Professional Documents

Culture Documents

(ICR18650-26B) IEC62133 CB Test Report - MH21015-D2-CB-3-Amendment-1

Uploaded by

hevenessaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

(ICR18650-26B) IEC62133 CB Test Report - MH21015-D2-CB-3-Amendment-1

Uploaded by

hevenessaCopyright:

Available Formats

Page 1 of 21 Report No.

BA-4786613384-A-1

Test Report issued under the responsibility of:

TEST REPORT

IEC 62133

Secondary cells and batteries containing alkaline or other non-acid

electrolytes – Safety requirements for portable sealed secondary cells,

and for batteries made from them, for use in portable applications

Report Number. .............................. : BA-4786613384-A-1

Date of issue ................................... : Reissue: 2013-07-17/ BA-13CA36829-A-1,

Amendment 1: 2014-10-29/ BA-4786613384-A-1

Total number of pages .................... 21

Applicant’s name ............................ : SAMSUNG SDI CO LTD

Address ........................................... : 508 SUNGSUNG-DONG CHEONAN-SI,

CHUNGCHEONGNAM-DO 331-300 KR

Test specification:

Standard .......................................... : IEC 62133: 2012 (Second Edition)

Test procedure ............................... : CB Scheme

Non-standard test method............. : N/A

Test Report Form No...................... : IEC62133B

Test Report Form(s) Originator .... : UL(Demko)

Master TRF ...................................... : Dated 2013-03

Copyright © 2013 Worldwide System for Conformity Testing and Certification of Electrotechnical

Equipment and Components (IECEE), Geneva, Switzerland. All rights reserved.

This publication may be reproduced in whole or in part for non-commercial purposes as long as the IECEE is acknowledged as

copyright owner and source of the material. IECEE takes no responsibility for and will not assume liability for damages resulting

from the reader's interpretation of the reproduced material due to its placement and context.

If this Test Report Form is used by non-IECEE members, the IECEE/IEC logo and the reference to the

CB Scheme procedure shall be removed.

This report is not valid as a CB Test Report unless signed by an approved CB Testing Laboratory

and appended to a CB Test Certificate issued by an NCB in accordance with IECEE 02.

Test item description ..................... : Cylindrical Li-ion Cell

Trade Mark ...................................... : Samsung SDI

Manufacturer ................................... : SAME AS APPLICANT

Model/Type reference .................... : ICR18650-26++ / ICR19/65

(++ These cells may have an optional single alphanumeric suffix or

blank not related safety)

Ratings ............................................ : 3.7Vdc or 3.63Vdc, 2600mAh

Page 2 of 21 Report No. BA-4786613384-A-1

Testing procedure and testing location:

CB Testing Laboratory: Underwriters Laboratories Taiwan Co., Ltd

Testing location/ address ....................... : 260 Da-Yeh Road 112 Peitou Taipei City, CHINESE

TAIPEI

Associated CB Testing Laboratory:

Testing location/ address ....................... :

Tested by (name + signature) .......... :

Approved by (name + signature) ..... :

Testing procedure: TMP

Testing location/ address ....................... : SAMSUNG SDI CO LTD / 508 SUNGSUNG-DONG

CHEONAN-SI, CHUNGCHEONGNAM-DO 331-300 KR

Tested by (name + signature) .......... : Joon Huh

Approved by (name + signature) ..... : Dora Lin

Testing procedure: WMT

Testing location/ address ....................... :

Tested by (name + signature) .......... :

Witnessed by (name + signature) .... :

Approved by (name + signature) ..... :

Testing procedure: SMT

Testing location/ address ....................... :

Tested by (name + signature) .......... :

Approved by (name + signature) ..... :

Supervised by (name + signature) .. :

TRF No. IEC62133B

Page 3 of 21 Report No. BA-4786613384-A-1

List of Attachments (including a total number of pages in each attachment):

National Differences ( 0 pages)

Enclosures ( 0 pages)

Summary of testing:

Tests performed (name of test and test Testing location:

clause):

Original Underwriters Laboratories Taiwan Co., Ltd.

4.2.1 - Continuous Low Rate Charging 1st Fl, 260 Da-Yeh Road, Peitou, Taipei City,

4.2.2 - Vibration Taiwan 112

4.2.4 - Temperature Cycling

4.3.2 - External Short Circuit: at 20°C ± 5°C

4.3.2 - External Short Circuit: at 55°C ± 5°C

4.3.3 - Free Fall

4.3.4 - Mechanical Shock (Crash Hazard)

4.3.5 - Thermal Abuse

4.3.6 - Crushing of Cells

4.3.7 - Low Pressure

4.3.9 - Overcharge for Lithium Systems

4.3.10 - Forced Discharge

4.3.11 - Cell Protection Against a High Charging

Rate (Lithium Systems Only)

Reissue Underwriters Laboratories Taiwan Co., Ltd.

8.1.2 – Charge (procedure 2)

1st Fl, 260 Da-Yeh Road, Peitou, Taipei City,

8.3.1 – External short circuit (cells)

Taiwan 112

Reissue SAMSUNG SDI CO LTD

8.1.2 – Charge (procedure 2)

508 SUNGSUNG-DONG CHEONAN-SI,

8.3.4 – Thermal abuse (cells)

CHUNGCHEONGNAM-DO 331-300 KR

8.3.5 – Crush (cells)

8.3.9 – Forced internal short circuit (cells)

Amendment 1(this report) SAMSUNG SDI CO LTD

8.2.1 – Continuous charging at constant voltage

508 SUNGSUNG-DONG CHEONAN-SI,

(cells)

CHUNGCHEONGNAM-DO 331-300 KR

8.3.1 – External short circuit (cells)

8.3.3 – Free fall

8.3.4 – Thermal abuse (cells)

8.3.5 – Crush (cells)

8.3.7 – Forced Discharge

8.3.9 – Forced internal short circuit (cells)

Summary of compliance with National Differences

List of countries addressed: N/A

8.3.9 Forced internal short circuit was considered for France, Japan, Korea and Switzerland.

No difference for EN 62133:2013.

TRF No. IEC62133B

Page 4 of 21 Report No. BA-4786613384-A-1

Copy of marking plate

The artwork below may be only a draft. The use of certification marks on a product must be

authorized by the respective NCBs that own these marks.

TRF No. IEC62133B

Page 5 of 21 Report No. BA-4786613384-A-1

Test item particulars...................................................:

Classification of installation and use.......................: N/A

Supply connection......................................................: N/A

Recommend charging method declaired by the

CC/CV

manufacturer ........................................................... :

Discharge current (0,2 It A) ................................... : 0.520A

Specified final voltage ............................................ : 2.75Vdc

Chemistry ............................................................... : nickel systems ....... lithium systems

Recommend of charging limit for lithium system

Upper limit charging voltage per cell .......................: 4.25Vdc

Maximum charging current .......................................: 2600mA

Charging temperature upper limit ............................: 45°C

Charging temperature lower limit.............................: 10°C

Polymer cell electrolyte type ................................. : gel polymer ............ solid polymer

Possible test case verdicts:

- test case does not apply to the test object ........... : N/A

- test object does meet the requirement.................. : P (Pass)

- test object does not meet the requirement ........... : F (Fail)

Testing.......................................................................... :

Date of receipt of test item ........................................ : 2014-10-10

Date (s) of performance of tests ............................... : 2014-10-10 to 2014-10-17

General remarks:

The test results presented in this report relate only to the object tested.

This report shall not be reproduced, except in full, without the written approval of the Issuing testing

laboratory.

"(See Enclosure #)" refers to additional information appended to the report.

"(See appended table)" refers to a table appended to the report.

Throughout this report a comma / point is used as the decimal separator.

Manufacturer’s Declaration per sub-clause 4.2.5 of IECEE 02:

The application for obtaining a CB Test Certificate Yes

includes more than one factory location and a Not applicable

declaration from the Manufacturer stating that the

sample(s) submitted for evaluation is (are)

representative of the products from each factory has

been provided ............................................................... :

When differences exist; they shall be identified in the General product information section.

TRF No. IEC62133B

Page 6 of 21 Report No. BA-4786613384-A-1

Name and address of factory (ies) .......................... : 1. TIANJIN SAMSUNG SDI CO LTD

DEVELOPING ZONE OF YI XIAN PARK WUQING

COUNTY TIANJIN 301726 CHINA

2. SAMSUNG SDI CO LTD

508 SUNGSUNG-DONG CHEONAN-SI ,

CHUNGCHEONGNAM-DO 331-300, Korea

3. SAMSUNG SDI ENERGY MALAYSIA SDN.BHD

Lot 635 & 660 Kawasan Perindustrian Tuanku Jaafar

71450 Sungai Gadut, Negeri Sembilan Darul Khusus

Malaysia

General product information:

The suffix,++ of the model name is not related safety.

This cell consists of Positive Electrode, Negative Electrode, Separator, Electrolyte and is covered by

Stainless Steel. This cell is also investigated to UL 1642.

The product was investigated to the following additional standards: EN 62133:2013

The product was complying with the latest version of IEC 62133:2012(2nd edition),

including revisions through revision date June 01, 2013.

The original report was issued in 2010-04-23. The original report no. is BA-10CA07110-A-1.

Amendment 1

-Add factory location and contact information

Amendment 2

-Correct the capacity from 2000mAh to 2600mAh. The original capacity was 2600mAh but for

amendment 1, the capacity was changed by error.

-The previous report was BA-11CA19490-A-1.

Amendment 3

-Alternate nominal voltage, 3.63Vdc without any construction change.

-Correct applicant address from 508 SUNGSUNG-DONG CHONAN-SHI CHONGCHONGNAM-DO,

Korea to 508 SUNGSUNG-DONG CHEONAN-SI , CHUNGCHEONGNAM-DO 331-300, Korea.

-The previous report is BA-11CA18646-C-1.

Reissue 1

-Previous report no. is BA-12CA18674-A-1

-Change model name from ICR18650-26++ / ICR18/65 to ICR18650-26++ / ICR19/65

-Change the address of Applicant and Manufacturer from SAMSUNG SDI CO LTD/ 508 SUNGSUNG-

DONG CHONAN-SHI CHONGCHONGNAM-DO, Korea to SAMSUNG SDI CO LTD/ 508

SUNGSUNG-DONG CHEONAN-SI , CHUNGCHEONGNAM-DO 331-300 KR

-Add factory, SAMSUNG SDI ENERGY MALAYSIA SDN.BHD / Lot 635 & 660 Kawasan Perindustrian

Tuanku Jaafar 71450 Sungai Gadut, Negeri Sembilan Darul Khusus Malaysia

-Change the address of Factory from SAMSUNG SDI CO LTD/ 508 SUNGSUNG-DONG CHONAN-

SHI CHONGCHONGNAM-DO, Korea to SAMSUNG SDI CO LTD/ 508 SUNGSUNG-DONG

CHEONAN-SI , CHUNGCHEONGNAM-DO 331-300 KR

-Add the comment for addition of evaluating standard EN 62133:2003.

-Add the explanation of suffix ++ of model name.

-This report is a reissue of CBTR Ref. No.: BA-10CA07110-A-1, BA-11CA19490-A-1, BA-11CA18646-

C-1 and BA-12CA18674-A-1.

Based on the previously conducted testing and the review of product technical documentation

including photos, schematics, wiring diagrams and similar, has been determined that the product

continues to comply with the standard.

TRF No. IEC62133B

Page 7 of 21 Report No. BA-4786613384-A-1

Reissue 2 / BA-13CA36829-A-1

st nd

- Upgrade standard from IEC 62133:2002 1 to IEC 62133:2012 2 .

- This report is a reissue of CBTR Ref. No.: BA-10CA07110-A-1, BA-11CA19490-A-1, BA-

11CA18646-C-1, BA-12CA18674-A-1 and 12CA43710-G-1, CB Test Certificate Ref. No. DK-

27544-UL. Based on previously conducted testing and the review of product construction, only

CONTINUOUS CHARGING AT CONSTANT VOLTAGE (CELL), EXTERNAL SHORT CIRCUIT

(CELL), THERMAL ABUSE TEST, CRUSHING OF CELLS, FORCED INTERNAL SHORT

CIRCUIT OF CELLS tests were deemed necessary.

Amendment 1/ BA-4786613384-A-1

- Previous report no. is BA-13CA36829-A-1

- Add alternate PTC, type SHA-26001 by SHIN HEUNG ENERGY & ELECTRONICS CO LTD.

- Add alternate PTC, type PTC-3996D by POLYTRONICS TECHNOLOGY CORP.

- Add alternate PTC, type SHD-26001 by SHIN HEUNG ENERGY & ELECTRONICS CO LTD.

- PTC-3996D and SHD-26001 are same rating of the previous certified model PSR-26039 by

RAYCHEM ELECTRONICS (SHANGHAI) LTD.

- Change technical data of PTC manufacturer name from Tyco Raychem Div to RAYCHEM

ELECTRONICS (SHANGHAI) LTD.

- Change technical data of PTC type name from PSR26039 to PSR-26039.

- Deleting factory information of SAMSUNG SDI CO LTD

PUSAN PLANT 818 KACHUN-RI ULJU-GUN, SAMNAM-MYUN ULSAN 689-810 KOREA.

- Adding alternate positive active material LiNiCoMnO2 (Lithium Nickel Cobalt Manganese

Oxide) + LiCoO2(Lithium cobalt oxide)

TRF No. IEC62133B

Page 8 of 21 Report No. BA-4786613384-A-1

IEC 62133

Clause Requirement + Test Result - Remark Verdict

8 Specific requirements and tests (lithium systems) Pass

8.1 Charging procedures for test purposes Pass

8.1.1 First procedure: Pass

This charging procedure applied to tests other than

those specified in 8.1.2

8.1.2 Second procedure: Pass

This charging procedure applied to the tests of

8.3.1, 8.3.2, 8.3.4, 8.3.5, and 8.3.9

If a cell’s specified upper and/or lower charging Charging temperature upper Pass

temperature exceeds values for the upper and/or limit: 45°C

lower limit test temperatures of Table 4, the cells Charging temperature lower

were charged at the specified values plus 5 °C for limit: 10°C

the upper limit and minus 5 °C for the lower limit

A valid rationale was provided to ensure the safety Pass

of the cell (see Figure A.1) ....................................... :

For a different upper limit charging voltage (i.e. Upper charging voltage: Pass

other than for lithium cobalt oxide systems at 4,25 4.25Vdc

V), the applied upper limit charging voltage and

upper limit charging temperatures were adjusted

accordingly

A valid rationale was provided to ensure the safety Pass

of the cell (see Figure A.1) ....................................... :

8.2 Intended use Pass

8.2.1 Continuous charging at constant voltage (cells) Pass

Results: No fire. No explosion .................................. : (See Table 8.2.1) Pass

8.3 Reasonably foreseeable misuse Pass

8.3.1 External short circuit (cell) Pass

The cells were tested until one of the following N/A

occurred:

- 24 hours elapsed; or

- The case temperature declined by 20% of the Pass

maximum temperature rise

Results: No fire. No explosion .................................. : (See Table 8.3.1) Pass

8.3.3 Free fall Pass

Results: No fire. No explosion. Pass

8.3.4 Thermal abuse (cells) Pass

The cells were held at 130°C ± 2°C for: Pass

- 10 minutes; or

- 30 minutes for large cells (gross mass of more N/A

than 500 g as defined in IEC 62281)

Oven temperature (°C) ............................................... : —

TRF No. IEC62133B

Page 9 of 21 Report No. BA-4786613384-A-1

IEC 62133

Clause Requirement + Test Result - Remark Verdict

Gross mass of cell (g) ................................................ : —

Results: No fire. No explosion. Pass

8.3.5 Crush (cells) Pass

The crushing force was released upon: Pass

- The maximum force of 13 kN ± 1 kN has been

applied; or

- An abrupt voltage drop of one-third of the original N/A

voltage has been obtained; or

- 10% of deformation has occurred compared to the N/A

initial dimension

Results: No fire. No explosion .................................. : (See Table 8.3.5) Pass

8.3.7 Forced discharge (cells) Pass

Results: No fire. No explosion .................................. : (See Table 8.3.7) Pass

8.3.9 Design evaluation – Forced internal short circuit Pass

(cells)

The cells complied with national requirement for ...... : France, Japan, Korea and —

Switzerland

The pressing was stopped upon: N/A

- A voltage drop of 50 mV has been detected; or

- The pressing force of 800 N (cylindrical cells) or 800 N for cylindrical cells. Pass

400 N (prismatic cells) has been reached

Results: No fire ......................................................... : (See Table 8.3.9) Pass

9 Information for safety Pass

The manufacturer of secondary cells ensures that Pass

information is provided about current, voltage and

temperature limits of their products.

The manufacturer of batteries ensures that N/A

equipment manufacturers and, in the case of direct

sales, end-users are provided with information to

minimize and mitigate hazards.

Systems analyses performed by device N/A

manufacturers to ensure that a particular battery

design prevents hazards from occurring during use

of a product

As appropriate, information relating to hazard N/A

avoidance resulting from a system analysis is

provided to the end user .......................................... :

Annex A Charging range of secondary lithium ion cells for safe use Pass

A.1 General Pass

A.2 Safety of lithium-ion secondary battery Pass

TRF No. IEC62133B

Page 10 of 21 Report No. BA-4786613384-A-1

IEC 62133

Clause Requirement + Test Result - Remark Verdict

A.3 Consideration on charging voltage Pass

A.3.1 General Pass

A.3.2 Upper limit charging voltage Pass

A.3.2.1 General Pass

A.3.2.2 Explanation of safety viewpoint Pass

A.3.2.3 Safety requirements, when different upper limit Pass

charging voltage is applied

A.4 Consideration of temperature and charging current Pass

A.4.1 General Pass

A.4.2 Recommended temperature range Pass

A.4.2.1 General Pass

A.4.2.2 Safety consideration when a different recommended Pass

temperature range is applied

A.4.3 High temperature range Pass

A.4.3.1 General Pass

A.4.3.2 Explanation of safety viewpoint Pass

A.4.3.3 Safety considerations when specifying charging Pass

conditions in high temperature range

A.4.3.4 Safety consideration when specifying new upper Pass

limit in high temperature range

A.4.4 Low temperature range Pass

A.4.4.1 General Pass

A.4.4.2 Explanation of safety viewpoint Pass

A.4.4.3 Safety considerations, when specifying charging Pass

conditions in low temperature range

A.4.4.4 Safety considerations when specifying a new lower Pass

limit in the low temperature range

A.4.5 Scope of the application of charging current Pass

A.5 Sample preparation Pass

A.5.1 General Pass

A.5.2 Insertion procedure for nickel particle to generate Pass

internal short

The insertion procedure carried out at 20°C±5°C Pass

and under -25 °C of dew point

A.5.3 Disassembly of charged cell Pass

A.5.4 Shape of nickel particle Pass

A.5.5 Insertion of nickel particle to cylindrical cell Pass

TRF No. IEC62133B

Page 11 of 21 Report No. BA-4786613384-A-1

IEC 62133

Clause Requirement + Test Result - Remark Verdict

A.5.5.1 Insertion of nickel particle to winding core Pass

A.5.5.2 Mark the position of nickel particle on the both end Pass

of winding core of the separator

A.5.6 Insertion of nickel particle to prismatic cell N/A

TRF No. IEC62133B

Page 12 of 21 Report No. BA-4786613384-A-1

IEC 62133

Clause Requirement + Test Result - Remark Verdict

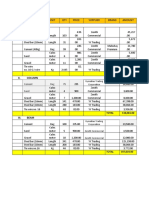

TABLE: Critical components information Pass

Object/part no. Manufacturer/ Type/model Technical data Standard Mark(s) of

1)

trademark conformity

Cells

- Case -- -- Stainless Steel -- --

- Electrolyte -- -- Ethylene -- --

carbonate, ethyl

methyl

carbonate,

fluorobenzene,

di-methyl

carbonate

- Separator -- -- PE or PP/PE/PP -- --

- SJ72-00XXXX

- Positive Lithium Nickel

Electrode Cobalt

-- -- Manganese

Oxide

(LiNiCoMnO2)

- Positive LiNiCoMnO2

Electrode; (Lithium Nickel

Alternate Cobalt

-- -- Manganese

Oxide) +

LiCoO2(Lithium

cobalt oxide)

- Negative -- -- Carbon and -- --

Electrode PVDF or SBR

-PTC RAYCHEM

ELECTRONICS 15Vdc, Ih= 2.9A,

PSR-26039 UL1434 RU

(SHANGHAI) It=7.7A

LTD

- PTC alternate 1 POLYTRONICS 15Vdc, Ih= 2.9A,

TECHNOLOGY PTC-3996D UL1434 RU

It=7.7A

CORP

- PTC alternate 2 SHIN HEUNG

ENERGY & 15Vdc, Ih= 2.9A,

SHD-26001 UL1434 RU

ELECTRONICS It=7.7A

CO LTD.

- PTC alternate 3 SHIN HEUNG

ENERGY & 15Vdc, Ih= 4.6A,

SHA-26001 UL1434 RU

ELECTRONICS It=12.3A

CO LTD.

TRF No. IEC62133B

Page 13 of 21 Report No. BA-4786613384-A-1

IEC 62133

Clause Requirement + Test Result - Remark Verdict

Supplementary information:

1)

Provided evidence ensures the agreed level of compliance. See OD-CB2039.

TRF No. IEC62133B

Page 14 of 21 Report No. BA-4786613384-A-1

IEC 62133

Clause Requirement + Test Result - Remark Verdict

8.2.1 TABLE: Continuous charging at constant voltage (cells) Pass

Model Recommended Recommended OCV at start of Results

charging voltage charging current test, (Vdc)

Vc, (Vdc) Irec, (A)

ICR18650-26++ 4.2 2.6 4.17 A

ICR18650-26++ 4.2 2.6 4.17 A

ICR18650-26++ 4.2 2.6 4.17 A

ICR18650-26++ 4.2 2.6 4.17 A

ICR18650-26++ 4.2 2.6 4.17 A

Supplementary information:

A - No fire or explosion

B - No leakage

C - Leakage

D - Fire

E - Explosion

F – Bulge

G - Others (please explain)

TRF No. IEC62133B

Page 15 of 21 Report No. BA-4786613384-A-1

IEC 62133

Clause Requirement + Test Result - Remark Verdict

8.3.1 TABLE: External short circuit (cell) Pass

Model Ambient, (°°C) OCV at start of Resistance of Maximum case Results

test, (Vdc) Ω)

circuit, (Ω temperature

rise ∆T, (°°C)

For alternate positive active material with alternate PTC model SHA-26001 by Shin Heung Samples

charged at charging temperature lower limit (-5°°C)

ICR18650-26++ 21.0 4.13 0.08 44.8 A,G

ICR18650-26++ 21.0 4.13 0.08 42.7 A,G

ICR18650-26++ 21.0 4.13 0.08 40.3 A,G

ICR18650-26++ 21.0 4.13 0.08 42.9 A,G

ICR18650-26++ 21.0 4.13 0.08 43.2 A,G

For alternate positive active material with alternate PTC model SHA-26001 by Shin Heung Samples

charged at charging temperature upper limit(55°°C)

ICR18650-26++ 21.0 4.21 0.08 41.4 A,G

ICR18650-26++ 21.0 4.21 0.08 34.1 A,G

ICR18650-26++ 21.0 4.21 0.08 35.1 A,G

ICR18650-26++ 21.0 4.21 0.08 34.3 A,G

ICR18650-26++ 21.0 4.21 0.08 35.4 A,G

For basic positive active material with alternate PTC model SHA-26001 by Shin Heung Samples

charged at charging temperature lower limit (-5°°C)

ICR18650-26++ 21.0 4.17 0.08 46.5 A,G

ICR18650-26++ 21.0 4.17 0.08 38.9 A,G

ICR18650-26++ 21.0 4.17 0.08 42.8 A,G

ICR18650-26++ 21.0 4.17 0.08 46.7 A,G

ICR18650-26++ 21.0 4.17 0.08 39.1 A,G

For basic positive active material with alternate PTC model SHA-26001 by Shin Heung Samples

charged at charging temperature upper limit(55°°C)

ICR18650-26++ 21.0 4.21 0.08 38.0 A,G

ICR18650-26++ 21.0 4.21 0.08 36.7 A,G

ICR18650-26++ 21.0 4.21 0.08 37.5 A,G

ICR18650-26++ 21.0 4.21 0.08 38.1 A,G

ICR18650-26++ 21.0 4.21 0.08 36.6 A,G

TRF No. IEC62133B

Page 16 of 21 Report No. BA-4786613384-A-1

IEC 62133

Clause Requirement + Test Result - Remark Verdict

Supplementary information:

A - No fire or explosion

B - No leakage

C - Leakage

D - Fire

E - Explosion

F – Bulge

G - Others (please explain) - The test was completed after the cell casing cooled to 20% of the

maximum temperature rise

Note) temperature rise and protective device was operated. Test was conducted at upper/lower

charging limit of 55/-5C which is more severe condition than at 45/10C

TRF No. IEC62133B

Page 17 of 21 Report No. BA-4786613384-A-1

IEC 62133

Clause Requirement + Test Result - Remark Verdict

8.3.2 TABLE: External short circuit (battery) N/A

Model Ambient, (°°C) OCV at start of Resistance of Maximum case Results

test, (Vdc) Ω)

circuit, (Ω temperature

rise ∆T, (°°C)

Samples charged at charging temperature upper limit

-- -- -- -- -- --

Samples charged at charging temperature lower limit

-- -- -- -- -- --

Supplementary information:

- No fire or explosion

- No leakage

- Leakage

- Fire

- Explosion

- Bulge

- Others (please explain)

TRF No. IEC62133B

Page 18 of 21 Report No. BA-4786613384-A-1

IEC 62133

Clause Requirement + Test Result - Remark Verdict

8.3.5 TABLE: Crush Pass

Model OCV at start of OCV at Width/ Required Results

test, (Vdc) removal of diameter of deformation

crushing force, cell before for crush,

(Vdc) crush, (mm) (mm)

Samples charged at charging temperature lower limit (5°°C)

ICR18650-26++ 4.14 4.14 -- 0.18 A,G

ICR18650-26++ 4.14 4.14 -- 0.18 A,G

ICR18650-26++ 4.14 4.14 -- 0.18 A,G

ICR18650-26++ 4.14 4.14 -- 0.18 A,G

ICR18650-26++ 4.14 4.14 -- 0.18 A,G

Samples charged at charging temperature upper limit (50°°C)

ICR18650-26++ 4.22 4.22 -- 0.18 A,G

ICR18650-26++ 4.22 4.22 -- 0.18 A,G

ICR18650-26++ 4.22 4.22 -- 0.18 A,G

ICR18650-26++ 4.22 4.22 -- 0.18 A,G

ICR18650-26++ 4.22 4.22 -- 0.18 A,G

Supplementary information:

A - No fire or explosion

B - No leakage

C - Leakage

D - Fire

E - Explosion

F – Bulge

G - Others (please explain): The values of diameter of cell were not measured. The test was conducted until

the test force was reached max. force.

Note) Test was conducted at upper/lower charging limit of 50/5°°C which is more severe condition

than at 45/10°°C.

TRF No. IEC62133B

Page 19 of 21 Report No. BA-4786613384-A-1

IEC 62133

Clause Requirement + Test Result - Remark Verdict

8.3.7 TABLE: Forced discharge (cells) Pass

Model OCV before Measured Time for reversed Results

application of Reverse charge It, charge, (minutes)

reverse charge, (A)

(Vdc)

ICR18650-26++ 2.75 2.6 90 A,B

ICR18650-26++ 2.75 2.6 90 A,B

ICR18650-26++ 2.75 2.6 90 A,B

ICR18650-26++ 2.75 2.6 90 A,B

ICR18650-26++ 2.75 2.6 90 A,B

Supplementary information:

A - No fire or explosion

B - No leakage

C - Leakage

D - Fire

E - Explosion

F – Bulge

G - Others (please explain)

TRF No. IEC62133B

Page 20 of 21 Report No. BA-4786613384-A-1

IEC 62133

Clause Requirement + Test Result - Remark Verdict

8.3.9 TABLE: Forced internal short circuit (cells) Pass

Model Chamber OCV at start of Particle Maximum Results

1)

ambient, (°°C) test, (Vdc) location applied

pressure, (N)

ICR18650-26++ 5 4.18 1 800 A,B

ICR18650-26++ 5 4.18 1 800 A,B

ICR18650-26++ 5 4.18 1 800 A,B

ICR18650-26++ 5 4.18 1 800 A,B

ICR18650-26++ 5 4.18 1 800 A,B

ICR18650-26++ 50 4.22 1 800 A,B

ICR18650-26++ 50 4.22 1 800 A,B

ICR18650-26++ 50 4.22 1 800 A,B

ICR18650-26++ 50 4.22 1 800 A,B

ICR18650-26++ 50 4.22 1 800 A,B

Supplementary information:

1)

Identify one of the following:

1: Nickel particle inserted between positive and negative (active material) coated area.

2: Nickel particle inserted between positive aluminium foil and negative active material coated area.

A - No fire or explosion

B - No leakage

C - Leakage

D - Fire

E - Explosion

F – Bulge

G - Others (please explain)

Note) Test was conducted at upper/lower charging limit of 50/5°°C which is more severe condition

than at 45/10°°C.

TRF No. IEC62133B

Page 21 of 21 Report No. BA-4786613384-A-1

List of test equipment used

(Note: This is an example of the required attachment. Other forms with a different layout but containing

similar information are also acceptable.)

Inst. ID Instrument Test Number +, Test Function/R Last Cal. Next Cal.

No. Type Title or Conditioning ange Date Date

253694 Power Supply CONTINUOUS CHARGING AT 5V,6A 2014-03-17 2015-03-17

CONSTANT VOLTAGE (CELL)

228662 Temperature THERMAL ABUSE TEST, 200 deg C 2013-10-24 2014-10-24

recorder FORCED-DISCHARGE TEST

211785 Temperature CHARGING PROCEDURE -10~100℃ 2014-10-14 2015-10-14

Controller

230628 Temperature THERMAL ABUSE TEST K 150 ℃ 2014-02-28 2015-02-28

Controller

226061 DC Power Supply CHARGING PROCEDURE, 20V/16A 2014-03-17 2015-03-17

FORCED-DISCHARGE TEST

200757 DATA acquisition THERMAL ABUSE TEST, 6V/0.01V 2014-04-24 2015-04-24

FORCED-DISCHARGE TEST 200℃/0.01C

228668 Steel Ruler FREE FALL 2000mm 2014-02-19 2015-02-19

229812 Temp Humidity ALL 0~33C, 2014-09-23 2015-09-23

Recorder 20~70%

209272 Digital Multimeter ALL 1000V, 10A 2014-02-16 2015-02-16

217817 Stop watch CONTINUOUS CHARGING AT 0.01 sec 2014-02-20 2015-02-20

CONSTANT VOLTAGE (CELL)

THERMAL ABUSE TEST,

FORCED-DISCHARGE

TEST

229815 Load Battery CRUSHING OF CELLS 3000Kg 2014-08-14 2015-08-14

125701 Load Battery CRUSHING OF CELLS 3000Kg 2013-12-18 2014-12-18

N/A Vernier Caliper Forced internal short circuit 0 ~ 300mm 2014-07-31 2015-07-31

120793 Temperature Forced internal short circuit -40~100℃ 2014-03-11 2015-03-11

Controller

226407 DATA acquisition Forced internal short circuit 0~10V 2014-06-30 2015-06-30

/ -10~400℃

226419 Crush tester Forced internal short circuit 0~1800N 2014-06-26 2015-06-26

TRF No. IEC62133B

You might also like

- MorphoAccess SIGMA Lite Series - Installation Guide - English (2015 - 0000007248-V9)Document80 pagesMorphoAccess SIGMA Lite Series - Installation Guide - English (2015 - 0000007248-V9)cesarillusNo ratings yet

- Aspire BrochureDocument2 pagesAspire BrochureAnitha PalanismayNo ratings yet

- C70 Modular Monitor SpecificationsDocument15 pagesC70 Modular Monitor SpecificationsDayani Gomez Escobar100% (1)

- 4 Channel ABS MicoDocument4 pages4 Channel ABS MicoRekhyttolemyNo ratings yet

- RN 02 00001 06 11 El WBG DG 000757Document1 pageRN 02 00001 06 11 El WBG DG 000757eiohat100% (1)

- Radc TR 85 91 - May1985Document441 pagesRadc TR 85 91 - May1985sezgin bayramNo ratings yet

- Iec 61400-25-6-2010Document36 pagesIec 61400-25-6-2010Yassine BecharNo ratings yet

- Single row angular contact ball bearings guideDocument43 pagesSingle row angular contact ball bearings guidezeljkoanNo ratings yet

- Low Density Polyethylene: DescriptionDocument2 pagesLow Density Polyethylene: DescriptionlyesNo ratings yet

- 9th Edition FireNET Installation Manual v1 92Document218 pages9th Edition FireNET Installation Manual v1 92mas zak danielNo ratings yet

- Insert - Calset FT4 III - Ms - 07976879190.V4.EnDocument2 pagesInsert - Calset FT4 III - Ms - 07976879190.V4.EnDiazz Ayu PrihandariniNo ratings yet

- Valve Magazine, Winter 2016Document52 pagesValve Magazine, Winter 2016GordinhorsNo ratings yet

- PTC 10 1997Document202 pagesPTC 10 1997Joel CieltoNo ratings yet

- Sen. Lankford Letter To CBP Chief MagnusDocument2 pagesSen. Lankford Letter To CBP Chief MagnusFox NewsNo ratings yet

- Open AMIPDocument8 pagesOpen AMIPmsyunakaNo ratings yet

- Techint Engenharia E Construção S.A.: Eneva Parnaiba V - Bottoming CycleDocument63 pagesTechint Engenharia E Construção S.A.: Eneva Parnaiba V - Bottoming Cycletatiana araujoNo ratings yet

- Manual de Serviço - DEP250Document237 pagesManual de Serviço - DEP250Anderson Gomes Resende (Gres)No ratings yet

- Aircraft Hangar Fire Protection Systems Design GuidanceDocument22 pagesAircraft Hangar Fire Protection Systems Design GuidanceNguyen Phu HaiNo ratings yet

- Wang 2020Document8 pagesWang 2020Sachin SinghNo ratings yet

- 4-13 TC Instrument Engineer HandbookDocument24 pages4-13 TC Instrument Engineer Handbooknabil mahmudNo ratings yet

- Electric Power Load Analysis for Surface ShipsDocument46 pagesElectric Power Load Analysis for Surface ShipsLincoln RibeiroNo ratings yet

- GM Cruise ProbeDocument2 pagesGM Cruise ProbeJoey KlenderNo ratings yet

- Falling Ball BDocument18 pagesFalling Ball BLeidi UrquijoNo ratings yet

- 545 E. Algonquin RD., Arlington Heights, IL 60005Document7 pages545 E. Algonquin RD., Arlington Heights, IL 60005flysch_ukNo ratings yet

- CDVI ATRIUM Software Version 7.0Document176 pagesCDVI ATRIUM Software Version 7.0Trevor FarrenNo ratings yet

- SNO-I-DS-004 - 0 Instrument Data Sheet For Orifice PlatesDocument106 pagesSNO-I-DS-004 - 0 Instrument Data Sheet For Orifice Platesono_czeNo ratings yet

- C4416 Optical Smoke Detector Features & Specs in 40 CharactersDocument2 pagesC4416 Optical Smoke Detector Features & Specs in 40 Charactersflee2yasirNo ratings yet

- AIC China RVSM 2007102473541105Document66 pagesAIC China RVSM 2007102473541105juanNo ratings yet

- Electrically Insulating Plastic Guard Equipment For Protection of WorkersDocument5 pagesElectrically Insulating Plastic Guard Equipment For Protection of WorkersOSCAR MAURICIO GUTIERREZ GOMEZNo ratings yet

- ReportTemplate PracticalTask or ProjectDocument27 pagesReportTemplate PracticalTask or ProjectDony Beast (DurraniFared)No ratings yet

- Paradip Final ReportDocument140 pagesParadip Final ReportArindam ChatterjeeNo ratings yet

- EVOLV DNA 250 ColorDocument23 pagesEVOLV DNA 250 ColorMuhammad AswinNo ratings yet

- BioTek 800 TS UserManualDocument60 pagesBioTek 800 TS UserManualAFWNo ratings yet

- FTF Aut f0234Document38 pagesFTF Aut f0234vishiwizardNo ratings yet

- IP TransitDocument14 pagesIP TransitFathurrohman Naim Syafi'iNo ratings yet

- Government Calibration Hierarchy in IndiaDocument3 pagesGovernment Calibration Hierarchy in IndiaNAYEEMNo ratings yet

- Conect OresDocument44 pagesConect OresManoloEskobarNo ratings yet

- Sfra MeggerDocument6 pagesSfra MeggerMehtab AhmedNo ratings yet

- Level 2 m200 Pahu Qa-Qc ChecksDocument10 pagesLevel 2 m200 Pahu Qa-Qc ChecksAnurag KumbhareNo ratings yet

- Fire Risk Assessment FormDocument20 pagesFire Risk Assessment FormAhmed Ibrahim100% (1)

- WindSonic GPA Manual 1405-PS-0019 Issue 25Document35 pagesWindSonic GPA Manual 1405-PS-0019 Issue 25eduardo ayalaNo ratings yet

- HIGH SPEED PRECISION LATHE INSTRUCTION AND SPARE PARTS MANUALDocument106 pagesHIGH SPEED PRECISION LATHE INSTRUCTION AND SPARE PARTS MANUALgohil abhijitNo ratings yet

- Foundry Diagnostic GuideDocument80 pagesFoundry Diagnostic GuidelightpaceNo ratings yet

- Reefer Test Simulation Icll CodexDocument24 pagesReefer Test Simulation Icll CodexEdwin Espinoza obandoNo ratings yet

- 057521Document20 pages057521M.Senthil VelavanNo ratings yet

- Juno Net Con SP1 MNDocument5 pagesJuno Net Con SP1 MNCarlos Eberhard Diaz TorresNo ratings yet

- I Q200 Rackmount ISMDocument58 pagesI Q200 Rackmount ISMMarios ApostolouNo ratings yet

- RE - 54 - confENc - (Application Manual)Document360 pagesRE - 54 - confENc - (Application Manual)Alexandre MorenoNo ratings yet

- SAUDI ARAMCO ID/PIEU INSPECTION CHECKLISTDocument13 pagesSAUDI ARAMCO ID/PIEU INSPECTION CHECKLISTnisha_khanNo ratings yet

- Emerson Control WaveDocument62 pagesEmerson Control WaveChristian CampaNo ratings yet

- State of Texas PricelistDocument675 pagesState of Texas PricelistAlexandreNo ratings yet

- Fiber Optics - Fiber Optic Systems Applied To Electric Power IndustryDocument77 pagesFiber Optics - Fiber Optic Systems Applied To Electric Power IndustryGerardo TillanoNo ratings yet

- FADPC Amphenol 1820416Document113 pagesFADPC Amphenol 1820416Omar Alfredo Del Castillo QuispeNo ratings yet

- Battery VRLA - Amaron Quanta 12V 26ah 12AL26 DatasheetDocument2 pagesBattery VRLA - Amaron Quanta 12V 26ah 12AL26 DatasheetJeep WillysNo ratings yet

- Astm A 194 - 2007aDocument12 pagesAstm A 194 - 2007axf zhang100% (1)

- Eletrical Machines (K-Wiki - Synchronous Machines)Document59 pagesEletrical Machines (K-Wiki - Synchronous Machines)qwer100% (1)

- Evm5515 TechRef RevbDocument76 pagesEvm5515 TechRef RevbManoj BhosaleNo ratings yet

- Artisan: DefinitiveDocument23 pagesArtisan: DefinitiveTrie WahyudiNo ratings yet

- JPx-SBRO-005-E TornatechDocument2 pagesJPx-SBRO-005-E TornatechIrcham MaulanaNo ratings yet

- Audio/video, Information and Communication Technology Equipment Part 1: Safety RequirementsDocument114 pagesAudio/video, Information and Communication Technology Equipment Part 1: Safety RequirementsMohamed HusseinNo ratings yet

- Datasheet EEMB CR123A CompletoDocument10 pagesDatasheet EEMB CR123A CompletohevenessaNo ratings yet

- 2023hazma Teaml Ithium Battery Shipping Guidein Teractiv Efebruary 2023Document94 pages2023hazma Teaml Ithium Battery Shipping Guidein Teractiv Efebruary 2023hevenessaNo ratings yet

- Xeno Catalog XL-060F - EDocument1 pageXeno Catalog XL-060F - EhevenessaNo ratings yet

- CRS 2017.18 Product CatalogDocument120 pagesCRS 2017.18 Product CataloghevenessaNo ratings yet

- BFGS Series Battery Formation and Testing System ManualDocument17 pagesBFGS Series Battery Formation and Testing System Manualhevenessa0% (1)

- Fluke DTX Cable AnalyzerDocument16 pagesFluke DTX Cable AnalyzerhevenessaNo ratings yet

- CS 303e, Assignment #10: Practice Reading and Fixing Code Due: Sunday, April 14, 2019 Points: 20Document2 pagesCS 303e, Assignment #10: Practice Reading and Fixing Code Due: Sunday, April 14, 2019 Points: 20Anonymous pZ2FXUycNo ratings yet

- 18a.security GSM & CDMADocument18 pages18a.security GSM & CDMAwcdma123No ratings yet

- SIRIM QAS Intl. Corporate ProfileDocument32 pagesSIRIM QAS Intl. Corporate ProfileHakimi BobNo ratings yet

- The Potential of Seaweed Waste Gracilaria SP and eDocument10 pagesThe Potential of Seaweed Waste Gracilaria SP and eAngelica Riviera Brery GirsangNo ratings yet

- Construction materials and supplies itemizationDocument7 pagesConstruction materials and supplies itemizationGintokiNo ratings yet

- OEVDocument2 pagesOEVVikash Khaliyav YadavNo ratings yet

- File HandlingDocument77 pagesFile Handlingchittaranjan baralNo ratings yet

- The HACCP Plan Form The StepsDocument4 pagesThe HACCP Plan Form The StepsAnonymous qfCJwxib7No ratings yet

- Lighting Calculations ExplainedDocument26 pagesLighting Calculations Explainedtalal ilyasNo ratings yet

- Robot Gripper DesignDocument51 pagesRobot Gripper DesignDug McCallumNo ratings yet

- Abs An Engineering PlasticDocument69 pagesAbs An Engineering PlasticPritha DasNo ratings yet

- Propylene, Propylene Oxide and Isopropanol: Course: Chemical Technology (Organic) Module VIIDocument12 pagesPropylene, Propylene Oxide and Isopropanol: Course: Chemical Technology (Organic) Module VIImaheshNo ratings yet

- 101 Test Cases For A PenDocument3 pages101 Test Cases For A PenGanesh Babu OrugantiNo ratings yet

- Transaction Acceptance Device Guide (TADG) : July 2014Document252 pagesTransaction Acceptance Device Guide (TADG) : July 2014norabidinNo ratings yet

- TRANSFORMER MVA SIZING IN ETAPDocument24 pagesTRANSFORMER MVA SIZING IN ETAPkhalidNo ratings yet

- CA ClarityPPM Integration Guide ENUDocument553 pagesCA ClarityPPM Integration Guide ENUvictorinovilaNo ratings yet

- Catalogue Produits OnanDocument6 pagesCatalogue Produits OnanJohn LarsonNo ratings yet

- Data Security SynopsisDocument5 pagesData Security SynopsisAmit ChauhanNo ratings yet

- Lecture 13 Yield CriterionDocument10 pagesLecture 13 Yield CriterionManoj MallickNo ratings yet

- Secondary Lightning EffectsDocument10 pagesSecondary Lightning EffectsAnkit SankheNo ratings yet

- Technical Guidline On Migration TestingDocument30 pagesTechnical Guidline On Migration Testingchemikas8389No ratings yet

- Trade Secret Complaint Against GoogleDocument24 pagesTrade Secret Complaint Against GoogleNitasha TikuNo ratings yet

- CHENNAI PORT AUCTION DETAILSDocument4 pagesCHENNAI PORT AUCTION DETAILSAjit ChauhanNo ratings yet

- 7.1 SSIS-Material, Eqiupment ListDocument5 pages7.1 SSIS-Material, Eqiupment ListHector PhamNo ratings yet

- MineSight Release NotesDocument16 pagesMineSight Release NotesEdwin FloresNo ratings yet

- Interseal 547: Surface Tolerant EpoxyDocument4 pagesInterseal 547: Surface Tolerant EpoxyTài Đỗ VănNo ratings yet

- Computaion IntelligentDocument624 pagesComputaion IntelligentThaiHuynhNgocNo ratings yet

- SAIS Inspection Report EN81 - 20Document21 pagesSAIS Inspection Report EN81 - 20Ali Diab100% (1)

- Experimental Investigation of Circular Concrete Filled Steel Tube Geometry On Seismic PerformanceDocument54 pagesExperimental Investigation of Circular Concrete Filled Steel Tube Geometry On Seismic PerformanceBara' alsayedNo ratings yet

- Lab Equipment List OD 04Document6 pagesLab Equipment List OD 04KHADAR VALINo ratings yet