Professional Documents

Culture Documents

Rohith R Fouress Report 1

Uploaded by

Nithish ChandrashekarOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Rohith R Fouress Report 1

Uploaded by

Nithish ChandrashekarCopyright:

Available Formats

FOURESS ENGINEERING India.

PVT Ltd 2022

KNOWLEDGE IS POWER

SCHOOL OF MECHANICAL ENGINEERING

INTERNSHIP REPORT ON

In fulfilment of the internship about the Butterfly valve

FOURESS ENGINEERING INDIA LTD

Name ROHITH .R

SRN No R19ME099

Company name FOURESS ENGINEERING

INDIA PVT LTD

Department PU – 1

Joining Date 26-07-2023

End Date 16- 08-2023

B. TECH MECHANICAL ENGG 1

FOURESS ENGINEERING India. PVT Ltd 2022

FOURESS ENGINEERING INDIA LTD

Peenya , 2nd Phase

Bangalore- 560058

CERTIFICATE

This is to certify that the internship in FOURESS ENGINEERING INDIA

PVT LIMITED is carried out by ROHITH.R (R19ME099) a bonafide student

at Reva University, towards the partial fulfilment for the award Bachelor of

Technology in Mechanical Engineering during the year 2022-2023. It is certified

that all corrections/suggestions indicated for continuous internal assessment

have been incorporated in the report to the best of our knowledge. This report

has been approved as it satisfies the requirements in respect of Internship.

MR. RAMESH. N. M MR. Y N SHANKAR MURTHY

SENIOR MANAGER EXECUTIVE HR

FOURESS ENGINEERING FOURESS ENGINEERING

B. TECH MECHANICAL ENGG 2

FOURESS ENGINEERING India. PVT Ltd 2022

ACKNOWLEDGEMENT

Interning at FOURESS INDIA PVT LTD. was a great learning experience and helped me grow, both as

a professional and as an individual.

Firstly, I would thank our DR. K. S. NARAYANASWAMY, Director of School of Mechanical

Engineering, REVA University, for always motivating me to learn something new.

I thank FOURESS INDIA PVT LTD. for accepting me as an intern and the HR Mr. Y SHANKAR

MURTHY for making the internship application process so smooth. I express my heartfelt gratitude to the

Managing Director of FOURESS INDIA PVT LTD., for constantly mentoring and guiding me for the

entire duration of my internship. I thank them for providing me with their precious time and for clearing all

my doubts. I would also like to take this opportunity to thank everyone at FOURESS INDIA PVT LTD.,

Bangalore for providing me with a prospect to intern along with helping me and clearing all my doubts.

Last but not the least; I would like to thank my parents for being my pillar of support throughout this

internship and even beyond.

I also extend my gratitude and regards to everyone who has helped me directly or indirectly throughout the

internship.

ROHITH.R

B. TECH MECHANICAL ENGG 3

FOURESS ENGINEERING India. PVT Ltd 2022

EXECUTIVE SUMMARY

This report summarizes my experience and learning as an intern at the Production Engineering Department

of FOURESS ENGINEERING INDIA PRIVATE LTD. from 26-07-2022 until 16-08-2022. My

internship mainly focused on the BUTTERFLY VALVES.

After thoroughly understanding the manufacturing process of valves, seat ring by observing the different

processes and machines, I focused mainly on the Inventory Atomization, spending most of my time

observing and talking to operators at the production unit responsible for the same and in the report, I've

tried to summarize the same.

The report contains all major observations and conclusions regarding my work as an intern. It also contains

various software and charts for easy understanding. The report aims at highlighting the process of Inventory

Atomization and different suggestions that could prove to be useful to reduce the time of inventory.

The report also summarizes the knowledge I have gained as an intern and the various practical aspects of

everything I had learnt so far in theory classes. I had the opportunity to see the practical application of

different topics I have learnt so far in my course beginning from the semester till the now. I am sure this

experience is also going to help me going further in my studies.

B. TECH MECHANICAL ENGG 4

FOURESS ENGINEERING India. PVT Ltd 2022

TABLE OF CONTENT:

• ACKNOWLEDGEMENT.......................................................................................... 3

• EXECUTIVE SUMMARY.........................................................................................4

• COMPANY PROFILE............................................................................................... 6

• CHAPTER - 1

About the departments

Production Unit 1: Design team

Production Unit 2: Machine shop

Production Unit 3: Assembly line

Production Unit 4: Fabrication

Production Unit 5: Inserts

• CASE STUDY -1 .................................................................................................... 19

• INTERNSHIP OUTCOMES

B. TECH MECHANICAL ENGG 5

FOURESS ENGINEERING India. PVT Ltd 2022

COMPANY PROFILE

From its inception over five decades ago, FOURESS was laid on a foundation of enterprise, integrity,

innovation. The Focus was to use core engineering strengths, to make valves in India on par with imported

products used in the Power and Water industries.

The FOURESS Group of companies is a premier global supplier for engineered products in industrial flow

related applications manufactured in India, to reach every industry in all parts of the world, on the strength

of its quality, competitiveness, and ability to meet the need-based delivery.

Our track record, built over decades of success, our customer-focused Design and R&D, our manufacturing

capabilities, competitive labour, and the spirit of reaching out to the opportunities have all provided the

right blend for growth and excellence.

FOURESS ENGINEERING (INDIA) PVT LTD is the flagship company of the FOURESS GROUP of

companies, and the leading supplier of Flow Control Devices for Power, Water, Wastewater, Steel, Oil &

Gas, Refinery & Petrochemical sectors in India. We commenced operations in 1962 with the manufacture

of carbon steel industrial valves at Thane, and in 1973 signed what was to be the first of many Foreign

Collaboration Agreements with world renowned Valve Manufacturers in the U.K, Germany, Switzerland,

and Japan.

Growing markets, shifts in production and the demand for a vast range of products and the latest technology

has further led to the setting up of 8 factories in India, including at Bangalore, Aurangabad, Chennai, and

Baroda. FOURESS specializes in custom-engineered Valves and Gas Tight Isolators (Dampers), knife gate

valve for power, water, steam, oil, and gas applications and has supplied reliable and durable products to

the projects in over 50 countries in 6 continents.

B. TECH MECHANICAL ENGG 6

FOURESS ENGINEERING India. PVT Ltd 2022

FOURESS ENGINEERING (INDIA) PVT LTD has emerged as a leading player in the

global market for industrial valves, isolators, high intensity dampers and gas line valves

GLOBAL PRESENCE INDUSTRIES SERVED

Algeria New Zealand Power

Australia Norway Steel & Metallurgical Plants

Bangladesh Panama Water Supply & Sewage

Belgium Saudi Arabia Cement

Brazil Singapore Oil & Gas

Chile Spain Refineries

China Sri Lanka Petrochemicals

Cuba Sudan Chemical & Fertilizers

Egypt Syria Sugar Plants

Germany Taiwan

Hongkong Thailand

Hungary Turkey

B. TECH MECHANICAL ENGG 7

FOURESS ENGINEERING India. PVT Ltd 2022

COMPANY OVERVIEW

• Fouress Engineering (India) Private limited is a non-government company, incorporated on 25 Jun

1971. It's a private unlisted company and is classified as ‘company limited.

• Company's authorized capital stands at Rs 1000.0 lakhs and has 75.0% paid-up capital which is Rs

750.0 lakhs. Fouress Engineering (India) limited last annual general meet (AGM) happened on 30 Sep,

2020. The company last updated its financials on 31 Mar, 2021as per Ministry of Corporate Affairs

(MCA).

• Production activities supported by work force of over 1000 and modern equipment’s.

• Global leaders in valves production.

• First or Second in every market they serve.

B. TECH MECHANICAL ENGG 8

FOURESS ENGINEERING India. PVT Ltd 2022

CHAPTER 1. BRIEF INTRODUCTION TO VALVES

• A valve is a device or natural object that regulates, directs or controls the flow of a fluid (gases, liquids,

fluidized solids, or slurries) by opening, closing, or partially obstructing various passageways.

• The use of valves to regulate the flow of water dates to Indus valley (1700 to 1800 BC).

• Major valve design began during era of industrial revolution and with use and development of steam

(1700 AD).

• Modern butterfly valve was first invented by Mr. Carl Benz in 1983 to regulate the flow of carburettor.

• Early 1920’s the emergence of hydropower technology and many companies developed the valves,

conducted model tests.1950 onwards. Butterfly valves were extensively used in Hydropower plant.

B. TECH MECHANICAL ENGG 9

FOURESS ENGINEERING India. PVT Ltd 2022

CHAPTER 1.1. FOURESS ENGINEERING VALVES AND TYPES

• Bangalore plant is into design and manufacturing of isolation valve like the following:

• Butterfly valves

• Triple eccentric spherical valves

• Knife gate valve

• Isolators

• Dampers.

.

• The butterfly valves are used in thermal power plants, Water treatment plants, process industry and

hydro power plants.

• Most cases these valves are used for isolation purposes however, butterfly valves are also used for

control/throttling duty.

Valves

Control valves Isolation

Angle valves Butterfly valve

Globe valves Spherical valve

Ball valves Check valve (NRV)

Gate valve Knife gate valve

B. TECH MECHANICAL ENGG 10

FOURESS ENGINEERING India. PVT Ltd 2022

GALLERY

1. 2.

3. 4.

1. 3100mm Hydraulically operated penstock protection valve to Wyangala hydroelectric Power Station,

Australia.

2. 3600mm electrically operated knife gate valve with super duplex ss blade and lining to Stone Cutter

Island, Hong Kong.

3. 17500mm x 4012mm electro-hydraulically operated multi louvre damper to Taiwan through Mitsui

Babcock, UK

4. 1400MM Electrically operated butterfly valve supplied to NKK, Japan.

B. TECH MECHANICAL ENGG 11

FOURESS ENGINEERING India. PVT Ltd 2022

ABOUT THE DEPARTMENTS

Production Units:

There are 5 Production Units (PUs) in Fouress Engineering Pvt Ltd., Bangalore plant for manufacturing a

range of butterfly valves, high performance valves. Most of these production units are a customer or

supplier to another production unit in the same plant.

Production Unit 1: Design Team

• In this unit, Designers are the key part of a design team. They are a group of design experts that create,

test, and iterate product design drafts again and again to ensure better product and user experiences.

• Crio and Solid works are the main design tools used to Build professional Projects.

• Design team is being induced right from DE state, where the informed requirements are understood &

clarified at each step & quoted accordingly to bag the order.

• Design team generate design output from the design input.

• Verification of design and ensure design output meets input requirements.

• Review of design documents drawings, specification sheet calculation for correctness, completeness,

and release for further processing.

• Initiate design changes based on feedback received.

• Checking of design documents and drawings, bill materials.

• Revisions in drawings/documents.

• Approval of part drawings as per instructions.

• Design team should check for calculations.

B. TECH MECHANICAL ENGG 12

FOURESS ENGINEERING India. PVT Ltd 2022

Production Unit 2: Production Machine Shop (Butterfly valve )

• Depending on the design submitted by the design team. As soon as the job pocket is prepared, it is

sent to the manufacturing supervisor, who then assigns the task to the operators to complete.

The main production of the machine shop are the parts for the valves

• Body

• Disc

• Steam and seat

• Drive shaft

• Stub shaft

• End cover plate

• Thrust pad

• A manufacturing company, Fouress engineering purchases raw materials and then processes them on

the machines available. Each part of the butterfly valve is made from scratch.

EXPLODED VIEW OF BUTTERFLY VALVE:

B. TECH MECHANICAL ENGG 13

FOURESS ENGINEERING India. PVT Ltd 2022

Manufacturing machinery:

1. RVTL (Russian vertical lathe)

• Vertical turning lathes (VTL) are machines that orient the spindle in the vertical plane in a fixed position.

The workpiece then spins, moving up and down to put it in line with the cutting head. These machines

are less complex than horizontal lathes. This machining option is best for pieces that focus on shaping a

single side of a part. While not suited for high-production runs, they excel at taking heavy cuts on

medium and large parts.

• There are certain applications where a vertical turning lathe machine has an advantage over other

machining solutions. We take advantage of this to produce better parts and more efficient machine piece.

This can handle operations of 1000 to 2400mm. Used for body and disc manufacturing.

• Turning Processes our machines can handle:

• Boring

• Cutting

• Drilling

• Facing

• Internal forming

• Knurling

• Necking

B. TECH MECHANICAL ENGG 14

FOURESS ENGINEERING India. PVT Ltd 2022

2. GVTL (German vertical turning lathe)

• Vertical turning lathes that use the main

spindle to load and unload themselves are

finding increasing acceptance as multitasking

capabilities make them efficient processing

centres for producing chucked parts.

• Vertical turning lathes give foundries with

machine shops as well as those that

outsource machining the ability to cut

bigger and heavier castings

• This machine is used for manufacturing

Body and disc of the valve and key way and

mainly used for 600 to 800mm.

3. Pegard boring machine (horizontal)

• This PEGARD Boring Machine was manufactured

in 1972 and has a production record of

approximately 32250 working hours.

• Boring machine, device for producing smooth and

accurate holes in a workpiece by enlarging existing

holes with a bore, which may bear a single cutting

tip of steel, cemented carbide, or diamond or may

be a small grinding wheel. Single-point tools,

gripped in a boring head attached to a rotating

spindle, are moved circularly against the sides of

the existing holes. The diameter of the hole swept

out by the tool is controlled by adjustment of the

boring head.

• The cutting tool is normally single point which are

made of M2 and M3 high-speed steel

• Forming operation

• Machining flat surface

• Taper boring operation

• Turning cylindrical surface

B. TECH MECHANICAL ENGG 15

FOURESS ENGINEERING India. PVT Ltd 2022

4. CNC Plasma Cutting Machine

• Plasma cutting is a process that cuts through electrically conductive materials by means of an

accelerated jet of hot plasma. Typical materials cut with a plasma torch include steel, stainless

steel, aluminium, brass and copper, although other conductive metals may be cut as well. Plasma

cutting is often used in fabrication shops, automotive repair and restoration, industrial construction,

and salvage and scrapping operations. Due to the high speed and precision cuts combined with low

cost, plasma cutting sees widespread use from large-scale industrial CNC applications down to small

hobbyist shops.

• Plasma cutting is an effective way of cutting thin and thick materials alike. Hand-held torches can

usually cut up to 38 mm (1.5 in) thick steel plate, and stronger computer-controlled torches can cut

steel up to 150 mm (6 in) thick. Since plasma cutters produce a very hot and very localized "cone" to

cut with, they are extremely useful for cutting sheet metal in curved or angled shapes.

• The arcs are generated in a three-step process. A high voltage spark briefly ionizes the air within the

torch head. This makes the air conductive and allows the "pilot arc" to form. The pilot arc forms within

the torch head, with current flowing from the electrode to the nozzle inside the torch head. The pilot

arc burns up the nozzle, a consumable part, while in this phase. The air then blows the plasma out the

nozzle towards the work, providing a current path from the electrode to the work. When the control

system senses current flowing from the electrode to the work, it cuts the electrical connection to the

nozzle.

B. TECH MECHANICAL ENGG 16

FOURESS ENGINEERING India. PVT Ltd 2022

Production Unit 3. Assembly Line

• An assembly line is a manufacturing process (often called a progressive assembly) in which parts

(usually interchangeable parts) are added as the semi-finished assembly moves from workstation to

workstation where the parts are added in sequence until the final assembly is produced. By mechanically

moving the parts to the assembly work and moving the semi-finished assembly from workstation to

workstation, a finished product can be assembled faster and with less labour than by having workers

carry parts to a stationary piece for assembly.

Production Unit 4. Fabrication

• Mild Steel Fabrication is made utilizing excellent paint just as combinations. These items are utilized

in different businesses, and we offer these items at industry driving costs to customers. Our items are

exceptionally known for their viable execution, and we offer these items in different examples, sizes,

structures and shapes and these items are effectively accessible in the market. A predominant quality

mills steel fabrication is done on different kinds of mild steel (MS) sections and plates. We have all the

accessible assets and a profoundly proficient group of laborers with us. Quality affirmation is a

significant need, and we profoundly trust in making our client fulfilled. Fabrication is done in an

altered way to fulfil each customer's needs in the most ideal way. We likewise put stock in conveying

our administration in a characterized stipulated period.

• The valves are usually made from mild steel. A body disc covers most of the valve's parts.

• Main Types of Paint Used with Steel Standard primers Specialty paints 1. Zinc 2. Epoxy 3.

Polyurethane

B. TECH MECHANICAL ENGG 17

FOURESS ENGINEERING India. PVT Ltd 2022

Production Unit 5. Inserts

• After the valve is manufactured and fabricated, it is ready for insertion into the next process.

• Fouress's core manufacturing process required bringing in gear boxes and actuators from OEM

vendors.

• In this case, the main suppliers are AUMA PVT LTD, they provide the gearbox and the actuators for

the valves

• Based on customer requirements, gear box is manufactured

• Lever operated, gear operated, electrically operated, and pneumatically operated.

• The operators are mainly produced from AUMA/ ROTANK manufacturing.

QUALITY CONTROL

• Quality control involves testing butterfly valves and determining if they are within the specifications

and Requirements for the final product. The purpose of the testing is to determine any needs for

corrective actions in the manufacturing process. Good quality control helps companies meet consumer

demands for better products.

• Carry out quality assessment measures of all the products ready to be shipped and incoming raw

materials

• Take a thorough look at the plans, specifications, and blueprints to understand the product requirements

• Reject all the incoming raw materials fail to meet quality expectations and report the issue to the

concerned department at the earliest

B. TECH MECHANICAL ENGG 18

FOURESS ENGINEERING India. PVT Ltd 2022

INTERNSHIP at FOURESS ENGINEERING

CASE STUDY - ASSEMBLY

Studying the Assembly of Valves

Introduction

Valve assembly is the last stage in the manufacturing process. Valve assembly is the process

of combining all parts and components of the valve together to make it a product. The

assembly process of several parts forming parts is called component assembly, and the

assembly process of several parts and components forming a valve is called general assembly.

Assembly work has a great impact on product quality. If the design is accurate and all the

parts are qualified but the assembly is improper, the valve will not meet the specified

requirements. Therefore, special care must be taken to adopt a fair assembly method to ensure

the quality of the final product of the valve.

The assembly process defined in the form of various documents in production is called the

assembly process specification. However, before assembling the parts of the valve, it is

necessary to remove any burrs formed by machining, welding residues and other to clean out

the parts properly. This is to make sure there are no impurities present which might

compromise the working of the valve

B. TECH MECHANICAL ENGG 19

FOURESS ENGINEERING India. PVT Ltd 2022

Planning and Process Flow Chart

Once a plan is set in place and all the raw materials have been sourced for development,

manufacturing of the valve can be set in motion. The manufacturing takes place according to

the process, steps and requirements as mentioned in the work document. Once all the parts of

a valve are made, a sequence of operations is put in place to determine in which order the

valve must be built up. This sequence of operations is mentioned in the assembly process

specification guide. Once the sequence of operations are put in place, work starts with

cleaning out each of the parts before assembly.

Cleaning of Valve Parts

Since valves are used in various verticals such as - Thermal, Hydro or Nuclear Power Plants,

Water and Irrigation, Water Treatment, Naval and Marine and Industries such as -

Metallurgical and Steel, Oil and Gas, Cement, Paper, Sugar and other Process Plants, - it is of

utmost importance that the inner cavity must be clean and functions properly. Valves used in

the nuclear power, medicine and food industries have stricter requirements on the cleanliness

of the valve cavity in order to ensure the purity of the medium and avoid medium infection.

Before assembling, the parts must be cleaned, the chipped material, the residual oil, coolant

and burrs, welding slag and other dirt on the parts should be washed and cleaned. The parts

are then ground and polished. The final cleaning is usually to clean the sealing surface with

gasoline and then dry it with compressed air and wipe it with a cloth.

Inspection

Inspection after every process is important to maintain the standard and quality of the final

product. Inspection is important while assembling any product, not just valves. The parts of

the valve are inspected after cleaning before they go on to further assembly. The ones that are

accepted go on to the next stage, the ones rejected are scrapped. Parts that are non-conforming

are sent back for rework. Rework could be anything in the form of - replacement, rectification,

downgrade for use or use for a different purpose.

B. TECH MECHANICAL ENGG 20

FOURESS ENGINEERING India. PVT Ltd 2022

Further Process and Testing

The valve is then assembled according to the assembly process specification, with inspection

being performed after every step.

Once the valve is completely assembled, tests are performed to ensure the working of the

valves. Some tests include - Valve Pressure Test, Valve Strength Test and a Valve Tightness

Test.

Valve Pressure Test

Low pressure, medium pressure and high pressure valves should be subjected to strength test

and tightness test. Alloy steel valves should also be subjected to spectrum analysis on the shell

and the material should be reviewed.

Valve Strength Test

The strength test of the valve is to test when the valve is open to check the leakage on the

outer surface of the valve. The test is done at 1.5 times the nominal pressure and lasts for not

less than 5 minutes.

Valve Tightness Test

This test is carried out with the valve in the fully closed state to check whether there is leakage

on the sealing surface of the valve. The test pressure, except for butterfly valves, check valves,

bottom valves and throttle valves should generally be carried out at the nominal pressure. At

working pressure, it can also be tested with 1.25 times the working pressure.

Conclusion

Once all the tests have passed, the valve undergoes a final round of inspection, the valve is

carefully packed and shipped out for installation.

B. TECH MECHANICAL ENGG 21

FOURESS ENGINEERING India. PVT Ltd 2022

INTERNSHIP OUTCOMES

• From the month-long experience interning at Fouress engineering, we were able to learn a lot about

the working of the company in terms of how the nine production units are linked in their production

activities with one unit acting as an internal customer for another in addition to manufacturing

components for dispatch to external customers.

• We observed the manufacture of products including disc\, bodies, shaft, etc. which were

customized solutions to problems that customers needed to resolve.

• The designs for these solutions were prepared in the Research & Development department who sent

the specifications through a drawing sheet to the concerned Production Unit for manufacture.

• We learnt the packing procedure of products in PU 1 (Shop floor)

• We also noted down different values such as speed, feed, and depth of cut, cycle time, and number of

passes for CNC machines in Pu - 1

B. TECH MECHANICAL ENGG 22

You might also like

- NISHANTH C G FOURESS REPORTDocument20 pagesNISHANTH C G FOURESS REPORTNithish ChandrashekarNo ratings yet

- Manish Kumar Fouress Report 1Document21 pagesManish Kumar Fouress Report 1Nithish ChandrashekarNo ratings yet

- Nithish Fouress Report 1Document21 pagesNithish Fouress Report 1Nithish ChandrashekarNo ratings yet

- Prem Fouress ReportDocument23 pagesPrem Fouress ReportNithish Chandrashekar100% (1)

- Iit 2 PDFDocument93 pagesIit 2 PDFKamesh SarodeNo ratings yet

- Ganesh Internship FinalDocument26 pagesGanesh Internship Finaljanraosunil961No ratings yet

- Rajeev Internship ReportDocument46 pagesRajeev Internship ReportrajivNo ratings yet

- ITR ReportDocument39 pagesITR ReportOm KalkeriNo ratings yet

- Shweta LokareDocument31 pagesShweta LokareAjinkya PethkarNo ratings yet

- Rubber Pipe Cutting MachineDocument18 pagesRubber Pipe Cutting MachineChinmayNo ratings yet

- Sharda Motors Industries Pvt. Ltd. Chakan, Pune.: Mr. Sarode Shubham RaosahebDocument36 pagesSharda Motors Industries Pvt. Ltd. Chakan, Pune.: Mr. Sarode Shubham Raosahebharsh WaghchaureNo ratings yet

- 3GN18CV402 Internship ReportDocument29 pages3GN18CV402 Internship ReportHP PAVILION100% (1)

- 8th Sem InternshipDocument29 pages8th Sem InternshipDharmeekNo ratings yet

- ITR Report FinalDocument50 pagesITR Report FinalLive WorldNo ratings yet

- Industrial Inplant Training - I: Gabriel India Pvt. LTDDocument50 pagesIndustrial Inplant Training - I: Gabriel India Pvt. LTDAshwin KumarNo ratings yet

- 1NH17ME716 Internship ReportDocument30 pages1NH17ME716 Internship ReportDanial VirajNo ratings yet

- Industrial Report of Sagar and Engineering Company (Mech Final Year Report 8-Sem)Document43 pagesIndustrial Report of Sagar and Engineering Company (Mech Final Year Report 8-Sem)saurabhNo ratings yet

- KMMLDocument38 pagesKMMLAlby ManuNo ratings yet

- Whripooll ProjectDocument35 pagesWhripooll ProjectGayathri VengadessinNo ratings yet

- Asegid InternDocument56 pagesAsegid InternElias nNo ratings yet

- Updated Cv-Faisal KhanDocument3 pagesUpdated Cv-Faisal KhanFaisalNo ratings yet

- Summer Internship Report PDFDocument66 pagesSummer Internship Report PDFsri balajee71% (7)

- Final Report Internship ShivshankarDocument33 pagesFinal Report Internship ShivshankarHRUSHIKESH MANENo ratings yet

- Under The Guidance ofDocument61 pagesUnder The Guidance ofYogesh AdsulNo ratings yet

- Visvesvaraya Technological University, Belgavi: Bachelor of Engineering IN Civil EngineeringDocument78 pagesVisvesvaraya Technological University, Belgavi: Bachelor of Engineering IN Civil EngineeringPrince ApsarNo ratings yet

- Inventory ManagementDocument76 pagesInventory ManagementDEEPAKNo ratings yet

- Industrial Training Report PDFDocument71 pagesIndustrial Training Report PDFNitin KumarNo ratings yet

- Faizan Khan Ayub KhanDocument22 pagesFaizan Khan Ayub KhanGani GaneyanNo ratings yet

- Summer Training Report Final EditDocument35 pagesSummer Training Report Final EditArpit KumarNo ratings yet

- ResorcinolDocument31 pagesResorcinolAkash GanganiNo ratings yet

- Final Output 1-1Document61 pagesFinal Output 1-1Subash SujithNo ratings yet

- Industrial Training Report (1) HemantDocument42 pagesIndustrial Training Report (1) HemantPrabhat Upadhyay60% (5)

- 181200109020-REPORT-Jay Panchal-1Document68 pages181200109020-REPORT-Jay Panchal-1Jaydev BhadeliyaNo ratings yet

- Intenship ReportDocument43 pagesIntenship ReportManoj KumarNo ratings yet

- Praveen InternshipDocument11 pagesPraveen InternshipAryan AmeenNo ratings yet

- New PPTX Presentation 1Document13 pagesNew PPTX Presentation 1GOPAL PALTHINo ratings yet

- It Report AmalDocument18 pagesIt Report Amalമനുഷ്യൻNo ratings yet

- Education: SkillsDocument2 pagesEducation: SkillsAlok TiwariNo ratings yet

- A Study On Customer Satisfaction About Deccan Pumpsets in Coimbatore PDFDocument10 pagesA Study On Customer Satisfaction About Deccan Pumpsets in Coimbatore PDFSurya SudhanNo ratings yet

- Iundustry FileDocument34 pagesIundustry FileHarsh ChauhanNo ratings yet

- 6 Week Internship Report ArvindDocument22 pages6 Week Internship Report ArvindThe Bhavuk's Channel100% (1)

- Internship DraftDocument17 pagesInternship DraftPoornima NNo ratings yet

- Internship Report REVISED 1Document40 pagesInternship Report REVISED 1Abdul MuieezNo ratings yet

- Under The Guidance ofDocument58 pagesUnder The Guidance ofYogesh AdsulNo ratings yet

- Vishnu Internship Report 1Document27 pagesVishnu Internship Report 1Vishnu ChitragarNo ratings yet

- Internship Report FinaleDocument29 pagesInternship Report FinaleShreyas GowdaNo ratings yet

- Learnvern Pvt. LTD.: A Report On Industrial Training atDocument6 pagesLearnvern Pvt. LTD.: A Report On Industrial Training atABHISHEK100% (1)

- Adv. Dip (V) Welding Tech. NSQF-6Document75 pagesAdv. Dip (V) Welding Tech. NSQF-6Om Ar TanNo ratings yet

- Shazli Internship Report 123Document40 pagesShazli Internship Report 123Shamvil KvNo ratings yet

- 1at16me023 - Goutham P KDocument45 pages1at16me023 - Goutham P KBalakrishna GNo ratings yet

- 20BBA025 Dhruva Dave OAP Intro ReportDocument6 pages20BBA025 Dhruva Dave OAP Intro ReportPREJA PATELNo ratings yet

- Archana Tata SteelDocument66 pagesArchana Tata SteelSanjay VeerabhadrakumarNo ratings yet

- Plastic Processing Operator PDFDocument35 pagesPlastic Processing Operator PDFVikram SutharNo ratings yet

- Movie Recommendation SystemDocument57 pagesMovie Recommendation SystemHALOGENNo ratings yet

- Hs8581 - Professional: Indira Institute of Engineering & Technology P TDocument63 pagesHs8581 - Professional: Indira Institute of Engineering & Technology P Tjagadeesh waran MNo ratings yet

- Training Report RACDocument33 pagesTraining Report RACTarun RaghavNo ratings yet

- Industry Immersion Project: Roots Industries India LimitedDocument30 pagesIndustry Immersion Project: Roots Industries India LimitedDeepthaNo ratings yet

- MID TERM REPORT FILE (LCO16178 Rupinder Singh) PDFDocument57 pagesMID TERM REPORT FILE (LCO16178 Rupinder Singh) PDFRupinder singhNo ratings yet

- Abhishek's Training Report (2) 1Document39 pagesAbhishek's Training Report (2) 1Vishal MallickNo ratings yet

- A Study of the Supply Chain and Financial Parameters of a Small Manufacturing BusinessFrom EverandA Study of the Supply Chain and Financial Parameters of a Small Manufacturing BusinessNo ratings yet

- Design and Simulation of Petcoke Steam GasificationDocument18 pagesDesign and Simulation of Petcoke Steam Gasificationsaahikrishna8100% (1)

- Organic Chem: RecrystallizationDocument4 pagesOrganic Chem: RecrystallizationpaoloNo ratings yet

- LB 1000 GeneralPurposeMQLDocument1 pageLB 1000 GeneralPurposeMQLLizette QuintanaNo ratings yet

- Selection & Reference Information: Cutting Orifice Reference Chart - Cutting Tip SizeDocument5 pagesSelection & Reference Information: Cutting Orifice Reference Chart - Cutting Tip SizecarlosNo ratings yet

- Tekin Boru Catalog Eng.Document11 pagesTekin Boru Catalog Eng.Delshad DuhokiNo ratings yet

- 11 TTTT Dual Circulating Sub 22jan18Document1 page11 TTTT Dual Circulating Sub 22jan18saman esfandiarpourNo ratings yet

- 04 Kemcure WDocument2 pages04 Kemcure WMohamed Osama AshmawyNo ratings yet

- Machine Safeguarding at The Point of Operation: A Guide For Finding Solutions To Machine HazardsDocument60 pagesMachine Safeguarding at The Point of Operation: A Guide For Finding Solutions To Machine HazardsYovanyCalPadillaNo ratings yet

- Application of PaintsDocument2 pagesApplication of PaintsfaithNo ratings yet

- Product Data Sheet Powernics 9701 Black Lead Free: Berger Nippon Paint Automotive Coatings Private LimitedDocument2 pagesProduct Data Sheet Powernics 9701 Black Lead Free: Berger Nippon Paint Automotive Coatings Private LimitedSamNo ratings yet

- Quality Assurance Procedure QAP 5945: 1. ScopeDocument5 pagesQuality Assurance Procedure QAP 5945: 1. ScopeDark CenobiteNo ratings yet

- E Beam WeldingDocument2 pagesE Beam WeldingDhilip DanielNo ratings yet

- Chemtech GM: Technical Data SheetDocument4 pagesChemtech GM: Technical Data SheetMounir BoutaghaneNo ratings yet

- Flamex S: Constructive SolutionsDocument4 pagesFlamex S: Constructive SolutionsSHAIK ASIMUDDINNo ratings yet

- Drills and Drilling Machines-1Document27 pagesDrills and Drilling Machines-1Tafadzwa E ChigwazaNo ratings yet

- By Product PlantDocument6 pagesBy Product PlantRajan BhandariNo ratings yet

- New Basic Chemistry 2 Solution (Ideal Solution and Colligative PropertiesDocument83 pagesNew Basic Chemistry 2 Solution (Ideal Solution and Colligative PropertiesRetno Ayu PuspitaNo ratings yet

- Structured Method Statement For Concrete Repair - 2Document10 pagesStructured Method Statement For Concrete Repair - 2m.umarNo ratings yet

- Method of Statement - Welding JointingDocument4 pagesMethod of Statement - Welding JointingAmirul Asyhraf ArsadNo ratings yet

- PetrominHydraulic Oil AwDocument1 pagePetrominHydraulic Oil AwfaisiiNo ratings yet

- Completion (Oil and Gas Wells)Document6 pagesCompletion (Oil and Gas Wells)sidharththerrothNo ratings yet

- Metal Forming Processes - Mechanical Engineering (MCQ) Questions and AnswersDocument5 pagesMetal Forming Processes - Mechanical Engineering (MCQ) Questions and AnswersrahmaNo ratings yet

- Diamond Dressing Tools - CatalogueDocument34 pagesDiamond Dressing Tools - CatalogueRZW RNo ratings yet

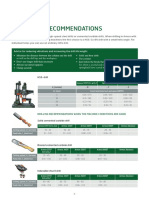

- Machining Recommendations: Advice For Reducing Vibrations and Increasing The Drill Life LengthDocument3 pagesMachining Recommendations: Advice For Reducing Vibrations and Increasing The Drill Life LengthbasaricaNo ratings yet

- Valmet Calender Roll Cover CODocument2 pagesValmet Calender Roll Cover COAmmar MalikNo ratings yet

- Krebs Cyclones For Chemical Industries: Excelling in Separation Solutions Since 1952Document2 pagesKrebs Cyclones For Chemical Industries: Excelling in Separation Solutions Since 1952ritoh8657No ratings yet

- Eaton PROGAF Filter Bags TechnicalDataSheet US LowRes PDFDocument2 pagesEaton PROGAF Filter Bags TechnicalDataSheet US LowRes PDFMartin ŠimurdaNo ratings yet

- LECTURE 15-1: Synthesis and Preparation of Nanomaterials (Crystalline and Thinfilm)Document30 pagesLECTURE 15-1: Synthesis and Preparation of Nanomaterials (Crystalline and Thinfilm)Sk. Laila AyeshaNo ratings yet

- Design & Analysis of Portable Shell Moulding MachineDocument5 pagesDesign & Analysis of Portable Shell Moulding MachineNeelNo ratings yet

- Vitrafix Accessories Brochure V2Document7 pagesVitrafix Accessories Brochure V2Nooong NooongNo ratings yet