Professional Documents

Culture Documents

SOP For Retest of Raw Materials

Uploaded by

RainMan750 ratings0% found this document useful (0 votes)

328 views3 pagesThis SOP outlines the procedure for re-testing raw materials. [1] It defines responsibilities for quality control and quality assurance personnel to implement re-testing. [2] Raw materials are assigned a retest date when initially approved, with active ingredients retested after one year and excipients after two years. [3] Materials are retested in the last month before their due date to determine if specifications are still met and the shelf life can be extended.

Original Description:

SOP for Retest of Raw Materials

Original Title

SOP for Retest of Raw Materials

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis SOP outlines the procedure for re-testing raw materials. [1] It defines responsibilities for quality control and quality assurance personnel to implement re-testing. [2] Raw materials are assigned a retest date when initially approved, with active ingredients retested after one year and excipients after two years. [3] Materials are retested in the last month before their due date to determine if specifications are still met and the shelf life can be extended.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

328 views3 pagesSOP For Retest of Raw Materials

Uploaded by

RainMan75This SOP outlines the procedure for re-testing raw materials. [1] It defines responsibilities for quality control and quality assurance personnel to implement re-testing. [2] Raw materials are assigned a retest date when initially approved, with active ingredients retested after one year and excipients after two years. [3] Materials are retested in the last month before their due date to determine if specifications are still met and the shelf life can be extended.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 3

SOP for Retest of Raw Materials

Objective To provide a written procedure for re-testing of raw materials.

Scope This SOP shall be applicable for QC and QA Departments.

Associated Documents:

1 QA Report of Materials

2 Sampling Procedure for Raw Materials

3 Handling and Disposition of Non-conforming Raw and Packaging Materials

Responsibility/Accountability

1 All QC and QA personnel shall be responsible for implementing the procedure.

2 Manager, Quality or his or Designee shall be accountable for training and

implementation of the procedure.

Abbreviations and Definitions

Raw Material

Active Ingredients

A substance or compound that is intended to be used in the manufacture of a

pharmaceutical product as a pharmacologically active compound (ingredient).

Excipient

Any ingredient other than the active ingredient added to a pharmaceutical product to

permit it to be formed into the proper shape and consistency; the vehicle for the

pharmaceutical product.

Procedure

1 All incoming raw materials when tested and approved for use, shall be assigned a retest

date by Manager, Quality.

2 The retest date shall be written in the analytical report sheet of specific raw material.

3 The retest date shall be assigned as follows:

Active Ingredients -Retest after one year

Excipient -Retest after two years

4 If there is a concern for stability of the material, the retest date shall be determined

accordingly.

5 In case of re-test date mentioned in COA, material shall be re-tested as per supplier’s

recommendation or as per frequency which is earlier and shelf-life can be extended up to

a period mentioned in COA.

6 If only re-test date is mentioned in COA, and no shelf-life is available then materials

should be re-tested and shelf-life shall be extended initially for one year.

7 For materials with no shelf-life or re-test date, carry out re-test every year and shelf-life

can be extended up to 60 months.

8 Re-testing of Raw Materials

8.1 In the last week of every month, QA Officer shall check “QA RAW MATERIAL

RETEST LOG BOOK” (Enclosure 10.1) and prepare a list of all raw materials to be re-

tested one month ahead of due date of re-testing.

8.2 QA Officer shall inform QC Officer, who shall plan the sampling in such a way that

both the sampling and testing shall be completed within 30 days.

8.3 In case of slow moving item, re-testing date shall be extended and re-testing shall be

done before use in Production.

8.4 Sampling shall be carried out in used drum as per SOP No. IONQC030.

8.5 During retest, full tests shall not be performed.

8.6 Certain test parameters shall be checked which are as follows:

Characteristic

pH / Acidity / Alkalinity

Loss on Drying / Water Content

Assay

Microbial Contamination and

Bacterial Endotoxins

8.7 New assay value on anhydrous/dried basis and water content/LOD shall be

incorporated in the system. If the “as is” assay value on re-analysis is found to be higher

than the initial “as is” assay value on anhydrous/dried basis, then the initial “as is” assay

value shall be reported with reference to new water content/LOD.

8.8 If the retest parameters comply, the Manager, Quality shall approve it. If not, reject

the material as per SOP No. IONQA018.

8.9 Manager, Quality then shall release/reject the raw material and issue

“Released/Rejected” label and affix the label on individual containers.

8.10 Manager, Quality shall inform Warehouse Officer of the re-approved/rejected

material through form no. QA015-01.

8.11 In case of rejection, the material shall be shifted to the assigned “Rejected Area”.

8.12 No material shall be available for use after the retest date, unless it is re-approved.

You might also like

- QCG - 001-2 SOP Handling OOS and OOT ResultsDocument8 pagesQCG - 001-2 SOP Handling OOS and OOT ResultsAftab S. Mirza100% (1)

- Pharmaceutical Industry Documents: 90 Pharmaceutical Quality Assurance Interview Questions & AnswersFrom EverandPharmaceutical Industry Documents: 90 Pharmaceutical Quality Assurance Interview Questions & AnswersNo ratings yet

- Title: Cleaning Validation Report For - ToDocument41 pagesTitle: Cleaning Validation Report For - TocpkakopeNo ratings yet

- SOP For Handling of Out of Specification Results in Microbiological Testing - Pharmaceutical GuidelinesDocument4 pagesSOP For Handling of Out of Specification Results in Microbiological Testing - Pharmaceutical Guidelinesalnzeer omerNo ratings yet

- ICH Quality Guidelines: An Implementation GuideFrom EverandICH Quality Guidelines: An Implementation GuideAndrew TeasdaleNo ratings yet

- Hold Time Study of 70% IpaDocument5 pagesHold Time Study of 70% IpaAshok Lenka100% (4)

- SOP Stability Finished ProductsDocument5 pagesSOP Stability Finished ProductsYousifNo ratings yet

- Annual Product Quality Review APQR FormatDocument9 pagesAnnual Product Quality Review APQR FormatDr.Sivakumar Selvaraj100% (1)

- Protocol Jacketed MFG Tank LV02Document7 pagesProtocol Jacketed MFG Tank LV02pooja aswal100% (3)

- JAGSONPAL HOLD TIME STUDYDocument3 pagesJAGSONPAL HOLD TIME STUDYAshok Lenka100% (2)

- Cleaning Validation Protocol TEMPLATEDocument9 pagesCleaning Validation Protocol TEMPLATEnatavceNo ratings yet

- MICROBIOLOGICAL GLPDocument10 pagesMICROBIOLOGICAL GLPknbiolabsNo ratings yet

- Pegasus Farmaco India Raw Material Requisition SlipDocument1 pagePegasus Farmaco India Raw Material Requisition Slipasit_mNo ratings yet

- Process Validation Interim / Final Report: (Enter Product Title, Number & Strength) Product CodeDocument4 pagesProcess Validation Interim / Final Report: (Enter Product Title, Number & Strength) Product CodevanessaNo ratings yet

- Cleaning Validation Rinsing TesDocument5 pagesCleaning Validation Rinsing TesUrsula HilleNo ratings yet

- Equipment Logbook 2 2Document7 pagesEquipment Logbook 2 2Belazouz BoualemNo ratings yet

- Hold Time Study of Cleaned EquipmentsDocument3 pagesHold Time Study of Cleaned EquipmentsShubam Sharma60% (5)

- 01.collection, Storage and Control of Reserve Samples For Drug ProductsDocument4 pages01.collection, Storage and Control of Reserve Samples For Drug ProductsBejoy KarimNo ratings yet

- Helix Pharma (Private) Limited: Validation ProtocolDocument4 pagesHelix Pharma (Private) Limited: Validation Protocolziauddin bukhari0% (2)

- Settle AIr Plate TechniqueDocument10 pagesSettle AIr Plate Techniquehoookooo100% (3)

- 8.3 Operation Qualification Protocol For Dispensing BoothDocument4 pages8.3 Operation Qualification Protocol For Dispensing BoothTanveer Ahmed Quadri100% (1)

- SOP of Glassware HandlingDocument1 pageSOP of Glassware HandlingPrince Moni100% (2)

- SOP For Analyst ValidationDocument5 pagesSOP For Analyst ValidationGencay Ergin100% (1)

- Procedure For Environmental Monitoring by Settle Plate MethodDocument2 pagesProcedure For Environmental Monitoring by Settle Plate Methodejazmaqsood100% (1)

- Analyst Qualification (Modified)Document6 pagesAnalyst Qualification (Modified)vasant ugale75% (4)

- Laboratory Quality Agreement TamplateDocument10 pagesLaboratory Quality Agreement TamplateMina Maher MikhailNo ratings yet

- Hold Time Study SOP Indian Pharma 1Document3 pagesHold Time Study SOP Indian Pharma 1ziadddNo ratings yet

- Hold Time Study 1Document3 pagesHold Time Study 1aboemadaldeenNo ratings yet

- Area Qualification ProtocolDocument19 pagesArea Qualification ProtocolBRIJENDRA KUMAR SINGH100% (1)

- Aphrin Pfs BPR p1 v-1Document13 pagesAphrin Pfs BPR p1 v-1ShagorShagorNo ratings yet

- Process Validation Sample Protocol - PharmaguidelineDocument3 pagesProcess Validation Sample Protocol - PharmaguidelineD Tech Dental Technologies100% (1)

- Annual Product Review Developing An SOPDocument26 pagesAnnual Product Review Developing An SOPanants2567% (3)

- SOP For Handling of Out of Specification Results-1Document54 pagesSOP For Handling of Out of Specification Results-1osamatqm9No ratings yet

- Vendor QualificationDocument2 pagesVendor QualificationDharmesh PatelNo ratings yet

- Labaid Pharmaceuticals Limited: Deviation Control Status Open Closed TotalDocument33 pagesLabaid Pharmaceuticals Limited: Deviation Control Status Open Closed TotalgolamnobiNo ratings yet

- SOP For Testing of Compressed Air and Nitrogen Gas For Viable Count - Pharmaceutical GuidelinesDocument2 pagesSOP For Testing of Compressed Air and Nitrogen Gas For Viable Count - Pharmaceutical GuidelinesAnonymous FZs3yBHh7No ratings yet

- BMR PraperationDocument9 pagesBMR PraperationwondwossengNo ratings yet

- PICS Inspection QC LabDocument18 pagesPICS Inspection QC LabMax HuangNo ratings yet

- Temperature Mapping For FG StoreDocument19 pagesTemperature Mapping For FG Storemehrdarou.qaNo ratings yet

- Bulk Holding Time Study ReportDocument8 pagesBulk Holding Time Study ReportFaress RabiNo ratings yet

- Standard Operating Procedure (Sop) Collecting Swab or Rinse Samples For Chemical and Microbiological AnalysisDocument11 pagesStandard Operating Procedure (Sop) Collecting Swab or Rinse Samples For Chemical and Microbiological AnalysisAbuNo ratings yet

- VMPDocument15 pagesVMPshah241No ratings yet

- Evaluating Product Quality and Process PerformanceDocument8 pagesEvaluating Product Quality and Process Performance刘朝阳100% (2)

- Example RA For Transport To Regulated MarketsDocument7 pagesExample RA For Transport To Regulated MarketsDoan Chi ThienNo ratings yet

- Ointment Process ValidationDocument25 pagesOintment Process ValidationTrinh Huy CongNo ratings yet

- Clean RoomDocument19 pagesClean Roomhouas menasriaNo ratings yet

- CV Protocol-Coated TabletsDocument22 pagesCV Protocol-Coated Tabletsqaheadjml007No ratings yet

- Cleaning Validation Protocol For PharmaceuticalsDocument5 pagesCleaning Validation Protocol For PharmaceuticalsManivannan Kathirvel100% (2)

- SOP For Handling of Spillage of Solid - Liquid Media Containing Growth - Pharmaceutical GuidelinesDocument1 pageSOP For Handling of Spillage of Solid - Liquid Media Containing Growth - Pharmaceutical GuidelinesJose Ramon Dalo BautistaNo ratings yet

- Validation Protocol For Efficacy of Chemical DisinfectantsDocument8 pagesValidation Protocol For Efficacy of Chemical DisinfectantsMohamed KamalNo ratings yet

- VAL-115 Process Validation For Liquid and Solid Dosage Manufacturing SampleDocument3 pagesVAL-115 Process Validation For Liquid and Solid Dosage Manufacturing SampleMarwa Ahmed100% (2)

- Capsule Filling Machine: 16 March, 2010Document37 pagesCapsule Filling Machine: 16 March, 2010prakash67% (3)

- CLEANING VALIDATION PROTOCOLDocument7 pagesCLEANING VALIDATION PROTOCOLArieTamaNo ratings yet

- Out of Specifications IIDocument39 pagesOut of Specifications IIHaekal Ramadhan100% (1)

- 02 LC of Double Cone Blender 02Document2 pages02 LC of Double Cone Blender 02Ravi YadavNo ratings yet

- VAL-085 Process Validation Guideline SampleDocument2 pagesVAL-085 Process Validation Guideline SampleVizit31No ratings yet

- Disinfection ValidationDocument25 pagesDisinfection ValidationSumitNo ratings yet

- Validation Protocol for Oral LiquidDocument24 pagesValidation Protocol for Oral LiquidAshutosh Shukla100% (2)

- Types of Lubricants Used For Phrmaceutical MachinesDocument2 pagesTypes of Lubricants Used For Phrmaceutical MachinesRainMan75No ratings yet

- SOP On Transferring Finished Products To Finished Goods StoresDocument3 pagesSOP On Transferring Finished Products To Finished Goods StoresRainMan7550% (2)

- PW Specification USPDocument2 pagesPW Specification USPRainMan75No ratings yet

- SOP Room Particle CountDocument3 pagesSOP Room Particle CountRainMan75100% (1)

- Laminar Air Flow SpecificationDocument2 pagesLaminar Air Flow SpecificationRainMan75No ratings yet

- SOP Filter Leakage TestDocument2 pagesSOP Filter Leakage TestRainMan75100% (1)

- SOP For Airflow Velocity and Uniformity TestDocument3 pagesSOP For Airflow Velocity and Uniformity TestRainMan75100% (1)

- Line Clearance Procedure at Pharma ManufacturingDocument3 pagesLine Clearance Procedure at Pharma ManufacturingRainMan75No ratings yet

- Sop of Operating Procedure For Operation and Cleaning of Insect Killer EquipmentDocument2 pagesSop of Operating Procedure For Operation and Cleaning of Insect Killer EquipmentRainMan75100% (1)

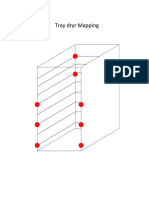

- Try DryerDocument2 pagesTry DryerRainMan75No ratings yet

- Sampling Procedure by ISO KineticDocument2 pagesSampling Procedure by ISO KineticRainMan75No ratings yet

- CAPA Corrective and Preventive Action in PharmaceuticalDocument5 pagesCAPA Corrective and Preventive Action in PharmaceuticalRainMan75No ratings yet

- Vacuum Cleaner SOP Operating and CleaningDocument2 pagesVacuum Cleaner SOP Operating and CleaningRainMan75No ratings yet

- Why Is Granulation NecessaryDocument2 pagesWhy Is Granulation NecessaryRainMan75No ratings yet

- Sop of Operation & Cleaning of Distillation AssemblyDocument2 pagesSop of Operation & Cleaning of Distillation AssemblyRainMan75No ratings yet

- Sop of Cleaning and Operation of Dispensing BoothDocument3 pagesSop of Cleaning and Operation of Dispensing BoothRainMan75100% (2)

- Sop of Operation and Cleaning of Mechanical StirrerDocument3 pagesSop of Operation and Cleaning of Mechanical StirrerRainMan75No ratings yet

- Training SOP Part - 1Document4 pagesTraining SOP Part - 1RainMan75No ratings yet

- Training SOP Part - 3Document4 pagesTraining SOP Part - 3RainMan75No ratings yet

- Aseptic and Sterile in PharmaceuticalDocument2 pagesAseptic and Sterile in PharmaceuticalRainMan75No ratings yet

- Good Weighing in Pharma - 3Document4 pagesGood Weighing in Pharma - 3RainMan75No ratings yet

- SOP-Storage-Labeling-Raw-PackagingDocument2 pagesSOP-Storage-Labeling-Raw-PackagingRainMan75No ratings yet

- Training SOP Part - 2Document3 pagesTraining SOP Part - 2RainMan75No ratings yet

- Procedure For Planned Internal Quality Audits in PharmaDocument5 pagesProcedure For Planned Internal Quality Audits in PharmaRainMan75No ratings yet

- Entry Exit Procedure SOPDocument4 pagesEntry Exit Procedure SOPRainMan75100% (1)

- Good Weighing in Pharma - 4Document6 pagesGood Weighing in Pharma - 4RainMan75No ratings yet

- SOP For Hot Air Oven Cleaning, Operation & Calibration of Hot Air OvenDocument3 pagesSOP For Hot Air Oven Cleaning, Operation & Calibration of Hot Air OvenRainMan75No ratings yet

- SOP For Cleaning, Operation & Calibration of Hot Plate ApparatusDocument3 pagesSOP For Cleaning, Operation & Calibration of Hot Plate ApparatusRainMan75100% (1)

- Good Weighing in Pharma - 5Document4 pagesGood Weighing in Pharma - 5RainMan75No ratings yet

- Good Weighing in Pharma - 2Document3 pagesGood Weighing in Pharma - 2RainMan75No ratings yet

- Guidelines For SubmisionDocument72 pagesGuidelines For SubmisionJamalNo ratings yet

- Liquoflow® Phlex DS 2XDocument2 pagesLiquoflow® Phlex DS 2XPankaj RajbharNo ratings yet

- 10.1007@s11947 018 2076 7Document15 pages10.1007@s11947 018 2076 7LÊ Nhơn ĐứcNo ratings yet

- TDS PACACEL L75-191 CR-89 April 2018Document4 pagesTDS PACACEL L75-191 CR-89 April 2018oscar veraNo ratings yet

- Software Design Sample - Pharmacy SystemDocument3 pagesSoftware Design Sample - Pharmacy Systemrockers91No ratings yet

- LPTDocument15 pagesLPTShikha SharmaNo ratings yet

- Lesson Plan in Epp Vi JoyDocument11 pagesLesson Plan in Epp Vi JoyRaf June Galve VillanuevaNo ratings yet

- Allklear 600 PdsDocument1 pageAllklear 600 Pdsben7251No ratings yet

- Microbial Safety of Minimally Processed FoodsDocument357 pagesMicrobial Safety of Minimally Processed FoodsGaganpreet KaurNo ratings yet

- 24 Ilukor 279289Document56 pages24 Ilukor 279289Masood AalamNo ratings yet

- Presentation On Ich Topics & Guidelines With A Special Reference ToDocument79 pagesPresentation On Ich Topics & Guidelines With A Special Reference ToVidyaNo ratings yet

- Avg VARIATION PDFDocument33 pagesAvg VARIATION PDFjanggakabNo ratings yet

- Conquering Shelf-Life Issues of Chocolate PDFDocument5 pagesConquering Shelf-Life Issues of Chocolate PDFtavibastiNo ratings yet

- SAP B1 Beas-WMS - Integration - Document - PDFDocument18 pagesSAP B1 Beas-WMS - Integration - Document - PDFOndřej HůrkaNo ratings yet

- 3M Scotchcast Electrical Insulating Resin 40 DatasheetDocument4 pages3M Scotchcast Electrical Insulating Resin 40 DatasheetEmeka IgweNo ratings yet

- Plexus Selector GuideDocument8 pagesPlexus Selector GuideLodewykbronnNo ratings yet

- DI333 541 561 EngDocument21 pagesDI333 541 561 EngKrishna Mohan.p.rNo ratings yet

- Nitoflor ET Slurry PDFDocument4 pagesNitoflor ET Slurry PDFriverwilliamsNo ratings yet

- Paquet Evaluation of Shelf Lifes of NCDocument18 pagesPaquet Evaluation of Shelf Lifes of NCAkhilNo ratings yet

- Maestro WB Primer 28830Document3 pagesMaestro WB Primer 28830Noman AhmedNo ratings yet

- Dispostivos Médicos - 2012 - RObert KochDocument142 pagesDispostivos Médicos - 2012 - RObert KochÂngelo LuisNo ratings yet

- Stud Bolt Coating - XYLAN - 10701Document3 pagesStud Bolt Coating - XYLAN - 10701scott100% (2)

- HPP - Meat 1Document2 pagesHPP - Meat 1Mian DestgirNo ratings yet

- DOST-OSEC Citizens Charter CY 2023Document1,015 pagesDOST-OSEC Citizens Charter CY 2023PatrickNo ratings yet

- 6.3 Quality Assurance Quality ControlDocument8 pages6.3 Quality Assurance Quality ControlPaul Darrel MenesesNo ratings yet

- Module Food FlowDocument14 pagesModule Food FlowMark Edrian RodriguezNo ratings yet

- Bachelor Food 2 Ed Steve DotyDocument113 pagesBachelor Food 2 Ed Steve DotySankhyaNo ratings yet

- Maturex Pro PDSDocument2 pagesMaturex Pro PDSMinh Quang HàNo ratings yet

- Ta Elastomer Cure DatesDocument3 pagesTa Elastomer Cure DatesRay FaiersNo ratings yet

- How to Estimate with RSMeans Data: Basic Skills for Building ConstructionFrom EverandHow to Estimate with RSMeans Data: Basic Skills for Building ConstructionRating: 4.5 out of 5 stars4.5/5 (2)

- A Place of My Own: The Architecture of DaydreamsFrom EverandA Place of My Own: The Architecture of DaydreamsRating: 4 out of 5 stars4/5 (242)

- Building Construction Technology: A Useful Guide - Part 2From EverandBuilding Construction Technology: A Useful Guide - Part 2Rating: 5 out of 5 stars5/5 (1)

- Field Guide for Construction Management: Management by Walking AroundFrom EverandField Guide for Construction Management: Management by Walking AroundRating: 4.5 out of 5 stars4.5/5 (3)

- The Art of Welding: Featuring Ryan Friedlinghaus of West Coast CustomsFrom EverandThe Art of Welding: Featuring Ryan Friedlinghaus of West Coast CustomsNo ratings yet

- Building Construction Technology: A Useful Guide - Part 1From EverandBuilding Construction Technology: A Useful Guide - Part 1Rating: 4 out of 5 stars4/5 (3)

- Welding for Beginners in Fabrication: The Essentials of the Welding CraftFrom EverandWelding for Beginners in Fabrication: The Essentials of the Welding CraftRating: 5 out of 5 stars5/5 (5)

- The Complete Guide to Building Your Own Home and Saving Thousands on Your New HouseFrom EverandThe Complete Guide to Building Your Own Home and Saving Thousands on Your New HouseRating: 5 out of 5 stars5/5 (3)

- 1,001 Questions & Answers for the CWI Exam: Welding Metallurgy and Visual Inspection Study GuideFrom Everand1,001 Questions & Answers for the CWI Exam: Welding Metallurgy and Visual Inspection Study GuideRating: 3.5 out of 5 stars3.5/5 (7)

- Nuclear Energy in the 21st Century: World Nuclear University PressFrom EverandNuclear Energy in the 21st Century: World Nuclear University PressRating: 4.5 out of 5 stars4.5/5 (3)

- Pressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedFrom EverandPressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedRating: 5 out of 5 stars5/5 (1)

- An Architect's Guide to Construction: Tales from the Trenches Book 1From EverandAn Architect's Guide to Construction: Tales from the Trenches Book 1No ratings yet

- Markup & Profit: A Contractor's Guide, RevisitedFrom EverandMarkup & Profit: A Contractor's Guide, RevisitedRating: 5 out of 5 stars5/5 (11)

- Practical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsFrom EverandPractical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsRating: 3.5 out of 5 stars3.5/5 (3)

- Industrial Waste Treatment HandbookFrom EverandIndustrial Waste Treatment HandbookRating: 5 out of 5 stars5/5 (1)

- Estimator's General Construction Manhour ManualFrom EverandEstimator's General Construction Manhour ManualRating: 4.5 out of 5 stars4.5/5 (20)

- How to Build a Tiny Portable House: With Plans and InstructionsFrom EverandHow to Build a Tiny Portable House: With Plans and InstructionsRating: 4 out of 5 stars4/5 (1)

- Civil Engineer's Handbook of Professional PracticeFrom EverandCivil Engineer's Handbook of Professional PracticeRating: 4.5 out of 5 stars4.5/5 (2)

- Piping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationFrom EverandPiping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationRating: 4 out of 5 stars4/5 (18)

- The Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialFrom EverandThe Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialNo ratings yet

- The Everything Woodworking Book: A Beginner's Guide To Creating Great Projects From Start To FinishFrom EverandThe Everything Woodworking Book: A Beginner's Guide To Creating Great Projects From Start To FinishRating: 4 out of 5 stars4/5 (3)