Professional Documents

Culture Documents

Abm R 2LB100 en

Uploaded by

Анатолий РябухаOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Abm R 2LB100 en

Uploaded by

Анатолий РябухаCopyright:

Available Formats

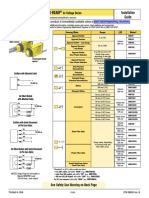

REQUIRED FREE DISTANCE BELOW WORKING LEVEL FOR WORKER PROTECTED WITH ENERGY ABSORBER WITH LANYARD

! free distance below working surface must be 6,2 m (see drawing no.1)

! drawings no.2 and no. 3 show free distance below working surface depending on location of Structural Anchor Point. Instruction Manual

Structural Anchor Point Read carefully ENERGY ABSORBER

1 2 3 min. 10 kN the manual

with double lanyard

before use

~1,5 m

Structural Anchor Point

min. 10 kN

the equipment EN 355:2002 Ref. BW200-R-2LB100 ABM-R-2LB100

EC type examination carried out by CETE APAVE SUDEUROPE, BP 193, 13322 Marseille, France - 0082

0,5 m - free fall

The energy absorber with lanyard is a component of personal fall arrest equipment and complies with EN355.

~1,5 m

~1,5 m

1,2 m - ultimate

Structural Anchor Point 2 m - free fall

elongation Fall arrest system consisted of energy absorber with lanyard, attached to the full body harness (complied with EN 361) and connected

min. 10 kN of the energy to the structural anchor point (complied with EN 795) can be used as a basic personal protective equipment against falls from a height.

absorber

3,5 m - free fall

0,2 m - displacement

Caution: The total length of the energy absorber with lanyard including terminations and connectors shall not exceed 2 m.

1,2 m - ultimate of the back attaching buckle (e.g. connector plus lanyard plus energy absorber plus connector)

elongation

of the energy

absorber CONSTRUCTION

0,2 m - displacement

1,8 m - man height Energy absorber with double lanyard ABM-R-2LB100 consists of energy absorber integrated with 2 adjustable lanyards. The lanyards

of the back attaching buckle

~3,2 m

1,2 m - ultimate are connected to the energy absorber by steel conneting ring. Energy absorber is made of 32 mm wide polyamide webbing.tThe body

elongation

of the absorber is protected by a special jacket made of a shrinkable, polyethylene tube. The lanyards are be made of ø12 mm

~4,7 m

of the energy

absorber

1,8 m - man height polyamide kernmantle rope. The lanyard is equipped with steel adjustment buckle.

~6,2 m

0,2 m - displacement

of the back attaching buckle +1 m - security

1. absorber's attachment loop

1,8 m - man height

2. energy absorber

+1 m - security

3. lanyard 1 9 3 4

4. lanyard's attachment loop

5. thimble

6. lanyard's seam

+1 m - security

7. adjustment buckle 2 8 6 7 6 5

IT IS THE RESPONSIBILITY OF THE USER ORGANISATION TO PROVIDE THE IDENTITY CARD AND TO FILL IN THE DETAILS REQUIRED.

8. connecting ring

THE IDENTITY CARD SHOULD BE FILLED IN BEFORE THE FIRST USE BY A COMPETENT PERSON, RESPONSIBLE INTHE USER ORGANIZATION FOR PROTECTIVE EQUIPMENT.

ANY INFORMATION ABOUT THE EQUIPMENT LIKE PERIODIC INSPECTIONS, REPAIRS, REASONS OF EQUIPMENT'S WITHDRAWN FROM USE SHALL BE NOTED INTO THE IDENTITY CARD BY A COMPETENT PERSON. 9. identity label

THE IDENTITY CARD SHOULD BE STORAGED DURING A WHOLE PERIOD OF EQUIPMENT UTILIZATION.

DO NOT USE THE EQUIPMENT WITHOUT THE IDENTITY CARD.

ALL RECORDS IN THE IDENTITY CARD CAN BE FILLED IN ONLY BY A COMPETENT PERSON.

IDENTITY CARD ATTENTION! The energy absorbers can be equipped only with certified (according to EN362) connectors.

MODEL AND TYPE OF EQUIPMENT

ADMISSIBLE TIME OF USE

REF. NUMBER The energy absorber with lanyard can be used for 5 years, counting from the date of putting the device into operation.

After 5 years of use the energy absorber must be withdrawn from use and destroyed.

SERIAL NUMBER DATE OF MANUF. The energy absorber must be withdrawn from use immediately and destroyed when it have been used to arrest a fall.

Withdrawn from use can be carried out only by a competent person responsible in a company for a safety equipment.

USER NAME

DATE OF PUTTING CONTENT OF THE DEVICE IDENTITY LABEL

DATE OF PURCHASE INTO OPERATION

A ENERGY ABSORBER WITH DOUBLE LANYARD Date F

of manufacture: 03.2002

PERIODIC EXAMINATION AND REPAIR HISTORY

REASON FOR DEFECTS NOTED, NAME AND SIGNATURE PERIODIC

B

C

ABM-R-2LB100 H

DATE ENTRY PERIODIC EXAMINATION

OR REPAIR

REPAIRS CARRIED OUT

AND OTHER REVELANT INFORMATIONS

OF COMPETENT PERSON EXAMINATION

NEXT DUE DATE

Ref.: BW 200-R-2LB100 Serial I

D EN 355:2002 number: 0000001

G

1

E the maximum length of the energy absorber with lanyard can’t exceed 2 m

2 A. type of the device G. number of the manufacturing series

B. marking of the model of energy absorber H. caution: read the manual

3 C. reference number of the device

D. CE marking with identity number of the notified body

I. marking of the manufacturer or distributor

controlling manufacturing of the equipment

4 (the article 11)

E. European standards (number/year)

F. month/year of the device manufacture

PROTEKT, 93-403 LODZ, ul. Starorudzka 9, POLAND, TEL: (48 42) 680 20 83, FAX: (48 42) 680 20 93, www.protekt.com.pl

ASSEMBLING A FALL ARREST SYSTEM

! after every12 months of utilization, personal protective equipment must be withdrawn from use to carry out periodical detailed inspection. The periodic inspection must be

WARNING !

WITH THE LOCKING GEAR

NECESSARILY PROTECT

THE SNAP HOOK GATE

1. Attach the energy carried out by a competent person for periodic inspection. The periodic inspection can be carried out also by the manufacturer or his authorized representative.

FORBIDDEN!

absorber's connector to a

In case of some types of the complex equipment e.g. some types of retractable fall arresters the annual inspection can be carried out only by the manufacturer or his

frontal or dorsal

attachment point of full

authorized representative.

body harness (conformed ! regular periodic inspections are the essential for equipment maintenance and the safety of the users which depends upon the continued efficiency and durability of the

to EN 361) - [1] equipment.

2. Connect the lanyard's

! during periodic inspection it is necessary to check the legibility of the equipment marking.

connector to the ! it is essential for the safety of the user that if the product is re-sold outside the original country of destination the reseller shall provide instructions for use, for

structural anchor point of maintenance, for periodic examination and for repair in language of the country in which the product is to be used.

resistance min. 10 kN ! personal protective equipment must be withdrawn from use immediately when any doubt arise about its condition for safe use and not used again until confirmed in

(conformed to EN 795) writing by equipment manufacturer or his representative after carried out the detailed inspection.

placed above the user: ! personal protective equipment must be withdrawn from use immediately and destroyed when it have been used to arrest a fall.

!- directly [2] ! a full body harness is the only acceptable body holding device that can be used, in a fall arrest system.

!- with a additional ! in full body harness use only attaching points marked with big letter "A" to attach a fall arrest system. Marking like "A/2'" or a half of "A" means the necessity of

connector [3], [4] 1 attaching a fall arrest system to both attaching points together simultaneously. It is strictly forbidden to attach a fall arrest system to the single attaching point marked

"A/2'" or a half of "A". See drawings below:

The shape of the structural A

HARNESS ATTACHING POINT HARNESS ATTACHING HALF POINTS

anchor point shall not let self-

FALL ARREST SYSTEM A

acting disconection of the FALL ARREST SYSTEM

device.

WARNING:

During use the energy

absorber with double lanyard

ABM-R-2LB100, it is strictly FORBIDDEN!

forbidden to attach the one

lanyard's connector to

harness attachment element

and the second lanyard's

connector to structural anchor

point [5].

2 3 4 5

! the anchor device or anchor point for the fall arrest system should always be positioned, and the work carried out in such a way, as to minimise both the potential for falls

and potential fall distance. The anchor device/point should be placed above the position of the user . The shape and construction of the anchor device/point shall not

allowed to self-acting disconnection of the equipment. Minimal static strength of the anchor device/point is 10 kN. It is recommended to use certified and marked

structural anchor point complied with EN795.

! it is obligatory to verify the free space required beneath the user at the workplace before each occasion of use the fall arrest system, so that, in the case of a fall, there

will be no collision with the ground or other obstacle in the fall path. The required value of the free space should be taken from instruction manual of used equipment.

! there are many hazards that may affect the performance of the equipment and corresponding safety precautions that have to be observed during equipment utilization,

THE ESSENTIAL PRINCIPLES FOR USERS OF PERSONAL PROTECTIVE EQUIPMENT AGAINST FALLS FROM A HEIGHT especially:

- trailing or looping of lanyards or lifelines over sharp edges,

! personal protective equipment shall only be used by a person trained and competent in its safe use. - any defects like cutting, abrasion, corrosion,

! personal protective equipment must not be used by a person with medical condition that could affect the safety of the equipment user in normal and emergency use. - climatic exposure,

! a rescue plan shall be in place to deal with any emergencies that could arise during the work. - pendulum falls,

! it is forbidden to make any alterations or additions to the equipment without the manufacturer's prior written consent. - extremes of temperature,

! any repair shall only be carried out by equipment manufacturer or his certified representative. - chemical reagents,

! personal protective equipment shall not be used outside its limitations, or for any purpose other than that for which it is intended. - electrical conductivity.

! personal protective equipment should be a personal issue item. ! personal protective equipment must be transported in the package (e.g.: bag made of moisture-proof textile or foil bag or cases made of steel or plastic) to protect it

! before use ensure about the compatibility of items of equipment assembled into a fall arrest system. Periodically check connecting and adjusting of the equipment against damage or moisture.

components to avoid accidental loosening or disconnecting of the components. ! the equipment can be cleaned without causing adverse effect on the materials in the manufacture of the equipment. For textile products use mild detergents for delicate

! it is forbidden to use combinations of items of equipment in which the safe function of any one item is affected by or interferes with the safe function of another. fabrics, wash by hand or in a machine and rinse in water. Plastic parts can be cleaned only with water. When the equipment becomes wet, either from being in use or

! before each use of personal protective equipment it is obligatory to carry out a pre-use check of the equipment, to ensure that it is in a serviceable condition and operates when due cleaning, it shall be allowed to dry naturally, and shall be kept away from direct heat. In metallic products some mechanic parts (spring, pin, hinge, etc.) can be

correctly before it is used. regularly slightly lubricated to ensure better operation.

! during pre-use check it is necessary to inspect all elements of the equipment in respect of any damages, excessive wear, corrosion, abrasion, cutting or incorrect acting, Other maintenance and cleaning procedures should be adhered to detailed instructions stated in the manual of the equipment.

especially take into consideration: ! personal protective equipment should be stored loosely packed, in a well-ventilated place, protected from direct light, ultraviolet degradation, damp environment, sharp

- in full body harnesses and belts - buckles, adjusting elements, attaching points, webbings, seams, loops; edges, extreme temperatures and corrosive or aggressive substances.

- in energy absorbers - attaching loops, webbing, seams, casing, connectors; ! using the energy absorber in connection with fall arrest system must be compatible with use instructions of the fall arrest systems and obligatory standards:

- in textile lanyards or lifelines or guidelines - rope, loops, thimbles, connectors, adjusting element, splices; - EN361 - for the safety harness;

- in steel lanyards or lifelines or guidelines - cable, wires, clips, ferrules, loops, thimbles, connectors, adjusting elements; - EN353-1, EN353-2, EN354, EN362 - for the fall arrest systems;

- in retractable fall arresters - cable or webbing, retractor and brake proper acting, casing, energy absorber, connector; - EN 795 - for anchorages

- in guided type fall arresters - body of the fall arrester, sliding function, locking gear acting, rivets and screws, connector, energy absorber; - EN358 - for the work positioning systems.

- in connectors - main body, rivets, gate, locking gear acting.

You might also like

- Electromagnetic Clutches and Couplings: International Series of Monographs on Electronics and InstrumentationFrom EverandElectromagnetic Clutches and Couplings: International Series of Monographs on Electronics and InstrumentationRating: 4 out of 5 stars4/5 (1)

- Manual AbmDocument2 pagesManual AbmАнатолий РябухаNo ratings yet

- ABWTR BW701 enDocument2 pagesABWTR BW701 enАнатолий РябухаNo ratings yet

- E701 E2 01 X+E3Z+DatasheetDocument24 pagesE701 E2 01 X+E3Z+DatasheetAndrea SperottoNo ratings yet

- ABMTR enDocument2 pagesABMTR enАнатолий РябухаNo ratings yet

- Multi Field Tester Otdr: All-in-One Handheld Optical Fiber Network Test ToolDocument6 pagesMulti Field Tester Otdr: All-in-One Handheld Optical Fiber Network Test ToolFrancisco SeNo ratings yet

- WEG-CFW500-installation-guide-10007168908 DDDD-en-es-pt-zhDocument12 pagesWEG-CFW500-installation-guide-10007168908 DDDD-en-es-pt-zhHENRIQUENo ratings yet

- Built-In Power Supply Photoelectric SensorDocument16 pagesBuilt-In Power Supply Photoelectric SensorEdi PurwantoNo ratings yet

- Pen r2500ns Leaflet 21Document2 pagesPen r2500ns Leaflet 21Sathish YANo ratings yet

- NM230-F Form-Fit Damper Actuator 8 NMDocument4 pagesNM230-F Form-Fit Damper Actuator 8 NMNenad MutavdzicNo ratings yet

- Bms en Drw171450aa 20180115 He 20180201Document1 pageBms en Drw171450aa 20180115 He 20180201Дмитрий РешетниковNo ratings yet

- Series: Cylindrical Type Easily Mountable With M18 ThreadDocument12 pagesSeries: Cylindrical Type Easily Mountable With M18 ThreadANDRES FABIAN BONILLA FERNANDEZNo ratings yet

- AQ1200 13EN 010 Vietnamese-Full PDFDocument6 pagesAQ1200 13EN 010 Vietnamese-Full PDFPhương Nguyễn VănNo ratings yet

- A - en - c11 UNIVERDocument5 pagesA - en - c11 UNIVERMohammad Adeel KhanNo ratings yet

- Proximity Switch (FO Venting) 106406 - EngDocument4 pagesProximity Switch (FO Venting) 106406 - EngfarisazharuNo ratings yet

- Haefely LL Mafs 151127 SpecDocument2 pagesHaefely LL Mafs 151127 SpecL EnriquezNo ratings yet

- Innolume Gain Chip Spec SheetDocument4 pagesInnolume Gain Chip Spec SheetJosh AdamsNo ratings yet

- LR-W500 (C) : Instruction ManualDocument8 pagesLR-W500 (C) : Instruction ManualAlin PopNo ratings yet

- Alveogaz A - EngDocument1 pageAlveogaz A - EngFadi HNo ratings yet

- Rele AheDocument11 pagesRele AhePavel KrižnarNo ratings yet

- Eaton-Ceag-El-Cps-Data-Sheet-Guideled SL 13051.1, 13052.1 CG-S-GBDocument2 pagesEaton-Ceag-El-Cps-Data-Sheet-Guideled SL 13051.1, 13052.1 CG-S-GBtestonsanNo ratings yet

- Programador Miniflat FM-SMDocument6 pagesProgramador Miniflat FM-SMdbricchiNo ratings yet

- SBEM Top Mounted Displacement SwitchDocument4 pagesSBEM Top Mounted Displacement SwitchvaibhavnriitmNo ratings yet

- Unigear zs1 BrochureDocument12 pagesUnigear zs1 BrochuremringkelNo ratings yet

- Nivocont KRK-512-5Document2 pagesNivocont KRK-512-5Dragoslav DzolicNo ratings yet

- R200 Folder ENDocument2 pagesR200 Folder ENEmmanuel OsorioNo ratings yet

- TSM-4485 r05Document2 pagesTSM-4485 r05Aldo Germán Pavez MoraNo ratings yet

- Optical Strain Gage - Os3100: Key Features DescriptionDocument2 pagesOptical Strain Gage - Os3100: Key Features DescriptionYi-jen ChanNo ratings yet

- Part68 Catalog ELMARK 2015 WEBDocument1 pagePart68 Catalog ELMARK 2015 WEBDino BradaricNo ratings yet

- Abb R-Mag Breaker Brochure 1val255101-Db Rev JDocument16 pagesAbb R-Mag Breaker Brochure 1val255101-Db Rev Jeu_mesmo123No ratings yet

- Total Surveying Solution: LGP-300N Series Total StationsDocument2 pagesTotal Surveying Solution: LGP-300N Series Total StationsJuan LopezNo ratings yet

- Tpi 12 Tune-R - enDocument2 pagesTpi 12 Tune-R - enKundzoNo ratings yet

- Brahma FM11Document6 pagesBrahma FM11Zoran ConstantinescuNo ratings yet

- ABB - Filament Wound ComponentDocument4 pagesABB - Filament Wound ComponentAbu Haydar Amin MustanginNo ratings yet

- Series: High Performance in Micro-Size DesignDocument10 pagesSeries: High Performance in Micro-Size DesigndhzhnznNo ratings yet

- Gas Tube Surge Arrestor Type N Male Female, Bulkhead: Product Data Sheet N-UC230-01Document2 pagesGas Tube Surge Arrestor Type N Male Female, Bulkhead: Product Data Sheet N-UC230-01João Carlos OliveiraNo ratings yet

- Marine Wideband Antenna MONO-A0032 Version 2.4Document2 pagesMarine Wideband Antenna MONO-A0032 Version 2.4Marco PoloNo ratings yet

- CXL 70-3LW HDocument3 pagesCXL 70-3LW HManuel EspnzaNo ratings yet

- Live Disconnection in Hazardous Areas: Technical Datasheet Technical DatasheetDocument4 pagesLive Disconnection in Hazardous Areas: Technical Datasheet Technical DatasheetRig 25 Sr. ElectricianNo ratings yet

- CXL 70-3LW H PDFDocument3 pagesCXL 70-3LW H PDFManuel EspnzaNo ratings yet

- EU DOC - LYND1901 - Lanyard - Rev1Document3 pagesEU DOC - LYND1901 - Lanyard - Rev1Frans HermantoNo ratings yet

- LK Linear-Couplings PDFDocument2 pagesLK Linear-Couplings PDFRuben Dario HerreraNo ratings yet

- Celula Carga HBMDocument12 pagesCelula Carga HBMTupa Ortiz EnriqueNo ratings yet

- Technical Sheet Operating Method: Wire Holding Pole (Stick)Document2 pagesTechnical Sheet Operating Method: Wire Holding Pole (Stick)Smk Bunda KandungNo ratings yet

- Banner Tach Technical SheetDocument4 pagesBanner Tach Technical SheetMILTON CÉSAR AGUILAR DE AZAMBUJANo ratings yet

- BJ SerieDocument7 pagesBJ SerieDương ThânNo ratings yet

- Huchez Winch 10 TonsDocument6 pagesHuchez Winch 10 TonsPhong DuongNo ratings yet

- N5900B 2 ManualDocument12 pagesN5900B 2 ManualYadgar ZanganaNo ratings yet

- Model LJM-D: Order GuideDocument5 pagesModel LJM-D: Order GuidetadiganeshNo ratings yet

- 191201-302 - Inspection and Testing Plan StrandDocument6 pages191201-302 - Inspection and Testing Plan Strandmonu yadavNo ratings yet

- PME Pneumatic cylinders-DATA SheetDocument2 pagesPME Pneumatic cylinders-DATA SheetGopal HegdeNo ratings yet

- BEN Series: Compact, Amplifier Built-In Type With Universal VoltageDocument7 pagesBEN Series: Compact, Amplifier Built-In Type With Universal VoltageCesarLavadoNo ratings yet

- 035 - 25 - Technical Manual - Mechanical Groupsets Rear Derailleur - Campagnolo - REV00!07!13Document6 pages035 - 25 - Technical Manual - Mechanical Groupsets Rear Derailleur - Campagnolo - REV00!07!13asfilbike bicicletasNo ratings yet

- Director Halogen Series-Cranes-Remote HeadsDocument16 pagesDirector Halogen Series-Cranes-Remote HeadsViktorasNo ratings yet

- Comunello Automation Limit - 500 - 5m 00 Scheda - Tecnica (44384) PDFDocument2 pagesComunello Automation Limit - 500 - 5m 00 Scheda - Tecnica (44384) PDFnasser22No ratings yet

- Power Supply Systems Spds Type 2: Dehnguard® Modular DG M TT 275 FMDocument2 pagesPower Supply Systems Spds Type 2: Dehnguard® Modular DG M TT 275 FMMohammad NasarNo ratings yet

- TS2 60 4 Axis Product Data Sheet enDocument3 pagesTS2 60 4 Axis Product Data Sheet enCHAMOUXNo ratings yet

- Wideband HF Monopole: 1 - 30 MHZ Product Code: Mono-A0025Document3 pagesWideband HF Monopole: 1 - 30 MHZ Product Code: Mono-A0025Marco PoloNo ratings yet

- Camus 2Document1 pageCamus 2shuckss taloNo ratings yet

- Diaphragm Vacuum Pumps For Autoclaves: Concept Areas of Use FeaturesDocument5 pagesDiaphragm Vacuum Pumps For Autoclaves: Concept Areas of Use Featuresnotaden1849No ratings yet

- MD0311 Ric MAXISTAB 2020Document84 pagesMD0311 Ric MAXISTAB 2020Анатолий РябухаNo ratings yet

- Lincoln Walker 93601 K, 93602 K, 93603 B Parts ListDocument4 pagesLincoln Walker 93601 K, 93602 K, 93603 B Parts ListАнатолий РябухаNo ratings yet

- Spare Parts Catalogue Manuals806n FM Spare Parts Manualpdf Spare Parts CatalogueDocument74 pagesSpare Parts Catalogue Manuals806n FM Spare Parts Manualpdf Spare Parts CatalogueАнатолий РябухаNo ratings yet

- Use and Maintenance Manual EFFER 1405 Part 1Document169 pagesUse and Maintenance Manual EFFER 1405 Part 1Анатолий РябухаNo ratings yet

- Hydraulic TanksDocument22 pagesHydraulic TanksАнатолий РябухаNo ratings yet

- Ab0321 - 16092-01 - E01-01 Fa2050202, Fa2050302, Fa2050301Document2 pagesAb0321 - 16092-01 - E01-01 Fa2050202, Fa2050302, Fa2050301Анатолий РябухаNo ratings yet

- A V Climtec Englisch 04-16Document20 pagesA V Climtec Englisch 04-16Анатолий РябухаNo ratings yet

- Tu701 enDocument2 pagesTu701 enАнатолий РябухаNo ratings yet

- Lincoln Walker J-953 Series P Parts ListDocument3 pagesLincoln Walker J-953 Series P Parts ListАнатолий РябухаNo ratings yet

- Certificate Number: 2777/10834-01/E01-01: Product Reference DescriptionDocument2 pagesCertificate Number: 2777/10834-01/E01-01: Product Reference DescriptionАнатолий РябухаNo ratings yet

- Webbing End InstructionsDocument2 pagesWebbing End InstructionsАнатолий РябухаNo ratings yet

- Ab0321 - 16069-01 - E01-01 Fa10101xx Fa10201xx Fa10202xxDocument2 pagesAb0321 - 16069-01 - E01-01 Fa10101xx Fa10201xx Fa10202xxАнатолий РябухаNo ratings yet

- Fa1020201 DC 5Document2 pagesFa1020201 DC 5Анатолий РябухаNo ratings yet

- KRATOS SAFETY Harnesses With W.P. Belt UIM (BKLKT53-13) - UKCA - EN358Document56 pagesKRATOS SAFETY Harnesses With W.P. Belt UIM (BKLKT53-13) - UKCA - EN358Анатолий РябухаNo ratings yet

- 2777 - 10349-04 - E04-01 Fa10101xx Fa10201xx Fa10202xxDocument2 pages2777 - 10349-04 - E04-01 Fa10101xx Fa10201xx Fa10202xxАнатолий РябухаNo ratings yet

- Tu430 Tu431 enDocument2 pagesTu430 Tu431 enАнатолий РябухаNo ratings yet

- FT Fa 40 903 XX Ce&ukcaDocument2 pagesFT Fa 40 903 XX Ce&ukcaАнатолий РябухаNo ratings yet

- WR020 enDocument2 pagesWR020 enАнатолий РябухаNo ratings yet

- AC012 EngDocument4 pagesAC012 EngАнатолий РябухаNo ratings yet

- WR020 enDocument2 pagesWR020 enАнатолий РябухаNo ratings yet

- MB14T Spare Parts ManualDocument24 pagesMB14T Spare Parts ManualАнатолий РябухаNo ratings yet

- MTX Composite Solid Outrigger Pads - MatraxDocument1 pageMTX Composite Solid Outrigger Pads - MatraxАнатолий РябухаNo ratings yet

- WT101 enDocument7 pagesWT101 enАнатолий РябухаNo ratings yet

- Af500 enDocument2 pagesAf500 enАнатолий РябухаNo ratings yet

- D SERIES CYLINDER OUTER COVERHiResenDocument8 pagesD SERIES CYLINDER OUTER COVERHiResenАнатолий РябухаNo ratings yet

- Edbro Information Bulletin Trunnion Greasing Oct 2017Document6 pagesEdbro Information Bulletin Trunnion Greasing Oct 2017Анатолий РябухаNo ratings yet

- Datasheet R930001664Document2 pagesDatasheet R930001664Анатолий РябухаNo ratings yet

- ECAN-U01S-UserManual EN V1.0Document17 pagesECAN-U01S-UserManual EN V1.0Edson KitaniNo ratings yet

- 722 800 PDFDocument4 pages722 800 PDFMAQUISAN0% (1)

- Ah Hydraulic Setting ToolDocument12 pagesAh Hydraulic Setting ToolCarlos HolguinNo ratings yet

- Heatsink: HSF Models 1000-1600 SCFMDocument34 pagesHeatsink: HSF Models 1000-1600 SCFMpedroNo ratings yet

- GC20P-5 Sb1096e14Document622 pagesGC20P-5 Sb1096e14GORD100% (1)

- Truck-Mounted Concrete Pump BSF 20-4.09 HDocument2 pagesTruck-Mounted Concrete Pump BSF 20-4.09 HJeff Neurauter100% (1)

- MERCRUISER 3.0L ManualAlphaOneMaintenance - 86017211Document137 pagesMERCRUISER 3.0L ManualAlphaOneMaintenance - 86017211bartp313100% (3)

- Crystal Radio CircuitsDocument11 pagesCrystal Radio CircuitsSubimal BawaliNo ratings yet

- Grid Connected Inverter Reference Design: Design Guide: TIDM-HV-1PH-DCACDocument50 pagesGrid Connected Inverter Reference Design: Design Guide: TIDM-HV-1PH-DCACSyed ZurnainNo ratings yet

- Schindler 9700 Operation & Maintenance Manual 2012Document8 pagesSchindler 9700 Operation & Maintenance Manual 2012KonstarothNo ratings yet

- Wings Automobile ProductsDocument5 pagesWings Automobile ProductsRitz AmbyyNo ratings yet

- Saudi Aramco Pre-Commissioning Form: Uninterruptible Power Supply SystemDocument2 pagesSaudi Aramco Pre-Commissioning Form: Uninterruptible Power Supply SystemHaleem Ur Rashid BangashNo ratings yet

- P1Document13 pagesP1adaptive4u4527No ratings yet

- IC-201 Restoration DL7MAJ 2018Document9 pagesIC-201 Restoration DL7MAJ 2018A KNo ratings yet

- Vertiv HPL Lithium Ion Data Sheet SL 70383Document4 pagesVertiv HPL Lithium Ion Data Sheet SL 70383nazar firmanNo ratings yet

- Trouble Codes OBDIIDocument55 pagesTrouble Codes OBDIIdaniwesa100% (1)

- Philips SW3660 Service ID4069Document14 pagesPhilips SW3660 Service ID4069sony reseNo ratings yet

- 87ae786948d705a6047e1ca5caf6541b.xlsxDocument255 pages87ae786948d705a6047e1ca5caf6541b.xlsxshubhamjain1993No ratings yet

- LG Www. Radioradar - NetDocument11 pagesLG Www. Radioradar - Netnidzat0% (1)

- User Manual lpc11xx lpc11cxxDocument407 pagesUser Manual lpc11xx lpc11cxxChetan PatilNo ratings yet

- Specifications: Refrigerators and FreezersDocument2 pagesSpecifications: Refrigerators and Freezersdwinanto100% (1)

- Pilot CementDocument295 pagesPilot CementjagadeeshNo ratings yet

- MSI 6507 IntelDocument36 pagesMSI 6507 Intelwoyokus2565No ratings yet

- Uninterruptible Power Supply Systems: January 2010Document24 pagesUninterruptible Power Supply Systems: January 2010Mahmoud M.AbdelalimNo ratings yet

- Fuel Systems: Ftrp1 - Manual Fuel PumpDocument1 pageFuel Systems: Ftrp1 - Manual Fuel PumpAmjadNo ratings yet

- The New BMW R 1250 Gs and R 1250 RTDocument40 pagesThe New BMW R 1250 Gs and R 1250 RTPhan LamNo ratings yet

- Datasheet of DS WSPWI T 08 & DS WSPLI T 08 Workstation V1.0 20190507Document4 pagesDatasheet of DS WSPWI T 08 & DS WSPLI T 08 Workstation V1.0 20190507RajeevNo ratings yet

- 7XV75 Catalog SIP E6Document2 pages7XV75 Catalog SIP E6Van TienNo ratings yet

- Neo2000®gamma Detection Service Manual Models 2000 & 2100 SystemDocument44 pagesNeo2000®gamma Detection Service Manual Models 2000 & 2100 SystemDanieleNo ratings yet

- Jyoti PDFDocument14 pagesJyoti PDFAanandNo ratings yet