Professional Documents

Culture Documents

WhatIsNEW UPDATE HFIR

Uploaded by

amarnath98252Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

WhatIsNEW UPDATE HFIR

Uploaded by

amarnath98252Copyright:

Available Formats

WORKFORCE PRODUCTIVITY –

INSPECTION ROUNDS

PRODUCT UPDATE NOTE

An easy to use, out-of-the-box, end-to-end software solution for field operations within

service and manufacturing companies. It is designed to enable the deployment of nimble

and dynamic strategies for daily field activities, higher productivity, improved safety, and

better data-driven decisions through insights from superior analytics.

SOLUTION

We are pleased to announce a new release of Honeywell

Forge Workforce Productivity – Inspection Rounds. Inspection

Rounds Release 7 is now available on the Honeywell hosted

cloud as well as for on-premises deployments.

Inspection Rounds optimizes field operations by enabling:

• Efficient data collection – Inspection Rounds digitizes

the complex and difficult to maintain operator checklists and

logs, enabling a field worker to have all the information on

rounds tasks and schedules on their mobile device.

• Compliance – Plant superintendents and

administrators can quickly gain insight on round completion

status and any asset health deviations outside of normal

operating conditions through centralized reporting. Enhancements include:

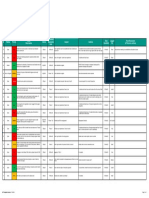

• Supports workflows requiring conditional task execution

• Views and captures images/videos during task execution

• Integration – Through tight coupling with CMMS,

• Supports historical data trend viewing

reporting and historian systems, rounds data captured in the

• Identifies assets through NFC tags (Android only)

field can be used to create work orders, update and inform

• GPS-based task execution geo-location validation

console operators on changing field conditions, and improve

• Enables multilevel approval workflows for rounds and

the predictive monitoring capabilities of asset performance

incidents

management systems.

• Escalation notifications using email

• Supports additional flexibility in configuring enterprise

hierarchies with multiple levels

ENHANCEMENTS • Creates reusable checklists and asset classes (you can

So, what exactly is the lates release all about? call it template if you prefer)

Inspection Rounds Release 7 introduces a host of new • Supports flexible shift models and advanced scheduling

features to enhance workflow, scheduling, visual information, options

and configuration functionality. • Provides enhanced bulk configuration export/import

capabilities

Contact your local Honeywell representative to learn more.

This document is a non-binding, confidential document that contains valuable proprietary and confidential information of

Honeywell and must not be disclosed to any third party without our written agreement. It does not create any binding obligations

on us to develop or sell any product, service or offering. Content provided herein cannot be altered or modified and must remain

in the format as originally presented by Honeywell. Any descriptions of future product direction, intended updates or new or

improved features or functions are intended for informational purposes only and are not binding commitments on us and the sale,

development, release or timing of any such products, updates, features or functions is at our sole discretion.

For More Information

To learn more visit Honeywell Forge Honeywell® is a trademark of

Honeywell International Inc.

Workforce Productivity or contact your Other brand or product

Honeywell Account Manager. names are trademarks of

their respective owners.

Honeywell Connected Enterprise

715 Peachtree Street NE

Atlanta, Georgia 30308

www.honeywellprocess.com

April 2022

© 2022 Honeywell International Inc.

You might also like

- Windows Server 2008 R2 Hyper-V: Insiders Guide to Microsoft's HypervisorFrom EverandWindows Server 2008 R2 Hyper-V: Insiders Guide to Microsoft's HypervisorNo ratings yet

- Honeywell Forge Apc Cpa PinDocument4 pagesHoneywell Forge Apc Cpa PinAdrianiNo ratings yet

- Modern Best Practices Internet of Things (Iot) and Adaptive Intelligence (Ai)Document8 pagesModern Best Practices Internet of Things (Iot) and Adaptive Intelligence (Ai)sanjeev19_ynrNo ratings yet

- FALCON For Manufacturing Brochure - Panasonic TV - Feb 2023 - Rev01Document5 pagesFALCON For Manufacturing Brochure - Panasonic TV - Feb 2023 - Rev01Baskaren RamachandranNo ratings yet

- Anin-Depthview: 1 Cleo - Cleo Harmony - An In-Depth ViewDocument8 pagesAnin-Depthview: 1 Cleo - Cleo Harmony - An In-Depth ViewSturm WolfeNo ratings yet

- Honeywell Forgefor Industrial PIN2019 MayDocument2 pagesHoneywell Forgefor Industrial PIN2019 MayAchraf ElectricNo ratings yet

- By Inlogic IT Solutions: PresentationDocument20 pagesBy Inlogic IT Solutions: PresentationNathaniel JoshuaNo ratings yet

- Cherwell One-Step™ Actions: Challenge: Manual, Inefficient Service Desk Tasks and WorkflowsDocument2 pagesCherwell One-Step™ Actions: Challenge: Manual, Inefficient Service Desk Tasks and WorkflowsGeorge AnadranistakisNo ratings yet

- Oracle Online Training Materials - Usage AgreementDocument19 pagesOracle Online Training Materials - Usage AgreementAnshuman Gahlot100% (1)

- Upgrade SiebelDocument84 pagesUpgrade Siebelkhalid BNo ratings yet

- Oracle Manufacturing Cloud - R13Document8 pagesOracle Manufacturing Cloud - R13thehaihnNo ratings yet

- ENOVIA Live Collaboration: in FormationDocument9 pagesENOVIA Live Collaboration: in FormationIlaiarajaNo ratings yet

- HP Openview Operations 7.5 For Windows Software: Data SheetDocument8 pagesHP Openview Operations 7.5 For Windows Software: Data Sheetlakbabi1035No ratings yet

- Asset Health Lifecycle Assessment PIN-September 2021Document2 pagesAsset Health Lifecycle Assessment PIN-September 2021Tien Nguyen TatNo ratings yet

- Cisco Collaboration RoadmapDocument115 pagesCisco Collaboration RoadmapZACK100% (1)

- Client Automation PortifólioDocument8 pagesClient Automation PortifóliobolinavazNo ratings yet

- Operational AssuranceDocument36 pagesOperational AssuranceTony FiniganNo ratings yet

- Pro-Watch 4.4 Data SheetDocument8 pagesPro-Watch 4.4 Data SheetTiago DutraNo ratings yet

- Information System For ManagersDocument12 pagesInformation System For ManagersTangerine Ila TomarNo ratings yet

- Delmia Apriso Process Builder DatasheetDocument2 pagesDelmia Apriso Process Builder Datasheetshubham.v.d.06No ratings yet

- CF-02 - InTouch Technology ModernizationDocument13 pagesCF-02 - InTouch Technology ModernizationGian Paolo Berardi GiampietroNo ratings yet

- Factorytalk® View Site Edition: Powerful, Scalable Visualization SolutionsDocument6 pagesFactorytalk® View Site Edition: Powerful, Scalable Visualization SolutionsJeremy AlfaroNo ratings yet

- Ebi R430Document42 pagesEbi R430Totto AlvesNo ratings yet

- ServiceNow + Microsoft Azure DevOps - Battle Card-FinalDocument2 pagesServiceNow + Microsoft Azure DevOps - Battle Card-FinalBayCreativeNo ratings yet

- Krishnan Ramanathan InternshipDocument14 pagesKrishnan Ramanathan InternshipAsish KumarNo ratings yet

- Ingles Phase Introduction v1.0Document16 pagesIngles Phase Introduction v1.0JAYANTA KUMAR BEHERANo ratings yet

- SCM - Product Management Cloud 21C Release OverviewDocument26 pagesSCM - Product Management Cloud 21C Release OverviewdavidjqNo ratings yet

- FusionCube 1000 (Hypervisor) - DatasheetDocument4 pagesFusionCube 1000 (Hypervisor) - DatasheetCarlos LeonardoNo ratings yet

- Veeva Platform Datasheet EUDocument2 pagesVeeva Platform Datasheet EUgzapata31No ratings yet

- Reporting Analytics Adv Cloud 2763408Document4 pagesReporting Analytics Adv Cloud 2763408Marcos Torres M.No ratings yet

- Verifone Intellinac: Transaction Infrastructure Made Faster and SmarterDocument4 pagesVerifone Intellinac: Transaction Infrastructure Made Faster and SmarterJairo Cristopher Ramos HernándezNo ratings yet

- Introduction To DevOps Slides PDFDocument104 pagesIntroduction To DevOps Slides PDFTanushriNo ratings yet

- ERP SidDocument25 pagesERP Sidsiddharth devnaniNo ratings yet

- Simplify Producer Life Cycle Management: Key FeaturesDocument4 pagesSimplify Producer Life Cycle Management: Key FeaturesSusantKumarNo ratings yet

- Why Scale AgileDocument11 pagesWhy Scale AgileSreeanand ChandranNo ratings yet

- Acumatica Manufacturing Evaluation Checklist 2Document8 pagesAcumatica Manufacturing Evaluation Checklist 2Hantech SystemsNo ratings yet

- Brochure Reqlogic LetterDocument8 pagesBrochure Reqlogic LetterJavier Mauricio VeraNo ratings yet

- Visualspc: Complete Shop Floor Quality Data Collection & Analysis SolutionDocument8 pagesVisualspc: Complete Shop Floor Quality Data Collection & Analysis SolutionDiego PovedaNo ratings yet

- DS Why Migrate To Automic ENDocument2 pagesDS Why Migrate To Automic ENPAVANN TNo ratings yet

- Pravinkumar M Desai: Represented As Volunteer in State Level Seminar Organized by CollegeDocument4 pagesPravinkumar M Desai: Represented As Volunteer in State Level Seminar Organized by CollegeGuruRakshithNo ratings yet

- Low-Code Application Development PlatformDocument2 pagesLow-Code Application Development PlatformKiranNo ratings yet

- Focusframe Feb21Document9 pagesFocusframe Feb21smartvananNo ratings yet

- Hc900 Controller BrochureDocument8 pagesHc900 Controller Brochurethanh_cdt01No ratings yet

- FusionHCM Day 1Document44 pagesFusionHCM Day 1Mohamed Shanab0% (1)

- Siemens SW-Siemens-Opcenter-Execution-Semiconductor-2210-Fact Sheet (1) - tcm27-109029Document4 pagesSiemens SW-Siemens-Opcenter-Execution-Semiconductor-2210-Fact Sheet (1) - tcm27-109029adarsh rajNo ratings yet

- Pro-Watch - 4.2 - DS - APAC-Rev.01Document8 pagesPro-Watch - 4.2 - DS - APAC-Rev.01Sarah BerlianiNo ratings yet

- Brochure Remote Migration ServicesDocument4 pagesBrochure Remote Migration ServicesNawel RahaliNo ratings yet

- Branch Office Desktops With LAN Convenience: Key BenefitsDocument2 pagesBranch Office Desktops With LAN Convenience: Key BenefitsOscarNo ratings yet

- Ooyala Flex Fact Sheet (July 2016)Document3 pagesOoyala Flex Fact Sheet (July 2016)RobertNo ratings yet

- Control of Work Work Permitting MobileDocument2 pagesControl of Work Work Permitting MobileukrtiNo ratings yet

- Guidewire Upgrade FactoryDocument12 pagesGuidewire Upgrade FactoryVenkatesh Venky DabbaraNo ratings yet

- ResumeDocument6 pagesResumenarasimha1005100% (3)

- G-Cloud 12: Wave Service DefinitionDocument4 pagesG-Cloud 12: Wave Service DefinitionlrNo ratings yet

- ENOVIA V6 Product PortfolioDocument24 pagesENOVIA V6 Product Portfoliosrvsd3sNo ratings yet

- Oracle NetSuite PresentationDocument9 pagesOracle NetSuite PresentationlisaNo ratings yet

- 770 Core PlatformDocument12 pages770 Core Platformandini eldanantyNo ratings yet

- Group Ii - December 2021Document71 pagesGroup Ii - December 2021ANISH KAFLENo ratings yet

- HPE OneView 5.0Document19 pagesHPE OneView 5.0Saqib AzizNo ratings yet

- HPE OneView 5.0 - The Foundation of Software-Defined Infrastructure - Golden Customer Pitch PDFDocument19 pagesHPE OneView 5.0 - The Foundation of Software-Defined Infrastructure - Golden Customer Pitch PDFLe Quang ThinhNo ratings yet

- PDC-CP24-2Document3 pagesPDC-CP24-2amarnath98252No ratings yet

- Acil Wiring Repeater1Document1 pageAcil Wiring Repeater1amarnath98252No ratings yet

- IO - Busses PDFDocument6 pagesIO - Busses PDFamarnath98252No ratings yet

- PDC IosetDocument3 pagesPDC Iosetamarnath98252No ratings yet

- Raid 5 TestDocument24 pagesRaid 5 Testamarnath98252No ratings yet

- Activities For First Term STD... IIIDocument6 pagesActivities For First Term STD... IIIamarnath98252No ratings yet

- Procedure SAVING LOG FILEDocument5 pagesProcedure SAVING LOG FILEamarnath98252No ratings yet

- Ob70 Red Io FLT1 PDFDocument2 pagesOb70 Red Io FLT1 PDFamarnath98252No ratings yet

- ANY-JB For LISTDocument24 pagesANY-JB For LISTamarnath98252No ratings yet

- NPS LeafletDocument2 pagesNPS LeafletMOHIT GUPTA jiNo ratings yet

- Block and Bleed - DWG and DatasheetDocument3 pagesBlock and Bleed - DWG and Datasheetamarnath98252No ratings yet

- My Valve BooksDocument4 pagesMy Valve Booksamarnath98252No ratings yet

- Balston Sample Filter Functions and Appl RecommendationsDocument6 pagesBalston Sample Filter Functions and Appl Recommendationsamarnath98252No ratings yet

- Advertisement For Fresh Graduates Second PDFDocument4 pagesAdvertisement For Fresh Graduates Second PDFamarnath98252No ratings yet

- OB81 Ps - FLT PDFDocument5 pagesOB81 Ps - FLT PDFamarnath98252100% (1)

- OB81 Ps - FLT PDFDocument5 pagesOB81 Ps - FLT PDFamarnath98252100% (1)

- For 3rd Quarter Oct 2019 To Dec 2019: Material Issued Under Asset Code 500000500 - CO2 Load Unload Scheme - TDI II DahejDocument2 pagesFor 3rd Quarter Oct 2019 To Dec 2019: Material Issued Under Asset Code 500000500 - CO2 Load Unload Scheme - TDI II Dahejamarnath98252No ratings yet

- en The Radar Sensor For Liquids VEGAPULS 64Document18 pagesen The Radar Sensor For Liquids VEGAPULS 64amarnath98252No ratings yet

- d2h Recommended PacksDocument20 pagesd2h Recommended Packsamarnath98252No ratings yet

- CV CALCULATION SHEET - 5 NovDocument10 pagesCV CALCULATION SHEET - 5 Novamarnath98252No ratings yet

- Control Valve SizingDocument21 pagesControl Valve Sizingamarnath982520% (1)

- Virtual Private Network: InternetDocument9 pagesVirtual Private Network: InternetNguyễn Phạm HoàngNo ratings yet

- SaxoTraderPRO IntroGuide GlobalDocument42 pagesSaxoTraderPRO IntroGuide GlobalParesh RamanlalNo ratings yet

- ERP All (Edited)Document41 pagesERP All (Edited)downloaddulieu100% (2)

- CIS775: Computer Architecture: Chapter 1: Fundamentals of Computer DesignDocument43 pagesCIS775: Computer Architecture: Chapter 1: Fundamentals of Computer DesignSwapnil Sunil ShendageNo ratings yet

- Machine Learning Models For Salary Prediction Dataset Using PythonDocument5 pagesMachine Learning Models For Salary Prediction Dataset Using PythonInés Margarita BravoNo ratings yet

- Acronis True Image - Create Boot CD Review and Tutorial PDFDocument5 pagesAcronis True Image - Create Boot CD Review and Tutorial PDFBetovhen Humberto SanzNo ratings yet

- Sample Practical File XI CSDocument5 pagesSample Practical File XI CSSahil JethwaniNo ratings yet

- MOTOTRBO™ XiR M8600i SERIES DIGITAL TWO-WAY RADIOSDocument4 pagesMOTOTRBO™ XiR M8600i SERIES DIGITAL TWO-WAY RADIOSHerman GunawanNo ratings yet

- Manual de Usuario Cobra 19 DX IV (11 Páginas)Document2 pagesManual de Usuario Cobra 19 DX IV (11 Páginas)hasiu.consultores.scNo ratings yet

- Installation of RSCADDocument11 pagesInstallation of RSCADNitin Upadhyay0% (1)

- Product Information DIGSI5 V06.20Document48 pagesProduct Information DIGSI5 V06.20feromagnetizamNo ratings yet

- ARM Notes From NPTELDocument3 pagesARM Notes From NPTELAnonymous pcNdMpNE100% (1)

- Cloud HypothesisDocument17 pagesCloud HypothesisrahulbwNo ratings yet

- Manual PiCar B V1.1 PDFDocument81 pagesManual PiCar B V1.1 PDFSubraman Krishna kanth MunukutlaNo ratings yet

- #04 WINDOWS - How To Install Procreate Lettering Composition Design KitDocument6 pages#04 WINDOWS - How To Install Procreate Lettering Composition Design KitbabytairNo ratings yet

- What Is Sap LSMWDocument13 pagesWhat Is Sap LSMWVinay PavanNo ratings yet

- Embedded Systems Assignment 3Document6 pagesEmbedded Systems Assignment 3ramrevolt55No ratings yet

- zVSE Release and Hardware UpgradeDocument55 pageszVSE Release and Hardware UpgradeRa SkynthNo ratings yet

- Issue-Log MyISCO MCash E-WalletDocument1 pageIssue-Log MyISCO MCash E-WalletJunaidi NordinNo ratings yet

- CORView Lite User Guide - 1506672UDocument129 pagesCORView Lite User Guide - 1506672UFrancisco RodríguezNo ratings yet

- Question Paper 8051 Microcontroller and ApplicationsDocument1 pageQuestion Paper 8051 Microcontroller and Applicationsveeramaniks408No ratings yet

- Call Transaction 2. Session Method 3. Direct Input MethodDocument9 pagesCall Transaction 2. Session Method 3. Direct Input MethodChris BaileyNo ratings yet

- Modern JavaScript Learning Path 2020Document1 pageModern JavaScript Learning Path 2020Java ManNo ratings yet

- Make HQ ComboDocument10 pagesMake HQ Combokalisi balkisiNo ratings yet

- Power Distribution System Load Flow Usin PDFDocument6 pagesPower Distribution System Load Flow Usin PDFbertovalenNo ratings yet

- Agreement ProtocolsDocument17 pagesAgreement ProtocolsYash AgrawalNo ratings yet

- Google: Designs, Lessons and Advice From Building Large Distributed SystemsDocument73 pagesGoogle: Designs, Lessons and Advice From Building Large Distributed SystemsOleksiy Kovyrin100% (3)

- Read Before Install!Document1 pageRead Before Install!cosmosSCRIBNo ratings yet

- KnimeDocument2 pagesKnimeabNo ratings yet

- FDocument111 pagesFnelsonshima7No ratings yet