Professional Documents

Culture Documents

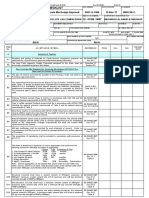

SAUDI ARAMCO ID/PIEU INSPECTION CHECKLIST

Uploaded by

nisha_khanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SAUDI ARAMCO ID/PIEU INSPECTION CHECKLIST

Uploaded by

nisha_khanCopyright:

Available Formats

SAUDI ARAMCO ID/PIEU-24-July-2018 - REV.2018.06.00 (Standards Cutoff - June 30,2018) Rev.2018.06.

00 30-Jun-18

SAIC NUMBER DATE APPROVED QR NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Electronic Control Systems - PLC - Material Receiving SAIC-J-6803 24-Jul-18 INST

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

EQUIPMENT ID NUMBER(S) EQUIPMENT DESCRIPTION EQPT CODE SYSTEM ID. PLANT NO.

LAYOUT DRAWING NUMBER REV. NO. PURCHASE ORDER NUMBER EC / PMCC / MCC NO.

SCHEDULED INSPECTION DATE & TIME ACTUAL INSPECTION DATE & TIME QUANTITY INSP. MH's SPENT TRAVEL TIME

SAUDI ARAMCO USE ONLY

SAUDI ARAMCO TIP NUMBER SAUDI ARAMCO ACTIVITY NUMBER WORK PERMIT REQUIRED?

SAUDI ARAMCO INSPECTION LEVEL CONTRACTOR INSPECTION LEVEL

ITEM

ACCEPTANCE CRITERIA REFERENCE PASS FAIL N/A RE-INSP DATE

No.

A Document Review and Certification

Schedule Q

A1 Review Quality Documentation for Material Receiving.

Att. IV

Material identification Procedure reviewed and shall be implemented for

all materials, parts and components, including partially fabricated Schedule Q

A2

assemblies. (Based on project specs, which define the length of tube and Att. IV

part number in the drawings).

Schedule G

A3 New and Unused - Instrumentation materials shall be new and unused.

Sec. 2.1

As Designed - Instrumentation materials shall be in accordance with the

Schedule G

A4 Saudi Aramco-approved project-specific design drawings, diagrams,

Sec. 2

schedules, lists, databases and associated documents.

Free of Damage - Instrumentation materials shall be free of damage. All

Schedule Q

incoming materials shall be visually inspected for damage and

A5 Att. IV

conformance to all applicable inspection releases with Material Test

Sec. 3.3

Report (MTR).

QC Before Installation - Instrumentation materials shall conform to all Schedule Q

A6 applicable requirements, standards and specifications prior to release to Att. IV

be used as part of the work. Sec. 3.3

Traceability - Instrumentation materials shall be traceable from the Schedule Q

A7 manufacturer and supplier through delivery, storage, fabrication, erection, Att. IV

installation, repair, modification and use. Sec. 4.3

Verify that the contractor or it's Saudi Aramco approved third party

Schedule Q

inspector performed the quality activities at the supplier and sub-supplier

A8 Att. III

locations as required by the inspection level assigned for the materials

Sec. 3.2

and equipment identified in SAEP-1150 Inspection Requirements.

The CONTRACTOR shall provide documentation that the required

Schedule Q

Storage, Handling and Preservation (SHP) activities have been performed

A9 Att. IV ,SAEP-385

in accordance with Appendix A SAEP-385 , MSAER, and manufacturer’s

Sec 4.3

instructions

System Support:

DCS vendor shall guarantee support of all hardware, firmware and

software associated with the controller and I/O subsystems and any

23-SAMSS-010

A10 proprietary communications equipment for a period of ten (10) years from

Sec. 6.4.1

the hardware freeze date. Support shall include spare parts and technical

support. This support shall not be contingent on the customer upgrading

to later releases of software or hardware.

Saudi Aramco: Company General Use

Design:

The Programmable Controller shall be designed, constructed and tested

in accordance with this specification and the following standards: 34-SAMSS-623

A11

a) NEMA IA 2.2 & 2.3 (IEC 61131, Parts-2&3) Sec. 6

b) UL 508, Part XVII

c) ANSI/IEEE C37.90.1

Required Vendor's Ducumentation:

Manufacturer's standard Programming, Installation, 34-SAMSS-623

A12

Maintenance/Troubleshooting Manuals, and processor, Power Supply, Sec. 16

Communications, I/O module specification sheets;

Required Vendor's Ducumentation:

34-SAMSS-623

A13 Factory Acceptance Test (FAT) document detailing the set-up and

Sec. 18.1

procedures for the Functional Test.

Document to prove that the following test has been conducted:

vendor shall provide testing results to confirm that the

equipment will operate without disturbance when energized and

subjected to an electromagnetic field from a radiating source equivalent to

a level 3 disturbance as detailed in IEC 61000-4-3. In particular, RF 34-SAMSS-623

A14

sources such as hand-held radio transceivers operating at 5 Watts within Sec. 5.7.2

the frequency ranges, 50-174 MHz, 406- 470MHz, and 800-870 MHz and

held at a distance off 1.0 meters from the equipment with cabinet doors

open shall not cause any malfunction, data corruption, or damage to the

equipment.

Inspection:

Items manufactured to this Specification are subject to the minimum 34-SAMSS-623

A15

Inspection Requirements as specified in Saudi Aramco Inspection Sec. 18

Requirement Form 175-344000.

Non-Material Requirements:

34-SAMSS-623

A16 The supplier shall provide non-material items as shown on Form NMR-

Sec. 18

7907.

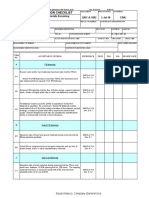

B Storage, Handling and Preservation

The manufacturer's storage, handling and preservation instructions to be Schedule Q

B1

followed. Att. IV

Individuals responsible for special handling, storage and preservation

Schedule Q

B2 shall be fully qualified to do so, and supplied with predetermined WORK

Att. IV

and inspection instructions.

Environmental Conditions:

All cabinet equipment and wiring shall be designed for continuous 34-SAMSS-820

B3

operation at 50 °C, and relative humidity 80% maximum (non-condensing) Sec. 5.2

and 20% minimum.

The PLC shall be self-checking, i.e., have automatic internal checking

capability (so-called "self-diagnostics"; see paragraph 6.1.2 and 6.1.3 for SAES-Z-001 Sec.

B4

details) to detect a failure. When a failure occurs, an alarm shall be 9.8

initiated.

Unless otherwise stated on Form ISS 8020-830-ENG, PLC system

SAES-Z-001 Sec.

B5 components shall be listed, labeled or designed to conform to UL, FM,

3.2

CSA or CENELEC guidelines.

Purchase Order and Instrument specification sheet criteria shall be

confirmed and compared with instrument stainless steel tags/labels and Schedule Q

B6

nameplates, and shipment checked for damage prior to acceptance of the Att. IV

shipment

The selected CPU operating mode (Program, Run, Lock/Unlock), shall be 34-SAMSS-623

B7

visually indicated on the front of the CPU module. Sec. 8.2.4

Saudi Aramco: Company General Use

Quick-Reference Charts:

Unless otherwise specified, laminated plastic quick-reference charts shall

34-SAMSS-623

B8 be permanently attached to the inside of the PLCs front door. The charts

Sec. 8.2.5

shall clarify proper module or PCB placement, and assist in the

interpretation of the status indicators.

I/O module types, quantities and respective signal levels shall be as 34-SAMSS-623

B9

indicated on attached ISS sheet. Sec.8.4.3

I/O modules shall be capable of being inserted into or removed from their

34-SAMSS-623

B10 rack without disturbing external wiring. Field I/O wiring shall be connected

Sec.8.4.4

to the I/O rack, via integral screw type terminals.

It shall be possible to mix all types of I/O modules in any given rack, 34-SAMSS-623

B11

irrespective of their voltage levels. Sec.8.4.5

All discrete I/O modules shall include local status indicators to monitor the

34-SAMSS-623

B12 status of each input and output. All analog modules shall include a local

Sec.8.4.7

status indicator to monitor the status of the module.

34-SAMSS-623

B13 All discrete I/O circuits shall be isolated from logic or processor circuitry.

Sec.8.4.8

All I/O circuits shall be designed so that accidental normal-mode

connection of 1000 VAC/DC to discrete I/O field terminals for an unlimited 34-SAMSS-623

B14

time shall not destroy any devices in I/O circuits other than the circuit to Sec. 13.2

which the voltage was applied.

All input and output points shall be individually fused or employ current

limiting circuitry, e.g., in the case of module "self powered" I/O. Fuses

34-SAMSS-623

B15 shall be located on an external termination panel, fused terminal strip or in

Sec.8.4.2

a location readily accessible for maintenance. Removal of I/O modules

shall not be necessary to accomplish fuse replacement.

Fuse ampacity ratings must be sized for the maximum expected load at

34-SAMSS-623

B16 the maximum operating temperature of the system, but not to exceed the

Sec.8.4.2

I/O module rating.

If remote I/O is selected, Vendor shall confirm, in writing, that the selected 34-SAMSS-623

B17

communications cable(s) meet the communications driver specification. Sec. 8.5.2

Communications driver software/firmware shall continuously monitor and

check the status of communication links and associated I/O. 34-SAMSS-623

B18

Communication status indication shall be provided on the face plate of Sec. 8.5.3

each associated module.

C Power Supplies, Protection and Fluctuations - Requirements

34-SAMSS-623

C1 Remote I/O cabinets shall incorporate their own power supply.

Sec8.7.4

Incoming power to the PLC system will be from Saudi Aramco supplied 34-SAMSS-623

C2

120 VAC power sources, which are over-current protected. Sec8.7.1

System Power Supplies:

The PLC system shall be designed such that all rack power supplies (e.g.,

main, expansion rack) are separate and distinct, connected via cabling or

internal bus structure. Each power supply shall be sized to provide 100% 34-SAMSS-623

C3

of the ampacity requirements (at rated voltage and maximum design Sec. 8.7.3

temperature) for the specified configuration of I/O cards, CPU, etc.,

including 25% spare modules, with all modules and outputs energized and

carrying their maximum connected load.

Saudi Aramco: Company General Use

Auxiliary Power Supplies:

Auxiliary power supplies used to power I/O field points shall be sized for

34-SAMSS-623

C4 125% of the ampacity requirements (at rated voltage and maximum

Sec. 8.7.4.3

design temperature). Power supply loads shall be calculated with all

points energized, and all outputs carrying their maximum connected load.

Protection:

Each power supply shall have its own internal fuse/circuit breaker

protection on the incoming line side. Fuses or circuit breakers shall be 34-SAMSS-623

C5

capable of being replaced or reset, without removal of the power supply or Sec.8.7.5

disconnecting any wiring terminations. Output protection shall be provided

by current-limiting circuitry.

Power Restoration:

The PLC system shall be designed such that, such that output modules

34-SAMSS-623

C6 de-energize when primary UPS power is cycled to the ESD system (i.e.,

Sec.8.7.7.1

applied, removed, or restored to the CPU or I/O

modules).

Communications Interface:

The controller shall as a minimum, support multiple EIA/RS-232 EIA/RS-

422, EIA/RS-485, or ANSI/IEEE 802.3 ports for

communicating with external devices such as a DCS, host

34-SAMSS-623

C7 computer, local area network gateway, program development

Sec.8.6.2.1

station, or printer. Acceptable data communications protocols

include Modbus/RTU, TCP/IP, and OPC - (Object linking and

embedding for Process Control). Specific porting requirements

will be identified on the ISS

Identification:

Each type of PLC module shall be uniquely identified by a type number,

34-SAMSS-623

C8 serial number and a revision or some other production lot identification

Sec. 16

code. In addition, each PLC Module shall clearly indicate the designed

field signal range, type and service; e.g., 120 VAC Digital Output, etc.

Indoor PLC cabinet construction and wiring shall comply with the

34-SAMSS-623

C9 requirements of 34-SAMSS-820 "Instrumentation Control Cabinets except

Sec. 3.2

as may be superseded within this specification.

System Spare Requirements:

In addition to the spare requirements of 34-SAMMS-820, each PLC

enclosure(s) shall be provided with the following spare capacity to allow

for future system modifications: 34-SAMSS-623

C10

a) 10% installed spare I/O modules, based on I/O points used. (minimum Sec. 8.8

one spare module of each different type configured within the application

program)

b) 15% empty rack space.

Assembly and Mounting:

PLC system modules (or cards) shall be solidly constructed and shall be

34-SAMSS-623

C11 capable of being inserted into or removed from their chassis or mounting

Sec.8.4.4

rail assemblies online and shall not require movement of system cables or

wiring, either external or internal

Assembly and Mounting:

If power supply units are mounted in the same enclosure as the processor 34-SAMSS-623

C12

unit, they shall never be mounted below the CPU and always in the upper Sec. 8

section or rack(s) of the cabinet.

Saudi Aramco: Company General Use

Assembly and Mounting:

Control cabinet which contains system components, such as

controllers, I/O and communication modules or which house

power supply modules shall be provided with a continuous analog 34-SAMSS-623

C13

temperature sensing device (RTD or Thermocouple). Sec. 9.3.2.3A

This device shall be interfaced to the DCS to provide

temperature indication and to provide high temperature

alarming to the operators.

Assembly and Mounting:

Cabinets which contain power supply modules shall be capable

of housing a High Sensitivity Smoke Detector (HSSD). 34-SAMSS-623

C14

The type and location of HSSD and responsibility for Sec.9.3.2.4

procurement, installation, and commissioning of the devices

shall be specified in the project specific FSD.

Assembly and Mounting: If so specified in the purchase order or ISS, a

strong pull-out tray shall be provided for the laptop/notebook programming 34-SAMSS-623

C15

workstation. The tray shall be positioned to conveniently view the CPU's Sec. 6

front indication panel.

Power and Signal Wiring:

Discrete inputs and outputs to field devices (which are not linemonitored,

in a current loop arrangement) shall be wired so 34-SAMSS-623

C16

that they switch the hot side of the line. Isolated commons Sec. 9.3.2.2

shall be used when passing signals between devices which

utilize different grounding systems.

Power and Signal Wiring:

I/O wiring for each process train (including duty/standby equipment) shall

be terminated on separate I/O modules. If racks are required to be 34-SAMSS-623

C17

powered down for replacing an I/O module, then each process train shall Sec. 9.3.2

be terminated in separate racks. This is to facilitate on-line maintenance

of each train without affecting the operation of the other train(s).

Power and Signal Wiring: 34-SAMSS-623

C18

All installed spare I/O modules are to be wired to spare terminal points. Sec. 9..3.2

D Input/Output Wiring, Cables and Wire Ways - Requirements

Wire Installation:

Segregation of parallel wiring internal to cabinets shall adhere to the

34-SAMSS-820

D1 following Table 2. Wiring that is required to be segregated shall cross at

Sec. 6.7.2.3

right angles and the spacing shall be maintained as close as practicable to

that shown in Table 2. [See Attachment 2]

Wire Specifications:

General 120/230 VAC power wiring shall be minimum 14 AWG stranded, 34-SAMSS-820

D2

copper, UL listed and PVC or XLPE insulated . Wire insulation shall be Sec. 6.7.3.1

rated for 600 volts, 75°C, minimum.

Wire Specifications:

Electronic signal wire shall be UL listed, stranded copper, minimum size

18 AWG, 300 V for single conductors or a minimum 20 AWG, 300 V for

multicore cable (assuming Class-2 circuits per NEC). Wire insulation shall 34-SAMSS-820

D3

be XLPE PVC, or PTFE, with a minimum temperature rating of 75°C. Sec. 6.7.3.2

Special electronic signal wires shall be as described in the Purchase

Order.

Saudi Aramco: Company General Use

Wiring Methods:

Cabinet internal wiring shall meet the requirements and applicable

requirements defined in 34-SAMSS-913. Internal cabinet wiring does 34-SAMSS-820

D4

need to be procured from approved/regulated suppliers. Any supplier Sec. 6.7.3.2

which meets or exceed the minimum specifications and requirements may

be used to source internal wiring.

Wiring Methods:

The following are exempted from the above rule:

Wiring for millivolt, micro amp, pulse and frequency signals under 1 Volt

34-SAMSS-820

D5 such as thermocouples, resistance temperature detectors (RTD), vibration

Sec. 6.7.6

elements, analyzer elements, thermistor elements and transmitters with

pulse outputs shall be directly connected to the I/O unless otherwise

specified in the Purchase Order.

Wiring Methods:

Exposed electrical connections with voltages greater than nominal 48 34-SAMSS-820

D6

volts AC/DC shall be shrouded by transparent, removable, insulating Sec. 6.7.4.1

plastic covers (or equivalent).

When screw-type terminals are provided on instruments and other

electrical devices, solder less crimp/compression connectors shall be

used for connecting stranded copper conductors. Insulated ring lugs, 34-SAMSS-820

D7

locking-fork or flanged- fork connectors, specifically designed to hold the Sec. 6.7.4.2

connector on the terminal in the event of loosening of the terminal screw,

shall be used on all such connections.

Terminal strip spacing shall allow ample room for plastic wire ducts

and permit lacing of cables, and fanning of individual wires to

termination points. Each terminal strip shall be labeled above or below

34-SAMSS-820

D8 with the terminal strip number, as shown on wiring diagrams.

Sec. 6.7.7.2

Terminals for similar (AC or DC) current service shall be grouped

together and physically separated from terminals for different service by

means of dividers, separate mounting rails or separate enclosures.

Standoffs for terminal strips are preferred to bring the terminal blocks

forward to be flush with the top of the plastic wire duct. This wiring method 34-SAMSS-820

D9

assures that all wires can be accessed without interference from other Sec. 6.7.7.3

wires as the wire duct is filled.

Where special cases of mixed ESD / Non-ESD signals occur in one

cabinet or control panel (e.g., Solid State / Relay Control Cabinets or

34-SAMSS-820

D10 Control Panels with ESD pushbuttons ), terminal strips for Emergency

Sec. 6.7.7.4

Shutdown (ESD) wiring shall be completely separate from all other wiring

including power, control and instrumentation.

Wiring for a given instrument loop shall be terminated on adjacent

34-SAMSS-820

D11 terminals on the terminal strip in order to organize and group all loop

Sec. 6.7.7.5

wiring.

Terminals for various types of general wiring (AC or DC), annunciator

34-SAMSS-820

D12 points and signal wiring shall be separately grouped and separated by

Sec. 6.7.9.1

dividers.

Plastic wire ducts with removable covers shall be installed in cabinets as

required to provide a means of routing and organizing wiring. A minimum

34-SAMSS-820

D13 of 50 mm shall be maintained between the duct and terminal strips. Wire

Sec. 7.9

markers shall be completely presented without being obscured by the

duct.

The maximum conduit/plastic wire duct fill (including spare capacity) shall 34-SAMSS-820

D14

not exceed the heat requirements of NFPA 70 Section 300.17. Sec. 6.7.9.3

In addition to the above, the maximum plastic wire duct fill (including 34-SAMSS-820

D15

spare capacity) shall not exceed 75% of its depth. Sec. 6.7.9.4

Saudi Aramco: Company General Use

Plastic wire ducts shall be mounted using screws. Double-sided tape is 34-SAMSS-820

D16

unacceptable. Sec. 6.7.9.5

Where space limitations preclude the use of plastic wire ducts, wiring shall

be neatly loomed and secured with plastic spiral wrapping or tie-wraps 34-SAMSS-820

D17

and anchors. Wiring between movable parts such as doors shall be Sec. 6.7.9.6

installed in flexible hoses.

34-SAMSS-820

D18 Loomed wiring shall not be installed near sharp-edged surfaces.

Sec. 6.7.9.7

Wiring shall not be threaded through undressed access holes. Glands or 34-SAMSS-820

D19

protective grommets shall be used. Sec. 6.7.9.8

Vendor-installed cables shall be supported and provided with a strain- 34-SAMSS-820

D20

relief mechanism for cable connectors. Sec. 6.7.10

34-SAMSS-820

D21 Wire ducts for ESD wiring shall not contain any other types of wiring.

Sec. 6.7.11.1

Wire Color Coding:

34-SAMSS-820

D22

Sec. 6.7.11.2

Cables with connector plugs shall be tagged at each end. Each cable tag

shall have two labels. The first label (closest to the plug connector) shall

34-SAMSS-820

D23 identify the device and socket to which the plug is to be connected. The

Sec. 6.7.11.2

second label shall identify the device and socket to which the opposite

end of the cable is connected.

I/O and interconnecting wiring shall be tagged at each end with two

identification tags (or the two may be combined into one tag with sufficient

separation between wire numbers). The first tag (closest to the end of the 34-SAMSS-820

D24

wire) shall identify the terminal number to which the wire is physically Sec. 6.7.11.3

connected. The second tag shall identify the terminal number to which the

opposite end of the wire is connected.

Identification shall be in accordance with designations shown on

instrument loop diagrams (ILDs). Where wires terminate on instrument or 34-SAMSS-820

D25

device terminals, the instrument tag number and terminal designation (+) Sec. 6.7.11.6

or (-) (if applicable) will be used in lieu of terminal strip identification.

Wire tag information shall be permanently marked in block alpha numeric

or typed on tubular, heat shrinkable, slip-on sleeves. Wrap-around, snap-

34-SAMSS-820

D26 on or self-adhesive markers shall not be used. Where shrink fit cable

Sec. 7.11.3

markers cannot be installed over pre-made cable and connectors, a

suitable tie-wrap or equivalent type permanent marker shall be used.

Spare pairs/triads in multi-pair/triad cables shall be labeled "SPARE" in

34-SAMSS-820

D27 addition to the destination and source terminal numbers. All spares are to

Sec. 7.11.6

be terminated.

E Indoor PLC Control Cabinets, Terminal Blocks, Termination and Grounding

No more than two bare wires shall be connected to each side of a single 34-SAMSS-820

E1

terminal block. Sec. 7.8.1

All terminal blocks shall be channel (rail)-mounted, strip-type, with a

tubular box clamp connector and compression bar or yoke for wire 34-SAMSS-820

E2

termination. As a minimum, the thickness of the terminals shall be 5 mm Sec. 7.8.2

or higher.

Terminals shall be made of fire retardant, halogen free, high strength

34-SAMSS-820

E3 material such as polyamide or equivalent in accordance with UL 94, V0.

Sec. 7.8.3

Brittle materials such as melamine shall not be used.

Saudi Aramco: Company General Use

A fused terminal block shall have a blown-fuse indicator. This may be a

34-SAMSS-820

E4 Light Emitting Diode (LED), visual sight indication through a port, or

Sec. 7.8.4

equivalent

The disconnect levers for fused terminals and knife-switch terminals shall 34-SAMSS-820

E5

be hinged. Sec. 7.8.5

Wires terminated on these terminal blocks shall not have the bare ends

coated with or dipped in solder ("tinned"). However, termination of wiring

34-SAMSS-820

E6 which has individual strands of the copper conductor tinned during

Sec. 7.8.6

manufacture (typical of shield drain wires or for corrosion protection) is

acceptable.

Direct termination of the bare wire end is acceptable. The terminal block

must be suited for the wire size. The use of crimp-on ferrules shall follow

the manufacturer's guidelines and the following:

a) One or two wire ferule is acceptable. (The use of ferrules to daisy chain 34-SAMSS-820

E7

is not acceptable). Sec. 7.8.7

b) Only one ferrule shall be connected to each side of a single terminal

block.

c) Ferrules shall be provided with plastic insulating collars.

Terminal blocks with a narrow, recessed screw entrance which require a

34-SAMSS-820

E8 special screwdriver or wrench may be used only if the insulation material

Sec. 7.8.8

is per Paragraph 7.8.3.

Multiple-deck and spring type terminal blocks shall not be used.

Exception: When provided as an integral part of manufactured electronic 34-SAMSS-820

E9

equipment, multiple-deck terminal blocks are allowed, but never for direct Sec. 7.8.9

termination of field cabling.

Vendor standard cables shall be designed and installed in such a way as SAES-Z-001 Sec.

E10

to allow cable disconnection in order to service the equipment. 16.2.4

Nameplates:

All Cabinets shall have a nameplate permanently attached indicating the SAES-Z-001 Sec.

E11

service description. Nameplates shall comply with the relevant sections of 16.1.2

34-SAMSS-820 specific to Nameplates.

Nameplates:

34-SAMSS-820

E12 Cabinets designed for both front and rear entry shall have a nameplate

Sec.6.5.6

attached to both the front and back.

Nameplates:

All push buttons, switches, lamps and other console mounted devices SAES-Z-001 Sec.

E13

shall have a nameplate permanently attached indicating the service 10.1.7

description.

Grounding:

Both safety ground and instrumentation circuit ground must conform to

34-SAMSS-820

E14 NEC, Article 250. Grounding system recommendations and requirements

Sec. 6.7.18.1

provided by manufacturers of instrumentation and control systems (e.g.,

Distributed Control Systems) shall be followed.

Grounding:

34-SAMSS-820

E15 Separate, electrically isolated grounding bars shall be provided, as

Sec. 6.7.18.2

required.

Grounding:

All ground buses shall be made of a solid copper measuring the following

34-SAMSS-820

E16 nominal dimensions 5mm x 40 mm x (y length), suitably drilled and tapped

Sec. 6.7.18.3

for screw terminals and wire lugs, or fitted with screw-type compression

lugs.

Grounding:

34-SAMSS-820

E17 The preferred location of the ground bus bars is at the bottom of the

Sec. 6.7.18.4

cabinet.

Grounding:

A No. 2 AWG screw-type compression lug shall be provided on both end 34-SAMSS-820

E18

of each ground bar for interconnection with the Master Instrument Ground Sec. 6.7.18.5

or Master Safety Ground.

Saudi Aramco: Company General Use

Grounding:

The ground bus bars shall be labeled and wired as follows:

"AC SAFETY GROUND" for all exposed metal surfaces of cabinets,

34-SAMSS-820

E19 racks, chassis GND connections, etc. Individual wiring interconnections

Sec. 6.7.18.6

shall be minimum 12 AWG copper wire, green or green with yellow tracer

insulation. This bus shall be directly bolted to the cabinet without the use

of insulators.

Grounding:

"INSTRUMENT CIRCUIT GROUND" for connecting cable and wire

shields and DC Common. Interconnections between shield consolidation 34-SAMSS-820

E20

points and the bus bar shall be minimum 12 AWG copper wire, green or Sec. 6.7.18.6

green with yellow tracer insulation. This bus bar shall be electrically

insulated from the cabinet structure.

Grounding:

When provided, AC power receptacle outlets shall be grounded using 34-SAMSS-820

E21

ground wire terminated on the receptacle grounding terminal. (e.g., A Sec. 6.7.18.7

receptacle utilizing the faceplate as a ground path is not permitted.)

Lighting, Convenience and Power Distribution Receptacle Outlets:

34-SAMSS-820

E22 Cabinet lights shall be installed where practical and necessary, as

Sec. 6.7.19.1

specified in the Purchase Order.

If specified, cabinet lights shall be 120/230 Volt, 60-watt incandescent

lamps, size IEC, type E27 or ES (Edison Medium Screw Base) fitting or

34-SAMSS-820

E23 15-watt minimum industrial grade, fluorescent lighting fixture(s) oriented in

Sec. 6.7.19.2

such a manner that the majority of the interior portions of the cabinet are

illuminated.

Incandescent lamps shall have a guard to help protect the lamp from

34-SAMSS-820

E24 accidental breakage. Fluorescent lamps shall have clear plastic sleeve

Sec. 6.7.19.3

guards to help contain broken glass in case of an accident.

Interior lamps and convenience outlets shall be wired to separate

thermal/magnetic circuit breakers which shall be powered from a 34-SAMSS-820

E25

proponent furnished AC distribution panel, independent of the UPS power Sec. 6.7.19.5

supply.

F Outdoor PLC Control Cabinet - Requirements

Equipment Mounted Internal to the Outdoor Cabinet shall operate

continuously under the following humidity conditions.

34-SAMSS-820

F1 Relative Humidity:

Sec. 5.2.2.1

5% Minimum

95% Maximum (non-condensing)

Portions of Equipment that are mounted externally on the Outdoor Cabinet

34-SAMSS-820

F2 shall operate continuously under the conditions sporadic water spray such

Sec. 5.2.2.2

as from rain.

The cabinets and its integral parts shall be protected against corrosion

and operational failure due to wind-borne sea water spray and the

accumulation of wetted salt (NaCl), if it is located at:

a) Outdoor offshore locations, or 34-SAMSS-820

F3

b) Outdoor onshore locations within one kilometer from the shoreline of Sec. 5.2.2.3

the Arabian Gulf; all of the Ras Tanura Refinery and Terminal; and within

three kilometers from the shoreline of the Red Sea.

Enclosures: In outdoor plant areas, the panel/cabinet shall be NEMA 34-SAMSS-820

F6

250/NEMA ICS 6 Type 4 or IEC 60529, Type IP65. Sec. 7.1.1

Saudi Aramco: Company General Use

In outdoor plant and other industrial areas located in severe corrosive

environments as defined in Paragraph 4.2, enclosures shall be NEMA 250

/ NEMA ICS 6 Type 4X or IEC 60529 Type IP66, manufactured of 316L

stainless steel. Door hinge, door stay, and door lock shall be made of

316L stainless steel. Galvanized and/or painted or coated carbon steel

34-SAMSS-820

F7 sheet metal enclosures are not permitted.

Sec. 7.1.2

Commentary Note:

In outdoor plant and other industrial areas located in severe corrosive

environments, 34 SAMSS-820 Paragraph 7.1.2 supersedes Paragraph

7.1.1.

All cabinets intended for outdoor applications shall be certified by one of

the approved IECEx certifying bodies. Certification shall also include

Ingress Protection (IP rating) per IEC 60529.

Commentary Note:

34-SAMSS-820

F8 For IP rating certification, a vendor would submit a sample to certifying

Sec. 7.1.3

agency and they will issue a compliance certificate and then the

manufacturer can mass produce that commodity as long as they adhere

to the specification of the type tested item. Only one certificate per type is

needed for all current and succeeding projects.

Area Classification: The panel/cabinet and all components within the

panel shall be suitable for the electrical area classification where the panel 34-SAMSS-820

F9

will be installed. The classification of the area in which the panel will be Sec. 7.2.2

used, shall be specified in the Purchase Order.

Conduit Entry: The entry (on non-explosion proof cabinets) shall have a

34-SAMSS-820

F10 removable blank gland plate as specified in the Purchase Order for

Sec. 7.2.3.1

Buyer's conduit entry.

Elevated outdoor control cabinets shall normally have conduit entry from 34-SAMSS-820

F11

the bottom. Sec. 7.2.3.2

Conduit terminations shall be suitably bushed to prevent cutting or 34-SAMSS-820

F12

abrasion of the wiring insulation. Sec. 7.2.3.3

Relays: Relays shall meet the area classification in which they are

34-SAMSS-820

F13 installed. They shall also be weather-proof to meet any required

Pushbuttons Sec. 7.2.3.4

environmental and Lights:such

conditions Pushas buttons andorlights

rain, dust, shall be industrial

corrosion.

quality. Push buttons shall have protective mechanisms to prevent

accidental activation as required by the detailed design specification.

Long-life type lamps or LED cluster lamps shall be used. It shall be

possible to access the lamp bulbs from the front for replacement. The

color of the pushbuttons or lights shall be green for “ON”/”OPEN” and red 34-SAMSS-820

F14

for “OFF/”CLOSE” positions. Only screw terminals shall be provided on Sec. 6.7.14

push buttons.

Exception:

Existing facilities that currently deviate from the above light color

specification may use other conventions in order to keep the lighting

philosophy consistent within the facility.

Lighting, Convenience and Power Distribution Receptacle Outlets

• Cabinet lights shall be installed where practical and necessary, as

specified in the Purchase Order.

• If specified, cabinet lights shall be 120/230 Volt, 60-watt incandescent

lamps, size IEC, type E27 or ES (Edison Medium Screw Base) fitting or

15-watt minimum industrial grade, fluorescent lighting fixture(s) oriented in

such a manner that the majority of the interior portions of the cabinet are

illuminated.

• Incandescent lamps shall have a guard to help protect the lamp from

accidental breakage. Fluorescent lamps shall have clear plastic sleeve 34-SAMSS-820

F15

guards to help contain broken glass in case of an accident. Sec. 6.7.19

• When specified in the Purchase Order, convenience outlets shall be

duplex-type and rated at 120/230 VAC, 10 amp as a minimum.

• Interior lamps and convenience outlets shall be wired to separate

thermal/magnetic circuit breakers which shall be powered from a

proponent-furnished AC distribution panel, independent of the UPS power

supply.

• A switch in the cabinet (in addition to the circuit breaker) shall control

each lamp where the lamp is installed. Automatic door switches for lamps

are allowed.

Saudi Aramco: Company General Use

Nameplates:

Nameplates shall be attached to the cabinets using stainless steel screws.

The nameplate shall be made of corrosion resistant material. The lettering 34-SAMSS-820

F17

shall be clearly legible. Internal nameplates (within the cabinet) shall also Sec. 7.3

be installed using stainless steel screws. Using adhesive nameplates is

not acceptable.

Convection-ventilated cabinets shall be provided with readily accessible,

removable filter screens inserted behind slotted louvers at the air inlets

and outlets. Louvers and filters shall be installed within the cabinet 34-SAMSS-820

F18

door(s). Louvers shall not be installed on the sides or back of the cabinet. Sec. 6.3.2

Fans with suitable filters and louvers may be used within control cabinets

to assist in heat removal. This can be achieved by installing a filter fan at

the air inlet (typically at the bottom of the cabinet door) to blow cool air

34-SAMSS-820

F19 into the cabinet or by installing an exhaust filter fan at the air outlet

Sec. 6.3.3

(typically at the upper section of the door) to draw hot air out of the

cabinet. The fan filter shall be easily accessible for maintenance or

replacement without dismantling the fan assembly.

Cabinet cooling fans shall be sized to handle 20% more air flow by

volume than the amount taken credit for in the heat dissipation calculation.

34-SAMSS-820

F20 Commentary Note:

Sec. 6.3.5

As an example, if the heat dissipation calculation considers the air volume

of the fan to be 150 CFM, fans should be sized to deliver 180 CFM.

Cabinets which contain redundant cooling fans shall be configured to have

one fans run continuously and the other fan to be energized based on the

34-SAMSS-820

F21 temperature inside the cabinet. Activation of the redundant fan shall be at

Sec. 6.3.6

30°C. A fan failure and over-temperature detection alarms are required in

the DCS.

The installation of fans on top of the cabinet should be avoided. However,

if it is deemed absolutely necessary to install the fans on top of the

34-SAMSS-820

F22 cabinet, the fan fixtures shall be protected by an additional cover or

Sec. 6.3.7

shroud to prevent dirt and debris from falling into the cabinet. In this case,

the cabinet shall be NEMA 12.

Where two or more front sections are required for a Control Panel, the 34-SAMSS-820

F23

interior shall be an open-frame construction. Sec. 6.3.8

Cabinet support bracing shall not restrict maintenance access to chassis,

34-SAMSS-820

F24 modules or components. Accessing any of the installed components or

Sec. 6.3.9

wiring shall not require the removal of other components.

34-SAMSS-820

F25 Each cabinet shall be provided with removable lifting rings.

Sec. 6.3.10

Cabinet doors shall be full-height. All doors shall be dust-tight and

34-SAMSS-820

F26 reinforced against buckling. The maximum door width shall be 900 mm

Sec. 6.3.11

(36 inches) unless otherwise specified in the Purchase Order.

Cabinets intended for marshalling may have front and rear access and

shall be designed per paragraph 5.2. The distance from the front surface

34-SAMSS-820

F27 to the surface of rear terminal blocks, shall not be more than 400 mm

Sec. 6.3.12

deep to provide for safe access. The cable entry to the marshalling

cabinet shall be through the bottom.

Saudi Aramco: Company General Use

All doors shall be capable of opening at least 90 degrees, preferably 180

34-SAMSS-820

F28 degrees, and shall be equipped with mechanical stops for holding the

Sec. 6.3.13

doors open

Control and marshalling cabinets may be combined into a single cabinet

for systems where the entire control and marshalling fit into a single

cabinet. This is typical for systems such as VMS, RTU, PLC, CCS, HIPS,

etc. For these systems, it is preferable to segregate control equipment

34-SAMSS-820

F29 from marshalling to the maximum extent possible. Front/rear separation

Sec. 6.3.14

shall be considered.

Exception:

For expansion to existing facilities, the existing cabinet design may be

used.

When front and rear accesses are provided for control cabinets, each

section shall have its own full size mounting plate. Cable routing shall be

34-SAMSS-820

F30 tightly secured either on the sides and/or through properly dressed holes.

Sec. 6.3.15

Wiring shall not be threaded through undressed access holes. Glands or

protective grommets shall be used.

All doors shall be provided with integral lockable door handles with the 34-SAMSS-820

F31

same lock and key combination, unless otherwise specified on the ISS. Sec. 6.3.16

Equipment that are installed within cabinets or panels and are normally

used by the operator shall be readable and operable with the operator in a 34-SAMSS-820

F32

standing position. Sec. 6.3.17

The inside of each door shall be equipped with a pocket suitable for 34-SAMSS-820

F33 holding A4 documents and/or cabinet drawings. Sec. 6.3.18

Cabinets intended for bottom cable entry shall be provided with a gland

plate at the bottom of the cabinet. 34-SAMSS-820

F34

Sec. 6.3.19

All cabinets intended for outdoor applications shall be certified by one of

the approved IECEx certifying bodies. Certification shall also include

Ingress Protection (IP rating) per IEC 60529.

Commentary Note:

34-SAMSS-820

F35 For IP rating certification, a vendor would submit a sample to certifying

Sec. 7.1.3

agency and they will issue a compliance certificate and then the

manufacturer can mass produce that commodity as long as they adhere

to the specification of the type tested item. Only one certificate per type is

needed for all current and succeeding projects.

REMARKS:

REFERENCE DOCUMENTS:

1. Schedule G - Material, Tools and Equipment (Pro Forma MP-IK-LS Contract),

2. Schedule Q - Quality Requirements (Pro Forma Contract)

3. NFPA 70 - National Electrical Code 2017

4. 23-SAMSS-010 - Distributed Control Systems, 24 December 2017

5. 34-SAMSS-820 - Instrument Control Cabinets 13 July 2016

6. SAEP-385 - Preservation of Project Materials and Equipment - 25 October 2017

7. SAES-Z-001 - Process Control System - 20 December 2017

ATTACHMENTS:

NOTES:

1. Approved - Acceptable to the authority having jurisdiction (i.e., Saudi Aramco ID).

2. Identified - Recognizable as suitable for the specific application by a qualified testing laboratory (i.e., listing and/or labeling).

3. Listed - Equipment and materials included in a list published by an approved qualified organization concerned with evaluation of products or

services, that maintains periodic inspection of production of listed equipment or materials or periodic evaluation of services, and whose listing states

that the equipment, material or services either meets appropriate designated standards or has been tested and found suitable for a specified purpose.

4. Labeled - Equipment or materials to which has been attached a label, symbol or other identifying mark of an approved qualified organization

concerned with product evaluation, that maintains periodic inspection of production of labeled equipment or materials, and by whose labeling the

manufacturer indicates compliance with appropriate standards or performance in a specified manner.

Contractor / Third-Party Saudi Aramco

Construction Representative* PMT Representative

Saudi Aramco: Company General Use

Work is Complete and Ready for Inspection: T&I Witnessed QC Record Reviewed Work Verified

Name, Initials and Date: Name, Initials and Date:

QC Inspector PID Representative

Performed Inspection Work / Rework May Proceed T&I Witnessed QC Record Reviewed Work Verified

Name, Initials and Date: Name, Initials and Date:

QC Supervisor Proponent and Others

Quality Record Approved: T&I Witnessed QC Record Reviewed Work Verified

Name, Organization,

Name, Sign and Date:

Initials and Date:

*Person Responsible for Completion of Quality Work / Test Y = YES N = NO F = FAILED

Saudi Aramco: Company General Use

You might also like

- Engineering Procedure: Saudi Aramco Desktop StandardsDocument11 pagesEngineering Procedure: Saudi Aramco Desktop StandardsAnonymous 4IpmN7OnNo ratings yet

- Master Copy of Saad Othman JSADocument11 pagesMaster Copy of Saad Othman JSAM. MagnoNo ratings yet

- Saudi Aramco Inspection ChecklistDocument6 pagesSaudi Aramco Inspection Checklistkarthi51289No ratings yet

- Saudi Aramco Inspection Checklist: Fire Alarm System - Pre-Commissioning Inspection SAIC-B-6108 3-Jul-18 InstDocument17 pagesSaudi Aramco Inspection Checklist: Fire Alarm System - Pre-Commissioning Inspection SAIC-B-6108 3-Jul-18 Instkarthi51289No ratings yet

- Saic J 6001Document7 pagesSaic J 6001sureshNo ratings yet

- Saudi Aramco Cable Testing ResultsDocument5 pagesSaudi Aramco Cable Testing Resultskarthi51289No ratings yet

- SAIC-P-3007 Rev 7 FinalDocument20 pagesSAIC-P-3007 Rev 7 FinalEnginerShahzadGhaffarNo ratings yet

- Saudi Aramco Inspection ChecklistDocument3 pagesSaudi Aramco Inspection ChecklistMeraj HassanNo ratings yet

- SAUDI ARAMCO CHECKLIST FOR INSTRUMENT ENCLOSURE INSTALLATIONDocument10 pagesSAUDI ARAMCO CHECKLIST FOR INSTRUMENT ENCLOSURE INSTALLATIONnisha_khan0% (1)

- SAES-B-071 Editorial Revision (10-28-2021)Document10 pagesSAES-B-071 Editorial Revision (10-28-2021)Daniel MeanaNo ratings yet

- Saudi Aramco Inspection ChecklistDocument21 pagesSaudi Aramco Inspection Checklistnisha_khanNo ratings yet

- 18-SAMSS-493 - Two Part Polyurethane Duct SealantDocument5 pages18-SAMSS-493 - Two Part Polyurethane Duct Sealantmedication abbasNo ratings yet

- Nonmaterial Requirements: FOR CONTROL PANELS PER 34 AMSS-820/821 (3/4)Document2 pagesNonmaterial Requirements: FOR CONTROL PANELS PER 34 AMSS-820/821 (3/4)Khaja MoinNo ratings yet

- CPP-NA2-PM-PLN-0027 Procedure For Cable and Conduit Seal InstallationDocument9 pagesCPP-NA2-PM-PLN-0027 Procedure For Cable and Conduit Seal InstallationAdil IjazNo ratings yet

- Installation of Main Steel Structure/ Platform & Steam SilencerDocument4 pagesInstallation of Main Steel Structure/ Platform & Steam SilencerzhangNo ratings yet

- SATR-J - 6801 - Rev 0 PDFDocument6 pagesSATR-J - 6801 - Rev 0 PDFAdel KlkNo ratings yet

- Bst-gen-crr-rpt-Aip-10033-10002-00-K-001 Temporary Cathodic Protection (TCP) System Design Report For PWD PipelineDocument43 pagesBst-gen-crr-rpt-Aip-10033-10002-00-K-001 Temporary Cathodic Protection (TCP) System Design Report For PWD PipelineRao DharmaNo ratings yet

- Saudi Aramco Inspection ChecklistDocument5 pagesSaudi Aramco Inspection ChecklistAbdul HannanNo ratings yet

- 34 Samss 718Document14 pages34 Samss 718Eagle SpiritNo ratings yet

- Saic LPT 2006Document12 pagesSaic LPT 2006jerinNo ratings yet

- Wps 001Document19 pagesWps 001Rizwan.descon DesconNo ratings yet

- Saic A 1002Document2 pagesSaic A 1002karthi51289No ratings yet

- J06 PT PDT 5988 5989 PDFDocument10 pagesJ06 PT PDT 5988 5989 PDFnashittNo ratings yet

- Satip P 121 01 Rev 7 MPDocument7 pagesSatip P 121 01 Rev 7 MPmohamedqcNo ratings yet

- Saudi Aramco Inspection ChecklistDocument6 pagesSaudi Aramco Inspection ChecklistAbdul HannanNo ratings yet

- SATIP-P-113-01 Rev 8 Final Induction Motor PDFDocument3 pagesSATIP-P-113-01 Rev 8 Final Induction Motor PDFSabheeh AliNo ratings yet

- Saes T 911 PDFDocument76 pagesSaes T 911 PDFjuliusNo ratings yet

- Saes T 629Document10 pagesSaes T 629Azhar Saqlain.No ratings yet

- Ac 036660 004Document1 pageAc 036660 004narutothunderjet216No ratings yet

- RasGas Onshore Expansion Project Instrument Cable InstallationDocument11 pagesRasGas Onshore Expansion Project Instrument Cable InstallationBharathiNo ratings yet

- Saudi Aramco Inspection Checklist: Review WPS & Process Control Procedure (Plant Piping) SAIC-W-2001 15-Jul-18 WeldDocument2 pagesSaudi Aramco Inspection Checklist: Review WPS & Process Control Procedure (Plant Piping) SAIC-W-2001 15-Jul-18 Weldm4metzNo ratings yet

- Saudi Aramco Inspection Checklist: Cast-In-Place Concrete Finishing and Curing Inspection SAIC-Q-1015 15-Nov-17 MAH-SA-CDocument4 pagesSaudi Aramco Inspection Checklist: Cast-In-Place Concrete Finishing and Curing Inspection SAIC-Q-1015 15-Nov-17 MAH-SA-CAbdul HannanNo ratings yet

- G16S-0202-07 - Two Layer PaintingDocument7 pagesG16S-0202-07 - Two Layer Paintingpuwarin naja100% (1)

- Saes T 903Document14 pagesSaes T 903Sayed HashemNo ratings yet

- Saudi Arabian Oil Company: Table 1 Minimum Cover RequirementsDocument1 pageSaudi Arabian Oil Company: Table 1 Minimum Cover RequirementsAswin KurupNo ratings yet

- Saudi Aramco Inspection ChecklistDocument4 pagesSaudi Aramco Inspection ChecklistJeffrey Lipata Jr.100% (1)

- 175 140500Document2 pages175 140500Abu Anas M.SalaheldinNo ratings yet

- Saes T 101 PDFDocument6 pagesSaes T 101 PDFQa QcNo ratings yet

- Equipotential Bonding Swimming PoolsDocument4 pagesEquipotential Bonding Swimming PoolsMohamad HssanNo ratings yet

- 2 - Hazards Indentification PlanDocument27 pages2 - Hazards Indentification PlanasanNo ratings yet

- Saudi Arabian Engineering Standards Saes J 904Document45 pagesSaudi Arabian Engineering Standards Saes J 904liuyx866No ratings yet

- Saudi Aramco Inspection Checklist: Geotechnical Field Works Inspection SAIC-A-1008 15-Nov-17 CivilDocument8 pagesSaudi Aramco Inspection Checklist: Geotechnical Field Works Inspection SAIC-A-1008 15-Nov-17 CivilAbdul HannanNo ratings yet

- New Floating Pontoon Coast Guard Construction InspectionDocument2 pagesNew Floating Pontoon Coast Guard Construction InspectionSabheeh AliNo ratings yet

- Saes B 053Document6 pagesSaes B 053Navaneeth PurushothamanNo ratings yet

- Work Method Statement: Installation of Site Perimeter FencingDocument9 pagesWork Method Statement: Installation of Site Perimeter FencingStansilous Tatenda NyagomoNo ratings yet

- Risk Assessment - ExcavationDocument6 pagesRisk Assessment - Excavationganesh gbNo ratings yet

- Toaz - Info Abu Dhabi National Oil Company Adnoc CCTV System Testing and Commissioning T PRDocument9 pagesToaz - Info Abu Dhabi National Oil Company Adnoc CCTV System Testing and Commissioning T PRNitin JadhavNo ratings yet

- SATIP-P-104-01 Rev 8 Final LV Cables PDFDocument2 pagesSATIP-P-104-01 Rev 8 Final LV Cables PDFSabheeh AliNo ratings yet

- SAIC-Q-1036 Raw Materials Sampling, Testing & Asphalt Mix Design ReviewDocument7 pagesSAIC-Q-1036 Raw Materials Sampling, Testing & Asphalt Mix Design ReviewAbdul HannanNo ratings yet

- General Instruction Manual: ScopeDocument14 pagesGeneral Instruction Manual: ScopeJithuRajNo ratings yet

- SAES-L-460 PDF Download - Pipeline Crossings Under Roads - PDFYARDocument7 pagesSAES-L-460 PDF Download - Pipeline Crossings Under Roads - PDFYARZahidRafiqueNo ratings yet

- Index For Checklist of ElectricalDocument16 pagesIndex For Checklist of ElectricalKamranNo ratings yet

- Saudi Aramco Test ReportDocument8 pagesSaudi Aramco Test ReportJagdishNo ratings yet

- Saudi Aramco Pre-Commissioning Form: Instrument TransformersDocument4 pagesSaudi Aramco Pre-Commissioning Form: Instrument TransformersJithuRaj0% (1)

- Saes P 119Document17 pagesSaes P 119drbabithameringeorgemdsorthoNo ratings yet

- Saudi Aramco Pre-Commissioning Form: Testing Guide LinesDocument4 pagesSaudi Aramco Pre-Commissioning Form: Testing Guide LinesSathiya SeelanNo ratings yet

- Saep 50Document33 pagesSaep 50Demac SaudNo ratings yet

- SATIP-T-492-01 Ver 08Document1 pageSATIP-T-492-01 Ver 08thezaidNo ratings yet

- 18-SAMSS-625 - Outside Plant - Fiber Optic Cable Specifications (Single Mode and Multi Mode)Document16 pages18-SAMSS-625 - Outside Plant - Fiber Optic Cable Specifications (Single Mode and Multi Mode)medication abbasNo ratings yet

- Saudi Aramco Inspection ChecklistDocument6 pagesSaudi Aramco Inspection Checklistnisha_khanNo ratings yet

- INSPECTION OF INSTRUMENT JUNCTION BOXESDocument4 pagesINSPECTION OF INSTRUMENT JUNCTION BOXESnisha_khanNo ratings yet

- For Office Use Application Serial Number: State Bank of IndiaDocument2 pagesFor Office Use Application Serial Number: State Bank of Indianisha_khanNo ratings yet

- Welding PositionsDocument8 pagesWelding Positionsnisha_khanNo ratings yet

- CamScanner 10-17-2021 22.37Document2 pagesCamScanner 10-17-2021 22.37nisha_khanNo ratings yet

- 4-ECTA-AP060 Certificate of Conformity-100216-Lot1.1Document21 pages4-ECTA-AP060 Certificate of Conformity-100216-Lot1.1nisha_khanNo ratings yet

- MTC PO Reference-100216-Lot1Document5 pagesMTC PO Reference-100216-Lot1nisha_khanNo ratings yet

- Saudi Aramco Inspection Checklist: Fire Alarm System - Pre-Commissioning Inspection SAIC-B-6108 24-Jul-18 InstDocument16 pagesSaudi Aramco Inspection Checklist: Fire Alarm System - Pre-Commissioning Inspection SAIC-B-6108 24-Jul-18 Instnisha_khanNo ratings yet

- Saudi Aramco Inspection Checklist: Receiving Inspection of Pressure Vessels-Internal SAIC-D-2003 24-Jul-18 MechDocument4 pagesSaudi Aramco Inspection Checklist: Receiving Inspection of Pressure Vessels-Internal SAIC-D-2003 24-Jul-18 Mechnisha_khanNo ratings yet

- Policy document defines key termsDocument12 pagesPolicy document defines key termsnisha_khanNo ratings yet

- Saudi Aramco Inspection ChecklistDocument9 pagesSaudi Aramco Inspection Checklistnisha_khanNo ratings yet

- Saudi Aramco Inspection ChecklistDocument2 pagesSaudi Aramco Inspection Checklistnadeem shaikhNo ratings yet

- D7072vdeeb0502k080001 00-2Document8 pagesD7072vdeeb0502k080001 00-2nisha_khanNo ratings yet

- Revision History: Rev. No. Description Date RemarksDocument1 pageRevision History: Rev. No. Description Date Remarksnisha_khanNo ratings yet

- SAUDI ARAMCO PRESSURE VESSEL INSPECTION CHECKLISTDocument2 pagesSAUDI ARAMCO PRESSURE VESSEL INSPECTION CHECKLISTnisha_khanNo ratings yet

- Inspection Assignment Sheet: Contractor Info: Sa-Client Contact DetailsDocument2 pagesInspection Assignment Sheet: Contractor Info: Sa-Client Contact Detailsnisha_khanNo ratings yet

- Inspection Assignment Package Checklist: Element Yes No RemarksDocument2 pagesInspection Assignment Package Checklist: Element Yes No Remarksnisha_khanNo ratings yet

- Saudi Aramco Inspection ChecklistDocument3 pagesSaudi Aramco Inspection Checklistnisha_khan0% (1)

- Inspection Assignment Sheet: Contractor Info: Sa-Client Contact DetailsDocument2 pagesInspection Assignment Sheet: Contractor Info: Sa-Client Contact Detailsnisha_khanNo ratings yet

- D7029 - Inspection Release Note FormatDocument2 pagesD7029 - Inspection Release Note Formatnisha_khanNo ratings yet

- D7029 - PIM Attendance RegisterDocument1 pageD7029 - PIM Attendance Registernisha_khanNo ratings yet

- Revision History: Rev. No. Description Date RemarksDocument1 pageRevision History: Rev. No. Description Date Remarksnisha_khanNo ratings yet

- Saudi Aramco Inspection Checklist: Acceptance Criteria Reference Pass Fail N/A Re-Insp Date Item NoDocument7 pagesSaudi Aramco Inspection Checklist: Acceptance Criteria Reference Pass Fail N/A Re-Insp Date Item Nonisha_khanNo ratings yet

- PIM AgendaDocument2 pagesPIM Agendanisha_khanNo ratings yet

- Saudi Aramco Inspection ChecklistDocument8 pagesSaudi Aramco Inspection Checklistnisha_khanNo ratings yet

- Saudi Aramco Inspection Checklist: General - Instrumentation Accessories - Material Receiving SAIC-J-6017 24-Jul-18 InstDocument4 pagesSaudi Aramco Inspection Checklist: General - Instrumentation Accessories - Material Receiving SAIC-J-6017 24-Jul-18 Instnisha_khanNo ratings yet

- Vendor Punch List FormatDocument1 pageVendor Punch List Formatnisha_khanNo ratings yet

- Supplier Inspection Report for Aramco Metering Systems UpgradeDocument4 pagesSupplier Inspection Report for Aramco Metering Systems Upgradenisha_khanNo ratings yet

- Saudi Aramco Inspection ChecklistDocument5 pagesSaudi Aramco Inspection Checklistnisha_khanNo ratings yet

- Saudi Aramco Inspection ChecklistDocument15 pagesSaudi Aramco Inspection Checklistnisha_khanNo ratings yet

- Saudi Aramco Inspection Checklist: Recorder / Indicator - Material Receiving SAIC-J-6016 24-Jul-18 InstDocument4 pagesSaudi Aramco Inspection Checklist: Recorder / Indicator - Material Receiving SAIC-J-6016 24-Jul-18 Instnisha_khan0% (1)

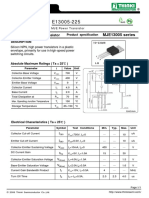

- DiodeDocument3 pagesDiodeAdrian TodeaNo ratings yet

- Qudra Piv - SP and Asset Details - Meb + North and South Salt Electrical Bldg.Document13 pagesQudra Piv - SP and Asset Details - Meb + North and South Salt Electrical Bldg.Virendranath Tiwari/UV/Al AinNo ratings yet

- GET8032C Spectra SwitchboardDocument84 pagesGET8032C Spectra SwitchboardestebanNo ratings yet

- English TestDocument3 pagesEnglish TestMaroua AissaniNo ratings yet

- 6 National CatalogDocument10 pages6 National CatalogHalfsharkNo ratings yet

- Busch Instruction Manual SECO SV SD 1010 1040 C en 0870569132 0004Document24 pagesBusch Instruction Manual SECO SV SD 1010 1040 C en 0870569132 0004Jquest_AdsNo ratings yet

- Emergency Public Address System Instruction ManualDocument68 pagesEmergency Public Address System Instruction Manualwandi rdNo ratings yet

- Three Phase Transformer Scott Connection PDFDocument11 pagesThree Phase Transformer Scott Connection PDFkaresanikas2004No ratings yet

- Microwave Solid State Diode Oscillator and AmplifierDocument20 pagesMicrowave Solid State Diode Oscillator and AmplifierdhanarajNo ratings yet

- Airworthiness Operator Message: AIRCRAFT MODELS: ATR42-500 and ATR72-212A ATA: 24 - 31Document16 pagesAirworthiness Operator Message: AIRCRAFT MODELS: ATR42-500 and ATR72-212A ATA: 24 - 31Pradeep K sNo ratings yet

- 8085 Microprocessor and 8051 MicrocontrollerDocument107 pages8085 Microprocessor and 8051 Microcontrollerparandaman.mechNo ratings yet

- M DigibusDocument178 pagesM DigibusmihaiNo ratings yet

- Ass 1Document1 pageAss 1Itefa AnisaNo ratings yet

- Entrelec 05Document56 pagesEntrelec 05baurzhan.kunkuzhayevNo ratings yet

- Chipanalog-CA-IF4820HS C2846827Document21 pagesChipanalog-CA-IF4820HS C2846827Mudassar RafiqNo ratings yet

- Biomedical Solenoid ValvesDocument3 pagesBiomedical Solenoid ValvesAll Engineering ElectronicsNo ratings yet

- Acb TroubleshootingDocument3 pagesAcb TroubleshootingSomu JaganathanNo ratings yet

- Al Lab Manual-2023Document73 pagesAl Lab Manual-2023wisari7978No ratings yet

- CA01303001EDocument106 pagesCA01303001EMarlon HumbertoNo ratings yet

- Carmanah MANUAL G-SeriesDocument96 pagesCarmanah MANUAL G-SeriesJuniorNo ratings yet

- AP Chem Lab Report - Galvanic CellDocument8 pagesAP Chem Lab Report - Galvanic CellGokce GozekNo ratings yet

- E13005 225 PDFDocument1 pageE13005 225 PDFDani ChisNo ratings yet

- CG Upc3 Controls enDocument26 pagesCG Upc3 Controls entornike dekanoidzeNo ratings yet

- EasyIssue DatasheetDocument2 pagesEasyIssue DatasheetFilipe LaínsNo ratings yet

- Workbook For Project Works in Mechatronics and Robotics: Master of EngineeringDocument29 pagesWorkbook For Project Works in Mechatronics and Robotics: Master of EngineeringRahul GaneshNo ratings yet

- REDARC BCDC Dual Battery Charger RangeDocument4 pagesREDARC BCDC Dual Battery Charger RangeStuNo ratings yet

- Vibrators CT ScreedDocument20 pagesVibrators CT ScreedMuhaiminNo ratings yet

- NO.:PJ4301I42-29H40P500: SpecificationDocument15 pagesNO.:PJ4301I42-29H40P500: Specificationnunca lereiNo ratings yet

- Over Current & Earth Fault Relay-Type Vn100R: FeaturesDocument4 pagesOver Current & Earth Fault Relay-Type Vn100R: Featuressujan723No ratings yet

- Survey of AI Based MPPT Algorithms in PV SystemsDocument8 pagesSurvey of AI Based MPPT Algorithms in PV Systemsindra setyawanNo ratings yet