Professional Documents

Culture Documents

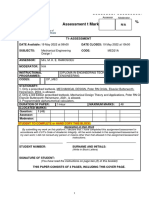

II Adv Prod Sys - Sy - 100511055449

Uploaded by

Atul PandeyOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

II Adv Prod Sys - Sy - 100511055449

Uploaded by

Atul PandeyCopyright:

Available Formats

MMCM 201 Supply Chain Management

Unit 1 INTRODUCTION: Logistics - Concepts, Definitions. approaches, factors affecting logistics. Supply chain - basic tasks of the supply chain - the new corporate model. Unit 2 SUPPLY CHAIN MANAGEMENT: The new paradigm, the modular company, the network relations. supply process, Procurement process - Distribution management. Unit 3 EVOLUTION OF SUPPLY CHAIN MODELSL: Strategy and structure - factors of supply chain - Manufacturing strategy stages, supply chain progress - model for competing through supply chain management - PLC grid, supply chain redesign Linking supply chain with customer. Unit 4 SUPPLY CHAIN ACTIVITY SYSTEMS: Structuring the SC, SC and new product, functional roles in SC, SC design frame-work, collaborative product commerce (CPC). Unit 5 SCM ORGANISATION AND INFORMATION SYSTEM: The management task, logistics organisation, the logistics information systems -Topology of SC application MRP, ERP, Warehouse management system, product data management - cases. Reference Books: 1. Scharj, P.B., Lasen, TS., Managing the global supply chain , Viva books, New Delhi 2. Ayers, J:B., "Hand book of supply chain management ", The St. Lencie press, 2000. 3. Nicolas, J:N., "Competitive manufacturing management-continuous improvement ", Lean production, customer focused quality, McGraw-Hill, NY; 1998. 4. Steudel, 1lJ: and Desruelle, P., "Manufacturing in the ninetees-How to become a mean, lean and world class competitor ", Van Nostrand Reinhold; NY, 1992.

MMCM 202 FMS and FEA

Unit-I: CM System Concurent engineering and design methodology, collaborative product development, Product data management for manufacturing and design data reuse product life cycle management, arid collaborative product, commerce, Advance manufacturing, Cellular, Synchronous Agile, Lear, Manufacturing system, concept of rapid prototyping, reverse engineering, re-engineering, case studies. Unit-2: FMS Definition of FMS, types and configuration, concept, types of flexibility and performance measures, Function ofFMS host computer, FMS host and area controller, function distribution. Development and implementation: Planning phase integration, system configuration, FMS layouts, simulation, FMS project development steps. Unit 3: Basics of FEM - Initial value and boundary value problems - weighted residual, Galerkin and Raleigh Ritz methods - Review of Variational calculus -Integration by parts - Basics of Variational formulation. Unit4: Steps In FEA - Descretization, interpolation, derivation of element characteristic matrix function, assembly and imposition of boundary conditions - Solution and post processing, One-dimensional analysis in solid mechanics and heat transfer. Unit 5: Global and Natural co-ordinates - Shape functions for one and two dimensional elements Three nodded triangular and four noded quadrilateral element - non linear analysis Isoparametric elements - Jacobian matrices and transformations - Basics of two dimensional axi symmetric analysis. Unit 6: FE analysis of metal casting - Special considerations, latent heat incorporation. gap element - Time stepping procedures - crank - Nicholson ,algorithm - Prediction of grain structure Basic concepts of plasticity - Solid and flow formulation - Small incremental deformation formulation - FE analysis of metal cutting. chip separation criteria, incorporation of strain rate dependency Reference Books: 1. Vajpayee, Principles of CIM, PHI 2. Seshu, Text book of Finite Element Analysis, PHI

MMCM 203 Operation Management

Unit 1 Operations Management: Introduction, Systems concept, Decisions, Organization, Objectives and Evolution of Operations Management, comparing production of tangible goods and services, Operations Strategy, Type of Production Systems, Role of Production Manager. Unit 2 Facilities Planning & Production Planning Control: Plant location, Plant layout and Material Handling, Layout analysis, Procedures such as CORELAP, CRAFT etc. Organization & Functions of PPC CAPP, Make or Buy Decision, Forecasting Methods & its relationship with Product Life Cycle, Case Studies. Unit 3 Aggregate Planning and Master Scheduling: Strategies of Aggregate Planning, Graphic & and Charting methods, Application of LP, Master Scheduling, Job Shop Scheduling and Sequencing Algorithms Gantt Chart, Line Balancing, LOB, Case Studies. Unit 4 Maintenance Management: Types of maintenance strategies, Breakdown, Preventive and Predictive maintenance, Individual and Group Replacement Policies, Case Studies. Unit 5 Materials Management as part of supply chain, Purchasing, stores and vendor selection, Inventory Models, Selective Inventory Control, MRP, MRP-II, Lot size Techniques, Just - In - Time system of manufacturing, Kaizen, Total Productive Maintenance (TPM), BPR, SCM, ERP etc.& Case Studies. References: 1. Hop W, Spearman M; Factory Physics; TMH 2. Charry S.N.; Production & Operations Management; TMH. 3. Chase, Acquilino, Production & Operations Managment, TMH. 4. Eilon S. Production Planning and Control, McMillon Pub. 5. Vollmann; Mfg planning and control for SCM; TMH 6. Nahmias Steven; Production and Operations analysis; TMH 7. Bedi Kaniska; Production and Operations Management; Oxford Pub 8. Dobler & Lee, Purchasing & Materials Management, PHI. 9. Chitle A.K., Gupta R.C. Materials Management, PHI. 10. Monk Joseph; Schaums outline of Operations Management; McGraw Hill.

MMCM 204 Robotics and Automated material Handling

1. INTRODUCTION: Basic concepts - Robot anatomy - Robot configurations - Basic robot motions - Types of drives - Applications - Material handling - processing Assembly and Inspection - safety considerations. 2. TRANSFORMATIONS AND KINEMATICS: Vector operations Translational transformations and Rotational transformations - Properties of transformation matricesHomogeneous transformations and Manipulator - Forward solution - Inverse solution. 3. CONTROLS AND END EFFECTORS: Control system concepts - Analysis - control of joints - Adaptive and optimal control - End effectors - Classification - Mechanical Magnetic -Vacuum - Adhesive - Drive systems - Force analysis and Gripper design. 4. ROBOT PROGRAMMING: Methods - Languages -Computer control and Robot Software -V AL system and Language. . 5. SENSORY DEVICES: Non optical and optical position sensors - Velocity and Acceleration -Range - Proximity - touch - Slip - Force - Torque - Machine vision - Image components -Representation - Hardware - Picture coding - Object recognition and categorization Software consideration. 6. Automated Material Handling and Storage: Functions types and analysis of material handling equipment, Design of conveyor and AGV system, Storage system performance, AS/RS, Carovsel storage system, WIP storage system, Interfacing handling, Storage with manufacturing Reference Books: 1. Fu KS., GonzalezR.C.., and Lee C.S.G., "Robotics control, sensing, vision, and intelligence McGraw-Hill Book Co., 1987. 2. Klafter R.D., Chmielewski TA. and Negm IV. .. Rohot Engineering An Intergrated approach Prentice Hall of India, New Delhi, 1994 3. Deb S.R., " Robotics Technology and Fle.rihle Auto"w(i('fl ", Tata McGraw-Hill Publishing Co., Ltd.. 1994. 4. Craig J..J. " 1ntroduction to Robotic.s Mechanics and Control ". Addison-Wesley, 1999. 5. Groover MP.. "/ndu.slriul roholic.s Technol()g}'. programming and applicution. McGraw-Hill Book Co., /995.

MMCM 205 Reliability and total productive maintenance

Unit 1 INTRODUCTION: Reliability function - MTBF - MTTF - mortality curve availability - Maintainability. Unit 2 FAILURE DATA ANALYSIS: Repair time distributions - exponential, normal, log normal. gamma, and Weibull- reliability data requirements - Graphical evaluation. Unit 3 RELIABILITY PREDICTION: Failure rate estimates - Effect of environrl:1ent and stress - Series and Parallel systems - RDB analysis - Standby Systems - Complex Systems. Unit 4 RELIABILITY MANAGEMENT: Reliability demonstration testing - Reliability growth testing - Duane curve -Risk assessment - FMEA, Fault tree. Unit 5 TOTAL PRODUCTIVE MAINTENANCE: Causes of Machine Fialures - Downtime -Maintenance policies - Restorability predictions - Replacement models - Spares provisioning - Maintenance management - Cleanliness and House Keeping. Reference Books: 1. Paul Kales, Reliability for technology, "En.",ineerin't'!; and Mana't'!;emefif ", Prentice Hall, New Jersey, 1998. 2. Modarres, "Reliability and Risk Analysis ", MeralDekkerlnc., 1993. 3. Gopalakrishnan.P, and Banerji A.K., " Maintenance and ,<;'pare Parts Management ", Prentice Hall of India, New Delhi, 1996.

You might also like

- Jack Frost PDF v2Document94 pagesJack Frost PDF v2Erick Adams100% (4)

- Medical Ethics in Clinical PracticeDocument216 pagesMedical Ethics in Clinical PracticeSonali MishraNo ratings yet

- Natural Blends Inc 1Document2 pagesNatural Blends Inc 1Álvaro Jurado0% (1)

- Activity 11.2 Observing Technology Integration in The Classroom InstructionsDocument5 pagesActivity 11.2 Observing Technology Integration in The Classroom InstructionsBon Ivan Firmeza0% (1)

- S8 Industrial Syllabus (2007-2011 Batch)Document5 pagesS8 Industrial Syllabus (2007-2011 Batch)PraveenCETNo ratings yet

- 8th Sem MechanicalDocument1 page8th Sem Mechanicalprince100% (1)

- Department Elective-Iii: Nme-031: Computer Aided Manufacturing (Cam) L T P 3 1 0 Unit-IDocument20 pagesDepartment Elective-Iii: Nme-031: Computer Aided Manufacturing (Cam) L T P 3 1 0 Unit-IPandit Animesh TripathiNo ratings yet

- List & Details of Some of The Subjects Studied in M.tech Industrial Engineering CurriculumDocument2 pagesList & Details of Some of The Subjects Studied in M.tech Industrial Engineering CurriculumkishorechakravarthyNo ratings yet

- Mtech Ie PDFDocument15 pagesMtech Ie PDFAnonymous 1kUvpdbWGNo ratings yet

- 7 ThsemsyllabusDocument8 pages7 ThsemsyllabusDhakshina KNo ratings yet

- Practice: Methodology, Problems and Difficulties - Economics of Reliability EngineeringDocument3 pagesPractice: Methodology, Problems and Difficulties - Economics of Reliability Engineeringgurjotsingh29No ratings yet

- First Sem PDFDocument5 pagesFirst Sem PDFRajvardhan JaidevaNo ratings yet

- Pom IeDocument5 pagesPom IepmagrawalNo ratings yet

- Syllabus Prod. MNGTDocument1 pageSyllabus Prod. MNGTNalini PuthranNo ratings yet

- IP5SEMSYLLABUSDocument6 pagesIP5SEMSYLLABUSAditya RaoNo ratings yet

- AU5SEMSYLLABUSDocument5 pagesAU5SEMSYLLABUSANKESH SHRIVASTAVANo ratings yet

- CRP 7th 8th Syllabus..Document34 pagesCRP 7th 8th Syllabus..Archana MaskeNo ratings yet

- Ravenshaw University Master in Computer Application First Semester MC - 1.1 Computer Organization and Architecture Unit 1Document28 pagesRavenshaw University Master in Computer Application First Semester MC - 1.1 Computer Organization and Architecture Unit 1Kartik ChaturvediNo ratings yet

- SCLM TM AmmDocument3 pagesSCLM TM Ammm3evNo ratings yet

- ME - 7th Semester Syllabus - MO 2016Document7 pagesME - 7th Semester Syllabus - MO 2016Kienzer San AgustinNo ratings yet

- SUPPLY CHAIN Is A Network of SupplierDocument4 pagesSUPPLY CHAIN Is A Network of Suppliernasir2277No ratings yet

- B.Tech Syllabus Aero 7Document9 pagesB.Tech Syllabus Aero 7KhushiNo ratings yet

- 4th Year - II Sem - MechDocument10 pages4th Year - II Sem - MechaareachyuthNo ratings yet

- S3 Syllabus Computer Science (Old Scheme)Document5 pagesS3 Syllabus Computer Science (Old Scheme)Rinku MerinNo ratings yet

- 4-1 Syllabus PDFDocument8 pages4-1 Syllabus PDFJohn CenaNo ratings yet

- S6 - Project Management and Quality AssuranceDocument3 pagesS6 - Project Management and Quality Assurances4ndzNo ratings yet

- InftDocument22 pagesInftapi-236544093No ratings yet

- Mtech Iem 2013Document12 pagesMtech Iem 2013Jaykrishnan GopalakrishnanNo ratings yet

- Syllabus For Eighth SemesterDocument4 pagesSyllabus For Eighth SemesterÂvï JâísNo ratings yet

- Viime - Sy - 290613040916Document17 pagesViime - Sy - 290613040916Vivek RajakNo ratings yet

- ME LM SyllabusDocument5 pagesME LM SyllabusSiddharth Narayanan ChidambareswaranNo ratings yet

- Syllabus IIDocument5 pagesSyllabus IIfelixsssNo ratings yet

- Industrial EngineeringDocument1 pageIndustrial EngineeringRajeevNo ratings yet

- 2007Document3 pages2007nanimanojrajivNo ratings yet

- CAD CAM II SemDocument13 pagesCAD CAM II SemSayyadh Rahamath BabaNo ratings yet

- SyllabusDocument2 pagesSyllabusvishnuNo ratings yet

- B.tech (CS) Fourth SemesterDocument20 pagesB.tech (CS) Fourth SemesterSadiaAslamNo ratings yet

- UntitledDocument2 pagesUntitled123_muthuNo ratings yet

- ME IE SyllabusDocument9 pagesME IE SyllabusSiddharth Narayanan ChidambareswaranNo ratings yet

- Planning Hierarchies in OperationsDocument3 pagesPlanning Hierarchies in Operationssatish5269115No ratings yet

- PE - 7th Semester Syllabus - MO 2016Document5 pagesPE - 7th Semester Syllabus - MO 2016Abhishek BhattNo ratings yet

- Revised Course of Study. Masters of Business Administration (MBA)Document30 pagesRevised Course of Study. Masters of Business Administration (MBA)Shailendra Nath GodsoraNo ratings yet

- Syll 2002 KMDocument59 pagesSyll 2002 KMPrashant MeshramNo ratings yet

- (332-345) IE - ElectiveDocument14 pages(332-345) IE - Electivegangadharan tharumarNo ratings yet

- My PH D SyllabusDocument7 pagesMy PH D SyllabusRing MasterNo ratings yet

- VII Semester Sl. No. Sub-Code Subject Dept/Board Hours/week CreditsDocument22 pagesVII Semester Sl. No. Sub-Code Subject Dept/Board Hours/week CreditsMurali Krishna GbNo ratings yet

- Mba Vtu 3 Sem SyullabusDocument8 pagesMba Vtu 3 Sem SyullabusShiva KumarNo ratings yet

- Unit I: B.E. 401 - Engineering Mathematics IiiDocument7 pagesUnit I: B.E. 401 - Engineering Mathematics Iii9y9aNo ratings yet

- MRSPTU 8th Sem Syllabus 2020Document4 pagesMRSPTU 8th Sem Syllabus 2020PiyushNo ratings yet

- Logistics Supply Chain and Management Mumbai UniveristyDocument3 pagesLogistics Supply Chain and Management Mumbai UniveristyPriti Vairagi0% (1)

- Semester Viii: Total Quality ManagementDocument4 pagesSemester Viii: Total Quality ManagementNano GowthamNo ratings yet

- Production Engineering Scheme18-19Document4 pagesProduction Engineering Scheme18-19atulcoldwarNo ratings yet

- SYBCA SyllabusDocument6 pagesSYBCA Syllabuspremsoni0143No ratings yet

- Mechsyll 8Document18 pagesMechsyll 8Anonymous SLKWYHBoNo ratings yet

- TE Electroncis Sem 6 University of MumbaiDocument11 pagesTE Electroncis Sem 6 University of MumbaiAbhijeet JadhavNo ratings yet

- Ba9221 Operations ManagementDocument2 pagesBa9221 Operations ManagementSonuSwathi0% (1)

- OSCM Sem III and IVDocument15 pagesOSCM Sem III and IVadeee31No ratings yet

- PomDocument6 pagesPomSana KhanNo ratings yet

- 5ead9production and Operations Management-Bba-6Document2 pages5ead9production and Operations Management-Bba-6Kavya KhandelwalNo ratings yet

- 1) Management Information SystemsDocument13 pages1) Management Information Systemssagar09100% (1)

- Industrial Engineering and Management: Detailed Syllabi For The M.Tech. Programme inDocument40 pagesIndustrial Engineering and Management: Detailed Syllabi For The M.Tech. Programme insafeer283No ratings yet

- Nature-Inspired Optimization Algorithms for Fuzzy Controlled Servo SystemsFrom EverandNature-Inspired Optimization Algorithms for Fuzzy Controlled Servo SystemsNo ratings yet

- Pysics LabDocument2 pagesPysics LabAtul PandeyNo ratings yet

- ReplyDocument2 pagesReplyAtul PandeyNo ratings yet

- DemingDocument2 pagesDemingAtul PandeyNo ratings yet

- MCDocument41 pagesMCAtul PandeyNo ratings yet

- COMTEC LeafletDocument4 pagesCOMTEC Leafletariksyaiful82No ratings yet

- Chapter 2-Life TablesDocument18 pagesChapter 2-Life TablesBoby ZooxNo ratings yet

- Nursing Philosophy PaperDocument6 pagesNursing Philosophy PaperDanielle AalderinkNo ratings yet

- Lebanese Medical LSK - pdf2Document96 pagesLebanese Medical LSK - pdf2Alaor LopesNo ratings yet

- Silver Iodide MSDS: Section 1: Chemical Product and Company IdentificationDocument5 pagesSilver Iodide MSDS: Section 1: Chemical Product and Company IdentificationelsadwihermiatiNo ratings yet

- Week 2 Measurement of Fluid PropertiesDocument7 pagesWeek 2 Measurement of Fluid PropertiesHafidzSecretzboyzNo ratings yet

- Raz Correlation ChartDocument1 pageRaz Correlation Chartapi-236762108No ratings yet

- EC8093-DIP - Model Exam QPDocument2 pagesEC8093-DIP - Model Exam QPSanthosh PaNo ratings yet

- Ava de JongeDocument2 pagesAva de Jongeapi-543815662No ratings yet

- 2022 01 MED21A T1-Assessment QestionPaperDocument4 pages2022 01 MED21A T1-Assessment QestionPaperIshmael MvunyiswaNo ratings yet

- Introduction To LogicDocument4 pagesIntroduction To LogicLykwhat UwantNo ratings yet

- Mini - First Lecture SymmetryDocument19 pagesMini - First Lecture SymmetryKhaled AbeedNo ratings yet

- OrgMan - Week 5 - Tools in Business DecisionDocument13 pagesOrgMan - Week 5 - Tools in Business DecisionSilfa De la CruzNo ratings yet

- Qualtrics Survey Software PostDocument13 pagesQualtrics Survey Software Postapi-283622630No ratings yet

- Aldous Huxley Between The Wars - Essays and Letters. - Free Online LibraryDocument4 pagesAldous Huxley Between The Wars - Essays and Letters. - Free Online LibraryHasan ArslanNo ratings yet

- Chap1 Lec1 Introduction To NLODocument3 pagesChap1 Lec1 Introduction To NLOUzair AslamNo ratings yet

- Practical MagnetotelluricsDocument14 pagesPractical MagnetotelluricsjesaduNo ratings yet

- Driving TRDocument62 pagesDriving TRmary jane garcinesNo ratings yet

- PMT Class XI Chemistry Atomic StructureDocument39 pagesPMT Class XI Chemistry Atomic StructureAurobinda MaharanaNo ratings yet

- NCERT Solutions Class 7 Science Chapter 15 LightDocument5 pagesNCERT Solutions Class 7 Science Chapter 15 LightJAI PRAJEN PRO HACKERNo ratings yet

- Manager Feedback Survey-GoogleDocument3 pagesManager Feedback Survey-GoogleJorge Pinho da CruzNo ratings yet

- W5-Comprehensive Local Juvenile Intervention PlanDocument5 pagesW5-Comprehensive Local Juvenile Intervention PlanSammy Codera100% (1)

- User Manual Auto-Reclosing ProtectorDocument8 pagesUser Manual Auto-Reclosing ProtectorThiago GusmãoNo ratings yet

- 362100deff40258 Exde03 35Document44 pages362100deff40258 Exde03 35Daniel SdNo ratings yet

- Test - Modulo 2Document3 pagesTest - Modulo 2Bayron Izuna CastilloNo ratings yet

- Argumentative EssayDocument8 pagesArgumentative Essayapi-272949288No ratings yet