Professional Documents

Culture Documents

Application of Unconventional Raw Materuals and Procedures in Wort Production

Uploaded by

_juliogsOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Application of Unconventional Raw Materuals and Procedures in Wort Production

Uploaded by

_juliogsCopyright:

Available Formats

Application of Unconventional Raw Materials, pp.275-278 Volume 105 No.

5, 1999

Application of Unconventional Raw Materials and Procedures

in Wort Production*

By Olgica Grujic

Faculty of Technology, Novi Sad, Yugoslavia

Received 17th July 1998

This paper deals with investigations of wort production by the application of unmalted raw

material - native barley as a partial sttbstitute for malt in grist Tliis adjunct was differently

treated: (1) thermal decomposition, (2) enzymic decomposition by the addition of commercial

enzyme "Termamyl", and (3) hydrothermic decomposition i.e. extruding.

Native barley prepared by these methods was added in proportions up to 70% of the grist,

without the addition of exogenous enzymes. Experiments were carried out on a laboratory scale

by using an infusion mashing procedure for wort production.

The results obtained indicated that the application of native barley as the adjunct, gelatinised

by heat treatment gave good results up to 10% as malt substitute. Larger amounts of barley

gelatinised by heat treatment decreased extract yields.

Malt substitution with pretreatment of barley with enzyme did not produce satisfactory

results. Worts had reduced levels of extract and soluble nitrogen, which were insufficient for the

production of high quality beer.

Application of barley flakes in quantities up to 50% produced wort which had good analytical

quality parameters.

Key Words: Adjuncts, barley, barley flakes, wort quality.

INTRODUCTION available on the domestic market, as well as inadequate

In Yugoslavia, as in most other countries in the world, capacities of brewhouses for summer peaks of beer

beer is brewed with the addition of adjuncts to malt consumption, which resulted in the consumption of

grists. The principal adjunct is maize, or refined maize high proportions of sugar-type adjuncts, mainly sucrose

grits, but, in the last decade, unmalted barley has also at that time. Today, the technical capacities of the

been applied. The quantities or types of adjuncts are not Yugoslav malting industry significantly exceed the

legally restricted, but breweries add up to 40% of maize needs of Yugoslav breweries, even if they produced only

starch or maize grits in the whole grist, normally with all-malt beers. In spite of that, low beer prices, high

commercial enzymes, but in some cases conversion in duties, and the small purchasing power of the

the brewhouse is performed only with enzymes from population, force the breweries to use adjuncts in high

brewer's malt. If used, barley represents some 20-30% of percentages.

the grist, and it is processed with enzymes which have Having that in mind, it was considered as useful to

liquefying (thermostabile a-amylase), saccharifying, examine whether one relatively new product on the

proteolytic and cytolytic (p-glucanase) activities10 7"15. In Yugoslav market, i.e. pregelatinised barley flakes, could

some breweries adjunct addition can be as high as 60%. be used to decrease further the costs of raw materials for

Small quantities of all-malt (specialty) beers are beer production.

produced in several of the 13 active breweries in

Yugoslavia while some minimal quantities of pure-malt EXPERIMENTAL

beers are produced by "butique" breweries.

Materials

The main current reason for the high proportion of The raw materials for mashing experiments were

adjuncts used is that of economics and starchy adjuncts commercial pale malt obtained from a commercial

are normally 2 or more times cheaper than malt. The Yugoslav malting plant; barley flour (fine grind, DLFU)

principal reasons for the use of adjuncts in Yugoslavia obtained from the winter barley Novosadski 183;

20-25 years ago were insufficient quantities of malt gelatinised (extruded) barley flakes, commercial

product of the "Agroseme" Co., Subotica, Yugoslavia;

* Presented at 1st International Conference of the Chemical Societies

of the South-East European Countries "Chemical Sciences and heat-stable a-amylase Termamyl™ 120 L (Novo,

Industry", Halkidiki, Greece, June 1-4, 1998 Copenhagen) and distilled water.

This document is provided compliments of the Institute of Brewing and Distilling www.ibd.org.uk Copyright - Journal of the Institute of Brewing

Journal of The Institute of Brewing 275

Volume 105, No. 5,1999 Application of Unconventional Raw Materials

Design of experiments TABLE II. Analyses of native barley and of the extruded barley

flakes

Experiments were performed on a laboratory scale,

using grists composed so that 0-70% extract content of NATIVE BARLEY BARLEY FLAKES

malt was replaced by an adjunct, based on the results of

Parameter Value Parameter Value

determination of the extract content for malt by the

Congress method3, extract content of crude barley Moisture content, % 11.2 Moisture content, % 7.9

according to the Graf method" and extract content of Extract, Graf, %DM 79.4 Extract, %DM 82.0

barley flakes according to De-Clerk's method of Ash content, %DM 2.1 Ash content, %DM 1.6

determination of extract of maize flakes4. In this way, Total nitrogen, %DM 1.64 Total nitrogen, %DM 1.80

grists were composed of 100-30% of malt together with Protein content, %DM 10.25 Protein content, %DM 11.25

calculated quantities of adjuncts, corresponding to a

TABLE HI. Analyses of worts obtained by replacing of (part of

total equivalent of grists of 50 grams of malt.

the) malt with barley flour gelatinised by heat treatment

Three series of experiments were performed. In the (cooking)

first series, 0-70% malt were replaced with barley flour Parameter Qua ntity <>f mal t repla cedb y,%

as an adjunct. This was gelatinised by cooking for 10 0 10 20 30 40 50 60 70

minutes, following the procedure given for the

Extract, % by weight 8.6 8.6 8.4 8.4 83 82 7.9 7.7

determination of extract of rice- or maize grits, in the Saccharificarion, min. 10-15 10-15 10-15 10-15 15-20 20-25 35-H) noMcdi

Analytica-EBO. This included mashing in the calculated Filtration rate normal

quantities of barley flour with 200 ml of water, heating Wort clarity slightly opalescent opalescent

to 90°C for gelatinisation, cooling to 75°C by addition of Wort colour. EBC 3.0 2.5 10

cold water, addition of 1 g of malt flour, liquefaction for Wort viscosity. 8.6%. mPa*s 1.7 1.7 1.7 1.7 1.8 1.8 10 22

WortpH 5.4 5.4 55 53 5.6 5.6 5.6 5.7

5 minutes, heating to boiling, boiling for 10 minutes,

Wort odor norma

cooling to 45°C and addition of 100 ml of water at 45°C.

Soluble N in wort mg/100ml 81.9 - 79.8 59.3 59.3 60.7 48.0 40.3

The second series of mashings was performed in a Limit attenuation, real, % 63.8 66.4 64.9 64.5 56.8 56.4 49.2 47.3

similar way, except for omitting the 1st gelatinisation at Limit attenuation, apparent, % 789 84.8 80.2 80.1 70.5 69.7 61.4 59.1

90°C and mashing in directly at 75°C the whole quantity

TABLE IV. Analyses of worts obtained by replacing of (part of

of barley flour with the addition of 0.05% (vol./wt) of

the) malt with barley flour liquified by enzyme preparation

Termamyl. In the third series, 0-70% of malt was Termamyl

replaced with the calculated quantities of barley flakes Parameter Qua ntity <>f mal trepla cedb y,%

and mashed-in with 200 ml of water at 45°C.

0 10 20 30 40 50 60 70

Further mashing, after addition of malt in the 1st and Extract. X by weight 8.6 8.4 83 8.2 83 8.1 8.0 7.9

2nd series was performed exactly according the Saccharificarjon. min. 10-15 10-15 10-15 10-15 15-20 20-25 30-35 no wcrfi

Congress mashing procedure in all series, but omitting Filtration rate normal

the additions of 100 ml of water at 70°C for the 1st and Wort clarity slightly opalescent opalescent

Wort colour, EBC 3.0 2.0 2.5

2nd series, and adjusting the weight of the mashes prior

Wort viscosity, 8.6%, mPa.s 17 1.7 1.7 1.7 1.8 1.9 2.1 25

to the filtration to 450 g in all cases.

WortpH 5.4 5.4 55 55 55 S3 55 56

Analyses Wort odour normal

Soluble N in wort, mg/ 100ml 81.9 76.9 69.9 65.7 62.1 60.7 51.5 48.7

All analyses were performed by standard techniques,2-12 Limit attenuation, real, % 63.8 57.8 59.3 59.7 59.7 50.4 52.1 51.6

with the exception that calculations of extract contents Limit attenuation, apparent, % 78.9 71.1 73.3 73.9 73.4 623 64.7 63.8

of the worts employed regression equations proposed

by Rosendal et a/.13. TABLE V. Analyses of worts obtained by replacing of (part of

the) malt with the extruded barley flakes

Parameter Quantity <)f mal t repb cedb y.%

TABLE I. Analyses of malt used for the experiments

0 10 20 30 40 50 60 70

Parameter Value Parameter Value Extract, % by weight 8.6 8.5 8.5 8.5 8.6 8.7 8.5 8.5

Sacehariricjtion, min. 10-15 10-15 10-15 10-15 15-20 20-25 30-35 4045

Hectolitre weight, kg 58.4 Wort viscosity, mPa«s, 8.6% 1.60

Filtration rate normal

Thousand corn weight, gDM 33.5 Wort pH value 53 Wort clarity slightly opalescent °«23 | slightly opalescent

Moisture content, % 5.3 Soluble nitrogen, mg/ 100ml 78.4 Wort colour, EBC 3.0 2.5 2.0

Wort viscosity, 8.6%, ml'a<s 1.7 1.7 1.8 1.8 2.0 2.0 2.2 2.4

Extract, fine grind, %DM 78.2 Total nitrogen, %DM 1.88

WortpH 5.4 55 5.4 5.4 5.4 5.4 5.3 5.3

Extract, coarse grind, %DM 77.1 Protein content, %DM 11.8

Wort odour normal

Extract difference, %DM 1.1 Kolbach index, % 37.0

Soluble N in wort, mg/ 100ml 81.9 91.8 88.2 81.9 635 64.2 515 41.7

Sjccharificjtion time, min. 10-15 Hartong number 3.9 Limit attenuation, real % 638 62.0 613 61.1 59.0 58.9 55.9 549

Colour of the wort, EBC 3.0 • Hartong 20cC% 21.0 limit attenuation, apparent, % 78.9 77.2 75.9 75.4 73.0 72.7 69.3 67.9

Wort odor normal • Hartong 45"C,% 34.5

RESULTS AND DISCUSSION

Wort clarity clear • Hartong 65"C, % 98.6

Table I shows the analyses of malt. Table II shows the

Rate of filtration, minutes 59 • Hartong 80°C % 93.9

analyses of native barley and extruded barley flakes

This document is provided compliments of the Institute of Brewing and Distilling www.ibd.org.uk Copyright - Journal of the Institute of Brewing

276 Journal of The Institute of Brewing

Application of Unconventional Raw Materials Volume 105 No. 5,1999

while Table III shows the analyses of worts obtained by shows wort viscosities as functions of adjuncts levels

replacing part of the malt with barley flour gelatinised and of their preparation procedures. Figure 3 shows soluble

by heat treatment (cooking). Table IV shows analyses of nitrogen contents in worts as functions of adjuncts levels

worts obtained by replacing part of the malt with barley and of their preparation procedures. Figure 4 shows

apparent attenuation degrees of worts as functions of

adjuncts levels and of their preparation procedures.

According to these data, malt used for the experiments

(Table I) showed average quality parameters, with

relatively low extract contents and slightly elevated

viscosity. The extract content of barley flakes was

significantly higher than that of native barley flour

(Table II) resulting in the fact that, for the same

substitution rate, the quantities of the flakes were lower

than those of the barley flours (for example, at 10%

substitution, grists were composed of 45 grams of malt

FIG. 1. Extract contents of worts. and 5.2 g of barley flour, but only 4.8 g of the flakes).

Considering the results of the worts (Tables III-V, Figs

1-4), it may be concluded that, by applying infusion or

Congress mashing conditions levels of barley adjuncts

were limited to about 30 to 40% irrespective of their type

or pretreatment. At the higher levels, saccharification

rates showed a tendency to be lower, and at 70%

substitution saccharification of the mashes were not

completed after 60 minutes at 70°C.

Comparison of the results obtained with barley flakes

with those obtained with native barley, irrespective of

pretreatment, showed that application of the extruded

FIG. 2. Viscosities of worts

barley flakes had several advantages including better

flour liquefied by enzyme preparation Termamyl. Table extract yields, which were at expected levels, whereas

V shows analyses of worts obtained by replacing part of extract yields for barley flours showed a tendency to be

the malt with extruded barley flakes. Figure 1 shows lower; higher nitrogen contents in the worts; a tendency

extract contents of worts as functions of their adjuncts of obtaining worts with higher acidities (lower pH

levels and of their preparation procedures. Figure 2 values); similar or better attenuation.

Barley pretreatment by cooking, with or without

external addition of enzymes for liquefaction showed a

better performance with respect to wort viscosities than

those obtained with pregelatinised barley flakes. At first

sight this seemed to contradict earlier findings of, for

example, Beubler el a/.5, who had showed that the use of

30% barley flour in the grist caused an increase in

viscosity of 10% wort from 1.83 at 2.235 mPa-s, or by

almost 0.4 mPa-s. Further, the finding that wort

viscosities were lower in the present experiments when

barley pretreatment was by heat (cooking) alone than in

FIG. 3. Soluble nitrogen in worts

corresponding experiments where liquefying enzyme

was used (Tables III and IV; Fig. 2) was also confusing.

These anomalous findings could be explained by

previous studies that suggest that p-glucan and related

viscosity-increasing substances are intimately bounded

with protein and starch, and that they could be

hydrolyzed by the p-glycolytic enzymes only after their

liberation from these materials, for example by

cooking8101305.

In these laboratory experiments, mashes were cooled

down to 45°C, i.e. to a temperature which was low

FIG. 4. Apparent attenuation of worts enough for expression of the activities of cytolytic

This document is provided compliments of the Institute of Brewing and Distilling www.ibd.org.uk Copyright - Journal of the Institute of Brewing

Journal of The Institute of Brewing 277

Volume 105, No. 5,1999 Application of Unconventional Raw Materials

enzymes from the malt, which are active between 35 and 5. Beubler, A., Demwolf, M. and Nielbuck, C: 2. Int.

45°C. Normally, for technical reasons this is not possible Symp. Gaerungsind., Leipzig 1968, Bd. 1/1,175.

in industrial practice, and temperatures after mixing the 6. Briggs, D. E., Wadeson, A., Statham, R. and Taylor,

•adjunct mash with the malt mash are considerably J. F., Journal of the Institute of Brewing, 1986, 92, 468.

higher (50-55, or even 60-63°C). The activities of malt P- 7. Delcour, A. J., Methilde, M.E.R., Van Craenenbroeck

glucanases are limited and heat stable cytolytic enzymes and Moerman, E., Journal of the Institute of Brexoing,

from microbial sources have to be used. 1989, 95, 271.

This applies to the mashes where barley flakes were 8. Erdal, K. and Gjersten, P., Proceedings of the European

used as an adjunct in these experiments. However, it is Breioery Convention Congress, Madrid, 1967,295.

important to point out that, with the barley flakes and 9. Fors, S. M. and Nordlov, H., Journal of the Institute of

malt as grist ingredients, the temperature of mashing in Brewing, 1987, 93, 496.

can be lower than with other barley adjuncts. This 10. Gacesa, S., "Dried Green Malt as a mean for

suggests that if green malt or malt dried at low Saccharification of the Increased Barley amounts in Beer

temperatures, with considerably higher cytolytic Production", Ph.D. Thesis, Faculty of Technology,

activities, is to be used as saccharifying agent, by Novi Sad 1973, (in Serbian).

mashing at, for example, 40-45°C, up to 70% of 11. Krajovan, V., Gacesa, S. and Ivkov-Grujiae, O.,

pregelatinised barley flakes as an adjunct should not "Handbook for Malt and Beer Analyses", Faculty of

cause any problems of P-glucan or starch conversion10. Technology, Novi Sad 1972, (in Serbian).

12. BRAUTECHNISCHE ANALYSENMETHODEN, -

CONCLUSIONS MEBAK, Band I, Selbstverlag der MEBAK, Freising-

1. The use of barley flour gelatinised by heat (cooking) Weihenstephan, 1979.

as adjunct was satisfactory only in the case of replacing 13. Rosendal, I. and Schmidt, F.. Monatsschrift fiir

of 10 per cents of malt in the grist. Increased quantities Brauwissenschaft, 1987, 40, 334.

of this adjunct caused lower extract yields, longer 14. Scott, R. W., Journal of the Institute of Braving, 1972,

saccharification times, increase of wort pH values, and 78,179.

reduced contents of soluble nitrogen in worts, resulting 15. Schuster, K., Weinfurtner, L., Narziss, L., "Die

in the production of low-quality beers with strange Technologie der Wiirzebereitung", 6. Aufl., Ferdinand

sensory qualities. Enke Verlag, Stuttgart 1985.

2. Application of enzymatically liquefied barley was

not satisfactory, because extract contents of the worts

obtained were low, saccharification times were

prolonged, pH values were too high, soluble nitrogen

contents were too low, as well as the apparent

attenuation of the worts.

3. Worts obtained from grists with extruded barley

flakes (hydrothermically modified barley flour) in the

quantities of up to 50% in the whole grist, were

characterised by good analytical parameters, with the

exception of the viscosity of wort, which must be

4 / j

corrected by addition of cytolytic enzymes.

4. Based on the savings of time and energy necessary

for preparation of adjuncts, and further possibilities for

application of flexible schemes of brewhouse processes, ' 1T ■

\\ \\

it could be concluded that extruding of barley could be

judged as the best process for barley pretreatment for

brewer's wort production.

< i I

' • \

REFERENCES i ; i

1. Albini, P.A., Briggs, D.E. and Wadeson, A., Journal of

li,1'

the Institute of Brewing, 1987, 93, 97. \\-

2. ANALYTICA EBC, 3. Ausgabe, Schweizer Brauerei-

Rundschau, Zurich, Schweiz, 1983.

3. ANALYTICA EBC, 3. Ausgabe, Schweizer Brauerei-

Rundschau, Zurich, Schweiz, 1983, D25-D28. -.. ■ / r

4. ANALYTICA EBC, 3. Ausgabe, Schweizer Brauerei-

Rundschau, Zurich, Schweiz, 1983, D43 (Dec. 1980)

This document is provided compliments of the Institute of Brewing and Distilling www.ibd.org.uk Copyright - Journal of the Institute of Brewing

278 Journal of The Institute of Brewing

You might also like

- Cheese Making How-To'sDocument33 pagesCheese Making How-To'snikoskassNo ratings yet

- Klangfarbenmelodie Amongst The Darmstadt Circle: Atmosphères at The Donaueschinger Musiktage, He WroteDocument48 pagesKlangfarbenmelodie Amongst The Darmstadt Circle: Atmosphères at The Donaueschinger Musiktage, He WroteBrandon McguireNo ratings yet

- Enzymes in BrewingDocument11 pagesEnzymes in BrewingReza RenardiNo ratings yet

- 001 Art-AppreciationDocument13 pages001 Art-AppreciationBtrz QnnsNo ratings yet

- BS 4999-143-1987 Requirements For Rotating Electrical MachinDocument8 pagesBS 4999-143-1987 Requirements For Rotating Electrical MachinJames AlejoNo ratings yet

- Steel - Structures, Instructions, 2017Document99 pagesSteel - Structures, Instructions, 2017Topaca PaecNo ratings yet

- Enzymes in Brewing - Biokemisk ForeningDocument9 pagesEnzymes in Brewing - Biokemisk ForeninggutaviedNo ratings yet

- LRFSTG00739-LTE-PRACH Parameter Planning Technical Guide-V2R3Document28 pagesLRFSTG00739-LTE-PRACH Parameter Planning Technical Guide-V2R3Hoang Duc Thanh100% (1)

- ADE Scale Service Manual PDFDocument15 pagesADE Scale Service Manual PDFBalaji Balasubramanian100% (3)

- Nsi Ethanol 22 1 16Document36 pagesNsi Ethanol 22 1 16Ajay guptaNo ratings yet

- Guide To Perform Initial DT With GENEX ProbeDocument19 pagesGuide To Perform Initial DT With GENEX Probewantwant56750% (2)

- Solution Manual For University Physics 13th Edition by YoungDocument24 pagesSolution Manual For University Physics 13th Edition by YoungShellySimsqdej100% (41)

- Komlaga 2021Document6 pagesKomlaga 2021StevenCarlNo ratings yet

- Pollock Et Al-1975-Journal of The Institute of BrewingDocument6 pagesPollock Et Al-1975-Journal of The Institute of Brewing_juliogsNo ratings yet

- Optimization of Mashing Process in Beer Production Using RiceDocument4 pagesOptimization of Mashing Process in Beer Production Using Rice_juliogsNo ratings yet

- j.2050-0416.2006.tb00737.x - CopieDocument10 pagesj.2050-0416.2006.tb00737.x - CopieSimu LinkNo ratings yet

- j.2050-0416.2006.tb00737.x - CopieDocument10 pagesj.2050-0416.2006.tb00737.x - CopieSimu LinkNo ratings yet

- Kinetic Modeling of Simultaneous Saccharification and Fermentation of Corn Starch For Ethanol ProductionDocument10 pagesKinetic Modeling of Simultaneous Saccharification and Fermentation of Corn Starch For Ethanol ProductionSeba GelsuminoNo ratings yet

- Jib 184Document7 pagesJib 184NicolaeNo ratings yet

- 32005mashing Unmalted 109Document15 pages32005mashing Unmalted 109Pulbere NeagraNo ratings yet

- Improvement of Mead Fermentation by Honey-Must SupplementationDocument6 pagesImprovement of Mead Fermentation by Honey-Must SupplementationDana HutuNo ratings yet

- KarabuğdayDocument8 pagesKarabuğdaySefa YücesoyNo ratings yet

- EnhancingDocument5 pagesEnhancingGuarocualquieraNo ratings yet

- Mechanism of Beer Foam Stabilization by Propylene Glycol AlginateDocument4 pagesMechanism of Beer Foam Stabilization by Propylene Glycol Alginateramon SilvaNo ratings yet

- Brewing With 100% Oat MaltDocument11 pagesBrewing With 100% Oat Maltbartolomej7No ratings yet

- Brewing Beer With Sorghum: Glen Osmond 5064, South AustraliaDocument12 pagesBrewing Beer With Sorghum: Glen Osmond 5064, South AustraliaSimon LexsNo ratings yet

- Propylene Glycol Alginate in BeerDocument4 pagesPropylene Glycol Alginate in BeerVõ Hữu Hồng ChiNo ratings yet

- Acetaldehyde Production in Saccharomyces: Cerevisiae Wine YeastsDocument6 pagesAcetaldehyde Production in Saccharomyces: Cerevisiae Wine YeastsSARATH BALANo ratings yet

- Mead Production: Selection and Characterization Assays of Saccharomyces Cerevisiae StrainsDocument7 pagesMead Production: Selection and Characterization Assays of Saccharomyces Cerevisiae StrainsMauricio A. KoochoiNo ratings yet

- Aem00154 0187Document8 pagesAem00154 0187HonganhNo ratings yet

- Enzymes in BrewingDocument8 pagesEnzymes in BrewingAlexandru TarțianNo ratings yet

- The Composition of Jerusalem Artichoke (Helianthus Tuberosus L.) Spirits Obtained From Fermentation With Bacteria and YeastsDocument4 pagesThe Composition of Jerusalem Artichoke (Helianthus Tuberosus L.) Spirits Obtained From Fermentation With Bacteria and YeastsIoanaAndreeaNo ratings yet

- En Zima Conserva Ça oDocument7 pagesEn Zima Conserva Ça oJonas TeixeiraNo ratings yet

- Production of Extracellular Amylase by Aspergillus Niger Under Submerged Fermentation Using Jack Fruit Rag As The Carbon SourceDocument6 pagesProduction of Extracellular Amylase by Aspergillus Niger Under Submerged Fermentation Using Jack Fruit Rag As The Carbon Sourcesyedt4140No ratings yet

- Cereals Alcohol Yield Process Conditions EffectDocument6 pagesCereals Alcohol Yield Process Conditions EffectDavidNo ratings yet

- Elaborar Con MielDocument8 pagesElaborar Con MielAntonio FuentesNo ratings yet

- Beet Sugar Bioethanol FermentationDocument12 pagesBeet Sugar Bioethanol FermentationDavidNo ratings yet

- 27763-Article Text-80150-93458-10-20231130Document11 pages27763-Article Text-80150-93458-10-20231130Halip pras28No ratings yet

- Permanasari 2018 IOP Conf. Ser. Earth Environ. Sci. 160 012002Document7 pagesPermanasari 2018 IOP Conf. Ser. Earth Environ. Sci. 160 012002yunitaknNo ratings yet

- Producción Enzimatica de Ethanol de Almidon de Yuca 1-S2.0-S0189724115300448-MainDocument8 pagesProducción Enzimatica de Ethanol de Almidon de Yuca 1-S2.0-S0189724115300448-MainTelesman1No ratings yet

- Ijfnr 2019 09 1805Document11 pagesIjfnr 2019 09 1805VictorNo ratings yet

- Mead Production: Selection and Characterization Assays of Saccharomyces Cerevisiae StrainsDocument7 pagesMead Production: Selection and Characterization Assays of Saccharomyces Cerevisiae StrainsVy NguyenNo ratings yet

- Fermentation of Starch To Ethanol by A Complementary Mixture of AnDocument4 pagesFermentation of Starch To Ethanol by A Complementary Mixture of Anmahoney2328100% (1)

- Production of Alcohol From Cassava Our Hydrolysate: July 2010Document8 pagesProduction of Alcohol From Cassava Our Hydrolysate: July 2010Simon LexsNo ratings yet

- Influence of Williopsis Saturnus Yeasts in Combination With Saccharomyces Cerevisiae On Wine FermentationDocument6 pagesInfluence of Williopsis Saturnus Yeasts in Combination With Saccharomyces Cerevisiae On Wine Fermentationdimas wisesaNo ratings yet

- Beer Production 02Document8 pagesBeer Production 02Denny SamuelNo ratings yet

- B.ing 2Document5 pagesB.ing 2Putu YogaNo ratings yet

- Continuous Ethanol Production From Carob Pod Extract by Immobilized in A Packed-Bed ReactorDocument7 pagesContinuous Ethanol Production From Carob Pod Extract by Immobilized in A Packed-Bed ReactorDaniall AbdanNo ratings yet

- BF 00132167Document6 pagesBF 00132167Bryan Roncal LlajarunaNo ratings yet

- Bioetanol 1Document9 pagesBioetanol 1Ezequiel QuinterosNo ratings yet

- Bài Thí nghiệm SLSFD - 2023 - ELITECHDocument6 pagesBài Thí nghiệm SLSFD - 2023 - ELITECHVan VietNo ratings yet

- Art 01Document8 pagesArt 01Lavinia Maria BucatariuNo ratings yet

- MT Report Journal15Document7 pagesMT Report Journal15bookslover1No ratings yet

- Page 76 79Document4 pagesPage 76 79Anonymous WCSB79IbNo ratings yet

- Fed-Batch Alcoholic Fermentation of Palm Juice (Arenga Pinnata Merr) : Influence of The Feeding Rate On Yeast, Yield and ProductivityDocument5 pagesFed-Batch Alcoholic Fermentation of Palm Juice (Arenga Pinnata Merr) : Influence of The Feeding Rate On Yeast, Yield and ProductivityindriNo ratings yet

- FAO Symposium OnDocument42 pagesFAO Symposium OnDhaval AcharyaNo ratings yet

- Riginal Rticle Production of Bioethanol From Cassava and Sweet Potato PeelsDocument5 pagesRiginal Rticle Production of Bioethanol From Cassava and Sweet Potato Peelswriteandrewpaul7707No ratings yet

- 10 HidromProdDocument11 pages10 HidromProdCarlos Barrios SánchezNo ratings yet

- Optimization of Process Variables For Minimization of Byproduct Formation During Fermentation of Blackstrap Molasses To Ethanol at Industrial ScaleDocument5 pagesOptimization of Process Variables For Minimization of Byproduct Formation During Fermentation of Blackstrap Molasses To Ethanol at Industrial ScaleMr pichakNo ratings yet

- Nutrients For Molasses FermentationDocument7 pagesNutrients For Molasses FermentationItezaz AhsanNo ratings yet

- Bioprocess Technology To Produce Bioethanol From Cassava by Co-CultureDocument7 pagesBioprocess Technology To Produce Bioethanol From Cassava by Co-Cultureyan_kadirNo ratings yet

- Effect of The Respiro Fermentative Balance During Yeast Propagation OnDocument9 pagesEffect of The Respiro Fermentative Balance During Yeast Propagation Oneric acuñaNo ratings yet

- Production of A-Amylase From Penicillium Chrysogenum Under Solid-State Fermentation by Using Some Agricultural By-ProductsDocument4 pagesProduction of A-Amylase From Penicillium Chrysogenum Under Solid-State Fermentation by Using Some Agricultural By-ProductspilotplanthtbsNo ratings yet

- Continuous Winemaking Fermentation Using Quince-Immobilized Yeast at Room and Low TemperaturesDocument6 pagesContinuous Winemaking Fermentation Using Quince-Immobilized Yeast at Room and Low TemperaturesLoc VotuongNo ratings yet

- Saccharomyces Cerevisiae Aspergillus Niger: Ethanol Production From Corn Cobs by Co-Cultures of ANDDocument3 pagesSaccharomyces Cerevisiae Aspergillus Niger: Ethanol Production From Corn Cobs by Co-Cultures of ANDAprilia Inggri ANo ratings yet

- Artigo Bioetanol 2008Document6 pagesArtigo Bioetanol 2008Brigida RodriguesNo ratings yet

- BRJ Volume 2 Issue 1 Pages 203-208Document6 pagesBRJ Volume 2 Issue 1 Pages 203-208sohanNo ratings yet

- Bamforth-1985-Journal of The Institute of BrewingDocument14 pagesBamforth-1985-Journal of The Institute of Brewing_juliogsNo ratings yet

- JRO NetoDocument9 pagesJRO Neto_juliogsNo ratings yet

- Donadini 2016Document47 pagesDonadini 2016_juliogsNo ratings yet

- Glicerol in BeerDocument11 pagesGlicerol in Beer_juliogsNo ratings yet

- Progress in Brewing Science BamforthDocument19 pagesProgress in Brewing Science Bamforth_juliogsNo ratings yet

- Nutritional Aspects of Beer-A ReviewDocument11 pagesNutritional Aspects of Beer-A Review_juliogsNo ratings yet

- Stephenson Et Al-2003-Journal of The Institute of BrewingDocument11 pagesStephenson Et Al-2003-Journal of The Institute of Brewing_juliogsNo ratings yet

- Quimica Dos Aromas de Lupulo Na Cerveja - IngDocument6 pagesQuimica Dos Aromas de Lupulo Na Cerveja - Ing_juliogsNo ratings yet

- Sulfites in BeerDocument9 pagesSulfites in Beer_juliogsNo ratings yet

- Smythe Et Al-2002-Journal of The Institute of BrewingDocument3 pagesSmythe Et Al-2002-Journal of The Institute of Brewing_juliogsNo ratings yet

- Smythe Et Al-2002-Journal of The Institute of BrewingDocument6 pagesSmythe Et Al-2002-Journal of The Institute of Brewing_juliogsNo ratings yet

- Yeast The Soul of Beer's Aroma A ReviewDocument13 pagesYeast The Soul of Beer's Aroma A Review_juliogsNo ratings yet

- Yeo Et Al-2014-International Journal of Food Science & TechnologyDocument12 pagesYeo Et Al-2014-International Journal of Food Science & Technology_juliogsNo ratings yet

- Diagnostic Test ResultsDocument1 pageDiagnostic Test ResultsGUILMOR PADILLANo ratings yet

- Syllabus Booklet of All Institute Courses ModifiedDocument88 pagesSyllabus Booklet of All Institute Courses ModifiedAdarshpatankarNo ratings yet

- Root Cause Failure Analysis of Superheated Steam TDocument6 pagesRoot Cause Failure Analysis of Superheated Steam TThanhluan NguyenNo ratings yet

- Tems Cellplanner: Driving Network ExcellenceDocument8 pagesTems Cellplanner: Driving Network ExcellenceTarasNo ratings yet

- Spatial vs. Frequency DomainDocument6 pagesSpatial vs. Frequency DomainakhorshidinetNo ratings yet

- Effect of Rim Seal On Evaporation Loss From Khark Island Storage Tanks 2157 7463 1 103 PDFDocument7 pagesEffect of Rim Seal On Evaporation Loss From Khark Island Storage Tanks 2157 7463 1 103 PDFHuynh Thanh TamNo ratings yet

- Marantz SR-7001 Service ManualDocument206 pagesMarantz SR-7001 Service ManualLucianoNo ratings yet

- HMT SKDocument60 pagesHMT SKsunilkewat11390No ratings yet

- Q1 Reconciliation by SKUsDocument38 pagesQ1 Reconciliation by SKUsErineNo ratings yet

- Fast and Reliable: Handheld TympanometerDocument4 pagesFast and Reliable: Handheld TympanometerKothapalli ChiranjeeviNo ratings yet

- Rytis Stasiunas - 1929995 - Assignsubmission - File - Modeling - of - Headphones Rytis Stasiunas Revised FinalDocument12 pagesRytis Stasiunas - 1929995 - Assignsubmission - File - Modeling - of - Headphones Rytis Stasiunas Revised FinalAdeline HaykalNo ratings yet

- PNP Assignment - Difference Between Phonetics and PhonologyDocument6 pagesPNP Assignment - Difference Between Phonetics and PhonologyMuhammad Jawwad Ahmed100% (1)

- Arranging Fractions Lesson PlanDocument5 pagesArranging Fractions Lesson PlanSusan TalusigNo ratings yet

- Comparing Quality Parameters of Yarn Produced by Ring, Rotor, and Compact Spinning SystemDocument17 pagesComparing Quality Parameters of Yarn Produced by Ring, Rotor, and Compact Spinning SystemMetasebia GizawNo ratings yet

- MRF1550 MotorolaDocument12 pagesMRF1550 MotorolaSILIO R PARAGUASSUNo ratings yet

- Ada 5 Condensadores PDFDocument2 pagesAda 5 Condensadores PDFTony Maldonado PinzonNo ratings yet

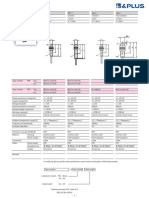

- B&Plus Proximity Sensor - 001.BES07e - Usm8-1Document1 pageB&Plus Proximity Sensor - 001.BES07e - Usm8-1Hussein RamzaNo ratings yet

- Batch 2017 4th Semester CSEDocument28 pagesBatch 2017 4th Semester CSEAzeem KhanNo ratings yet

- PHUL Sheet TemplateDocument3 pagesPHUL Sheet TemplatetiandalfaNo ratings yet

- Cost-Volume-Profit Relationships: Mcgraw-Hill /irwinDocument82 pagesCost-Volume-Profit Relationships: Mcgraw-Hill /irwinXu FengNo ratings yet

- Internship ReportDocument29 pagesInternship ReportPooja koreNo ratings yet