Professional Documents

Culture Documents

WW Massal v9 1

Uploaded by

wael72Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

WW Massal v9 1

Uploaded by

wael72Copyright:

Available Formats

BERMAD Waterworks

Surge Tank

Bladder Surge Tanks

Water hammer and surge

protection for potable water, sea water

and wastewater systems

The bladder surge tank serves as an

important component of combined surge

protection systems protecting against both

positive and negative pressure surges.

The tank’s internal flexible bladder separates

the fluid from air that is pre-compressed

between the metal tank housing and the

bladder. This design prolongs the system’s life

span and reduces the need for maintenance.

Features and Benefits

■

Visual, Magnetic or Weight level reading accessories ensures full control and optimal operation

of the bladder surge tank.

■ Surge simulation and analysis – customer support from the early design stages of the project

■ Full separation between liquid and air – prevents corrosion and eliminates the need for auxiliary

air compression systems

BERMAD Waterworks

Surge Tank

Operation Principles

1. System layout

Bermad’s Bladder Surge tanks are available for vertical or horizontal installation.

The steel tank contains a flexible bladder which is fixed to the tank’s connection with the main pipe of the water

system. The bladder shape is similar to the tank’s shape so it can expand to the full capacity of the tank. Compressed

air is confined between the bladder and the external tank’s housing in pressure level compatible with the system

requirements. The bladder’s internal and external pressures are always equal; enabling inbound and outbound flows of

water as needed.

2. Operation upon Pump Start - Up

When the pump starts the system pressure rises; water flows into the bladder, expand it and presses the air to the

system’s pressure level. This restrains the transient pressure increase and enables safe transit from static state to

regular operation state.

3. Operation upon Pump Stop

A pump stop causes a pressure drop as the traveling column of water, with its inherent inertia, continues traveling

along the pipe. At this stage severe vacuum conditions start to develop near the pump. The high air pressure in the

tank pushes the water out of the bladder into the pipeline, preventing by this the vacuum conditions development and

the risk of pipes collapse. When the water column depletes its inertia and starts to move backwards in the pump’s

direction the tank is filled again, so the compressed air absorbs the high pressure wave. The process oscillates till it

completely stops.

PE5WE15-BST Rev. 1 November 2014

BERMAD Waterworks

Surge Tank

Technical Data

Capacity Liter Gallon

Fixed Size 18-2000 4.7-528

Custom Made 2000-100,000 528-26,420

BAR PSI

Pressure Rating

4,10,16,25,40,64,100 58,145,232,362,580,928,1450

Outlet Flange DN25-DN1200 mm 1”-48”

Max Water Temperature

Tank Volume Bladder Type Temperature

Liter Gallon C° F°

18-100 4.7-26.4 EPDM 110 230.0

200-500 52.8-132.1 EPDM 88 190.4

500-100,000 132.1- 26,420 Polyurethane 110 230.0

Packing

Tank Volume

Liter Gallon

≤ 2000 ≤ 528.4 Pallets

> 2000 > 528.4 Cradle

Standard Material: Steel

Interchangeable Bladder: Yes

Feet and ears for handling: Included

Pre-inflation Valve: Included for bladder pressure vessel

Tanks 18-100,000 Liter Tanks 750-100,000 Liter

BERMAD Waterworks

Surge Tank

Surge Analysis

Surge Tank Calculation

Performing surge analysis is crucial for determining the required tank volume and its optimal operation conditions in

order to ensure safe operation during the various transient operation stages of the system.

BERMAD Engineers use the KYPipe Surge software, which is leading surge software, to offer its customers with engineering

calculations of tank volumes required for optimal operation.

info@bermad.com • www.bermad.com

The information herein is subject to change without notice. BERMAD shall not be held liable for any errors. All rights reserved.

© Copyright by BERMAD. PE5WE15-BST Rev. 1 November 2014

You might also like

- WW Massal v9 1Document4 pagesWW Massal v9 1tunlinooNo ratings yet

- Datasheet Municipal Bladder Surge TanksDocument4 pagesDatasheet Municipal Bladder Surge TanksjdNo ratings yet

- Desuperheater That Combines Proven Technologies For Better Operational EconomyDocument4 pagesDesuperheater That Combines Proven Technologies For Better Operational Economyhappale2002No ratings yet

- Antivacuum Valve BrochureDocument2 pagesAntivacuum Valve BrochureblindjaxxNo ratings yet

- pdf140 PDFDocument8 pagespdf140 PDFRobson Custódio de SouzaNo ratings yet

- M322-Final 2014-4-3Document13 pagesM322-Final 2014-4-3Luis Fernando Flores FigueirasNo ratings yet

- Aosmith HeatersDocument48 pagesAosmith HeatersAli Kamel AkilNo ratings yet

- VRCA Relief ValveDocument8 pagesVRCA Relief Valvenenad135No ratings yet

- DESUPERHEATERDocument4 pagesDESUPERHEATERghkashyap1No ratings yet

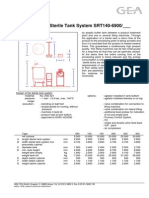

- Technical Data: Sterile Tank System SRT140-6900Document2 pagesTechnical Data: Sterile Tank System SRT140-6900Luis Guillermo Echeverri LopezNo ratings yet

- Commercial Gas Water Heaters: BTR-151 (A) BTR-201 (A)Document2 pagesCommercial Gas Water Heaters: BTR-151 (A) BTR-201 (A)Viswanath NeswaNo ratings yet

- ProductsDocument8 pagesProductsLe ChauveNo ratings yet

- NRVSB 0062 enDocument7 pagesNRVSB 0062 enshashikanth79No ratings yet

- Catalog of WEIR-Steam Conditioning Control ValveDocument8 pagesCatalog of WEIR-Steam Conditioning Control ValveTim KuNo ratings yet

- Bopp & Reuther CatalogueDocument60 pagesBopp & Reuther CatalogueIrfan BagwanNo ratings yet

- Cylinder Testing StationDocument2 pagesCylinder Testing StationVINATI UPADHYAYNo ratings yet

- Api CPRDocument7 pagesApi CPRMarco OrdoñezNo ratings yet

- JamJoom Pharma - Technical Offer - 113Document8 pagesJamJoom Pharma - Technical Offer - 113Ramy MahmoudNo ratings yet

- Bladder Accumulator - BA Series - BrasilDocument8 pagesBladder Accumulator - BA Series - BrasilGabriel Jamariqueli BueresNo ratings yet

- Es Lf474aDocument2 pagesEs Lf474aWattsNo ratings yet

- Cryogenic OfferDocument10 pagesCryogenic OfferGurjeet SinghNo ratings yet

- BLADDER TANK PROPORTIONING SYSTEM TECHNICAL DATADocument12 pagesBLADDER TANK PROPORTIONING SYSTEM TECHNICAL DATARomando BragasNo ratings yet

- Turbine Bypass ValveDocument12 pagesTurbine Bypass ValveRam MohanNo ratings yet

- 2011 R22 DX Type Screw ChillerDocument41 pages2011 R22 DX Type Screw ChillerDiêm Công ViệtNo ratings yet

- Modern High-Efficiency Heat PumpsDocument14 pagesModern High-Efficiency Heat PumpsbejntNo ratings yet

- Condensate Recovery-Sales Brochure PDFDocument20 pagesCondensate Recovery-Sales Brochure PDFSasitharan MNo ratings yet

- Types and Applications of DeSuperheatersDocument3 pagesTypes and Applications of DeSuperheatersmn_sundaraamNo ratings yet

- Metrex Valve - How To Size A Water Regulating Valves, R410a Valves, Water Pressure Regulating Valves, Seawater Condensing Valve, Marine ValvesDocument5 pagesMetrex Valve - How To Size A Water Regulating Valves, R410a Valves, Water Pressure Regulating Valves, Seawater Condensing Valve, Marine ValvesKyriakos MichalakiNo ratings yet

- Foamproport Bladder TankDocument6 pagesFoamproport Bladder Tankgpskumar22No ratings yet

- Lochinvar Water HeatersDocument52 pagesLochinvar Water HeatersJohn MoreNo ratings yet

- Safety valves for pressure relief in accordance to PED, DIN/EN and ASMEDocument48 pagesSafety valves for pressure relief in accordance to PED, DIN/EN and ASMEEnerprec SASNo ratings yet

- TesDocument68 pagesTesOFINo ratings yet

- Spraymaster Boiler BookDocument6 pagesSpraymaster Boiler Bookfauzi endraNo ratings yet

- ARITA Valve CatalogueDocument68 pagesARITA Valve CatalogueMuhamad Ilyas60% (5)

- Hot Water SpecDocument2 pagesHot Water SpecsafinditNo ratings yet

- Raw Pyrolysis Gas Cooler Preventive MaintenanceDocument21 pagesRaw Pyrolysis Gas Cooler Preventive MaintenanceNelbert SumalpongNo ratings yet

- Maag Gear Pumps For PolymersDocument12 pagesMaag Gear Pumps For PolymersADITYA_PATHAK100% (1)

- IMI Bopp+Reuther SIRADocument4 pagesIMI Bopp+Reuther SIRAangelo100% (1)

- Condensate Storage Tanks GuideDocument4 pagesCondensate Storage Tanks Guidefauzi endraNo ratings yet

- Air Eliminator: Low Pressure ServiceDocument6 pagesAir Eliminator: Low Pressure Servicematteo2009No ratings yet

- IMI Bopp-Reuther Product SIRA AW LRESDocument4 pagesIMI Bopp-Reuther Product SIRA AW LRESPratik SinghNo ratings yet

- A Flooded Screw ChillerDocument29 pagesA Flooded Screw ChillerDiêm Công Việt100% (3)

- Thermax BoilerDocument10 pagesThermax Boileramitrawal0100% (1)

- GT Tank Series: GT-D With Double DiaphragmDocument2 pagesGT Tank Series: GT-D With Double Diaphragmqsa000No ratings yet

- Hydrostatic 2006Document4 pagesHydrostatic 2006juliyanto88No ratings yet

- PumpsDocument5 pagesPumpsEloi Magpantay HernandezNo ratings yet

- Sample Coolers for Safe and Accurate Boiler Water SamplingDocument3 pagesSample Coolers for Safe and Accurate Boiler Water SamplingBehzad Totakhaneh BonabNo ratings yet

- Cryogenic Pressure Regulator GuideDocument4 pagesCryogenic Pressure Regulator GuidedhaktodesatyajitNo ratings yet

- Sotera Diaphragm Pumps (DV Motor)Document8 pagesSotera Diaphragm Pumps (DV Motor)Imran Shahzad KhanNo ratings yet

- 40 BAR OIL-FREE PET COMPRESSORSDocument8 pages40 BAR OIL-FREE PET COMPRESSORSСергей Колесников100% (1)

- Operation Instructions For Duplex-Body Flow Meter SkidDocument21 pagesOperation Instructions For Duplex-Body Flow Meter SkidGeorge GuoNo ratings yet

- Design Buckstay in Steam BoilersDocument9 pagesDesign Buckstay in Steam BoilerszaidinNo ratings yet

- AquaFuse PolyBaSS CatalogueDocument11 pagesAquaFuse PolyBaSS Catalogueani_datNo ratings yet

- Maximizing Water-Cooled TIG PerformanceDocument4 pagesMaximizing Water-Cooled TIG PerformanceDoral DNo ratings yet

- Series 825YD Specification SheetDocument2 pagesSeries 825YD Specification SheetFEBCONo ratings yet

- 15-Pressure Safety ValvesDocument33 pages15-Pressure Safety ValvesUmair A. KhanNo ratings yet

- Panwater PET 300 & 400 FC Series Cooling Towers PDFDocument4 pagesPanwater PET 300 & 400 FC Series Cooling Towers PDFkingathur26681No ratings yet

- Emulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingFrom EverandEmulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingRating: 5 out of 5 stars5/5 (3)

- Lesson 27_ Chemical Feed Pump CalculationsDocument9 pagesLesson 27_ Chemical Feed Pump Calculationswael72No ratings yet

- Pages from 1 - Pump data sheets and curvesDocument1 pagePages from 1 - Pump data sheets and curveswael72No ratings yet

- worksheet27Document2 pagesworksheet27wael72No ratings yet

- HPR - DN800 PN40 - Min ZetaDocument1 pageHPR - DN800 PN40 - Min Zetawael72No ratings yet

- Vedlegg 4 Foreløpige Trykkstøtsberegninger (1)Document22 pagesVedlegg 4 Foreløpige Trykkstøtsberegninger (1)wael72No ratings yet

- CurveDocument1 pageCurvewael72No ratings yet

- DUCTILE IRON FITTINGS MANUFACTURING AND TESTING STANDARDSDocument72 pagesDUCTILE IRON FITTINGS MANUFACTURING AND TESTING STANDARDSAhmed TalaatNo ratings yet

- 25901329Document6 pages25901329wael72No ratings yet

- Roughly Estimated Wet VolumeDocument1 pageRoughly Estimated Wet Volumewael72No ratings yet

- ZS 4, ZS 4 VSD & ZS 4 VSD+ - enDocument32 pagesZS 4, ZS 4 VSD & ZS 4 VSD+ - enwael72No ratings yet

- DEWA Specification 01 NPD26XL R LDocument2 pagesDEWA Specification 01 NPD26XL R Lwael72No ratings yet

- PBR EDRV220704 ERH EN WebDocument5 pagesPBR EDRV220704 ERH EN Webwael72No ratings yet

- Staggered Pump Operation Minimum Submergence LevelsDocument1 pageStaggered Pump Operation Minimum Submergence Levelswael72No ratings yet

- Design Recommendations - For Pump Stations With Large Centrifugal Flygt Wastewater Pumps PDFDocument16 pagesDesign Recommendations - For Pump Stations With Large Centrifugal Flygt Wastewater Pumps PDFlsaishankarNo ratings yet

- Sewage Lift StationDocument1 pageSewage Lift Stationwael72No ratings yet

- WellsDocument5 pagesWellswael72No ratings yet

- Sewage pumping station design and layoutDocument1 pageSewage pumping station design and layoutwael72No ratings yet

- SPS249 Bladder Surge VesselsDocument35 pagesSPS249 Bladder Surge Vesselswael72No ratings yet

- Dismantling Joints VJ IOM 1221 EN-DR10951CDocument8 pagesDismantling Joints VJ IOM 1221 EN-DR10951Cwael72No ratings yet

- Couplings, Adaptors and SleevesDocument28 pagesCouplings, Adaptors and Sleeveswael72No ratings yet

- Bladder Tank SWG BRS A4 15Document4 pagesBladder Tank SWG BRS A4 15wael72No ratings yet

- 1334p Addendumno1 15460 SuDocument10 pages1334p Addendumno1 15460 Suwael72No ratings yet

- BBVA OpenMind Book Change 19 Key Essays On How Internet Is Changing Our Lives Technology Internet InnovationDocument7 pagesBBVA OpenMind Book Change 19 Key Essays On How Internet Is Changing Our Lives Technology Internet InnovationSissiErricoNo ratings yet

- DET-2 Service ManualDocument105 pagesDET-2 Service Manualkriotron50% (2)

- Campus Event ReflectionDocument2 pagesCampus Event ReflectiondntbenfordNo ratings yet

- AshfaqDocument9 pagesAshfaqAnonymous m29snusNo ratings yet

- Detailed Lesson PlanDocument7 pagesDetailed Lesson PlanPrecious BuenafeNo ratings yet

- Common Phrasal VerbsDocument2 pagesCommon Phrasal VerbsOscar LasprillaNo ratings yet

- Email Address For RationalDocument25 pagesEmail Address For RationalpinoygplusNo ratings yet

- Counting Discrete Math ChoicesDocument2 pagesCounting Discrete Math ChoicesAfizah NazatulNo ratings yet

- National Drinking Water Quality StandardDocument26 pagesNational Drinking Water Quality Standardiffah nazira100% (2)

- ExxonMobil History, Strategies, and Financial PerformanceDocument50 pagesExxonMobil History, Strategies, and Financial PerformanceJose FrancisNo ratings yet

- Guide To Low Voltage Busbar Trunking Systems-BeamaDocument20 pagesGuide To Low Voltage Busbar Trunking Systems-BeamaGhayath Omer100% (1)

- Plates of The Dinosaur Stegosaurus - Forced Convection Heat Loos FinsDocument3 pagesPlates of The Dinosaur Stegosaurus - Forced Convection Heat Loos FinsJuan Fernando Cano LarrotaNo ratings yet

- Sample SHARKS Worksheet PDFDocument10 pagesSample SHARKS Worksheet PDFAmruta Chhajed100% (2)

- Ahu KitDocument37 pagesAhu KitLaurentiu LapusescuNo ratings yet

- Mainf 517-527Document11 pagesMainf 517-527Upeksha PereraNo ratings yet

- Unit 9 The Post Office: Grammar: Omission of Relative PronounsDocument5 pagesUnit 9 The Post Office: Grammar: Omission of Relative PronounsTrung Lê TríNo ratings yet

- Pre CRM at RelianceDocument3 pagesPre CRM at RelianceSonali SinghNo ratings yet

- Physical Education 8 Quarter 2 - Module 1: Physical Activities Related To Team SportsDocument49 pagesPhysical Education 8 Quarter 2 - Module 1: Physical Activities Related To Team SportsHannah Katreena Joyce JuezanNo ratings yet

- PearsonDocument7 pagesPearsonJimmy M TaopanNo ratings yet

- Mercruiser 4.3L Mpi SpecsDocument2 pagesMercruiser 4.3L Mpi Specssalvatore dalessandro100% (1)

- Referral 9b66451b 9b66451bDocument1 pageReferral 9b66451b 9b66451bleonelale95No ratings yet

- EZPC/SC FAQ Covers Installation and Use of Smart Card ReadersDocument7 pagesEZPC/SC FAQ Covers Installation and Use of Smart Card ReadersDjuroLjPosticNo ratings yet

- 5 - BOSCH I - O ModuleDocument21 pages5 - BOSCH I - O ModuleFELIPE ANGELES CRUZ ROMONo ratings yet

- Inorganic Polymers: Classification and PropertiesDocument46 pagesInorganic Polymers: Classification and PropertiesGokul KannanNo ratings yet

- International Journal of Pressure Vessels and PipingDocument3 pagesInternational Journal of Pressure Vessels and PipingVikas SharmaNo ratings yet

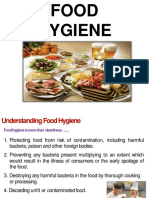

- UNDERSTANDING FOOD HYGIENEDocument22 pagesUNDERSTANDING FOOD HYGIENESahilDalalNo ratings yet

- Range Brochure Wardrobes 2012Document23 pagesRange Brochure Wardrobes 2012Uci DutzuNo ratings yet

- CLSI M100-S20 (2010) Cephalosporin and Aztreonam Breakpoint Revisions Fact Sheet I. Terminology / ProcessesDocument10 pagesCLSI M100-S20 (2010) Cephalosporin and Aztreonam Breakpoint Revisions Fact Sheet I. Terminology / ProcessesCarol TieppoNo ratings yet

- Calculus (Solution To Assignment Iv) : February 12, 2012Document4 pagesCalculus (Solution To Assignment Iv) : February 12, 2012Mawuena MelomeyNo ratings yet

- Content Focus (And Interaction) : Example: Live Lecture (Online or On Campus)Document6 pagesContent Focus (And Interaction) : Example: Live Lecture (Online or On Campus)Dominic LibradillaNo ratings yet