Professional Documents

Culture Documents

Saudi Aramco Inspection Checklist: Receiving Inspection of Pressure Vessels-Internal SAIC-D-2003 24-Jul-18 Mech

Uploaded by

nisha_khanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Saudi Aramco Inspection Checklist: Receiving Inspection of Pressure Vessels-Internal SAIC-D-2003 24-Jul-18 Mech

Uploaded by

nisha_khanCopyright:

Available Formats

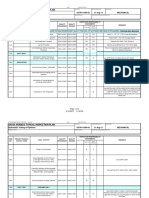

SAUDI ARAMCO ID/PIEU-24-July-2018 - REV.2018.06.00 (Standards Cutoff - June 30,2018) Rev.2018.06.

00 30-Jun-18

SAIC NUMBER DATE APPROVED QR NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Receiving Inspection of Pressure Vessels- Internal SAIC-D-2003 24-Jul-18 MECH

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

EQUIPMENT ID NUMBER(S) EQUIPMENT DESCRIPTION EQPT CODE SYSTEM ID. PLANT NO.

LAYOUT DRAWING NUMBER REV. NO. PURCHASE ORDER NUMBER EC / PMCC / MCC NO.

SCHEDULED INSPECTION DATE & TIME ACTUAL INSPECTION DATE & TIME QUANTITY INSP. MH's SPENT TRAVEL TIME

SAUDI ARAMCO USE ONLY

SAUDI ARAMCO TIP NUMBER SAUDI ARAMCO ACTIVITY NUMBER WORK PERMIT REQUIRED?

SAUDI ARAMCO INSPECTION LEVEL CONTRACTOR INSPECTION LEVEL

ITEM RE-INSP

ACCEPTANCE CRITERIA REFERENCE PASS FAIL N/A

No. DATE

For trayed vessels/columns, Non-Material Reqmts (NMR-7919-2) for 32-SAMSS-020,

A1

Column trays were available on site & verified per SAIC-D-2001. Par. 15.1

All welded joints of category A, B, C and D are complete fusion full

32-SAMSS-004,

A2 penetration welds, except for joint welds of slip-on flanges specified per

Par. 7.1.8

par. 8.1.3(d).

All fixed and removable internals, including trays, packing, distributors,

screens (Demister Pads) were installed as per the vessel/column data

sheet or Vessel detail drawing with respect to the following items:

a) Demister thickness

32-SAMSS-004,

A3 b) Demister framed with top and bottom grid of 25mm high.

Par. 9.1

c) beam supports were slotted

d) demister material used (SS or CS)

e) tie wire material, size and spacing

(NOTE: Refer to Library Drawing-C/D-DD-950004)

The finished overlay surface shall be free of overlaps, undercutting, and

SAES-W-014,

A4 notches and shall be relatively smooth. All flux and slag shall be

Par. 6.9

completely removed.

All internal and external attachments, including clips, welded directly to

32-SAMSS-004,

A5 pressure-retaining parts, are fully seal welded, except for blank square

Par. 13.2.9

nuts used for external insulation where tack welding is allowed.

Reinforcing and wear pads for all internal welded attachments are sized

to meet requirements of paragraph 7.11.4 of this specification. Pads shall

be a

32-SAMSS-004,

A6 a) Minimum of 10 mm (3/8") thick, but shall not exceed the shell thickness

Par. 11.9.1

b) All of their corners rounded to a minimum radius of 50 mm.

c) Distance from any edge of the attachment to the closest edge of the

reinforcing pad shall not be less than 50 mm.

Internal ladder rungs shall be provided by the Vessel Manufacturer 32-SAMSS-004,

A7

according to PIP document VEFV1100. Par. 9.5

SAES-D-001,

Internal Coating system applied conformed with the Vessel Data Sheet Par. 6.7.4 &

A8 and SAES-H-001 Para 7.3. For specific applications, verify APCS system SAES-H-001,

used meets design parameters (Serv & temp) Para.

7.3

Saudi Aramco: Company General Use

For GOSP traps, degassers, & WOSEP's in wet sour service, entire

interior surface including all internals has been coated except for anodes SAES-H-001,

A9

& heating coils. For wet sweet service, coat 0.3 m above maximum Par. 7.3 (H)

expected water level. Coating is not reqd for dry service.

For desalters and dehydrators, the bottom 60% including all internals

SAES-H-001,

A10 except anodes, were coated up to this level. Also coat the last 25-50 mm

Par. 7.3 (H)(2)

of the tips of the grid.

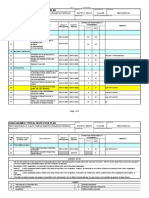

The dry film thickness shall be within the minimum and maximum

SAES-H-001,

A11 limits allowed in the applicable APCS. Dry film thickness shall be

Para 9.3.5 (a)

checked in accordance with SSPC PA2.

Internal Coating have no application related defects such as:

Runs, sags, drips, dry spray or foreign matter and uniform in appearance, SAES-H-001,

A12

blisters, cracked, porous or below minimum dry film thickness as given in Par. 9.3.5 (b) (c (e

the applicable APCS.

Internal coating on vessels have been holiday checked using a wet

SAES-H-001

A13 sponge at 67.5 volts if coating thickness does not exceed 500 micron.

Par. 9.4.5

Holidays detected have been repaired.

All internal piping systems, such as feed and reflux distributors, are 32-SAMSS-020,

A14

supported from the vessel shell or head, and not from trays. Par. 9.1.10

All tray support rings and other attachments required for supporting trays

32-SAMSS-020,

A15 shall be welded to the vessel shell. The welding of tray sub-assemblies

Par. 12.1.1

and tray decks to tray supports is prohibited.

Each tray shall be provided with one or more manways designed for

32-SAMSS-020,

A16 removal from above and below the tray deck. Whenever possible, the

Par. 9.1.6

minimum clear opening dimension shall be 380 mm x 460 mm.

Tray manways shall be located so as to provide the required open

32-SAMSS-020,

A17 dimensions (per 9.1.6) in vertical alignment (to allow climbing up through

Par. 9.1.7

column) and to provide access to all sections of the vessel.

The clearance under tray support beams shall be a minimum of 450 mm.

Where the tray spacing is 450 mm, the clearance may be reduced to a

32-SAMSS-020,

A18 minimum of 380 mm to account for the depth of tray panel trusses. If this

Par. 9.1.8

is not achievable, manways shall be provided on both sides of beams for

both tray above and below.

Bolts diameter smaller than 10 mm shall not be used. The lengths of

32-SAMSS-020,

A19 miscellaneous assembly bolts shall be grouped by 10-mm increments.

Par. 9.1.11

The minimum length for bolts is 25 mm for tray panels

32-SAMSS-020,

A20 Caps shall be removable from above the tray.

Par. 9.1.12

32-SAMSS-020,

A21 Blind trays shall be seal welded after installation.

Par. 9.1.13

Spacing between two adjacent bolt holes or clamps shall not exceed 150

mm (or 6”) for standard design loads. For trays and internals design with

32-SAMSS-020,

A22 uplift of 1psi or greater, this minimum spacing shall be 100 mm (or 4”).

Par. 9.1.15

The spacing between two adjacent tray sections on the support ring is

exempt from this requirement.

Saudi Aramco: Company General Use

The minimum thickness of tray parts, in USS gage, including corrosion

allowance shall be in accordance with Table 2, Minimum Thickness of

Tray Components.

32-SAMSS-020,

A23

Par. 9.3.1

The minimum design thickness for tray decks and downcomer sheets 32-SAMSS-020,

A24

shall be not less than 1.5 mm. Par. 9.3.2

The minimum thickness of downcomer bars shall be 6.4 mm for carbon 32-SAMSS-020,

A25

steel and 5 mm for alloy steels. Par. 9.3.3

All materials for vessels in sour service shall conform to ISO 15156 and 32-SAMSS-020,

A26

SAES-L-133. Par. 10.3

The use of non-ASTM materials shall be approved by the Saudi Aramco 32-SAMSS-020,

A27

Engineer. Par. 10.5

Gasket materials shall be asbestos-free and compatible with the service 32-SAMSS-020,

A28

conditions of the vessel. Par. 10.6

Entire valve unit, i.e., valves, guides and stops, shall be a minimum of

32-SAMSS-020,

A29 type 410 stainless steel for all new and revamped columns, unless a

Par. 10.7

higher grade material is specified in the data sheet.

All tray support rings and other attachments required for supporting trays

32-SAMSS-020,

A30 shall be welded to the vessel shell. The welding of tray sub-assemblies

Par. 12.1.1

and tray decks to tray supports is prohibited

All segments of valve trays that contain valves shall be installed after the 32-SAMSS-020,

A31

vessel has been hydrotested, thoroughly dried, and cleaned. Par. 12.1.2

Vessel circumferential seams shall not be covered by the tray or tray 32-SAMSS-020,

A32

support installations. Par. 12.1.3

Internals shall be installed according to the following levelness

requirements. Tolerances provided are the difference between the

minimum and maximum readings taken.

a) Tray supports shall present a flat surface for metal-to-metal contact

with the tray sections. As such, support members shall be installed to be

level within ±1 mm per 300 mm of chord length.

b) Weir height shall be uniform within ±3 mm of the specified height.

c) Downcomer clearance shall be uniform within ±3 mm of the specified

clearance.

d) Trays shall be level to within the following tolerances:

32-SAMSS-020,

A33

Par. 12.1.4

Tray bolts shall be tightened, using a calibrated torque wrench, to the Tray 32-SAMSS-020,

A34

Manufacturer's instructions and engaged to the full depth of the nuts. Par. 12.1.6

Saudi Aramco: Company General Use

Welding of Shell Attachments

1. Attachments supporting light loads, which will result in tensile or shear

stress less than 6.9 MPa (1,000 psi), may be welded directly to the

cladding.

2. Attachments other than those specified in paragraph 12.2.1 (1) of this 32-SAMSS-020,

A35

specification shall be welded directly to the base metal. The attachment Par. 12.2.1

shall have a full penetration weld to the base material. Where attachment

is to be welded to the base metal after cladding the vessel, clad shall be

stripped-back to weld the attachment. The attachment and the stripped-

back area shall be then weld overlaid.

Welding of Other Attachments

1. All welding procedures and welders shall be qualified in accordance

with ASME SEC IX and SAES-W-010.

2. Approved processes are SMAW and GTAW. Any other process

requires the approval of the Saudi Aramco Engineer.

3. The filler metal shall match the composition and mechanical properties

of the base metal. If two different base metals are to be joined, the filler

metal selection shall be approved by the Saudi Aramco Engineer.

4. A weld map shall be prepared to indicate which welding procedure will

32-SAMSS-020,

A36 be used for each weld joint.

Par. 12.2.2

5. All WPSs, PQRs and Weld Maps shall be submitted for approval to the

Saudi Aramco Engineer prior to the start of the job. All WPSs, PQRs and

weld maps shall be available at the work site for review at any time.

6. All full-penetration groove welds shall be welded from both sides,

except when this is not feasible due to thickness or geometry of the joint.

Double-sided welds shall be ground or gouged to sound metal prior to

welding the second side.

7. Thermally cut or gouged surfaces of all material shall be ground to

bright (un-oxidized) material prior to welding.

After installation, all trays shall be visually inspected for conformance to 32-SAMSS-020,

A37

the Tray Manufacturer's drawings and installation tolerances. Par. 13.2.1

Bubble cap and valve trays are to be inspected by using a strong light.

Any open seams, holes or gaps, which exceed 6 mm, shall be closed by 32-SAMSS-020,

A38

non-asbestos gaskets and bolt tightening. Openings less than 6 mm shall Par. 13.2.2

be repaired by bolt tightening or gaskets.

The addition of gaskets and/or ceramic rope is to be regarded as the last 32-SAMSS-020,

A39

course of action to be taken to seal trays. Par. 13.2.3

Materials for gaskets and rope must be compatible with the design 32-SAMSS-020,

A40

conditions of the vessel and chemically resistant to the service. Par. 13.2.4

REMARKS:

REFERENCE DOCUMENTS:

1- 32-SAMSS-004 -- Manufacture of Pressure Vessels (1 February 2018)

2- 32-SAMSS-020 -- Manufacture of Trays and Packing, (29 September 2016)

3- SAES-W-014 -- Weld Overlays and Welding of Clad Materials, (29 September 2016)

4- SAES-H-001 -- Coating Selection and Application Requirements for Industrial Plants and Equipment, (21 February 2018)

5- SAES-D-001 -- Design Criteria for Pressure Vessels, (20 August 2017)

Contractor / Third-Party Saudi Aramco

Construction Representative* PMT Representative

Work is Complete and Ready for Inspection: Work

T&I Witnessed QC Record Reviewed

Verified

Name, Initials and Date: Name, Initials and Date:

QC Inspector PID Representative

Work

Performed Inspection Work / Rework May Proceed T&I Witnessed QC Record Reviewed

Verified

Name, Initials and Date: Name, Initials and Date:

QC Supervisor Proponent and Others

Quality Record Approved: Work

T&I Witnessed QC Record Reviewed

Name, Organization, Verified

Name, Sign and Date:

Initials and Date:

*Person Responsible for Completion of Quality Work / Test Y = YES N = NO F = FAILED

Saudi Aramco: Company General Use

You might also like

- SAUDI ARAMCO PRESSURE VESSEL INSPECTION CHECKLISTDocument2 pagesSAUDI ARAMCO PRESSURE VESSEL INSPECTION CHECKLISTnisha_khanNo ratings yet

- Saudi Aramco Inspection ChecklistDocument3 pagesSaudi Aramco Inspection ChecklistAbdul HannanNo ratings yet

- Materials System SpecificationDocument7 pagesMaterials System Specificationaanouar77No ratings yet

- SAIC-D-2006 Rev 2Document2 pagesSAIC-D-2006 Rev 2ரமேஷ் பாலக்காடுNo ratings yet

- Satr-W-2010Document1 pageSatr-W-2010Joni Carino SuniNo ratings yet

- Saudi Aramco Inspection ChecklistDocument5 pagesSaudi Aramco Inspection ChecklistAbdul HannanNo ratings yet

- Saic L 2008 PDFDocument4 pagesSaic L 2008 PDFHesham HelalNo ratings yet

- Saudi Aramco Typical Inspection Plan: Pre-Engineered Metal Buildings SATIP-M-100-04 30-Apr-13 CivilDocument2 pagesSaudi Aramco Typical Inspection Plan: Pre-Engineered Metal Buildings SATIP-M-100-04 30-Apr-13 CivilJeffrey Lipata Jr.No ratings yet

- SAIC-A-2016 Rev 0Document2 pagesSAIC-A-2016 Rev 0philipyapNo ratings yet

- Saudi Aramco Test Report Pre-Pressure Test Checklist (Form)Document2 pagesSaudi Aramco Test Report Pre-Pressure Test Checklist (Form)Rijwan MohammadNo ratings yet

- Saudi Aramco Inspection Checklist: Pre-Test Punch Listing of On-Plot Piping SAIC-A-2010 31-Aug-11 PipingDocument12 pagesSaudi Aramco Inspection Checklist: Pre-Test Punch Listing of On-Plot Piping SAIC-A-2010 31-Aug-11 PipingAnonymous 4e7GNjzGWNo ratings yet

- Saic A 1005.Document5 pagesSaic A 1005.Fazal HaqNo ratings yet

- Saic D 2022Document7 pagesSaic D 2022sureshNo ratings yet

- Saudi Aramco Inspection Checklist: Storage and Preservation of Valves SAIC-L-2041 30-Apr-17 MechDocument2 pagesSaudi Aramco Inspection Checklist: Storage and Preservation of Valves SAIC-L-2041 30-Apr-17 Mechsuresh100% (1)

- Saudi Aramco Test ReportDocument7 pagesSaudi Aramco Test ReportziaNo ratings yet

- Materials System SpecificationDocument21 pagesMaterials System Specificationnadeem shaikhNo ratings yet

- SAIC-K-2026 Rev 0Document2 pagesSAIC-K-2026 Rev 0philipyapNo ratings yet

- Saudi Aramco checklist for buttering jointsDocument1 pageSaudi Aramco checklist for buttering jointskarioke mohaNo ratings yet

- 175 043000Document1 page175 043000Fahad AhmadNo ratings yet

- Saudi Aramco Inspection Checklist: Review of Flange Joint-Gasket Verification and Bolt Tightening ProcedureDocument2 pagesSaudi Aramco Inspection Checklist: Review of Flange Joint-Gasket Verification and Bolt Tightening ProcedureMAZHARULNo ratings yet

- SAIC-A-2009 Rev 2Document5 pagesSAIC-A-2009 Rev 2ரமேஷ் பாலக்காடுNo ratings yet

- Satr-W-2008 Atyb TRDocument6 pagesSatr-W-2008 Atyb TRDeo MNo ratings yet

- III. Applicable Codes & Standards for Aramco ProjectsDocument5 pagesIII. Applicable Codes & Standards for Aramco ProjectsZain Ali KidwaiNo ratings yet

- Ad 036821 001Document1 pageAd 036821 001AmolNo ratings yet

- 175 091300Document2 pages175 091300Abu Anas M.SalaheldinNo ratings yet

- Saudi Aramco Test Report: Positive Material Identification (PMI) Report 30-Oct-17 MechDocument2 pagesSaudi Aramco Test Report: Positive Material Identification (PMI) Report 30-Oct-17 MechJagdishNo ratings yet

- 32 Samss 017Document11 pages32 Samss 017naruto256No ratings yet

- SAIC-A-2015 Saudi Aramco Inspection ChecklistDocument8 pagesSAIC-A-2015 Saudi Aramco Inspection Checklistkarthi51289No ratings yet

- SAES-W-012 - Google Search3Document1 pageSAES-W-012 - Google Search3fayceal0% (1)

- SAIC-W-2006 Rev 0 PDFDocument4 pagesSAIC-W-2006 Rev 0 PDFMidhun K ChandraboseNo ratings yet

- SAIC-L-2136 Rev 0Document3 pagesSAIC-L-2136 Rev 0philipyapNo ratings yet

- 175-Ir171300, (850146), 11.30.2015Document2 pages175-Ir171300, (850146), 11.30.2015Rami ELLOUMINo ratings yet

- Saic M 1060Document1 pageSaic M 1060Hussain Nasser Al- NowiesserNo ratings yet

- 32 Samss 020Document18 pages32 Samss 020naruto256No ratings yet

- Saudi Aramco Inspection Checklist: Cast-In-Place Concrete Formwork Stripping Inspection SAIC Q-1016 15-Nov-17 MAH-SA-CDocument3 pagesSaudi Aramco Inspection Checklist: Cast-In-Place Concrete Formwork Stripping Inspection SAIC Q-1016 15-Nov-17 MAH-SA-CAbdul HannanNo ratings yet

- 34 Samss 711 PDFDocument26 pages34 Samss 711 PDFFlorin Daniel AnghelNo ratings yet

- Satip A 004 03Document3 pagesSatip A 004 03Anonymous 4e7GNjzGW100% (1)

- Saudi Aramco waterproofing inspectionDocument3 pagesSaudi Aramco waterproofing inspectionSatheesh Rama SamyNo ratings yet

- Saudi Aramco Typical Inspection Plan: Valve Inspection, Testing & Installation SATIP-L-108-01 8-Nov-15 MechanicalDocument12 pagesSaudi Aramco Typical Inspection Plan: Valve Inspection, Testing & Installation SATIP-L-108-01 8-Nov-15 MechanicalAhdal NoushadNo ratings yet

- Saudi Aramco Inspection Checklist: Buttering and / or Weld Build-Up - Offshore Structures SAIC-W-1311 WeldDocument1 pageSaudi Aramco Inspection Checklist: Buttering and / or Weld Build-Up - Offshore Structures SAIC-W-1311 Weldkartik_harwani4387No ratings yet

- SAIC-D-2007 Rev 2Document4 pagesSAIC-D-2007 Rev 2ரமேஷ் பாலக்காடுNo ratings yet

- SAIC-A-2008 Rev 0Document3 pagesSAIC-A-2008 Rev 0Kristine Caye DatarioNo ratings yet

- Saudi Aramco Test ReportDocument2 pagesSaudi Aramco Test ReportEswari AnandNo ratings yet

- QMIS RFI RaisedDocument2 pagesQMIS RFI RaisedSulman YounasNo ratings yet

- Active Doc ListDocument405 pagesActive Doc Listnadeem UddinNo ratings yet

- Handling and Storage of FBE Coated BarsDocument2 pagesHandling and Storage of FBE Coated BarsMo'tasem SerdanehNo ratings yet

- Saudi Aramco Typical Inspection PlanDocument2 pagesSaudi Aramco Typical Inspection PlanMAZHARULNo ratings yet

- Saudi Aramco Inspection Checklist: Receiving Inspection - Bolts, Nuts & Washers For Structural ConnectionsDocument6 pagesSaudi Aramco Inspection Checklist: Receiving Inspection - Bolts, Nuts & Washers For Structural ConnectionsAbdul HannanNo ratings yet

- Saic L 2007 PDFDocument7 pagesSaic L 2007 PDFHesham HelalNo ratings yet

- SATIP B 019 01 (Revision 4)Document2 pagesSATIP B 019 01 (Revision 4)Anonymous 4e7GNjzGWNo ratings yet

- Saic M 1034Document2 pagesSaic M 1034noor mohamedazeezNo ratings yet

- Saic M 1033Document7 pagesSaic M 1033noor mohamedazeezNo ratings yet

- SAIC-D-2002 Rev 8Document5 pagesSAIC-D-2002 Rev 8Syed ImranNo ratings yet

- SAUDCO INSPECTION CHECKLIST FOR SMALL TANKSDocument4 pagesSAUDCO INSPECTION CHECKLIST FOR SMALL TANKSAnonymous S9qBDVkyNo ratings yet

- Saudi Aramco Inspection Checklist: Fireproofing Concrete Application Inspection SAIC-B-1002 1-Nov-09 CivilDocument3 pagesSaudi Aramco Inspection Checklist: Fireproofing Concrete Application Inspection SAIC-B-1002 1-Nov-09 CivilWaleed MedhatNo ratings yet

- Saudi Aramco Inspection Checklist: Receiving Inspection of Air-Cooled Heat Exchanger SAIC-E-2005 15-Nov-17 MechDocument13 pagesSaudi Aramco Inspection Checklist: Receiving Inspection of Air-Cooled Heat Exchanger SAIC-E-2005 15-Nov-17 MechmominNo ratings yet

- Saudi Aramco Inspection Checklist: In-Process Inspection of Intumescent Fireproofing Mat'ls SAIC-B-2007 3-Jul-18 MechDocument3 pagesSaudi Aramco Inspection Checklist: In-Process Inspection of Intumescent Fireproofing Mat'ls SAIC-B-2007 3-Jul-18 Mechkarthi51289No ratings yet

- Aramco Receiving Inspection Checklist for Air-Cooled Heat ExchangerDocument13 pagesAramco Receiving Inspection Checklist for Air-Cooled Heat ExchangerjerinNo ratings yet

- Saic B 1002Document2 pagesSaic B 1002Hussain Nasser Al- NowiesserNo ratings yet

- SAICbDocument2 pagesSAICbAfzal HussainNo ratings yet

- MTC PO Reference-100216-Lot1Document5 pagesMTC PO Reference-100216-Lot1nisha_khanNo ratings yet

- For Office Use Application Serial Number: State Bank of IndiaDocument2 pagesFor Office Use Application Serial Number: State Bank of Indianisha_khanNo ratings yet

- Welding PositionsDocument8 pagesWelding Positionsnisha_khanNo ratings yet

- CamScanner 10-17-2021 22.37Document2 pagesCamScanner 10-17-2021 22.37nisha_khanNo ratings yet

- 4-ECTA-AP060 Certificate of Conformity-100216-Lot1.1Document21 pages4-ECTA-AP060 Certificate of Conformity-100216-Lot1.1nisha_khanNo ratings yet

- INSPECTION OF INSTRUMENT JUNCTION BOXESDocument4 pagesINSPECTION OF INSTRUMENT JUNCTION BOXESnisha_khanNo ratings yet

- Saudi Aramco Inspection Checklist: Fire Alarm System - Pre-Commissioning Inspection SAIC-B-6108 24-Jul-18 InstDocument16 pagesSaudi Aramco Inspection Checklist: Fire Alarm System - Pre-Commissioning Inspection SAIC-B-6108 24-Jul-18 Instnisha_khanNo ratings yet

- Policy document defines key termsDocument12 pagesPolicy document defines key termsnisha_khanNo ratings yet

- Saudi Aramco Inspection ChecklistDocument9 pagesSaudi Aramco Inspection Checklistnisha_khanNo ratings yet

- Inspection Assignment Sheet: Contractor Info: Sa-Client Contact DetailsDocument2 pagesInspection Assignment Sheet: Contractor Info: Sa-Client Contact Detailsnisha_khanNo ratings yet

- D7072vdeeb0502k080001 00-2Document8 pagesD7072vdeeb0502k080001 00-2nisha_khanNo ratings yet

- Revision History: Rev. No. Description Date RemarksDocument1 pageRevision History: Rev. No. Description Date Remarksnisha_khanNo ratings yet

- Saudi Aramco Inspection ChecklistDocument2 pagesSaudi Aramco Inspection Checklistnadeem shaikhNo ratings yet

- Revision History: Rev. No. Description Date RemarksDocument1 pageRevision History: Rev. No. Description Date Remarksnisha_khanNo ratings yet

- D7029 - Inspection Release Note FormatDocument2 pagesD7029 - Inspection Release Note Formatnisha_khanNo ratings yet

- Saudi Aramco Inspection ChecklistDocument8 pagesSaudi Aramco Inspection Checklistnisha_khanNo ratings yet

- Inspection Assignment Sheet: Contractor Info: Sa-Client Contact DetailsDocument2 pagesInspection Assignment Sheet: Contractor Info: Sa-Client Contact Detailsnisha_khanNo ratings yet

- D7029 - PIM Attendance RegisterDocument1 pageD7029 - PIM Attendance Registernisha_khanNo ratings yet

- Supplier Inspection Report for Aramco Metering Systems UpgradeDocument4 pagesSupplier Inspection Report for Aramco Metering Systems Upgradenisha_khanNo ratings yet

- Inspection Assignment Package Checklist: Element Yes No RemarksDocument2 pagesInspection Assignment Package Checklist: Element Yes No Remarksnisha_khanNo ratings yet

- Saudi Aramco Inspection Checklist: Acceptance Criteria Reference Pass Fail N/A Re-Insp Date Item NoDocument7 pagesSaudi Aramco Inspection Checklist: Acceptance Criteria Reference Pass Fail N/A Re-Insp Date Item Nonisha_khanNo ratings yet

- Vendor Punch List FormatDocument1 pageVendor Punch List Formatnisha_khanNo ratings yet

- Saudi Aramco Inspection ChecklistDocument3 pagesSaudi Aramco Inspection Checklistnisha_khan0% (1)

- Saudi Aramco Inspection Checklist: General - Instrumentation Accessories - Material Receiving SAIC-J-6017 24-Jul-18 InstDocument4 pagesSaudi Aramco Inspection Checklist: General - Instrumentation Accessories - Material Receiving SAIC-J-6017 24-Jul-18 Instnisha_khanNo ratings yet

- Saudi Aramco Inspection ChecklistDocument15 pagesSaudi Aramco Inspection Checklistnisha_khanNo ratings yet

- PIM AgendaDocument2 pagesPIM Agendanisha_khanNo ratings yet

- Saudi Aramco Inspection ChecklistDocument5 pagesSaudi Aramco Inspection Checklistnisha_khanNo ratings yet

- Saudi Aramco Inspection Checklist: Recorder / Indicator - Material Receiving SAIC-J-6016 24-Jul-18 InstDocument4 pagesSaudi Aramco Inspection Checklist: Recorder / Indicator - Material Receiving SAIC-J-6016 24-Jul-18 Instnisha_khan0% (1)

- REF33.Design of PortalFrame Buildings,,, PDFDocument358 pagesREF33.Design of PortalFrame Buildings,,, PDFharishram123456No ratings yet

- Stephen C. Cowin, Jay D. Humphrey Cardiovascular Soft Tissue Mechanics 2002Document259 pagesStephen C. Cowin, Jay D. Humphrey Cardiovascular Soft Tissue Mechanics 2002Juan Pablo BulaciosNo ratings yet

- Bicycle Frame Optimization Using Advanced Gradient MethodDocument16 pagesBicycle Frame Optimization Using Advanced Gradient MethodowobiwidahsugabNo ratings yet

- Buried Flexible Pipes: Design Considerations in Applying AS2566 StandardDocument16 pagesBuried Flexible Pipes: Design Considerations in Applying AS2566 StandardMarco FigueiredoNo ratings yet

- How JACKS Work: Analysis of Scissor Jack ComponentsDocument31 pagesHow JACKS Work: Analysis of Scissor Jack Componentsemba2015No ratings yet

- Seismic and wind load calculations for vessel support structureDocument3 pagesSeismic and wind load calculations for vessel support structurecordajohnNo ratings yet

- Introduction To Bio MechanicsDocument26 pagesIntroduction To Bio MechanicsSudeepNo ratings yet

- Full Solution Manual For Mechanics of Materials An Integrated Learning System 4Th Edition by Philpot PDF Docx Full Chapter ChapterDocument36 pagesFull Solution Manual For Mechanics of Materials An Integrated Learning System 4Th Edition by Philpot PDF Docx Full Chapter Chapterwhitwallpaludal0iare100% (17)

- Strut and Tie Model For Deep Beam Design (To ACI Building Code)Document8 pagesStrut and Tie Model For Deep Beam Design (To ACI Building Code)yyanan1118No ratings yet

- Horizontal Directional Drilling CalculationDocument60 pagesHorizontal Directional Drilling CalculationMauricio CascellaNo ratings yet

- MHB4219 stresses and strainsDocument7 pagesMHB4219 stresses and strainsNakandhrakumar RamaswamyNo ratings yet

- 14 531Lecture3-SoilStressesDocument25 pages14 531Lecture3-SoilStressesJay Ryan SantosNo ratings yet

- Refference For Residual StressesDocument18 pagesRefference For Residual Stressespavanmech42No ratings yet

- Mechanical performance and FE analysis of 3D woven glass fiber sandwich compositesDocument21 pagesMechanical performance and FE analysis of 3D woven glass fiber sandwich compositesAfnan H KhanNo ratings yet

- Evaluation Pressure Vessel ASME Division 2-7Document2 pagesEvaluation Pressure Vessel ASME Division 2-7evrim77No ratings yet

- Flexural Analysis and Design of BeamnsDocument15 pagesFlexural Analysis and Design of BeamnsAdil Javed ChaudharyNo ratings yet

- DF5.7.1 Application ManualDocument121 pagesDF5.7.1 Application ManualJimmy_Chung_1492No ratings yet

- Sample Fixed Tubesheet Heat Exchanger ReportDocument73 pagesSample Fixed Tubesheet Heat Exchanger Report9913489806No ratings yet

- CE1001 Basic CivilDocument3 pagesCE1001 Basic CivilMayank AgarwalNo ratings yet

- Mixing Performance of A Curved-Ribbon Impeller During Blending of Food PowdersDocument7 pagesMixing Performance of A Curved-Ribbon Impeller During Blending of Food PowdersAmal ..No ratings yet

- Compensation Calculation for Vessel OpeningDocument16 pagesCompensation Calculation for Vessel Openingdurgesh patelNo ratings yet

- ICAR Rheometer Users ManualDocument24 pagesICAR Rheometer Users ManualJAVIER ANDRADE MARTINEZNo ratings yet

- Lecture Notes On RC-I (2023-2024)Document53 pagesLecture Notes On RC-I (2023-2024)tekalignNo ratings yet

- Complicaciones de Los Microimplantes en Ortodoncia - Revisión de La LiteraturaDocument31 pagesComplicaciones de Los Microimplantes en Ortodoncia - Revisión de La LiteraturaxamarraNo ratings yet

- Edexcel Higher Fluid Mechanics H1 Unit 8 NQF Level 4 Outcome 2 Viscosity Tutorial 2 - The Viscous Nature of FluidsDocument10 pagesEdexcel Higher Fluid Mechanics H1 Unit 8 NQF Level 4 Outcome 2 Viscosity Tutorial 2 - The Viscous Nature of FluidsTejas PatelNo ratings yet

- Linear Failure Criteria With Three Principal StressesDocument74 pagesLinear Failure Criteria With Three Principal StressesAgroEmpresario ExportadorNo ratings yet

- 893 - Effects of Manual Therapy Connective Tissue PDFDocument10 pages893 - Effects of Manual Therapy Connective Tissue PDFDiego EstradaNo ratings yet

- Kenya's National Planning and Building Regulations 2009Document637 pagesKenya's National Planning and Building Regulations 2009Bon InteriorsNo ratings yet

- Triaxial Stress AnalysisDocument7 pagesTriaxial Stress Analysisbymohamed100% (1)