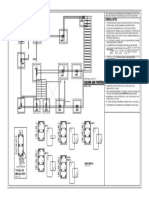

GENERAL NOTES

GENERAL NOTES :

STRUCTURAL DRAWINGS SHALL BE READ IN CONJUNCTION WITH

ARCHITECTURAL & SERVICES DRAWINGS AND THE "ARCHDOME" SPECIFICATIONS

1. MATERIALS 2. FOUNDATIONS 8. R.C. WALLS FOR BASEMENTS, SWIMMING POOLS AND U.G. WATER TANKS 14. NON-STRUCTURAL BLOCKWORK

1. GENERAL ALL MATERIALS TO BE USED IN THE CONJUNCTION 1. UNLESS SHOWN TO THE CONTRARY ON THE DRAWINGS, ALL 200mm THICK

1. EXCAVATIONS FOR FOUNDATIONS SHALL BE CARRIED OUT BY MECHANICAL 1. THE CONTRACTOR IS TO VERIFY THE LEVEL OF THE WATER TABLE ON SITE

SHALL COMPLY WITH THE REQUIREMENTS OF CURRENT BLOCKWALL PANELS EXCEEDING 12 m2 IN AREA SHALL BE PROVIDED WITH

MEANS, EXCEPT FOR THE LAST 200mm OF EXCAVATION WHCIH IS TO AND COMPARE THIS WITH THE ASSUMED WATER TABLE LEVEL SHOWN ON THE RESTRAINTS AS SHOWN IN FIGURES 9 & 10.

RELEVANT BRITISH STANDARDS AND THE ARCHDOME DRAWINGS, IN THE EVENT THAT THE SITE WATER TABLE IS HIGHER, THE BASE

SPECIFICATION UNLESS NOTED BELOW. BE CARRIED OUT BY MANUAL METHODS. 2. UNLESS SHOWN TO THE CONTRARY ON THE DRAWINGS, ALL 150mm THICK

SLAB THICKNESS WILL BE INCREASED BY A SUITABLE AMOUNT TO COMPENSATE

2. CONCRETE UNLESS OTHERWISE NOTED CONCRETE SHALL BE :- 2. ASSUMED SAFE BEARING PRESSURE BELOW PAD AND STRIP FOUNDATIONS FOR HYDROSTATIC UPLIFT. 100mm THICK BLOCKWALL PANELS EXCEEDING 8 m2 IN AREA SHALL BE

2.1 BLINDING CONCRETEGRADE 20/20 SULPHATE RESISTING CEMENT CONTENT IS REF. TO SOIL REPORT THE DEPTH SHOWN ON THE DRAWINGS, SHOULD A PROVIDED WITH RESTRAINTS AS SHOWN IN FIGURES 9 & 10.

200 Kg/m3 MINIMUM. 2. 75mm CONCRETE BLINDING GRADE C10/20 IS TO BE PLACED

SUITABLE BEARING LAYER NOT BE FOUND AT THE DEPTH SHOWN THE BELOW THE WATER TANK BASE SLAB. 3. HORIZONTAL AND VERTICAL CHASES IN BLOCKWALLS WILL BE PERMITTED ONLY

MAXIMUM AGGREGATE SIZE 20mm.

GRADE 40/20 S. 28 DAYS CHARACTERISTIC CUBE EXCAVATION SHALL CONTINUED DOWN TO A DEPTH DEEMED SUITABLE WITH THE APPROVAL OF THE ENGINEER.

2.2 SUBSTRUCTURE 3. THE CONTRACTOR SHALL SUBMIT TO THE ENGINEER FOR APPROVAL A PLAN

STRENGTH 40 N/mm2, SULPHATE RESISTING CEMENT BY THE ENGINEER, AND BACK FILLED WITH CONCRETE GRADE 10/20

UP TO THE LEVEL, SHOWN ON THE DRAWINGS. MARKED UP TO SHOW LOCATIONS OF CONSTUCTION JOINTS. 15. REINFORCED BLOCKWORK

CONTENT 370 Kg/m3 MINIMUM. 4. CONCRETE COVER TO MAIN REINFORCEMENT IS TO BE :-

MAXIMUM AGGREGATE SIZE 20mm. 3. FORMATION LEVELS OF FOUNDATIONS SHALL BE DETERMINED BY THE 1. HORIZONTAL AND VERTICAL REINFORCEMENT SHALL BE PROVIDED AS SHOWN

WATER RETAINING FACES 60 mm

MAXIMUM FREE WATER / CEMENT RATIO 0.45. ENGINEER BASED UPON EXISTING ROAD LEVELS, WATER TABLE LEVEL, IN FIGURE 11.

EXPOSED AND EARTH RETAINING FACES 40 mm 2. CELLS CONTAINING REINFORCEMENT SHALL BE GROUTED SOLID WITH CONCRETE

2.3 SUPER STRUCTURE GRADE 40/20 28 DAYS CHARACTERISTIC CUBE SERVICES REQUIREMENTS, AND SHALL BE SUBJECT TO A MINIMUM

STRENGTH 40 N/mm2, ORDINARY PORTLAND CEMENT DEPTH AS SHOWN IN FIGURE 1. 5. WATER BARS ARE TO BE INCORPORATED IN ALL VERTICAL AND HORIZONTAL GRADE 35/10. THE GROUT IS TO BE PLACED IN LIFTS NOT EXCEEDING 1200mm

350 Kg/m3 MINIMUM. CONSTRUCTION JOINTS. WITH A MINIMUM OF 1 HOUR INTERVAL BETWEEN CONSECUTIVE LIFTS.

MAXIMUM AGGREGATE SIZE 20mm. 4. SHOULD THE FORMATION LEVELS OF TWO OR MORE FOUNDATIONS

6. ALL WALL KICKERS ARE TO BE CAST MONOLITHICALLY WITH THE BASE SLAB. 3. HORIZONTAL CHASES WILL NOT BE PERMITTED IN REINFORCED BLOCKWORK.

MAXIMUM FREE WATER / CEMENT RATIO 0.50. ADJACENT TO EACH OTHER BE DIFFERENT, THE DIFFERENCE IN LEVEL VERTICAL CHASES WILL BE PERMITTED ONLY WITH THE APPROVAL OF THE

2.4 ALL REINFORCED CONCRETE IS TO MADE FROM CEMENT, FINE AGGREGATE IS TO BE MADE UP BY CONCRETE GRADE 10/20 (ie THE AREA SHALL BE 7. UNLESS OTHERWISE SHOWN ON THE DRAWINGS THE WATER TANK SHALL BE ENGINEER.

(SAND AND CRUSHER FINES) COARSE, AGGREGATE (10mm AND 20mm) EXCAVATED TO THE FORMATION LEVEL OF THE LOWER FOUNDATION AND INTERNALLY PLASTERED WITH TWO COATS OF APPROVED WATERPROOF PLASTER

AND WATER. 4. OPENINGS OTHER THAN SHOWN ON THE DRAWINGS, WILL BE PERMITTED ONLY

A THICKER BLINDING USED FOR THE FOUNDATION HAVING THE HIGHER AND PAINTED WITH TWO COATS OF 2 PART NON-TOXIC EPOXY PAINT. WITH THE APPROVAL OF THE ENGINEER.

2.5 THE CONTRACTOR IS TO SUBMIT PROPOSED MIX DESIGNS, TOGETHER WITH FORMATION LEVEL, AS SHOWN IN FIGURE 2.

NOT LESS THAN 4 Nos. 7 DAYS AND 4 Nos. 28 DAYS CUBE TEST RESULTS 9. R.C. RETAINING WALLS 16. INTERLOCKING CONCRETE BLOCK PAVING (LIGHT VEHICULAR TRAFFIC)

FOR APPROVAL WELL BEFORE COMMENCEMENT OF CONCRETE WORKS. 5. THE RELATIONSHIP OF BLINDING CONCRETE WITH RESPECT TO THE

2.6 THE FOLLOWING TEST RESULTS ARE TO BE SUBMITTED ALONG WITH SURROUNDING GROUND LEVEL IS SHOWN IN FIGURE 1. 1. CONCRETE PAVING BLOCKS ARE TO COMPLY WITH B5 6717 (PART 1)

1. R.C. RETAINING WALLS SHALL HAVE 20mm WIDE MOVEMENT JOINT AS SHOWN

THE PROPOSED MIX DESIGNS. IN FIGURE 3 AT A MAXIMUM OF 6.0 METRE CENTRES. 2. ALL BLOCKS ARE TO BE MANUFACTURED WITH SULPHATE RESISTING CEMENT

CEMENT TESTS TO SHOW COMPLIANCE WITH BS12 (OPC) OR 6. THE FORMATION LEVELS OF FOUNDATIONS SHALL BE WATERED AND (MINIMUM CEMENT CONTENT 400Kg/mm2)

BS 4027 (SRC) MECHANICALLY COMPACTED PRIOR TO PLACING BLINDING CONCRETE. 2. RETAINING WALLS SHALL BE PROVIDED WITH DRAINAGE AND DRAINAGE

3. BLOCKS SHALL HAVE A 28 DAYS CHARACTERISTIC STRENGTH OF 49 N/mm2

FINE AGGREGATE SEIVE ANALYSIS, CHEMICAL ANALYSIS,(CHLORIDES OUTLETS TO THE APPROVAL OF THE ENGINEER. (MINIMUM INDIVIDUAL STRENGTH 40 N/mm2)

7. THE FORMATION LEVELS OF FOUNDATIONS ARE TO BE INSPECTED AND

AND SULPHATES), ABSORPTION TESTS. APPROVED BY THE ENGINEER BEFORE BLINDING CONCRETE IS PLACED. 10. GROUND BEARING SLABS 4. BLOCKS ARE TO BE 60mm THICK, LAID IN HERRING BONE OR OTHER PATTERN

SOUNDNESS, POTENTIAL ALKALI REACTIVITY. AS SHOWN ON THE DRAWINGS.

COARSE AGGREGATE SEIVE ANALYSIS, CHEMICAL ANALYSIS,(CHLORIDES 8. A 50mm LAYER OF BLINDING CONCRETE GRADE 10/20 IS TO BE PLACED

1. BACKFILL IS TO COMPRISE SELECTED GRANULAR MATERIAL PLACED IN LAYERS 5. BLOCKS ARE TO BE LAID ON A GRADED SAND BED 50mm THICK OVER A

AND SULPHATES), ELONGATION INDEX, FLAKINESS UNDER ALL PAD AND STRIP FOUNDATIONS.

150mm THICK AND COMPACTED TO A MINIMUM OF 95% OF MAXIMUM 300mm SUB - BASE COMPACTED TO A MINIMUM OF 95% OF MAXIMUM

INDEX, ABSORPTION TESTS, SOUNDNESS, POTENTIAL 9. ALL CONCRETE OF THE FOUNDATIONS AND SUBSTRUCTURE IS TO BE DRY DENSITY.

ALKALI REACTIVITY. DRY DENSITY.

PROTECTED WITH ONE LAYER OF 1000 GAUGE POLYTHENE SHEET AND

WATER DISSOLVED SOLIDS. 2. GROUND BEARING SLABS SHALL BE CONSTRUCTED AS SHOWN IN FIGURE 4.

APPROVED BITUMEN EMULSION.

3. UNLESS SHOWN TO THE CONTRARY ON THE DRAWINGS, THE GROUND BEARING

DETAILS OF ADMIXTURE AND ADDITIVES ARE TO BE SUBMITTED ALONG VERTICAL FACES ARE TO BE PROTECTED BY ONE LAYER FIBRE BOARD

SLABS SHALL BE CAST MONOLITHICLY WITH THE TIE BEAMS AND COLUMNS

WITH THE PROPOSED MIX DESIGNS. OR SIMILAR APPROVED MATERIAL. WITH CONTINUITY OF REINFORCEMENT IN THE GROUND FLOOR SLAB.

THE BITUMEN EMULSION IS TO BE APPLIED IN TWO COATS OVER AN

3. REINFORCEMENT APPROPRIATE PRIMER ALL IN ACCORDANCE WITH THE MANUFACTURER'S 4. INTERNAL GROUND FLOOR SLABS ARE TO BE CONSTRUCTED IN BAYS NOT

EXCEEDING 35 m2 BAYS ARE TO BE SEPARATED BY CONTROL JOINTS ABBREVIATIONS / SYMBOLS :

INSTRUCTIONS.

3.1 'T' DENOTES HOT ROLLED DEFORMED HIGH YIELD BOND STEEL AS SHOWN IN FIGURE 5.

REINFORCEMENT, CHARACTERISTIC STRENGTH 425 N/mm2. 3. FOUNDATION ADJACENT TO EXISTING STRUCTURES GENERAL

5. EXTERNAL GROUND FLOOR SLABS ARE TO BE CONSTRUCTED IN BAYS NOT

3.2 'R' DENOTES ROUND MILD STEEL REINFORCEMENT CHARACTERISTIC EXCEEDING 18 m2 BAYS ARE TO BE SEPARATED BY 12mm ISOLATION JOINT REINFORCED CONCRETE --- RC

STRENGTH 250 N/mm2. 1. THE CONTRACTOR IS TO EXCAVATE TRIAL PITS NEXT TO EXISTING BLOCKWORK --- BLK

AS SHOWN IN FIGURE 6. --- BRK

FOUNDATIONS TO DETERMINE THE NATURE AND LEVEL OF EXISTING BRICKWORK

6. LOCATION OF SPECIFICALLY REQUIRED JOINTS ARE SHOWN ON THE DRAWINGS. DRAWING --- DRG

3.3 THE FOLLOWING TEST RESULTS, FOR EACH BAR DIAMETER AND EACH FOUNDATIONS.

THE CONTRACTOR SHALL SUBMIT TO THE ENGINEER FOR APPROVAL A MARKED NOT TO SCALE --- NTS

SOURCE OF SUPPLY, ARE TO BE SUBMITTED FOR APPROVAL. 2. THE CONTRACTOR IS TO INFORM THE ENGINEER OF THE NATURE AND LEVEL DIAMETER --- �/��ͬ�T

UP PLAN TO SHOW LOCATIONS OF THE REMAINING CONTROL JOINTS. REFER

- TENSION TESTS (YIELD AND ULTIMATE) OF EXISTING FOUNDATIONS, THE ENGINEER WILL MODIFY THE PROPOSED CENTRES --- CRS

- ELONGATION TO FIGURE 5. EXPANSION JOINTS ARE TO BE PROVIDED AT INTERVALS NOT

FOUNDATION DETAILS AS REQUIRED. EXCEEDING 15 METRES. SETTING OUT POINT --- SOP

- CROSS - SECTIONAL AREA

- CHEMICAL ANALYSIS 3. THE CONTRACTOR IS TO TAKE ALL PRECAUTIONS TO ENSURE THE INTEGRITY SETTING OUT LINE --- SOL

7. CONSTRUCTION JOINTS SHALL BE AS SHOWN IN FIGURE 5a. --- CL

- BEND AND REBEND TESTS OF NEIGHBOURING PROPERTY DURING EXCAVATIONS AND THE CONSTRUCTION CENTRE-LINE

OF THE WORKS. FINISHED FLOOR LEVEL --- FFL

3.4 THE CONTRACTOR SHALL SUBMIT REINFORCEMENT DETAIL DRAWINGS 11. REINFORCED CONCRETE UPSTANDS, BALCONY AND PLANTER WALLS STRUCTURAL FLOOR LEVEL--- SFL

AND BENDING SCHEDULE FOR ALL STRUCTURAL ELEMENTS FOR 4. FOUNDATIONS OF MAIN STRUCTURE ADJACENT TO EXISTING LEVEL --- EL

APPROVAL. 1. CONCRETE UPSTANDS SHALL BE CAST AFTER THE FOLLOWING TREATMENT HAS HORIZONTAL --- HOR

UNDERGROUND STRUCTURES --- VER

3.5 CONCRETE COVER TO MAIN REINFORCEMENT IS TO BE :- BEEN CARRIED OUT TO THE FLOOR SLABS. VERTICAL

SUB STRUCTURE SUPER STRUCTURE 1. EXCAVATION AND CONSTRUCTION OF FOUNDATIONS AROUND UNDERGROUND - THE CONCRETE SURFACE OF THE SLAB SHALL BE HACKED BACK TO EXPOSE

FOUNDATION - 50mm ALL FACES COLUMNS - 40mm

STRUCTURES (SEPTIC TANKS, SOAKAWAYS, MANHOLES, UNDERGROUND THE AGGREGATE. RELATING TO REINFORCEMENT

PILE CAPS - 75mm TOP & SIDES WALLS - 30mm WATER TANKS AND THE LIKE) SHALL PROCEED CONCURRENTLY WITH THE - VERTICAL REINFORCEMENT SHALL BE THOROUGHLY CLEANED. FAR FACE (OUTER LAYER) --- F1

CONSTRUCTION OF THE UNDERGROUND STRUCTURES. - TWO COATS OF AN APPROVED BONDING AGENT SHALL BE APPLIED OVER F1

- 100mm BOTTOM BEAMS - 40mm SIDES, TOP & BOTTOM

2. THE FORMATION LEVELS OF FOUNDATIONS AROUND UNDERGROUND A PRIMER COAT TO THE SLAB SURFACE. FAR FACE (SECOND LAYER) --- F2

TIE BEAMS - 40mm ALL FACES STRIP BEAMS - 30mm SIDES, TOP & BOTTOM F2

COLUMNS - 50mm SLAB - 20mm TOP & BOTTOM STRUCTURES SHALL BE TAKEN DOWN TO THE FORMATION LEVEL OF THE - THE APPLICATION OF PRIMER AND BONDING AGENT SHALL BE IN ACCORDANCE

WITH THE MANUFACTURERS INSTRUCTIONS. NEAR FACE (OUTER LAYER) --- N1 N1

WALLS - 40mm - 25mm TOP FOR EXPOSED UNDERGROUND STRUCTURE (REFER TO FIGURE 2)

SURFACES 2. ALL PLANTER WALL SHALL HAVE REINFORCED CONCRETE BASES 300mm THICK

- 25mm BOTTOM FOR RIB SLABS 5. CONCRETE WORKMANSHIP NEAR FACE (SECOND LAYER) --- N2 N2

AND WALL 200mm THICK UNLESS SHOWN OTHERWISE ON THE DRAWINGS.

(OR HOURDI SLAB)

PARAPETS - 30mm ALL FACES 3. PLANTERS SHALL BE WATERPROOFED ON INSIDE FACES WITH TWO COATS OF BOTTOM FACE (OUTER LAYER) --- B1 T1 T2

1. ALL DAYWORK AND CONSTRUCTION JOINTS IN CONCRETE MEMBERS SHALL BE AN APPROVED LIQUID APPLIED BITUMEN MEMBRANE.

OR AS NOTED ON THE DRAWINGS AT PREDETERMINED LOCATIONS AS APPROVED BY THE ENGINEER.

BOTTOM FACE (SECOND LAYER)--- B2

3.7 REINFORCEMENT LAP LENGTHS ARE TO BE :- 2. VERTICAL JOINTS SHALL BE FORMED WITH TIMBER FORMWORK COATED WITH 12. REINFORCED CONCRETE PARAPETS

TENSION - 51 TIMES DIAMETER OF SMALLER LAPPED BAR (EPOXY COATED BARS) AN APPROVED SURFACE RETARDER, THE VERTICAL FACE IS TO BE WASHED TOP FACE (OUTER LAYER) --- T1

REINF'T - 40 TIMES DIAMETER OF SMALLER LAPPED BAR (UNCOATED BARS) 1. ALL REINFORCED CONCRETE AND BLOCKWORK PARAPETS ARE TO HAVE

TO EXPOSE THE AGGREGATE BEFORE FINAL SET OF THE CONCRETE HAS B1 B2

COMP'N. - 30 TIMES DIAMETER OF SMALLER LAPPED BAR (EPOXY COATED BARS) MOVEMENT JOINTS AS SHOWN IN FIGURE 7. THE JOINTS ARE TO BE LOCATED TOP FACE (SECOND LAYER) --- T2

REINF'T - 30 TIMES DIAMETER OF SMALLER LAPPED BAR (UNCOATED BARS) TAKEN PLACE.

TO SUIT ARCHITECTURAL CONSIDERATIONS, BUT AT INTERVALS NOT EXCEEDING

- 300 mm FOR MESH REINFORCEMENT. 3. HORIZONTAL JOINTS SHALL BE SCABBLED TO REMOVE ALL LAITANCE AND 3 METRES AND AT NOT MORE THAN 500 mm FROM ANY CHANGE OF DIRECTION

- OR AS SHOWN ON REINFORCEMENT DRAWINGS. WEAK CONCRETE BEFORE CONCRETE FOR THE NEXT LIFT IS PLACED. STRUCT'L. LEVEL (ON PLAN) --- + 3000 SFL

POSITIONS OF ALL MOVEMENT JOINTS WILL BE SUBJECT TO THE ENGINEER'S

4. ALL UNPLASTERED CONCRETE IS TO BE FAIRFACE FINISH UNLESS NOTED APPROVAL. + 3000

4. CONCRETE BLOCKS FOR WALLS & SLABS TO THE CONTRARY. 2. CONCRETE PARAPETS SHALL BE CAST AFTER THE FOLLOWING TREATMENT HAS FINISHED FLOOR LEVEL (ON PLAN) --- + 3000 FFL

5. ALL CONCRETE SURFACES TO RECEIVE PLASTER ARE TO BE HACKED TO BEEN CARRIED OUT TO THE FLOOR SLAB.

4.1 AGGREGATE FOR CONCRETE BLOCKS SHALL COMPLY WITH THE PROVIDE AN ADEQUATE SURFACE KEY. - THE CONCRETE SURFACE OF THE SLAB SHALL BE HACKED BACK TO EXPOSE RC SLAB THICKNESS --- 200 THK.

REQUIREMENTS OF BS 882. 6. ALL CONCRETE IS TO BE CURED BY AN APPROVED METHOD-WATER PONDING, THE AGGREGATE.

4.2 CONCRETE BLOCKS AND MORTAR FOR USE BELOW GROUND FLOOR SLAB

POLYTHENE/HESSIAN SHEET, CURING COMPOUND.

+ 3000 SFL

LEVEL SHALL BE MADE WITH SULPHATE RESISTING CEMENT. - VERTICAL REINFORCEMENT SHALL BE THOROUGHLY CLEANED.

- TWO COATS OF AN APPROVED BONDING AGENT SHALL BE APPLIED OVER A STRUCT'L. LEVEL (ELEVATION/SECTION) ---

4.3 MAXIMUM PERMITTED SALT CONTENT IN AGGREGATE :- 6. BUILDERS WORK REQUIREMENTS

FINE COARSE PRIMER COAT TO THE SLAB SURFACE. GROUND LEVEL

1. THE CONTRACTOR SHALL SUBMIT FOR APPROVAL DRAWINGS SHOWING DETAILS - THE APPLICATION OF PRIMER AND BONDING AGENT SHALL BE IN ACCORDANCE GROUND LEVEL (ELEVATION/SECTION) ---

ACID SOLUBLE CHLORIDE (SRC) 0.03 % 0.02 %

ACID SOLUBLE CHLORIDE (OPC) 0.05 % 0.04 % OF ALL HOLES, CHASES, SLEEVES, FIXINGS, PLINTHS & OTHER BUILDERS WITH THE MANUFACTURERS INSTRUCTIONS.

ACID SOLUBLE SULPHATE 0.30 % 0.30 % WORK ITEMS WHICH ARE REQUIRED TO BE CONSTRUCTED INTO THE WORKS.

13. MOVEMENT JOINTS IN ROOFS

4.4 COMPRESSIVE STRENGTH OF BLOCKS SHALL BE :-

7. WATER & DRAINAGE PIPES WITHIN COLUMNS 1. MOVEMENT JOINTS IN ROOFS SHALL BE CONSTRUCTED AS SHOWN IN FIGURE 8.

MINIMUM AVERAGE OF 10

NON LOAD BEARING WALLS 6.5 N/mm2 7.5 N/mm2 1. THE CONTRACTOR SHALL SUBMIT FOR APPROVAL DETAILS OF EXIT AND ENTRY 2. CONCRETE UPSTANDS WHICH FORM THE JOINT SHALL BE CAST OVER THE ROOF

LOAD BEARING WALLS 10.0 N/mm2 12.5 N/mm2 OF WATER PIPES THROUGH COLUMNS. SLAB AS DESCRIBED IN SECTION (12)2.

FLOOR SLABS (HOURDI BLOCKS)3.5 N/mm2 4.0 N/mm2 2. EXIT AND ENTRY POINTS ARE TO HAVE ADDITIONAL FUSION BONDED EPOXY

4.5 MORTAR IS TO BE 1 : 4 CEMENT : SAND. COATED REINFORCEMENT PLACED AROUND THE PIPE.