Professional Documents

Culture Documents

Saudi Aramco Inspection Checklist

Uploaded by

nisha_khanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Saudi Aramco Inspection Checklist

Uploaded by

nisha_khanCopyright:

Available Formats

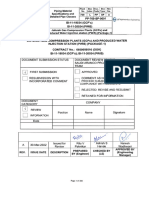

SAUDI ARAMCO ID/PIEU-24-July-2018 - REV.2018.06.00 (Standards Cutoff - June 30,2018) Rev.2018.06.

00 30-Jun-18

SAIC NUMBER DATE APPROVED QR NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Electronic Control Systems - DCS / ESD Manufacturer's Data

SAIC-J-6804 24-Jul-18 INST

Highway Cable - Material Receiving

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

EQUIPMENT ID NUMBER(S) EQUIPMENT DESCRIPTION EQPT CODE SYSTEM ID. PLANT NO.

LAYOUT DRAWING NUMBER REV. NO. PURCHASE ORDER NUMBER EC / PMCC / MCC NO.

SCHEDULED INSPECTION DATE & TIME ACTUAL INSPECTION DATE & TIME QUANTITY INSP. MH's SPENT TRAVEL TIME

SAUDI ARAMCO USE ONLY

SAUDI ARAMCO TIP NUMBER SAUDI ARAMCO ACTIVITY NUMBER WORK PERMIT REQUIRED?

SAUDI ARAMCO INSPECTION LEVEL CONTRACTOR INSPECTION LEVEL

ITEM

ACCEPTANCE CRITERIA REFERENCE PASS FAIL N/A RE-INSP DATE

No.

A Document Review and Certification

Schedule Q

A1 Review Quality Documentation for Material Receiving.

Att. IV

Material identification Procedure reviewed and shall be implemented for

all materials, parts and components, including partially fabricated Schedule Q

A2

assemblies. (Based on project specs, which define the length of tube and Att. IV

part number in the drawings)

Schedule G

A3 New and Unused - Instrumentation materials shall be new and unused.

Sec. 2.1

As Designed - Instrumentation materials shall be in accordance with the

Schedule G

A4 Saudi Aramco-approved project-specific design drawings, diagrams,

Sec. 2

schedules, lists, databases and associated documents.

Free of Damage - Instrumentation materials shall be free of damage. All

Schedule Q

incoming materials shall be visually inspected for damage and

A5 Att. IV

conformance to all applicable inspection releases with Material Test

Sec. 3.3

Report (MTR).

QC Before Installation - Instrumentation materials shall conform to all Schedule Q

A6 applicable requirements, standards and specifications prior to release to Att. IV

be used as part of the work. Sec. 3.3

Traceability - Instrumentation materials shall be traceable from the Schedule Q

A7 manufacturer and supplier through delivery, storage, fabrication, erection, Att. IV

installation, repair, modification and use. Sec. 4.3

Verify that the contractor or it's Saudi Aramco approved third party

Schedule Q

inspector performed the quality activities at the supplier and sub-supplier

A8 Att. III

locations as required by the inspection level assigned for the materials

Sec. 3.2

and equipment identified in SAEP-1150 Inspection Requirements.

The CONTRACTOR shall provide documentation that the required

Schedule Q

Storage, Handling and Preservation (SHP) activities have been performed

A9 Att. IV,SAEP-385

as per the requirmnents of Appendix A SAEP-385 , MSAER, and

Sec 4.3

manufacturer’s instructions.

Reliability:

Equipment supplied as part of the DCS system shall meet or exceed the

MTBF data specified in the table below at the equipment's design

temperature. MTBF figures shall be "Predicted" data calculated using the 23-SAMSS-010

A10 Bellcore Reliability Prediction Procedure: Sec. 6.5

Saudi Aramco: Company General Use

Commentary Note:

Requirements for MTBF do not apply to workstations and peripheral

23-SAMSS-010

A11 devices (such as monitors, keyboards, printers, etc.). Requirements for

Sec. 6.5

MTBF apply to all other components supplied by the vendor as part of the

system whether they be vendor proprietary or COTS equipment.

B Storage, Handling and Preservation

Schedule Q

The manufacturer's storage, handling and preservation instructions to be

B1 Att. IV , SAEP-

followed along with the requirments as specified in SAEP-385

385 Sec 4.3

Instrument and control wire and cable systems shall be designed and

B2 installed in accordance with ANSI/NFPA 70 National Electrical code 34-SAMSS-820

unless otherwise supplemented by this specification (34-SAMSS-820).

Purchase Order and Instrument specification sheet criteria shall be

confirmed and compared with instrument stainless steel tags/labels and Schedule Q

B3

nameplates, and shipment checked for damage prior to acceptance of the Att. IV

shipment

C Input/Output Wiring, Cables and Wire ways

Copper data link cables shall be specified per system manufacturers' SAES-J-902

C1

recommendations. Sec.12.3.2

Any cable which is used to interconnect equipment which is physically

SAES-Z-001

C2 located in different cabinets, shall be tagged with source and destination

Sec.16.1.1

on both ends.

Vendor standard cables shall be designed and installed in such a way as

to allow cable disconnection in order to service the equipment.

Commentary Note:

SAES-Z-001

C3 Vendor standard cables refers to cables which are pre-manufactured and

Sec.16.2.4

have a standard DCS vendor part number. These cables are most often

used for interconnecting chassis within a system cabinet and

communications between various components of the system.

Segregation of parallel wiring internal to cabinets shall adhere to the

34-SAMSS-820

C4 following Table 2. All dimensions are shown in millimeters.

Sec. 7.2.3

Separate plastic ducts are preferable for all Signal Categories that require

separation for organization and noise reduction. Signal Categories with

upper values of zero separation may be mixed in a plastic duct. Signal 34-SAMSS-820

C5

Categories shall not be mixed within any single multicore cable. Sec. 7.2.3.1

Example: 24 VDC digital and 24 VDC 4-20 mA may be run in the same

plastic duct, but not within a single multicore cable.

Wiring that is required to be segregated shall cross at right angles and the

34-SAMSS-820

C6 spacing shall be maintained as close as practicable to that shown in Table

Sec. 7.2.3.2

2. [Attachment 2]

General 120 VAC power wiring shall be minimum 14 AWG stranded,

34-SAMSS-820

C7 copper, UL listed PVC-insulated or cross-linked polyethylene. Wire

Sec. 7.3.1

insulation shall be rated for 600 volts, 75°C, minimum.

Electronic signal wire shall be UL listed , stranded copper, minimum size

18 AWG, 300 V for single conductors or a minimum 20 AWG, 300 V for

multicore cable (assuming Class-2 circuits per NEC). Wire insulation shall

34-SAMSS-820

C8 be XLPE PVC, or PTFE, with a minimum temperature rating of 75°C.

Sec. 7.3.2

Special electronic signal wires shall be as described in the Purchase

Order.

Saudi Aramco: Company General Use

Cabinets containing electronic equipment with field inputs/outputs (I/O)

(e.g., field termination assemblies, I/O modules, etc.) shall have the I/O

34-SAMSS-820

C9 device pre-wired to:

Sec. 7.4.1

1) intermediate terminal strips within the same cabinet shipping section, or

2) Ready for connection to marshalling cabinets or other control cabinets.

The following are exempted from the above rule:

Wiring for mill volt, micro amp, pulse and frequency signals under 1 Volt

such as thermocouples, resistance temperature detectors (RTD), vibration 34-SAMSS-820

C10

elements, analyzer elements, thermistor elements and transmitters with Sec. 7.6

pulse outputs shall be directly connected to the I/O unless otherwise

specified in the Purchase Order.

Exposed electrical connections with voltages greater than nominal 48

34-SAMSS-820

C11 volts AC/DC, shall have exposed wiring/terminations shrouded by

Sec. 7.4.2

transparent, removable, insulating plastic covers (or equivalent).

When screw-type terminals are provided on instruments and other

electrical devices, solder less crimp/compression connectors shall be

used for connecting stranded copper conductors. Insulated ring lugs, 34-SAMSS-820

C12

locking-fork or flanged- fork connectors, specifically designed to hold the Sec. 7.4.3

connector on the terminal in the event of loosening of the terminal screw,

shall be used on all such connections.

Terminal strip spacing shall allow ample room for plastic wire ducts and

permit training and lacing of cables, and fanning of individual wires to

termination points. Each terminal strip shall be labeled above or below

34-SAMSS-820

C13 with the terminal strip number, as shown on wiring diagrams. Terminals

Sec. 7.7.2

for similar (AC or DC) current service shall be grouped together and

physically separated from terminals for different service by means of

dividers, separate mounting rails or separate enclosures.

Standoffs for terminal strips are preferred to bring the terminal blocks

forward to be flush with the top of the plastic wire duct. This wiring method 34-SAMSS-820

C14

assures that all wires can be accessed without interference from other Sec. 7.7.3

wires as the wire duct is filled.

Where special cases of mixed ESD / Non-ESD signals occur in one

cabinet or control panel (e.g., Solid State / Relay Control Cabinets or

34-SAMSS-820

C15 Control Panels with ESD pushbuttons ), terminal strips for Emergency

Sec. 7.7.4

Shutdown (ESD) wiring shall be completely separate from all other wiring

including power, control and instrumentation.

Wiring for a given instrument loop shall be terminated on adjacent

34-SAMSS-820

C16 terminals on the terminal strip in order to organize and group all loop

Sec. 7.7.5

wiring.

Terminals for various types of general wiring (AC or DC), annunciator

34-SAMSS-820

C17 points and signal wiring shall be separately grouped and separated by

Sec. 7.7.6

dividers.

Wire Ducts and Looms:

Plastic wire ducts with removable covers shall be installed in cabinets as

required to provide a means of routing and organizing wiring. A minimum 34-SAMSS-820

C18

of 50 mm shall be maintained between the duct and terminal strips. Wire Sec. 7.9.1

markers shall be completely presented without being obscured by the

duct.

The maximum conduit/plastic wire duct fill (including spare capacity) shall 34-SAMSS-820

C19

not exceed the heat requirements of NFPA 70 Section 300.17. Sec. 7.9.2

In addition to the above, the maximum plastic wire duct fill (including 34-SAMSS-820

C20

spare capacity) shall not exceed 75% of its depth. Sec. 7.9.3

Plastic wire ducts shall be mounted using screws. Double-sided tape is 34-SAMSS-820

C21

unacceptable. Sec. 7.9.4

Saudi Aramco: Company General Use

Where space limitations preclude the use of plastic wire ducts, wiring shall

be neatly loomed and secured with plastic spiral wrapping or tie-wraps 34-SAMSS-820

C22

and anchors. Wiring between movable parts such as doors shall be Sec. 7.9.5

installed in flexible hoses.

34-SAMSS-820

C23 Loomed wiring shall not be installed near sharp-edged surfaces.

Sec. 7.9.6

Wiring shall not be threaded through undressed access holes. Glands or 34-SAMSS-820

C24

protective grommets shall be used. Sec. 7.9.7

Vendor-installed cables shall be supported and provided with a strain- 34-SAMSS-820

C25

relief mechanism for cable connectors. Sec. 7.9.8

34-SAMSS-820

C26 Wire ducts for ESD wiring shall not contain any other types of wiring.

Sec. 7.9.9

Wire Color Coding:

34-SAMSS-820

C27

Sec. 7.10

Cables with connector plugs shall be tagged at each end. Each cable tag

shall have two labels. The first label (closest to the plug connector) shall

identify the device and socket to which the plug is to be connected. The 34-SAMSS-820

C28

second label shall identify the device and socket to which the opposite Sec. 7.11.1

end of the cable is connected. The two tag may be combined into one tag

with sufficient seperation between two lables.

Interconnecting wiring shall be tagged at each end with two identification

tags (or the two may be combined into one tag with sufficient separation

between wire numbers). The first tag (closest to the end of the wire) shall 34-SAMSS-820

C29

identify the terminal number to which the wire is physically connected. The Sec. 7.11.2

second tag shall identify the terminal number to which the opposite end of

the wire is connected.

Identification shall be in accordance with designations shown on

instrument loop diagrams (ILDs). Where wires terminate on instrument or 34-SAMSS-820

C30

device terminals, the instrument tag number and terminal designation (+) Sec. 7.11.2

or (-) (if applicable) will be used in lieu of terminal strip identification.

Wire tag information shall be permanently marked in block alpha numerics

or typed on tubular, heat shrinkable, slip-on sleeves. Wrap-around, snap-

34-SAMSS-820

C31 on or self-adhesive markers shall not be used. Where shrink fit cable

Sec. 7.11.3

markers cannot be installed over pre-made cable and connectors, a

suitable tie-wrap or equivalent type permanent marker shall be used.

Spare pairs/triads in multi-pair/triad cables shall be labeled "SPARE" in

34-SAMSS-820

C32 addition to the destination and source terminal numbers. All spares are to

Sec. 7.11.6

be terminated.

D Control Network and Internal Communications

All DCS internal communications shall utilize redundant or fault tolerant 23-SAMSS-010

D2

paths. Sec.11.2.1

DCS internal communication shall be designed such that no single failure

will degrade the performance of the system. This requirement applies to 23-SAMSS-010

D3

all communication between DCS modules, including communication Sec.11.2.4

between controllers to their I/O modules.

DCS shall continously monitor the health of both the active and backup

communication paths to ensure the availability of both. The system shall 23-SAMSS-010

D4

check the status of both paths a minimum of once every every ten Sec.11.2.2

seconds.

Saudi Aramco: Company General Use

Failure of any single device that is connected to DCS network shall not

23-SAMSS-010

D5 affect the ability of the system to communicate with other devices on the

Sec.11.2.5

network.

The system shall have the capability to run redundant or fault tolerant 23-SAMSS-010

D6

communication cables in separate conduits or paths. Sec.11.2.3

Redundant communication interfaces shall be supplied for any interface

which is used to send commands from the DCS to an auxiliary system for SAES-Z-001

D7

operation and control. The requirement for redundant communications Sec.15.1.5

applies to both the DCS and the auxiliary systems interface.

Where redundant communications are specified, no single component SAES-Z-001

D8

failure shall result in the loss of communication to any subsystem. Sec.15.1.7

All devices connected to the DCS communication network shall be

23-SAMSS-010

D9 monitored for loss of communications and hardware failures. A system

Sec. 18.3.1

alarm shall be generated for each failure detected.

The system shall support communications using Modbus Serial protocol

in RTU or ASCII mode. Communications implemented over modbus serial

23-SAMSS-010

D10 shall support RS-232C, RS-422, and RS-485 interface with full or half-

Sec. 22.2.1

duplex operation using the following configurable baud rates: 9600,

19,200, and 38,800.

REMARKS:

REFERENCE DOCUMENTS:

1. Schedule G - Material, Tools and Equipment (Pro Forma MP-IK-LS Contract),

2. Schedule Q - Quality Requirements (Pro Forma Contract),

3. SAES-J-902 - Electrical Systems for Instrumentation, 1 January 2018

4. NFPA 70 - National Electric Code 2017

5. 23-SAMSS-010 - Distributed Control Systems,24 December 2017

6. 34-SAMSS-820 - Instrument Control Cabinets - Indoor, 17 June 2015

7. SAEP-385 - Preservation of Project Materials and Equipment - 25 October 2017

8. SAES-Z-001 - Process Control Systems, 20 December 2017

ATTACHMENTS:

NOTES:

1. Approved - Acceptable to the authority having jurisdiction (i.e., Saudi Aramco ID).

2. Identified - Recognizable as suitable for the specific application by a qualified testing laboratory (i.e., listing and/or labeling).

3. Listed - Equipment and materials included in a list published by an approved qualified organization concerned with evaluation of products or

services, that maintains periodic inspection of production of listed equipment or materials or periodic evaluation of services, and whose listing states

that the equipment, material or services either meets appropriate designated standards or has been tested and found suitable for a specified purpose.

4. Labeled - Equipment or materials to which has been attached a label, symbol or other identifying mark of an approved qualified organization

concerned with product evaluation, that maintains periodic inspection of production of labeled equipment or materials, and by whose labeling the

manufacturer indicates compliance with appropriate standards or performance in a specified manner.

Contractor / Third-Party Saudi Aramco

Construction Representative* PMT Representative

Work is Complete and Ready for Inspection: T&I Witnessed QC Record Reviewed Work Verified

Name, Initials and Date: Name, Initials and Date:

Saudi Aramco: Company General Use

QC Inspector PID Representative

Performed Inspection Work / Rework May Proceed T&I Witnessed QC Record Reviewed Work Verified

Name, Initials and Date: Name, Initials and Date:

QC Supervisor Proponent and Others

Quality Record Approved: T&I Witnessed QC Record Reviewed Work Verified

Name, Organization,

Name, Sign and Date:

Initials and Date:

*Person Responsible for Completion of Quality Work / Test Y = YES N = NO F = FAILED

Saudi Aramco: Company General Use

You might also like

- Saudi Aramco Inspection Checklist: CP Accessories - Material Receiving SAIC-X-3002 CPDocument3 pagesSaudi Aramco Inspection Checklist: CP Accessories - Material Receiving SAIC-X-3002 CPImran khanNo ratings yet

- Saudi Aramco Inspection Checklist: SAIC-J-6002 24-Jul-18 Inst General Piping and Tubing System - Materials ReceivingDocument7 pagesSaudi Aramco Inspection Checklist: SAIC-J-6002 24-Jul-18 Inst General Piping and Tubing System - Materials Receivingnisha_khanNo ratings yet

- Cyclone Collection Efficiency Comparison of Experimental Results With Theoretical PredictionsDocument16 pagesCyclone Collection Efficiency Comparison of Experimental Results With Theoretical PredictionsLucasLeãoNo ratings yet

- Ed Q 01.00 I 02Document22 pagesEd Q 01.00 I 02joseellargoNo ratings yet

- Vendor Front Sheet: Sao Vang and Dai Nguyet Development ProjectDocument4 pagesVendor Front Sheet: Sao Vang and Dai Nguyet Development ProjectjfdlksaNo ratings yet

- DRP001-OUF-GAL-RAM-E-000-191 Rev-S! PDFDocument10 pagesDRP001-OUF-GAL-RAM-E-000-191 Rev-S! PDFMohammad AftabNo ratings yet

- DRP001-OUF-GAL-PRO-Q-000-067 Rev-S1Document61 pagesDRP001-OUF-GAL-PRO-Q-000-067 Rev-S1Rafat KhanNo ratings yet

- VD V013 ZPM Pro 1507Document105 pagesVD V013 ZPM Pro 1507abdulNo ratings yet

- Comment Resolution Sheet 19009 Welding DossierDocument1 pageComment Resolution Sheet 19009 Welding DossierDheeraj E MohananNo ratings yet

- Paint Specification Package CDocument32 pagesPaint Specification Package CMohammedNo ratings yet

- Engineering Flow ChartDocument1 pageEngineering Flow ChartThamotharanNo ratings yet

- SP-2376-Piping - Engineering & Layout Design RequirementsDocument82 pagesSP-2376-Piping - Engineering & Layout Design RequirementsVenkat RanganNo ratings yet

- 2.63 Transmittal Log (PO-PGB-MBRD-0001) (VIT1)Document8 pages2.63 Transmittal Log (PO-PGB-MBRD-0001) (VIT1)zhangNo ratings yet

- Material Request For Approval (MRA)Document2 pagesMaterial Request For Approval (MRA)مهندس حسينNo ratings yet

- Tepng Onshore Const Itt Project Quality PlanDocument45 pagesTepng Onshore Const Itt Project Quality PlanTrustEmmaNo ratings yet

- 1 ITB For Scour Protection at SLTS PROJECTDocument13 pages1 ITB For Scour Protection at SLTS PROJECTEng Muhammad Afzal AlmaniNo ratings yet

- Design Integrity Procedure PR - 1232Document9 pagesDesign Integrity Procedure PR - 1232kattabommanNo ratings yet

- GENERAL NCR R0 RevDocument6 pagesGENERAL NCR R0 RevGanjar Dreadlocks NugrahaNo ratings yet

- WI-SSA-ENGTEC-001-E - 1 - Verification of Process Engineering DocumentsDocument14 pagesWI-SSA-ENGTEC-001-E - 1 - Verification of Process Engineering Documentsanghel_florin82No ratings yet

- 000 ZA E 09403 SITE NC MNGMT ProcedureDocument11 pages000 ZA E 09403 SITE NC MNGMT Procedurealinor_tn100% (1)

- ICM-SU-5102-C.3 CV Selection & FabricationDocument67 pagesICM-SU-5102-C.3 CV Selection & FabricationShivani DubeyNo ratings yet

- Previews MSS SP 61 2013 PreDocument4 pagesPreviews MSS SP 61 2013 PreHoàng Vinh0% (1)

- Agip KCO: Kashagan Field Development Project Experimental ProgrammeDocument27 pagesAgip KCO: Kashagan Field Development Project Experimental ProgrammeMaffone NumerounoNo ratings yet

- As-Built Valve Tagging Man HoursDocument5 pagesAs-Built Valve Tagging Man HoursMorgan Kaycee.No ratings yet

- Ansi/I - 75.08.07-: Face-to-Face Dimensions For Separable Flanged Globe-Style Control Valves (Classes 150, 300, and 600)Document12 pagesAnsi/I - 75.08.07-: Face-to-Face Dimensions For Separable Flanged Globe-Style Control Valves (Classes 150, 300, and 600)Yatã SantojaNo ratings yet

- 29008.eng - Cpi.std - Qualification Requirements For Painting SystemsDocument34 pages29008.eng - Cpi.std - Qualification Requirements For Painting SystemsMatteo100% (1)

- Ras Markaz Crude Oil Park Project (Phase1)Document16 pagesRas Markaz Crude Oil Park Project (Phase1)ANIL PLAMOOTTILNo ratings yet

- 12.PDE-CMG-G000-EC-00003 - 000 - 02 - ES Welding of Storage TanksDocument12 pages12.PDE-CMG-G000-EC-00003 - 000 - 02 - ES Welding of Storage TanksIonut FloricaNo ratings yet

- 2 Instructions To Bidders (ITB)Document265 pages2 Instructions To Bidders (ITB)Saurabh Kumar SharmaNo ratings yet

- SP 2094Document48 pagesSP 2094ArshadNo ratings yet

- 9686-8470-SP-000-4005 - 01 Welding and NDT SpecDocument53 pages9686-8470-SP-000-4005 - 01 Welding and NDT SpecvenkateshNo ratings yet

- Ac 036660 004Document1 pageAc 036660 004narutothunderjet216No ratings yet

- NPK 000 N1 GS 6001 K Rev 3 Spesification For Painting and CoatingDocument33 pagesNPK 000 N1 GS 6001 K Rev 3 Spesification For Painting and CoatingDangolNo ratings yet

- RevisionDocument154 pagesRevisionhalyNo ratings yet

- Material Approval: Sub Contractor Submission Date Name of Material Sample Supplier Specification DetailsDocument1 pageMaterial Approval: Sub Contractor Submission Date Name of Material Sample Supplier Specification DetailsM Helmi Yunan PanggabeanNo ratings yet

- Saipem - Serept - Piping ClassDocument67 pagesSaipem - Serept - Piping ClassAHMED AMIRANo ratings yet

- TE-419888-001 - 869-U-1004 - ANTIFOAM INJECTION PACKAGE - Rev.BDocument13 pagesTE-419888-001 - 869-U-1004 - ANTIFOAM INJECTION PACKAGE - Rev.Brizwan.zamanNo ratings yet

- Technical Query LogDocument29 pagesTechnical Query LogJobJobNo ratings yet

- SPRDDocument49 pagesSPRDnomurapreNo ratings yet

- Sa 7902 PDFDocument3 pagesSa 7902 PDFAdil SyedNo ratings yet

- IP02-Bend Check List 01Document1 pageIP02-Bend Check List 01Laith SalmanNo ratings yet

- Supplier Comments Response Sheet: Ain Tsila DevelopmentDocument22 pagesSupplier Comments Response Sheet: Ain Tsila DevelopmentZaidiNo ratings yet

- Company Specifications: Eni S.p.A. Exploration & Production DivisionDocument21 pagesCompany Specifications: Eni S.p.A. Exploration & Production DivisionAshraf AmmarNo ratings yet

- Toaz - Info Abu Dhabi National Oil Company Adnoc CCTV System Testing and Commissioning T PRDocument9 pagesToaz - Info Abu Dhabi National Oil Company Adnoc CCTV System Testing and Commissioning T PRNitin JadhavNo ratings yet

- Itp TTRK PDFDocument5 pagesItp TTRK PDFrahmath nawazNo ratings yet

- Off Shore Piping Design, Layout and Stress Analysis (Project Standards and Specifications)Document5 pagesOff Shore Piping Design, Layout and Stress Analysis (Project Standards and Specifications)sachin nagavkarNo ratings yet

- Petroject Corporate FilesDocument33 pagesPetroject Corporate FilesRRHH0% (1)

- Saes M 009Document55 pagesSaes M 009Shanmugapriya BalaramanNo ratings yet

- 2.2.ak GPO-EN-SPE-34211 PDFDocument26 pages2.2.ak GPO-EN-SPE-34211 PDFRatna Giridhar KavaliNo ratings yet

- KR Parco Ps6 Ms 0001 M.S For ConcreteDocument11 pagesKR Parco Ps6 Ms 0001 M.S For ConcretebulzaeNo ratings yet

- Aa - Req - 000131 - Quality Requirements Third Party Design VerificationDocument11 pagesAa - Req - 000131 - Quality Requirements Third Party Design Verificationjonodo89No ratings yet

- Saep 12Document39 pagesSaep 1269badbutchNo ratings yet

- Witness Joint & Sampling MatrixDocument13 pagesWitness Joint & Sampling MatrixPazhamalai RajanNo ratings yet

- 5.3. 402020-01391-08-PI-SPC-0002 Rev0 PDFDocument136 pages5.3. 402020-01391-08-PI-SPC-0002 Rev0 PDFsumit kumarNo ratings yet

- Technical Doc 1 - Technical Scope of Work Drs Eac181Document25 pagesTechnical Doc 1 - Technical Scope of Work Drs Eac181bhargavpansuria09No ratings yet

- JGCP Pms PP 769 SP 0001Document398 pagesJGCP Pms PP 769 SP 0001Ahmed BoraeyNo ratings yet

- BSST-TECH-CPJ17348-001 MDS-Material Approval Request For Application of CoatingDocument83 pagesBSST-TECH-CPJ17348-001 MDS-Material Approval Request For Application of CoatingAhmed MahjoubNo ratings yet

- Chemical Process Retrofitting and Revamping: Techniques and ApplicationsFrom EverandChemical Process Retrofitting and Revamping: Techniques and ApplicationsGade Pandu RangaiahNo ratings yet

- Welding PositionsDocument8 pagesWelding Positionsnisha_khanNo ratings yet

- MTC PO Reference-100216-Lot1Document5 pagesMTC PO Reference-100216-Lot1nisha_khanNo ratings yet

- Saudi Aramco Inspection ChecklistDocument9 pagesSaudi Aramco Inspection Checklistnisha_khanNo ratings yet

- 1) - D7072 - EMERSON - (ALL-EEB05-0002-0-01) - 100216-NOI-1 Rev.1Document4 pages1) - D7072 - EMERSON - (ALL-EEB05-0002-0-01) - 100216-NOI-1 Rev.1nisha_khanNo ratings yet

- 4-ECTA-AP060 Certificate of Conformity-100216-Lot1.1Document21 pages4-ECTA-AP060 Certificate of Conformity-100216-Lot1.1nisha_khanNo ratings yet

- ICICI Pru LifeStage RP U48 Ver 3 01feb2009 To 31dec2009Document12 pagesICICI Pru LifeStage RP U48 Ver 3 01feb2009 To 31dec2009nisha_khanNo ratings yet

- CamScanner 10-17-2021 22.37Document2 pagesCamScanner 10-17-2021 22.37nisha_khanNo ratings yet

- For Office Use Application Serial Number: State Bank of IndiaDocument2 pagesFor Office Use Application Serial Number: State Bank of Indianisha_khanNo ratings yet

- D7072vdeeb0502k080001 00-2Document8 pagesD7072vdeeb0502k080001 00-2nisha_khanNo ratings yet

- Saudi Aramco Inspection ChecklistDocument2 pagesSaudi Aramco Inspection Checklistnadeem shaikhNo ratings yet

- Saudi Aramco Inspection Checklist: Fire Alarm System - Pre-Commissioning Inspection SAIC-B-6108 24-Jul-18 InstDocument16 pagesSaudi Aramco Inspection Checklist: Fire Alarm System - Pre-Commissioning Inspection SAIC-B-6108 24-Jul-18 Instnisha_khanNo ratings yet

- Revision History: Rev. No. Description Date RemarksDocument1 pageRevision History: Rev. No. Description Date Remarksnisha_khanNo ratings yet

- Saudi Aramco Inspection Checklist: Receiving Inspection of Pressure Vessels-Internal SAIC-D-2003 24-Jul-18 MechDocument4 pagesSaudi Aramco Inspection Checklist: Receiving Inspection of Pressure Vessels-Internal SAIC-D-2003 24-Jul-18 Mechnisha_khanNo ratings yet

- Saudi Aramco Inspection Checklist: Receiving Inspection of Pressure Vessels-External SAIC-D-2002 24-Jul-18 MechDocument2 pagesSaudi Aramco Inspection Checklist: Receiving Inspection of Pressure Vessels-External SAIC-D-2002 24-Jul-18 Mechnisha_khanNo ratings yet

- Inspection Assignment Sheet: Contractor Info: Sa-Client Contact DetailsDocument2 pagesInspection Assignment Sheet: Contractor Info: Sa-Client Contact Detailsnisha_khanNo ratings yet

- Inspection Assignment Sheet: Contractor Info: Sa-Client Contact DetailsDocument2 pagesInspection Assignment Sheet: Contractor Info: Sa-Client Contact Detailsnisha_khanNo ratings yet

- D7029 - PIM Attendance RegisterDocument1 pageD7029 - PIM Attendance Registernisha_khanNo ratings yet

- PIM AgendaDocument2 pagesPIM Agendanisha_khanNo ratings yet

- Saudi Aramco Inspection ChecklistDocument8 pagesSaudi Aramco Inspection Checklistnisha_khanNo ratings yet

- Inspection Assignment Package Checklist: Element Yes No RemarksDocument2 pagesInspection Assignment Package Checklist: Element Yes No Remarksnisha_khanNo ratings yet

- Revision History: Rev. No. Description Date RemarksDocument1 pageRevision History: Rev. No. Description Date Remarksnisha_khanNo ratings yet

- D7029 - Supplier Inspection Report FormatDocument4 pagesD7029 - Supplier Inspection Report Formatnisha_khanNo ratings yet

- D7029 - Inspection Release Note FormatDocument2 pagesD7029 - Inspection Release Note Formatnisha_khanNo ratings yet

- Saudi Aramco Inspection Checklist: Acceptance Criteria Reference Pass Fail N/A Re-Insp Date Item NoDocument7 pagesSaudi Aramco Inspection Checklist: Acceptance Criteria Reference Pass Fail N/A Re-Insp Date Item Nonisha_khanNo ratings yet

- Saudi Aramco Inspection Checklist: General - Instrumentation Accessories - Material Receiving SAIC-J-6017 24-Jul-18 InstDocument4 pagesSaudi Aramco Inspection Checklist: General - Instrumentation Accessories - Material Receiving SAIC-J-6017 24-Jul-18 Instnisha_khanNo ratings yet

- Saudi Aramco Inspection ChecklistDocument15 pagesSaudi Aramco Inspection Checklistnisha_khanNo ratings yet

- Saudi Aramco Inspection ChecklistDocument3 pagesSaudi Aramco Inspection Checklistnisha_khan0% (1)

- Vendor Punch List FormatDocument1 pageVendor Punch List Formatnisha_khanNo ratings yet

- Saudi Aramco Inspection Checklist: Recorder / Indicator - Material Receiving SAIC-J-6016 24-Jul-18 InstDocument4 pagesSaudi Aramco Inspection Checklist: Recorder / Indicator - Material Receiving SAIC-J-6016 24-Jul-18 Instnisha_khan0% (1)

- Saudi Aramco Inspection ChecklistDocument5 pagesSaudi Aramco Inspection Checklistnisha_khanNo ratings yet

- Assignment-3: Marketing Management (MGT201)Document6 pagesAssignment-3: Marketing Management (MGT201)Rizza L. MacarandanNo ratings yet

- Draft Technical Notes SGLG 2023 - National OrientationDocument109 pagesDraft Technical Notes SGLG 2023 - National OrientationZane ZyneNo ratings yet

- BLE Catalogue 2013Document21 pagesBLE Catalogue 2013Shahina Parvin ShaikNo ratings yet

- Group3 The Development of Moral Character of Moral Agent EspantoHipolitoLepitinNamoc 1Document5 pagesGroup3 The Development of Moral Character of Moral Agent EspantoHipolitoLepitinNamoc 1Novelyn DuyoganNo ratings yet

- NS2-DVN-2540.Rev4 - Profomal Packing List BLR Piping Hanger Support Beam-Unit 2 - 20200710Document27 pagesNS2-DVN-2540.Rev4 - Profomal Packing List BLR Piping Hanger Support Beam-Unit 2 - 20200710PHAM PHI HUNGNo ratings yet

- QBM101Document37 pagesQBM101Shang BinNo ratings yet

- Annual Implementation Plan FinalDocument3 pagesAnnual Implementation Plan FinalMichelle Ann Narvino100% (2)

- Pengaruh PH Ekstraksi Terhadap Rendemen, Sifat Fisiko-Kimia Dan Fungsional Konsentrat Protein KACANG GUDE (Cajanus Cajan (L.) Millsp.)Document11 pagesPengaruh PH Ekstraksi Terhadap Rendemen, Sifat Fisiko-Kimia Dan Fungsional Konsentrat Protein KACANG GUDE (Cajanus Cajan (L.) Millsp.)Rezaa RezNo ratings yet

- Pertemuan Ke 12 - The Passive VoiceDocument5 pagesPertemuan Ke 12 - The Passive VoiceZarNo ratings yet

- Case Study - of Chapel of San Pedro CalungsodDocument5 pagesCase Study - of Chapel of San Pedro CalungsodJosielynNo ratings yet

- Research ProposalDocument2 pagesResearch Proposalsmh9662No ratings yet

- LNMIIT Course Information Form: A. B. C. D. E. FDocument2 pagesLNMIIT Course Information Form: A. B. C. D. E. FAayush JainNo ratings yet

- Julia Kristeva IntroDocument7 pagesJulia Kristeva IntroShweta SoodNo ratings yet

- Sociology Internal AssessmentDocument21 pagesSociology Internal AssessmentjavoughnNo ratings yet

- CM658 Time - MNGT - 10 - Getting Know The Class - NewNormDocument12 pagesCM658 Time - MNGT - 10 - Getting Know The Class - NewNormLee BañezNo ratings yet

- Music and Yoga Are Complementary To Each OtherDocument9 pagesMusic and Yoga Are Complementary To Each OthersatishNo ratings yet

- GW1101-1DI (3IN1) DatasheetDocument6 pagesGW1101-1DI (3IN1) DatasheetGina HuachoNo ratings yet

- 02 - Consumerism Then and NowDocument28 pages02 - Consumerism Then and NowGeorge TsangNo ratings yet

- Wooden Buildings: exposed to tiếp xúc với dramatic renewal sự làm mới đáng kểDocument6 pagesWooden Buildings: exposed to tiếp xúc với dramatic renewal sự làm mới đáng kểNguyễn Phạm Thảo NguyênNo ratings yet

- Polyethylene PolyamineDocument6 pagesPolyethylene PolyamineAV kayanNo ratings yet

- How To Plant Thoughts in Her Mind Ross Jeffries: TranscriptDocument12 pagesHow To Plant Thoughts in Her Mind Ross Jeffries: TranscriptAlcajNo ratings yet

- Water Cement RatioDocument5 pagesWater Cement RatioCastro FarfansNo ratings yet

- Guru Stotram-1Document5 pagesGuru Stotram-1Green WattNo ratings yet

- Dunhill The Old WindmillDocument2 pagesDunhill The Old WindmillMaría Hernández MiraveteNo ratings yet

- New Criticism Hills Like White Elephants FinalDocument4 pagesNew Criticism Hills Like White Elephants Finalapi-313631761No ratings yet

- Alien Bestiary PDFDocument450 pagesAlien Bestiary PDFDũng Lê100% (13)

- Advanced Calculus For Applications - Francis B Hilderand 1962Document657 pagesAdvanced Calculus For Applications - Francis B Hilderand 1962prabu201No ratings yet

- HLSS 310 Critical Infrastructure ProtectionDocument12 pagesHLSS 310 Critical Infrastructure ProtectionMoffat HarounNo ratings yet

- Orifice Plate Calculator Pressure Drop CalculationsDocument4 pagesOrifice Plate Calculator Pressure Drop CalculationsAnderson Pioner100% (1)

- Naaladiyar: Watch Free MoviesDocument6 pagesNaaladiyar: Watch Free MoviesVijayaLakshmi IyerNo ratings yet