Professional Documents

Culture Documents

Saudi Aramco Inspection Checklist: Review of Flange Joint-Gasket Verification and Bolt Tightening Procedure

Uploaded by

MAZHARULOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Saudi Aramco Inspection Checklist: Review of Flange Joint-Gasket Verification and Bolt Tightening Procedure

Uploaded by

MAZHARULCopyright:

Available Formats

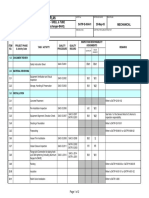

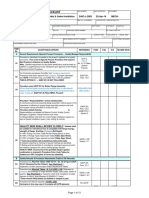

SAUDI ARAMCO ID/PIEU - 30-Nov-2017- REV. 2017.09.00 (Standards Cutoff - September 30, 2017) Rev. 2017.09.

00 30-Sep-17

SAIC NUMBER DATE APPROVED QR NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

REVIEW OF FLANGE JOINT-GASKET VERIFICATION AND SAIC-L-2002 30-Nov-17 MECH-

BOLT TIGHTENING PROCEDURE

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

REPLACE EMERGENCY STEAM TURBINE GENERATORS- SITE DEVELOPMENT PACKAGE 10-00163 SINOPEC ENGINEERING GROUP( SEG)

EQUIPMENT ID NUMBER(S) EQUIPMENT DESCRIPTION EQPT CODE SYSTEM ID. PLANT NO.

LAYOUT DRAWING NUMBER REV. NO. PURCHASE ORDER NUMBER EC / PMCC / MCC NO.

SCHEDULED INSPECTION DATE & TIME ACTUAL INSPECTION DATE & TIME QUANTITY INSP. MH's SPENT TRAVEL TIME

SAUDI ARAMCO USE ONLY

SAUDI ARAMCO TIP NUMBER SAUDI ARAMCO ACTIVITY NUMBER WORK PERMIT REQUIRED?

SATIP-L-350-01 1.2

SAUDI ARAMCO INSPECTION LEVEL CONTRACTOR INSPECTION LEVEL

RH RH

ITEM

ACCEPTANCE CRITERIA REFERENCE PASS FAIL N/A RE-INSP DATE

No.

A General Requirements (Special Process Procedure) ... Quality Manager Responsibility

All Procedures and Personnel Qualification shall be submitted for Schedule Q,

A1 review and/or approval at least twenty one (21) calendar days Attachment IV

prior to the start of WORK. Clause 2.1

The Procedure is identified & traceable to the project's updated list

of quality documents. Schedule Q,

A2 Note: Detailed requirement for document identification shall be listed Attachment IV

as addition or supplementary to this checkpoint upon approval of the Clause 4

Project Document Control Procedure.

A bolt up procedure based on the requirement of this document and

SAEP-351

A3 ASME PCC-1 shall be developed for each flange assembly and

Section 4.2

shall be approved by Saudi Aramco.

B Particular Requirements

SAEP-351

References- shall indicate the referencing documents used.

B1 Sec. 2.0

Responsibilities of personnel should be defined:

SAEP-351,

a. The contractor personnel executing the flange assembly.

B2 Sec. 3.2.2 &

b. The construction personnel executing the flange assembly

3.2.3

activities shall be qualified per Section 5 of SAES-L-351

Pre-Assembly Inspection requirements that will cover the following:

a. verification of gasket, SAEP-351,

b. flanges and bolt materials

B3

c. Lubricant to be used

Sec. 6.0 & 8.2

d. Verification tightening tools for adequacy,

performance and calibration.

Saudi Aramco: Company General Use

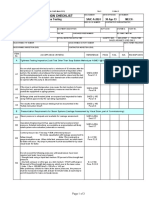

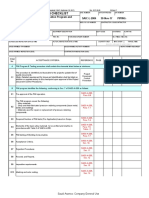

SAUDI ARAMCO ID/PIEU - 30-Nov-2017- REV. 2017.09.00 (Standards Cutoff - September 30, 2017) Rev. 2017.09.00 30-Sep-17

SAIC NUMBER DATE APPROVED QR NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Review Procedure - Flange Joint Assembly & Gasket

Installation

SAIC-L-2002 30-Nov-17 MECH-

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

REPLACE EMERGENCY STEAM TURBINE GENERATORS- SITE DEVELOPMENT PACKAGE 10-00163 SINOPEC ENGINEERING GROUP( SEG)

ITEM

ACCEPTANCE CRITERIA REFERENCE PASS FAIL N/A RE-INSP DATE

No.

The bolt up procedure shall clearly detail:

1. Cleaning and Examination of Flange and Fastener Contact

Surfaces

2. Alignment of Flanged Joints

SAEP 351

3. Installation of Gasket

B4 sections 6, 7, 8

4. Lubrication of “Working” Surfaces

&9

5. Installation of Bolts

6. Numbering of Bolts

7. Tightening of Bolts

8. Tightening Sequence

The bolt up procedure shall explain how to determine Target Bolt

SAEP-351

B5 Prestress for each joint and subsequently how the target torque is

section 10

identified.

The bolt up procedure shall explain how to prepare a joint assembly

ASME PCC-1

B6 record for each assembled joint, particularly those that are deemed

section 14

to be in critical service or deemed to be prone to leakage.

REMARKS:

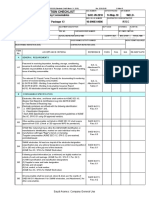

REFERENCE DOCUMENTS:

1. SAEP-351 (11 January 2017) - Bolted Flange Joints Assembly

2. SAES-L-350 (11 March 2014) - Construction of Plant Piping

3. SAES-L-450 (12 October 2015) - Construction of On-Land & Near Shore Pipelines

4. ASME PCC-1 (2013 Edition) Guidelines for Pressure Boundary Bolted Flange Joint Assembly

Contractor / Third-Party Saudi Aramco

Construction Representative* PMT Representative

Work is Complete and Ready for Inspection: T&I Witnessed QC Record Reviewed Work Verified

Name, Initials and Date: CHENG CONG Name, Initials and Date:

QC Inspector PID Representative

Performed Inspection Work / Rework May Proceed T&I Witnessed QC Record Reviewed Work Verified

Name, Initials and Date: Name, Initials and Date:

MOHAMMED QAMARUDDIN

QC Supervisor Proponent and Others

Quality Record Approved: T&I Witnessed QC Record Reviewed Work Verified

JAFFAR J. ALI Name, Organization,

Name, Sign and Date:

Initials and Date:

*Person Responsible for Completion of Quality Work / Test Y = YES N = NO F = FAILED

Saudi Aramco: Company General Use

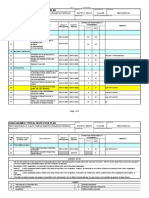

You might also like

- Saep 351Document24 pagesSaep 351Raj KumarNo ratings yet

- SAIC-D-2007 Rev 2Document4 pagesSAIC-D-2007 Rev 2ரமேஷ் பாலக்காடுNo ratings yet

- SAIC-L-2014 Flange Joint Insp PDFDocument7 pagesSAIC-L-2014 Flange Joint Insp PDFAnonymous S9qBDVkyNo ratings yet

- Saudi Aramco Inspection ChecklistDocument3 pagesSaudi Aramco Inspection ChecklistAbdul HannanNo ratings yet

- SAUDI ARAMCO PRESSURE VESSEL INSPECTION CHECKLISTDocument2 pagesSAUDI ARAMCO PRESSURE VESSEL INSPECTION CHECKLISTnisha_khanNo ratings yet

- Saudi Aramco System Lay-up ReportDocument2 pagesSaudi Aramco System Lay-up Reportdeepa narayan100% (1)

- Vessel/S&T Heat Exchanger Standard Details (Metric Units)Document7 pagesVessel/S&T Heat Exchanger Standard Details (Metric Units)Jamil AhmadNo ratings yet

- Saudi Aramco Inspection Checklist: Storage and Preservation of Valves SAIC-L-2041 30-Apr-17 MechDocument2 pagesSaudi Aramco Inspection Checklist: Storage and Preservation of Valves SAIC-L-2041 30-Apr-17 Mechsuresh100% (1)

- Saudi Aramco Inspection Checklist: Pre-Test Punch Listing of On-Plot Piping SAIC-A-2010 31-Aug-11 PipingDocument12 pagesSaudi Aramco Inspection Checklist: Pre-Test Punch Listing of On-Plot Piping SAIC-A-2010 31-Aug-11 PipingAnonymous 4e7GNjzGWNo ratings yet

- Evaluación requisitos código API 510 reparacionesDocument3 pagesEvaluación requisitos código API 510 reparacionesJuan Jose Espinoza BarandiaranNo ratings yet

- Saic L 2008 PDFDocument4 pagesSaic L 2008 PDFHesham HelalNo ratings yet

- Satr-W-2010Document1 pageSatr-W-2010Joni Carino SuniNo ratings yet

- Materials System SpecificationDocument7 pagesMaterials System Specificationaanouar77No ratings yet

- Inspection Procedure EDRDocument8 pagesInspection Procedure EDRaamirtec301No ratings yet

- Saudi Aramco Air Cooled Heat Exchanger Inspection PlanDocument2 pagesSaudi Aramco Air Cooled Heat Exchanger Inspection PlanAnonymous S9qBDVkyNo ratings yet

- Saudi Aramco Test Report Pre-Pressure Test Checklist (Form)Document2 pagesSaudi Aramco Test Report Pre-Pressure Test Checklist (Form)Rijwan MohammadNo ratings yet

- Saudi Aramco tank inspection requirementsDocument2 pagesSaudi Aramco tank inspection requirementssridhar100% (1)

- 34 Samss 611Document8 pages34 Samss 611naruto256No ratings yet

- Saudi Aramco Test ReportDocument4 pagesSaudi Aramco Test Reportkarthi51289No ratings yet

- III. Applicable Codes & Standards for Aramco ProjectsDocument5 pagesIII. Applicable Codes & Standards for Aramco ProjectsZain Ali KidwaiNo ratings yet

- Saudi Aramco Test ReportDocument2 pagesSaudi Aramco Test ReportEswari AnandNo ratings yet

- SATR-A-2011 Rev 2 - Re-Instatement Checklist (Form)Document2 pagesSATR-A-2011 Rev 2 - Re-Instatement Checklist (Form)deepa narayanNo ratings yet

- 1 SATIP-E-004-01 H Exc Installation-Shell and Tube-Rev1Document2 pages1 SATIP-E-004-01 H Exc Installation-Shell and Tube-Rev1Anonymous S9qBDVkyNo ratings yet

- SAUDI ARAMCO INSPECTION CHECKLIST FOR LEAK TESTINGDocument3 pagesSAUDI ARAMCO INSPECTION CHECKLIST FOR LEAK TESTINGpookkoya thangalNo ratings yet

- Welding Standards for Corrosion-Resistant Piping MaterialsDocument10 pagesWelding Standards for Corrosion-Resistant Piping MaterialsRaj AryanNo ratings yet

- Materials System SpecificationDocument21 pagesMaterials System Specificationnadeem shaikhNo ratings yet

- 00 Saip 06Document4 pages00 Saip 06Selvakpm06No ratings yet

- SAIC-K-2026 Rev 0Document2 pagesSAIC-K-2026 Rev 0philipyapNo ratings yet

- Satr W 2012Document1 pageSatr W 2012Mohammed Hamed BaganNo ratings yet

- 32 Samss 017Document11 pages32 Samss 017naruto256No ratings yet

- 04 Samss 035Document28 pages04 Samss 035SamiNo ratings yet

- Saudi Aramco Inspection ChecklistDocument2 pagesSaudi Aramco Inspection ChecklistJoni Carino SuniNo ratings yet

- Inspection Procedure: 00-SAIP-81 23 July 2017Document37 pagesInspection Procedure: 00-SAIP-81 23 July 2017John BuntalesNo ratings yet

- Saudi Aramco Typical Inspection Plan Cross Country Above Ground PipeliDocument5 pagesSaudi Aramco Typical Inspection Plan Cross Country Above Ground PipeliShahbaz AhmadNo ratings yet

- 32 Samss 011Document27 pages32 Samss 011naruto256No ratings yet

- 34 Samss 711 PDFDocument26 pages34 Samss 711 PDFFlorin Daniel AnghelNo ratings yet

- Saes A 007Document29 pagesSaes A 007NagarjunNo ratings yet

- Saudi Aramco Inspection Checklist: Welding Overlay Workmanship Assessment SAIC-W-2027 31-Aug-11 MechDocument1 pageSaudi Aramco Inspection Checklist: Welding Overlay Workmanship Assessment SAIC-W-2027 31-Aug-11 MechAnonymous 4e7GNjzGWNo ratings yet

- SAIC-A-2015 Saudi Aramco Inspection ChecklistDocument8 pagesSAIC-A-2015 Saudi Aramco Inspection Checklistkarthi51289No ratings yet

- Saes L 101Document13 pagesSaes L 101samsurendran_mech4020No ratings yet

- SAUDI ARAMCO BOILER INSPECTION PLANDocument4 pagesSAUDI ARAMCO BOILER INSPECTION PLANAnonymous 4e7GNjzGWNo ratings yet

- Materials System SpecificationDocument17 pagesMaterials System Specificationnadeem shaikhNo ratings yet

- SAIC-L-2136 Rev 0Document3 pagesSAIC-L-2136 Rev 0philipyapNo ratings yet

- Saudi Aramco Typical Inspection Plan: Pre-Engineered Metal Buildings SATIP-M-100-04 30-Apr-13 CivilDocument2 pagesSaudi Aramco Typical Inspection Plan: Pre-Engineered Metal Buildings SATIP-M-100-04 30-Apr-13 CivilJeffrey Lipata Jr.No ratings yet

- Saep 1144Document23 pagesSaep 1144Amit shahNo ratings yet

- Saudi Aramco Inspection ChecklistDocument6 pagesSaudi Aramco Inspection ChecklistAnonymous 4e7GNjzGWNo ratings yet

- 32 Samss 007Document38 pages32 Samss 007naruto256No ratings yet

- 175 091300Document2 pages175 091300Abu Anas M.SalaheldinNo ratings yet

- Sabp D 002Document16 pagesSabp D 002engforever AdnanNo ratings yet

- SAIC-A-2009 Rev 2Document5 pagesSAIC-A-2009 Rev 2ரமேஷ் பாலக்காடுNo ratings yet

- 00 Saip 71Document19 pages00 Saip 71balajiNo ratings yet

- SAUDICHECK - WELD TRACKING DATABASEDocument5 pagesSAUDICHECK - WELD TRACKING DATABASEManoj KumarNo ratings yet

- SAES-J-604 - Protective Rotating PDFDocument12 pagesSAES-J-604 - Protective Rotating PDFinfo_shakib100% (1)

- Saic L 2002Document13 pagesSaic L 2002chidambaramNo ratings yet

- Saudi Aramco flange inspection procedureDocument13 pagesSaudi Aramco flange inspection procedurebiplabpal2009No ratings yet

- SAIC-L-2094 Rev 7Document18 pagesSAIC-L-2094 Rev 7Jaseel KanhirathingalNo ratings yet

- SAUDI ARAMCO HOT TAP INSPECTION CHECKLISTDocument18 pagesSAUDI ARAMCO HOT TAP INSPECTION CHECKLISTkarthi51289No ratings yet

- Saudi Aramco Inspection Checklist: Final Insp / Walkthrough of Diesel Engine Installation SAIC-K-2020 25-Apr-18 MechDocument2 pagesSaudi Aramco Inspection Checklist: Final Insp / Walkthrough of Diesel Engine Installation SAIC-K-2020 25-Apr-18 MechjunaidNo ratings yet

- Saudi Aramco Post-Test Reinstatement ChecklistDocument15 pagesSaudi Aramco Post-Test Reinstatement Checklistpookkoya thangalNo ratings yet

- Saudi Aramco refractory installation checklistDocument3 pagesSaudi Aramco refractory installation checklistAnonymous S9qBDVkyNo ratings yet

- Master Gas Project Paint Store Temperature Record: Date Time Temp Humidity % Time Temp Humidity % RemarksDocument1 pageMaster Gas Project Paint Store Temperature Record: Date Time Temp Humidity % Time Temp Humidity % RemarksMAZHARULNo ratings yet

- SAUDIPIPINGMATTRACEDocument9 pagesSAUDIPIPINGMATTRACEMAZHARULNo ratings yet

- Saudi Aramco Inspection ChecklistDocument10 pagesSaudi Aramco Inspection ChecklistMAZHARULNo ratings yet

- Saudi Aramco Inspection ChecklistDocument2 pagesSaudi Aramco Inspection ChecklistMAZHARULNo ratings yet

- Jose Salomia Mazharul Haque: Available Tools With QC, Jubail Sr. NoDocument2 pagesJose Salomia Mazharul Haque: Available Tools With QC, Jubail Sr. NoMAZHARULNo ratings yet

- 02.186 - F - Satr-Nde-2008 Revised (003) 010817 SS JointsDocument2 pages02.186 - F - Satr-Nde-2008 Revised (003) 010817 SS JointsMAZHARULNo ratings yet

- Saudi Aramco Inspection Checklist: Validation of Welding Equipment (Plant Piping) SAIC-W-2011 21-Oct-18 WeldDocument4 pagesSaudi Aramco Inspection Checklist: Validation of Welding Equipment (Plant Piping) SAIC-W-2011 21-Oct-18 WeldMAZHARULNo ratings yet

- Date Time S. TEMP (TS) C RH% Remarks Atm Temp (Ta) Dew Pint Temp (TD) CDocument5 pagesDate Time S. TEMP (TS) C RH% Remarks Atm Temp (Ta) Dew Pint Temp (TD) CMAZHARULNo ratings yet

- Jubail Workshp QCDocument1 pageJubail Workshp QCMAZHARULNo ratings yet

- Saic B 4001 PDFDocument2 pagesSaic B 4001 PDFMAZHARULNo ratings yet

- SAIC-K-4041 Rev 7Document2 pagesSAIC-K-4041 Rev 7shahzadaNo ratings yet

- Saudi Aramco Sanitary Sewer Manhole Inspection ChecklistDocument1 pageSaudi Aramco Sanitary Sewer Manhole Inspection ChecklistMAZHARULNo ratings yet

- Saic B 4006 PDFDocument1 pageSaic B 4006 PDFMAZHARULNo ratings yet

- SAIC-K-4041 Rev 7Document2 pagesSAIC-K-4041 Rev 7shahzadaNo ratings yet

- Saudi Aramco Inspection Checklist: Emergency Eyewash/Shower System Installation SAIC-B-4002 30-Apr-13 PlumbDocument2 pagesSaudi Aramco Inspection Checklist: Emergency Eyewash/Shower System Installation SAIC-B-4002 30-Apr-13 PlumbMAZHARULNo ratings yet

- Saudi Aramco Inspection Checklist: Emergency Eyewash/Shower System Installation SAIC-B-4002 30-Apr-13 PlumbDocument2 pagesSaudi Aramco Inspection Checklist: Emergency Eyewash/Shower System Installation SAIC-B-4002 30-Apr-13 PlumbMAZHARULNo ratings yet

- SAIC-K-4041 Rev 7Document2 pagesSAIC-K-4041 Rev 7shahzadaNo ratings yet

- WeldingDocument1 pageWeldingMAZHARULNo ratings yet

- Saic K 4006Document2 pagesSaic K 4006mohamadNo ratings yet

- Saudi Aramco Typical Inspection PlanDocument2 pagesSaudi Aramco Typical Inspection PlanMAZHARULNo ratings yet

- Saic K 4006Document2 pagesSaic K 4006mohamadNo ratings yet

- WeldingDocument1 pageWeldingMAZHARULNo ratings yet

- Product Data Sheet - BIRKOSIT Dichtungskitt ®Document2 pagesProduct Data Sheet - BIRKOSIT Dichtungskitt ®Le Thanh HaiNo ratings yet

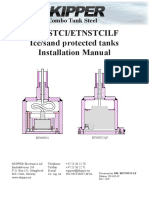

- Etnstci/Etnstcilf Ice/sand Protected Tanks Installation ManualDocument14 pagesEtnstci/Etnstcilf Ice/sand Protected Tanks Installation ManualRafael ReisNo ratings yet

- Joint Integrity Procedure - GQP-ENG-014Document32 pagesJoint Integrity Procedure - GQP-ENG-014mohd as shahiddin jafriNo ratings yet

- ONIXline BJ Series Dimensions GuideDocument5 pagesONIXline BJ Series Dimensions Guidemarcusa85No ratings yet

- Piping Design STD PDIL 138Document134 pagesPiping Design STD PDIL 138Anonymous ZFnjdaMR100% (2)

- Engineering Services for 100kTPA Chloromethane plant at Dahej, GujaratDocument6 pagesEngineering Services for 100kTPA Chloromethane plant at Dahej, Gujaratsumit kumarNo ratings yet

- Remote Operated Shutoff Valves SpecificationDocument31 pagesRemote Operated Shutoff Valves SpecificationSharath KrishnanNo ratings yet

- Butterfly Valves GuideDocument1 pageButterfly Valves Guideimtz2013No ratings yet

- MOTOMAN-MH5S II DX200 INSTRUCTIONSDocument68 pagesMOTOMAN-MH5S II DX200 INSTRUCTIONSBhumikaNo ratings yet

- Pipe Stress Analysis of Dumai Gas StationDocument27 pagesPipe Stress Analysis of Dumai Gas StationsendyNo ratings yet

- JCB Service Manual Sections GuideDocument423 pagesJCB Service Manual Sections GuideredNo ratings yet

- Zirconia AnalyzerDocument60 pagesZirconia AnalyzeraudithiraNo ratings yet

- B2920HSD TractorDocument308 pagesB2920HSD Tractorjhoward000No ratings yet

- GFK - Operating Instructions - 06.2014Document4 pagesGFK - Operating Instructions - 06.2014brotaccristianNo ratings yet

- 2100.015 SHORTSTOPP 300D Split Tee and SHORTPLUG WGBDocument4 pages2100.015 SHORTSTOPP 300D Split Tee and SHORTPLUG WGBMORELLI silvio100% (1)

- Cast Iron Valves: JIS 5K/10K, Class 125Document20 pagesCast Iron Valves: JIS 5K/10K, Class 125Alexjohn2009No ratings yet

- 8L22HLX Parts CatalogDocument95 pages8L22HLX Parts CatalogRafael HerreraNo ratings yet

- Yokogawa Eja110e PDFDocument17 pagesYokogawa Eja110e PDFAdrian MendozaNo ratings yet

- Warren FSXB Series Spec SheetDocument3 pagesWarren FSXB Series Spec SheetEmmanuel Ber SNo ratings yet

- Pamphlet 6 Piping Systems For Dry Chlorine - CiDocument80 pagesPamphlet 6 Piping Systems For Dry Chlorine - Cifagb1978100% (4)

- Ductile Iron Flanged Fittings: SpecificationsDocument20 pagesDuctile Iron Flanged Fittings: SpecificationsTarun ChakrabortyNo ratings yet

- PCCFL001Document16 pagesPCCFL001Hermann KlierNo ratings yet

- Waverunner VXR: Vx1800A-N Vx1800A-NDocument60 pagesWaverunner VXR: Vx1800A-N Vx1800A-NJorjNo ratings yet

- Stress Analysis and Evaluation of A Rectangular Pressure VesselDocument10 pagesStress Analysis and Evaluation of A Rectangular Pressure Vesselmatodelanus100% (1)

- AHLSTAR End-Suction Single-Stage Centrifugal PumpsDocument24 pagesAHLSTAR End-Suction Single-Stage Centrifugal PumpsDoanh VoNo ratings yet

- Catalogue 2018 PDFDocument84 pagesCatalogue 2018 PDFmartinNo ratings yet

- Flange Kit, Khs Subsea Ball Valve: Model CodeDocument4 pagesFlange Kit, Khs Subsea Ball Valve: Model CodepeterNo ratings yet

- Atomac BrochureDocument28 pagesAtomac BrochureManish TulaskarNo ratings yet

- A 1475 Thru A 14499 Series - Rev 011105Document1 pageA 1475 Thru A 14499 Series - Rev 011105Pero Plemeniti SimicNo ratings yet

- Catalogo Listino 2012 IngleseDocument19 pagesCatalogo Listino 2012 Inglesekaniappan sakthivelNo ratings yet