ratings yet

- SG Pharma ENA4Document32 pagesSG Pharma ENA4Kojovici Mihai ValentinNo ratings yet

- Cisco SD-WAN: Introduction and Technical Deep DiveDocument61 pagesCisco SD-WAN: Introduction and Technical Deep DiveshubhamNo ratings yet

- Machine Design - March 2019 PDFDocument85 pagesMachine Design - March 2019 PDFPrasad AdigaNo ratings yet

- Access Control Systems1Document11 pagesAccess Control Systems1Justus CyrilNo ratings yet

- Retail Brochure Revise 2Document10 pagesRetail Brochure Revise 2ag1982agNo ratings yet

- Digital Transformation WebinarDocument12 pagesDigital Transformation WebinarDen NisNo ratings yet

- CPG & FMCG: WWW - Senseye.ioDocument2 pagesCPG & FMCG: WWW - Senseye.iomvrmurtyNo ratings yet

- Catálogo BalluffDocument136 pagesCatálogo Balluffaluno.lucas.correaNo ratings yet

- Pitch WiztricDocument16 pagesPitch WiztricjslgreenhomesNo ratings yet

- 2019 - Introduction To Ipaccess MNO Aug 2019 v1.0Document29 pages2019 - Introduction To Ipaccess MNO Aug 2019 v1.0Zeeshan SiddiqueNo ratings yet

- Estimating The Cost of Cyber Projects-Identifying The Key Cost Drivers For Cyber HygieneDocument33 pagesEstimating The Cost of Cyber Projects-Identifying The Key Cost Drivers For Cyber Hygieneعلي الاسمريNo ratings yet

- BHCS39504 MViQ+ Brochure - R7Document12 pagesBHCS39504 MViQ+ Brochure - R7siienergia.uniNo ratings yet

- WiproDocument8 pagesWiproSomesh GoelNo ratings yet

- Wisys Innovations: Company ProfileDocument10 pagesWisys Innovations: Company ProfileBabu SumanNo ratings yet

- Small Servo Drive System enDocument72 pagesSmall Servo Drive System enGary ChanNo ratings yet

- IMI-Case StudyDocument7 pagesIMI-Case Studyfazela shaukatNo ratings yet

- EntrepriseDocument16 pagesEntrepriseIdir BenferhatNo ratings yet

- Industry 4.0 Catalog - India Informative Event - January 2022Document7 pagesIndustry 4.0 Catalog - India Informative Event - January 2022Known FriendNo ratings yet

- Wireless Operations Ind Network WPDocument24 pagesWireless Operations Ind Network WPkia haniNo ratings yet

- AP01 - Spectrum Controls Practical Applications For OEMs - Secure Remote Connectivity To Machines ROKTechED 2016Document24 pagesAP01 - Spectrum Controls Practical Applications For OEMs - Secure Remote Connectivity To Machines ROKTechED 2016Dany MecNo ratings yet

- CCTV CataloqueDocument48 pagesCCTV CataloquesujiNo ratings yet

- Vanshita Kedia Megvii Research Report RemovedDocument21 pagesVanshita Kedia Megvii Research Report Removedsunnykumar.m2325No ratings yet

- PcVue Solutions 2018 enDocument40 pagesPcVue Solutions 2018 enAct SriNo ratings yet

- Lesson 07 - ByOD and BeyondDocument33 pagesLesson 07 - ByOD and BeyondZ OureelNo ratings yet

- Company and Product Profile 2019 No QRDocument28 pagesCompany and Product Profile 2019 No QRaeaccorp1224No ratings yet

- Sigfox Introduction - Construction PPDocument15 pagesSigfox Introduction - Construction PPStratek DVNo ratings yet

- ReedTech - Prepare Now For EUDAMED - UDIDocument70 pagesReedTech - Prepare Now For EUDAMED - UDIВлад КасьяненкоNo ratings yet

- Eigen Innovations: Revolutionizing Industrial Technology: by Manish SadhuDocument8 pagesEigen Innovations: Revolutionizing Industrial Technology: by Manish SadhuManish SadhuNo ratings yet

- Swissbit WORM SD CardDocument48 pagesSwissbit WORM SD CardLaurentiu M.No ratings yet

- Cyber Security in The Power SectorDocument10 pagesCyber Security in The Power Sectorrajdeep aroraNo ratings yet

- $licensing! Find The Right Solution That Meets Your Budget With WonderwareDocument40 pages$licensing! Find The Right Solution That Meets Your Budget With Wonderwarefahim47No ratings yet

- Villari Introduction MAR-2021Document13 pagesVillari Introduction MAR-2021BosNo ratings yet

- CCTV Report MCMCDocument36 pagesCCTV Report MCMCMuhammad Syamim KamsolNo ratings yet

- AB - Cube Vigilance Software SolutionsDocument2 pagesAB - Cube Vigilance Software SolutionsKumar KumarNo ratings yet

- Financial Project On Microtek (1) 2Document65 pagesFinancial Project On Microtek (1) 2Rohit Chanana0% (1)

- Automation Fair 2018 - F05 - Material Handling ForumDocument12 pagesAutomation Fair 2018 - F05 - Material Handling ForumangelpadronaNo ratings yet

- Freedom DICOM Print ServerDocument4 pagesFreedom DICOM Print ServerVivek MehrotraNo ratings yet

- Neurotechnology Brochure 2023-10-26 EnglishDocument48 pagesNeurotechnology Brochure 2023-10-26 EnglishAung Kyaw HtoonNo ratings yet

- VYVO Token WhitepaperDocument8 pagesVYVO Token WhitepaperSteven SengNo ratings yet

- Industry 4.0 For You: © 2016-2019 Autobits Labs PVT Ltd. All Rights ReservedDocument5 pagesIndustry 4.0 For You: © 2016-2019 Autobits Labs PVT Ltd. All Rights ReservedwasimNo ratings yet

- The Meraki Platform: A Solid Foundation That Helps Your Business ThriveDocument66 pagesThe Meraki Platform: A Solid Foundation That Helps Your Business ThriveSon Phan100% (1)

- Four-Faith IoT Product Catalog 2023 - BPTDocument30 pagesFour-Faith IoT Product Catalog 2023 - BPTpatricksabaNo ratings yet

- Maxw GS 2020R2 en Le01Document63 pagesMaxw GS 2020R2 en Le01Asad ShahbazNo ratings yet

- Computer Vision in Manufacturing 0920Document8 pagesComputer Vision in Manufacturing 0920alexverde3No ratings yet

- Touching N Ntelligent World: MethodologyDocument6 pagesTouching N Ntelligent World: MethodologyLearn ON-Line CoursesNo ratings yet

- General Brochure 2021Document14 pagesGeneral Brochure 2021Ivan Rudolf De FretesNo ratings yet

- AN-nir065Document4 pagesAN-nir065Mihaly JNo ratings yet

- Barreiro 2008Document6 pagesBarreiro 2008Mihaly JNo ratings yet

- ATS UV-VIS On - Offline - Q-Doc - PCT - EGIS - R&D - S100010363Document9 pagesATS UV-VIS On - Offline - Q-Doc - PCT - EGIS - R&D - S100010363Mihaly JNo ratings yet

- Guide - NIR - Calibration Best Practice - GBDocument19 pagesGuide - NIR - Calibration Best Practice - GBMihaly JNo ratings yet

- 11 - Application of NIR Spectroscopy For Tablets Manufacturing ControlDocument40 pages11 - Application of NIR Spectroscopy For Tablets Manufacturing ControlMihaly JNo ratings yet

- Ramancikk 2Document23 pagesRamancikk 2Mihaly JNo ratings yet

- Antaris II FT-NIR ProspektusDocument8 pagesAntaris II FT-NIR ProspektusMihaly JNo ratings yet

- Method Transfer Across Multiple Micronir Spectrometers Raw Material Identifica Application Notes enDocument9 pagesMethod Transfer Across Multiple Micronir Spectrometers Raw Material Identifica Application Notes enMihaly JNo ratings yet

- Fido X3 Datasheet USDocument2 pagesFido X3 Datasheet USMihaly JNo ratings yet

- NIRLAB Brochure - ENDocument4 pagesNIRLAB Brochure - ENMihaly JNo ratings yet

- Investigation of The Activity of Acinetobacter Calcoaceticus Biodemulsifier To Break Stable Water in Oil EmulsionsDocument7 pagesInvestigation of The Activity of Acinetobacter Calcoaceticus Biodemulsifier To Break Stable Water in Oil EmulsionsMohamed AlhayaniNo ratings yet

- FLTM BP 153-01 Method A - Migration StainingDocument4 pagesFLTM BP 153-01 Method A - Migration StainingFrancesco VignaliNo ratings yet

- Astm E1180 - 08Document4 pagesAstm E1180 - 08Akinbuwa PeterNo ratings yet

- 12 - Chapter 3 PDFDocument122 pages12 - Chapter 3 PDFsushant kadamNo ratings yet

- Environmental Technology & InnovationDocument13 pagesEnvironmental Technology & InnovationSamuel ArelianoNo ratings yet

- Advanced Anode Materials For Sodium Ion Batteries CarbodiimidesDocument12 pagesAdvanced Anode Materials For Sodium Ion Batteries CarbodiimidesMaria OktaviaNo ratings yet

- Solutions - Chapter 3: Kevin S. HuangDocument16 pagesSolutions - Chapter 3: Kevin S. Huangdiego espinozaNo ratings yet

- Formal ReportDocument30 pagesFormal Reportapi-495325406No ratings yet

- Plant Extract Ac As A Acid Base IndicatorsDocument4 pagesPlant Extract Ac As A Acid Base IndicatorsNindya GaluhNo ratings yet

- Curiculum VitaeDocument3 pagesCuriculum Vitaeardanrizqul18No ratings yet

- Plasmadyeing 200320162358Document24 pagesPlasmadyeing 200320162358Ayman SebaeiNo ratings yet

- Blasting Painting Procedure (002) - MFAADocument11 pagesBlasting Painting Procedure (002) - MFAAZamri AhmadNo ratings yet

- Physical Chemistry All PYQsDocument176 pagesPhysical Chemistry All PYQsborntwofukNo ratings yet

- Human AST Protocol Book v1 Ab263881 (Website)Document32 pagesHuman AST Protocol Book v1 Ab263881 (Website)Oanna ChippNo ratings yet

- How To Analyze Calcium Lignosulfonate - GREEN AGROCHEMDocument4 pagesHow To Analyze Calcium Lignosulfonate - GREEN AGROCHEMNagy AliNo ratings yet

- Scientific Report - Cellular RespirationDocument10 pagesScientific Report - Cellular Respirationnicole alcantaraNo ratings yet

- Experiment 9: Separation of Amino Acid Mixture by Paper ChromatographyDocument8 pagesExperiment 9: Separation of Amino Acid Mixture by Paper Chromatographyfilzah haziqahNo ratings yet

- BS en Iso 12782-5-2012Document32 pagesBS en Iso 12782-5-2012Amine DiabyNo ratings yet

- Self-Directed Learning Module in Science: Quarter 1, Weeks 3 To 4Document26 pagesSelf-Directed Learning Module in Science: Quarter 1, Weeks 3 To 4Ma. Victoria LlameraNo ratings yet

- Coordination: Complexes CobaltDocument3 pagesCoordination: Complexes CobaltAitor PastorNo ratings yet

- General Chemistry 2 - Q3 - SLM5Document10 pagesGeneral Chemistry 2 - Q3 - SLM5Jonnel RoqueNo ratings yet

- Orders of Reactions - Rate LawsDocument17 pagesOrders of Reactions - Rate LawsJillian PeteNo ratings yet

- PhysioEx Nuzla Emira Potensial AksiDocument7 pagesPhysioEx Nuzla Emira Potensial AksiPine's FauNo ratings yet

- Electrochemical Mechanical Polishing Technology: Recent Developments and Future Research and Industrial NeedsDocument16 pagesElectrochemical Mechanical Polishing Technology: Recent Developments and Future Research and Industrial NeedsSumantra AaryaNo ratings yet

- CHM 131 2Document10 pagesCHM 131 2Zunnurain AmniNo ratings yet

- 01 PDFDocument12 pages01 PDFMihai MihaiNo ratings yet

- United States Patent 0: Patented Sept. 30, 1969Document2 pagesUnited States Patent 0: Patented Sept. 30, 1969هیمن مNo ratings yet