Professional Documents

Culture Documents

Summary Layout For Drawing

Uploaded by

Suhail AhamedOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Summary Layout For Drawing

Uploaded by

Suhail AhamedCopyright:

Available Formats

80 MM

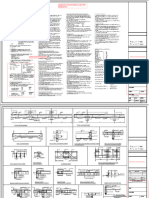

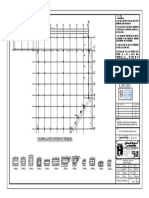

Generally all the materials used in the construction shall comply with relevant a. Generally all the ground floor slab shall be 8" (200 mm) thick. LAPS SHOWN IN TYPICAL DETAILS OF THE BEAMS ARE

and uptodate B.S. codes of practice and contract specifications. ACCEPTABLE POSITIONS OF LAPS WHEN ESSENTIAL.

b. All ground floor slab shall be cast on well compacted fill with one layer of 1000 gauge polythene

CONTRACTOR MAY AVOID THE LAPS IF REINFORCEMENT IS

under the slab. The ground slab shall be reinforced with two layer of B.R.C. mesh A-193. SIMILAR ON BOTH SIDES OF THE LAP AND CAN BE PROVIDED

CONTINUOUS WITHOUT A LAP.

a. Concrete grades/strengths shall be as follows:

Substructure : Grade 35/20 concrete with minimum M.S.R. cement content of

including Gr. Slab TOP REINFORCEMENT AT SUPPORTS FOR CONTINUOUS BEAMS

380 kgs/cu.m. and maximum free water cement ratio of 0.450. SHALL BE HIGHER OF THE TWO SPECIFIED REINFORCEMENT FOR

Superstructure : Grade 30/20 concrete with minimum O.P. cement content pf

Generally all the blockwork shall be constructed as per contract specifications

All blockwork shall comply with D.M. local order no: 44 1990 & the related subjects in local THE TWO BEAMS IN THE `MID SUPPORT' COLUMN IN THE CONSTRUCTION JOINT DETAIL

i nstr uction # 108 90 and t he e xplanat ion of som e of its ite ms i n l ocal inst ruct ion # 171 90 SCHEDULE OF BEAMS.

370 kgs/cu.m. and maximum free water cement ratio of 0.45.

laboratory results should be approved by D.M. research section & Quality control section.

Blinding : Grade 25/20 concrete with minimum M.S.R. cement content of

LAPS IN THE REINFORCEMENT SHOWN IN TYPICAL BEAM

300 kgs/cu.m. and maximum free water cement ratio of 0.50. All nibs/projections (less than 400mm) adjacent to the R.C. columns & walls shall be nominally DETAILS, WHEN PROVIDED AT POSITIONS SHOWN ON THIS

reinforced concrete (0.4% reinforcement) cast monolithic with the columns/walls. The structural DRAWING WILL BE MINIMUM 30 x BAR DIA.

b. All the reinforced concrete shall be made up with sand, crusher fines and 10

and 20 mm aggregates. The contractor shall submit his AS BUILT mix designs drawings generally indicate the main structural members & the contractor is expexted to co-ordinate

with 3 nos - 7 days and 4 nos - 28 days cube test results well prior to with the architectural drawings for the requirement of the non structural

concrete works for engineer's approval. drops/parapets/planters/upstands/lintels etc. All such non structural concrete members shall be

80 MM

nominally reinforced concrete (with 0.2% reinforcement) cast monolithic with the adjacent structural

c. Following test results shall be submitted along with the AS BUILT mix design. :-

members. The contractor shall submit shop drawings showing the AS BUILT details of these

Cement : Full physical and chemical tests.

non-structural elements to the engineer for approval. All the "UNPROTECTED" ends of the

Aggregates : Sieve analysis, chemical analysis

Soundness tests for 10mm and 20mm aggregates. blockwork (including both sides of door/window openings) shall be grouted solid (i.e. the last cell

Absorption tests for fine and coarse aggregates. adjacent to the openings shall be. grouted solid).

d. All day-work or construction joints in slabs, beams etc. shall be at predetermined

locations and shall be agreed with the engineer prior to construction. Following details for the parapets shall be used (unless otherwise shown) :

Parapets upto 4'-8" high: 8" Thick, with T10 @ 8" (V) & T10 @ 8" (H) E.F.

e. Curing : Water curing for a minimum period of 7 days shall be done with hessian

Parapets upto 8'-0" high: 8" Thick, with T10 @ 6" (V) & T10 @ 8" (H) E.F.

and polythene sheet in accordance with B.S.8110 Part-1 section 6.2.3 CONTRACTION JOINTS DETAIL

Alternatively curing compound (to engineer's approval) may be used.

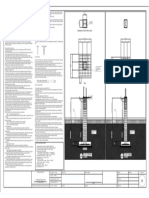

1-ALL DIMENSIONS TO BE CHECKED ON SITE BY STEEL FABRICATION CONTRACTOR AND SHALL SUBMIT SHOP

a. Tensile test reports for all AS BUILT types of steel and bend-rebend test on FABRICATION DRGS. TO THE CONSULTANT FOR APPROVAL PRIOR TO FABRICATION. (MIN. THREE COPIES) EXISTING GROUND LEVEL

Prefix `T' denotes high yield steel deformed (HYSD) bars (Min.yield stress 460 N/MM2).

bars over 16mm diameter shall be submitted to engineer for approval. 2-ALL BOLTS TO BE M16.8.8 GRADE UNLESS OTHERWIS SPECIFIED AND MINIMUM TWO BOLTS TO BE PROVIDED IN ALL BOLT

CONNECTION UNLESS MENTIONED OTHERWISE 200*

b. Testing shall conform to B.S.4449 and will include a carbon content test. 3-ALL WELDS SHALL BE CONTINUOUS UNLESS SPECIFIED OTHERWISE AND MINIMUM SIZE OF WELD BEING NOT LESS THAN

6mm THK. FOR STRUCTURAL CONNECTION AND SHALL COMPLY WITH B.S. 5135

200*

c. The contractor shall submit shop drawings and bar bending schedules for

4-ALL EXPOSED SURFACES OF STEEL WORKS SHALL BE CLEANED TO B.S 4232 BEFORE ANY PROTECTIVE TREATEMENT IS

115

all the reinforcement for foundations, slabs, beams etc. to engineer for approval.

FLOOR

COMMENCED. STEEL WORK SHALL BE DEGREASED AND SHOT OR GRIT BLASTED TO SA 2 1/2 QUALITY STANDARD WITH A

SLAB

d. Unless otherwise stated clear covers to any reinforcement shall be as follows: SURFACE AMPUTED OF 50-75 MICRONS T0 REMOVE RUST AND MILL SCALE, DUST & DEBRIS SHALL BE REMOVED BY

Foundations 50mm all sides. Columns 40mm all sides. VACUUM CLEANER, COMPRESSED AIR OR BRUSH PROTECTIVE COATING SHALL BE APPLIED AS MENTIONED BELOW : P.C.C BED 10 cm THK

FOUNDATION

Tiebeams: 40mm all sides. Hourdi slabs: 20mm top & bot.

---------------------------------------------------------- LEVEL

Beams (200 or more wide): 25mm all sides. Hidden beams: 20mm top & bot. NO OF COATS MAT RIAL DFT

---------------------------------------------------------- EXCAVATION

10

Ground floor slab : 30mm 1st COAT INC RICH PRIM R 40- 5 MICRONS LEVEL

2nd COAT MICAC OUS IRON O ID PO Y 125-150 MICRONS

25

e. Laps wherever essential shall be provided at predetermined locations to be

3rd COAT HIGH BUILD PO Y 110-125 MICRONS

approved by the engineer. Minimum lap length shall be 50 x bar diameter. ----------------------------------------------------------

TOTAL DFT. OR PAINT SHALL NOT BE LESS THAN 270 MICRONS OR AS PER JAFZA'S JAFZA'S RULES AND REGULATIONS

1 LAYER OF ROAD BASE 25 CM THK

5-STEEL SECTION ENCASED IN CONCRETE HAVE AT LEST MIN. 50mm CLEAR COVER ON EITHER SIDE OF SECTION

EXCAVATED SURFACE COMPACTED COMPACTED TO MIN 95% OF MAX. DRY

a. Generally mechanical excavators/shovels etc. are acceptable for excavation 6-THE STEEL SECTION TO BE ENCASED MUST BE UNPAINTED FREE FROM OIL,GREASE, DUST OR LOOSE RUST AND NILL BY HEAVY VIBRATOR ROLLER.DENSITY BY HEAVY VIBRATORY ROLLER.

but last 8" of the excavation upto the formation level of foundations (i.e. level to SCALE

the soffit of blinding under foundations) must be carried out by manual methods. 7-THE STEEL SETION IS SOLIDLY ENCASED IN DENSE STRUCTURAL CONCRETE WITH CONCRETE GRADE M 35/10 TYP. FOUNDATION SECTION

b. The formation level of all foundations shall be watered and mechanically

8-CONCRETE IS THOROUGHLY COMPACTED ESPECIALLY IN AREAS UNDER CLEAT AND CAP PLATES

compacted immediately prior to laying of the blinding concrete.

c. All foundations and substructure concrete including solid blockwall shall be protected 9-HOLD DOWN BOLTS NOT TO BE GROUTED IN UNTIL STEEL WORK HAS BEEN PLUMBED AND LEVELLED, GROUTING IN OF

HOLD DOWN BOLTS ARE TO BE COMPLETED BEFORE LOADS ARE PLACED ON THE STEEL FRAME AND GROUTING SHALL BE

with 2 coats of "NITO PROOF-30"(or equivalent to approval) with one coat of EXPANDING TYPE WITH MTN CRUSHING STRENGTH OF 70 N/mm2 AND MUST BE APPROVED BY THE ENGINEER

primer as per manufacturer's instructions and recommendations. S.NO: DESCRIPTION DATE REMARK

10-CONTRACTOR TO BE RESPONSIBLE FOR ALL TEMPORARY BRACING AND NECESSARY SAG BOLTS SHALL BE PROVIDED IN

d. Prior to commencing any work on site, top soil and loose material shall be ACCORDANCE WITH B.S. 449

removed from whole site to clear debris, plants, vegetation & all organic matter. 11-ALL STRUCTURAL STEEL SHALL GRADE 43A

e. After removal of top soil the excavation may proceed upto the required formation 12-DESIGN BASED ON B.S 449 & 5950 AND ALL STRUCTURAL STEEL WORK TO COMPLY AS PER B.S SPECIFICATIONS. 150

level of the foundations.

200

f. In accordance with soil investigation report shallow strip or pad footings are

designed for a safe soil bearing capacity of 100 kn/m2 after soil improvement. 200 200 200 200

g. In accordance with the soil investigation report the formation level of the footings shall

be Min.1200mm below interlock tile level.

PROJECT:

PROPOS D (G M) CO R D SH D - 2 Nos , ( G 1) OFFIC BLOC ,

0.33L1 OR 0.33L2 WHICHEVER IS BIGGER

0.33L1 OR 0.33L2 WHICHEVER IS BIGGER ( G.F) S R IC BLOC ,

0.25 x L1

UTILITY AR A, U.G. AT R TAN & BOUNDARY

OWNER:

M/S. LINE INTERNATIONAL FZE

DEPTH (D) > 750 mm

GOVT.: 4D-01F-1,2,3&4 HAMRIYAH FREEZONE

PLOT N0: AREA:

0.66 x D

MULK : (PHASE -2 )

0.10xL1

0.15xL1 0.15xL2 0.15xL2 0.15xL3

SPAN L1 SPAN L2

House of Architecture

ENGINEERING CONSULTANTS L.L.C

0.33L2 OR 0.33L3 WHICHEVER IS BIGGER TEL. NO: 06-525 4612

FAX. NO: 06-525 4617

P.O. BOX : 1833

1.5 x CANTILEVER SPAN L1 0.25xL1 0.25xL1 SHARJAH, U.A.E.

email:: 1houseofarch@gmail.com

DRAWING TITLE:

L L

ARCHITECT: RASHID SCALE : N.T.S

0.1xL1 0.1xL1

STRUCTURAL ENGR: SUHAIL DRAWN: SREEJITH

CANTILEVER SPAN L1 SPAN L2 MEP.ENGR: N.ABDUL DESIGN FOR : G+M

SPAN L1

CHECKED: RAJA DATE: 13-12-2020

DRAWING NO. REV.

. 0 0 1 TY-01 0

You might also like

- Eecmy Mys Residential Building BoqDocument81 pagesEecmy Mys Residential Building BoqErkiyhu EliasNo ratings yet

- Reinforced Concrete Grade Beams, Piles & Caissons: A Practical Guide for Hillside ConstructionFrom EverandReinforced Concrete Grade Beams, Piles & Caissons: A Practical Guide for Hillside ConstructionNo ratings yet

- Eecmy Mys Residential Building G+2 BoqDocument73 pagesEecmy Mys Residential Building G+2 BoqErkiyhu Elias100% (1)

- Specifications (San Carlos Heights)Document10 pagesSpecifications (San Carlos Heights)Bryan Soriano PascualNo ratings yet

- Annexure B': (Scope of Work & Specifications)Document6 pagesAnnexure B': (Scope of Work & Specifications)district officesNo ratings yet

- AAB 042200 Concrete Unit MasonryDocument6 pagesAAB 042200 Concrete Unit MasonrytewodrosNo ratings yet

- General NotesDocument1 pageGeneral NotesMuhammad Idrees KhanNo ratings yet

- SpecificationDocument5 pagesSpecificationChristian Paul RafolNo ratings yet

- Kubs-Bill 8 - Ancillary BuildingsDocument47 pagesKubs-Bill 8 - Ancillary BuildingsSharkeela ShukriNo ratings yet

- DXB-478-STR - Drawing CommentsDocument19 pagesDXB-478-STR - Drawing Commentsdubai eyeNo ratings yet

- 3.0 Specification Compound Wall BardoliDocument14 pages3.0 Specification Compound Wall BardoliPranav ChovatiyaNo ratings yet

- Precast Reinforced Concrete BarriersDocument30 pagesPrecast Reinforced Concrete BarriersAdnan NajemNo ratings yet

- Eecmy Mys Residental Building G+4Document55 pagesEecmy Mys Residental Building G+4Erkiyhu EliasNo ratings yet

- Project: Proposed Three-Storey Commercial Building Location: 187 J.P. Rizal ST., Brgy. Tejeros Makati City Owner: Anabelle OrinaDocument7 pagesProject: Proposed Three-Storey Commercial Building Location: 187 J.P. Rizal ST., Brgy. Tejeros Makati City Owner: Anabelle Orinatyn de guzmanNo ratings yet

- Purchaser Name: Andrew Henderson Revision Initial Date: ACN: 610 855 260 TNC Engineering Pty LTDDocument18 pagesPurchaser Name: Andrew Henderson Revision Initial Date: ACN: 610 855 260 TNC Engineering Pty LTDSwaminathan VivekananthamNo ratings yet

- Technical Guidance Note: Omnia Wideslab Permanent Formwork Guide To SpecifiersDocument1 pageTechnical Guidance Note: Omnia Wideslab Permanent Formwork Guide To SpecifiersBogdanBNo ratings yet

- Application of Interior Gypsum Plaster: Standard Specification ForDocument9 pagesApplication of Interior Gypsum Plaster: Standard Specification ForMalak HindiNo ratings yet

- Concrete BundsDocument12 pagesConcrete BundsPaul JamesonNo ratings yet

- North West View 1 North East View 2: ClientDocument1 pageNorth West View 1 North East View 2: ClientCSEC Uganda Ltd.No ratings yet

- SAES-Q-001 SAES-Q-001: Criteria For Design and Construction of Concrete StructuresDocument6 pagesSAES-Q-001 SAES-Q-001: Criteria For Design and Construction of Concrete StructuresAbdul HannanNo ratings yet

- Technical Specifications:: Construction of Concrete Pavement For Parking AreaDocument2 pagesTechnical Specifications:: Construction of Concrete Pavement For Parking AreaAnton_Young_1962No ratings yet

- Ech-Boq (Revised - 07-03-2018)Document153 pagesEch-Boq (Revised - 07-03-2018)shaffequeNo ratings yet

- Proposed Multipurpose Building - S1Document1 pageProposed Multipurpose Building - S1Eric Estremera EstilleroNo ratings yet

- Bill No. New-16, Construction of WSS Administration Bldg. (G+3)Document26 pagesBill No. New-16, Construction of WSS Administration Bldg. (G+3)Solomon GuyassaNo ratings yet

- Morth 1700 Structural ConcreteDocument23 pagesMorth 1700 Structural ConcreteRamesh88% (40)

- Model Infrastructure SpecsDocument13 pagesModel Infrastructure Specsjordan waldmanNo ratings yet

- SpecificationsDocument21 pagesSpecificationsamsdeleon.12No ratings yet

- General Notes and Specifications For Structural Works (Issued As A Supplement To The Structural Plans)Document12 pagesGeneral Notes and Specifications For Structural Works (Issued As A Supplement To The Structural Plans)Brian SantosNo ratings yet

- Compound Wall OfferDocument4 pagesCompound Wall OfferMd AbidNo ratings yet

- SECTION 03170 Concrete Finishing: Caltrain Standard SpecificationsDocument10 pagesSECTION 03170 Concrete Finishing: Caltrain Standard Specificationsابراهيم ابو المجدNo ratings yet

- Section 03370-ShotcreteDocument7 pagesSection 03370-ShotcreteMØhãmmed ØwięsNo ratings yet

- Prity Abstract SheetDocument3 pagesPrity Abstract Sheetsachin shingadeNo ratings yet

- 2304191854-Price BidDocument11 pages2304191854-Price BidpanikarickyNo ratings yet

- TDS - Bronco Cemshield SBSDocument2 pagesTDS - Bronco Cemshield SBSShreyansh UdaniNo ratings yet

- ML-15 - Concrete Coating PDFDocument13 pagesML-15 - Concrete Coating PDFDeepakNo ratings yet

- t000005030 - Filename2 - Final Tender ScheduleDocument71 pagest000005030 - Filename2 - Final Tender SchedulePratik VermaNo ratings yet

- Total Cost For Boundary WallDocument1 pageTotal Cost For Boundary WallVenkata PrasadNo ratings yet

- TPI: Thermal Performance IndexDocument8 pagesTPI: Thermal Performance IndexKavya MadhuNo ratings yet

- Concrete Part 5Document3 pagesConcrete Part 5hasanabdul5923No ratings yet

- IS218.02B - Suggested Specification For Concrete Parking AreasDocument2 pagesIS218.02B - Suggested Specification For Concrete Parking AreasfarhanNo ratings yet

- عمار الانشائي - compressedDocument36 pagesعمار الانشائي - compressedzakariaNo ratings yet

- Section 11 - TankingDocument5 pagesSection 11 - TankingShing Faat WongNo ratings yet

- Guideline Notes For RCC WorkDocument10 pagesGuideline Notes For RCC Workvikas WaghmareNo ratings yet

- Fountain ProgressiveDocument14 pagesFountain Progressivebetelehem hailuNo ratings yet

- Take OffDocument33 pagesTake OffAhmed KelifNo ratings yet

- 17.sec.1700 (Structural Concrete)Document16 pages17.sec.1700 (Structural Concrete)aalignup arc & const. pvt ltdNo ratings yet

- General Notes: Masonry Option Notes (Cont.) :: FDOT 2014 Design Standards FDOT 2014Document10 pagesGeneral Notes: Masonry Option Notes (Cont.) :: FDOT 2014 Design Standards FDOT 2014Arjie alimNo ratings yet

- Concrete ToppingDocument8 pagesConcrete ToppingStraus WaseemNo ratings yet

- 12 Marla BoqDocument20 pages12 Marla BoqNaouman Bin BashirNo ratings yet

- Construction of Theatre in Chulaimbo HospitalDocument18 pagesConstruction of Theatre in Chulaimbo HospitalJoshuaNo ratings yet

- EARLY WORKS - Civil & Preliminary BOQDocument1 pageEARLY WORKS - Civil & Preliminary BOQDeepa Junnarkar DegwekarNo ratings yet

- Project Title: Construction of One Storey Residential Building Location: Brgy. Ubagan, Sto. Tomas, La Union Project Owner: Mrs. Teresita CanlasDocument14 pagesProject Title: Construction of One Storey Residential Building Location: Brgy. Ubagan, Sto. Tomas, La Union Project Owner: Mrs. Teresita CanlasArnold VercelesNo ratings yet

- Package Lot A - Upper and Lower Dams Upper Cisokan Pumped Storage Power Plant Project Section Teclmical SpecificationsDocument1 pagePackage Lot A - Upper and Lower Dams Upper Cisokan Pumped Storage Power Plant Project Section Teclmical Specificationsdana setiawanNo ratings yet

- Boq of Praposed Public Library at Pune: NO Item Qty. Unit Rate AmountDocument20 pagesBoq of Praposed Public Library at Pune: NO Item Qty. Unit Rate AmountSaurabh KotechaNo ratings yet

- To Rectify Spalling Concrete at Block 4 Level 6Document2 pagesTo Rectify Spalling Concrete at Block 4 Level 6atienzajury24No ratings yet

- Project:: Date & Revision NODocument4 pagesProject:: Date & Revision NODeepa Junnarkar DegwekarNo ratings yet

- 0809201713-Tender For Civil Work - Price Bid - 07.09.2020Document7 pages0809201713-Tender For Civil Work - Price Bid - 07.09.2020Prakash InteriorsNo ratings yet

- 3CC System Technical SpecificationDocument3 pages3CC System Technical SpecificationAnonymous qTP5oq7gNo ratings yet

- West Trading DocsDocument1 pageWest Trading DocsSuhail AhamedNo ratings yet

- Crane Combination SheetDocument4 pagesCrane Combination SheetSuhail AhamedNo ratings yet

- Wind Loading With Cp3Document4 pagesWind Loading With Cp3Suhail AhamedNo ratings yet

- Water E-Form NewDocument2 pagesWater E-Form NewSuhail AhamedNo ratings yet

- Design of Tie Beam Design Of: Tb5 at AxisDocument7 pagesDesign of Tie Beam Design Of: Tb5 at AxisSuhail AhamedNo ratings yet

- Structural Design Calculations: Rev: 00 Job RK-21227 Building A1 Date: 31-Oct-22Document172 pagesStructural Design Calculations: Rev: 00 Job RK-21227 Building A1 Date: 31-Oct-22Suhail AhamedNo ratings yet

- S-002 Compound Wall ExtDocument1 pageS-002 Compound Wall ExtSuhail AhamedNo ratings yet

- Pedestal For The Steel ColumnDocument1 pagePedestal For The Steel ColumnSuhail AhamedNo ratings yet

- Beam Col ConnectionDocument1 pageBeam Col ConnectionSuhail AhamedNo ratings yet

- Layout For The SkirmDocument1 pageLayout For The SkirmSuhail AhamedNo ratings yet

- Tie Beam and Floor DetailDocument1 pageTie Beam and Floor DetailSuhail AhamedNo ratings yet

- Footing Layout: Schedule of R.C.C FootingsDocument1 pageFooting Layout: Schedule of R.C.C FootingsSuhail AhamedNo ratings yet

- Car Parking Steel Structural DetailDocument1 pageCar Parking Steel Structural DetailSuhail AhamedNo ratings yet

- Column Layout (Above Tie Beam) : F N F NDocument1 pageColumn Layout (Above Tie Beam) : F N F NSuhail AhamedNo ratings yet

- Mechanical Structural Layout On Production UnitDocument1 pageMechanical Structural Layout On Production UnitSuhail AhamedNo ratings yet

- Shear Friction: Get The Code Based Concept Once and For All .Document14 pagesShear Friction: Get The Code Based Concept Once and For All .Suhail AhamedNo ratings yet

- Pipe Rack DesignDocument8 pagesPipe Rack DesignSuhail AhamedNo ratings yet

- Andyrahman Brings Traditional Indonesian Architecture To 'Omah Boto'Document24 pagesAndyrahman Brings Traditional Indonesian Architecture To 'Omah Boto'Suhail AhamedNo ratings yet

- Ministry of Foreign Affairs and International Cooperation: Application Number: Created OnDocument2 pagesMinistry of Foreign Affairs and International Cooperation: Application Number: Created OnSuhail AhamedNo ratings yet

- Villa STR Sudan SampleDocument21 pagesVilla STR Sudan SampleSuhail AhamedNo ratings yet

- Minutes of Meeting TemplateDocument2 pagesMinutes of Meeting TemplateSuhail AhamedNo ratings yet

- Air TicketDocument4 pagesAir TicketSuhail AhamedNo ratings yet

- Molecular Biology Report: Test Result MethodologyDocument1 pageMolecular Biology Report: Test Result MethodologySuhail AhamedNo ratings yet

- Bike ParkingDocument1 pageBike ParkingSuhail AhamedNo ratings yet

- S-241 - ARCH - 04.05.2022-ModelDocument1 pageS-241 - ARCH - 04.05.2022-ModelSuhail AhamedNo ratings yet

- Covid-19 Vaccination Card: Peer Mohamed Sayan Sheik Abdul Khader V2018686 V2018686 784198926524178 784198926524178Document1 pageCovid-19 Vaccination Card: Peer Mohamed Sayan Sheik Abdul Khader V2018686 V2018686 784198926524178 784198926524178Suhail AhamedNo ratings yet

- Peer PlotDocument1 pagePeer PlotSuhail AhamedNo ratings yet

- A Zees PassportDocument2 pagesA Zees PassportSuhail AhamedNo ratings yet

- Industry 4.0 Deployment in The Construction Industry: A Bibliometric Literature Review and UK-based Case StudyDocument25 pagesIndustry 4.0 Deployment in The Construction Industry: A Bibliometric Literature Review and UK-based Case StudySuhail AhamedNo ratings yet

- Xenon 21-22 Sheet Without Answer (EUDIOMETRY)Document3 pagesXenon 21-22 Sheet Without Answer (EUDIOMETRY)Krishna GoyalNo ratings yet

- Copia de 2. Head-Less Frozen Shimp Flow DiagramDocument10 pagesCopia de 2. Head-Less Frozen Shimp Flow DiagramjonathanNo ratings yet

- Piping Link-Seal CatalogDocument42 pagesPiping Link-Seal CatalogChandravadanNo ratings yet

- Shaurya Cement Industries Private LimitedDocument14 pagesShaurya Cement Industries Private LimitedValipireddy NagarjunNo ratings yet

- Zoltek™ Px30 Knit Fabric (Kf07) : Technical DatasheetDocument1 pageZoltek™ Px30 Knit Fabric (Kf07) : Technical DatasheetkebenshanNo ratings yet

- Rates For TilesDocument5 pagesRates For TilesLamichhane SauravNo ratings yet

- Casting Manufacturing Lab Report2Document16 pagesCasting Manufacturing Lab Report2Naeem DeenNo ratings yet

- Friction and Friction Coefficients For Various MaterialsDocument7 pagesFriction and Friction Coefficients For Various MaterialsHilman NurzenNo ratings yet

- 2020 11 Isolation-Rooms PlumbingDocument13 pages2020 11 Isolation-Rooms PlumbingZidd PerezNo ratings yet

- Process Flow Chart of Weaving - Textile LearnerDocument4 pagesProcess Flow Chart of Weaving - Textile LearnerGOWTHAM CHANDRUNo ratings yet

- Etching Titanium With HF and Nitric Acid SolutionsDocument13 pagesEtching Titanium With HF and Nitric Acid SolutionsKazuoNo ratings yet

- The Effects of Heat Treating A Martensitic Stainless SteelDocument62 pagesThe Effects of Heat Treating A Martensitic Stainless SteelNoel FrancisNo ratings yet

- Additive Manufacturing of Bimetallic StructuresDocument40 pagesAdditive Manufacturing of Bimetallic StructuresJuan JimenezNo ratings yet

- Manufacturing and PerformanceDocument13 pagesManufacturing and PerformanceALEXA FRYNo ratings yet

- Bamboo Industry Value Chain PresentationDocument39 pagesBamboo Industry Value Chain Presentationapi-19975232No ratings yet

- Piping Basis of DesignDocument19 pagesPiping Basis of DesignMajid DixonNo ratings yet

- A Break Through Fluid Technology in Acidizing SandstoneDocument12 pagesA Break Through Fluid Technology in Acidizing SandstoneRamanamurthy PalliNo ratings yet

- International Standard: Plain Bearings - Multilayer Materials For Thin-Walled Plain BearingsDocument12 pagesInternational Standard: Plain Bearings - Multilayer Materials For Thin-Walled Plain BearingsabramNo ratings yet

- Processing and Properties of Sewing Threads: Indian Journal of Textile Research August 2009Document10 pagesProcessing and Properties of Sewing Threads: Indian Journal of Textile Research August 2009Randhir Kumar GuptaNo ratings yet

- ACI 325.9R - Guide For Construction of Concrete Pavements and Bases (R1997)Document27 pagesACI 325.9R - Guide For Construction of Concrete Pavements and Bases (R1997)tariqkhanNo ratings yet

- Micronutrient Deficiencies in Blueberries and Their Correction Dr. David Kissel University of Georgia Athens GADocument27 pagesMicronutrient Deficiencies in Blueberries and Their Correction Dr. David Kissel University of Georgia Athens GADavid GluhićNo ratings yet

- 2012 International Buyer's Guide: Materials Preparation and Analysis Consumables Equipment and AccessoriesDocument53 pages2012 International Buyer's Guide: Materials Preparation and Analysis Consumables Equipment and AccessoriesAndrés RodríguezNo ratings yet

- Sell Sheet Optal XP en FinalDocument2 pagesSell Sheet Optal XP en Finalalguna54No ratings yet

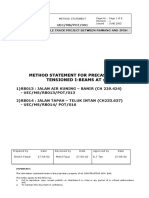

- Method Statement For Precast Post Tensioned I-Beams atDocument8 pagesMethod Statement For Precast Post Tensioned I-Beams atMAYMODERN STEELNo ratings yet

- BS en Iso 1833-12-2010Document12 pagesBS en Iso 1833-12-2010EmkFataAliraqNo ratings yet

- Technical Data Sheet: Rhenocure® DPGDocument2 pagesTechnical Data Sheet: Rhenocure® DPGKeremNo ratings yet

- Manufacturing of Plastic Sand Bricks From Polypropylene and Polyethylene Waste PlasticDocument8 pagesManufacturing of Plastic Sand Bricks From Polypropylene and Polyethylene Waste Plasticgalolo9334No ratings yet

- Managing An On-Premises LaundryDocument4 pagesManaging An On-Premises LaundryGil TeodosipNo ratings yet

- UPVC Pressure Pipes Brochure NEW AW DigitalDocument16 pagesUPVC Pressure Pipes Brochure NEW AW Digitalhazzaa3091993 rashidNo ratings yet

- Sae J525Document6 pagesSae J525brunoNo ratings yet