Professional Documents

Culture Documents

Accelerating Biopharmaceutical Tech Transfer-Compressed

Uploaded by

John Tracy0 ratings0% found this document useful (0 votes)

5 views3 pagesOriginal Title

Accelerating_biopharmaceutical_tech_transfer-compressed

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

5 views3 pagesAccelerating Biopharmaceutical Tech Transfer-Compressed

Uploaded by

John TracyCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 3

Accelerating

biopharmaceutical

tech transfer to address

unmet medical needs

K ey activities and strategies to accelerate biopharmaceutical tech transfer,

and challenges to overcome in order to support

faster development and manufacturing programs

About the author

Anthony Newcombe

Senior Director of Project Management at Samsung Biologics

Diana Brown

Senior Specialist in Project Management at Samsung Biologics

Anthony Newcombe, PhD, is a Diana Brown, MBA, is a Senior

Senior Director of Project Manage- Specialist in Project Management.

ment at Samsung Biologics. Dr. Ms. Brown holds a Masters in

Newcombe holds a PhD in Biochem- Business Administra�on from the

istry from the MRC Na�onal Ins�tute Kenan Flagler Business School at the

for Medical Research, London, UK University of North Carolina at

and is a Fellow of the Royal Society Chapel Hill and a bachelors of

of Chemistry (FRSC), UK. Chemical Engineering from North

Carolina State University.

Copyright Samsung Biologics. All rights reserved.

Availability of Equipment and and support troubleshoo�ng if required. As part

Biopharmaceu�cal development is a long of an accelerated program, laboratory scale

Facility Fit

journey with uncertain�es, and outsourc- verifica�on runs may need to be undertaken

ing the manufacturing service serves as The success of an accelerated tech transfer concurrently with a large scale engineering run

an integral component of successful depends on equipment availability, facility fit, or may be considered op�onal depending on

product launch. Technology Transfer is and o�en the robustness of the process the level of process understanding and

the ini�al step of outsourcing and transferred. Lead �mes for the purchase and characteriza�on undertaken prior to tech

well-designed tech transfer is cri�cal for delivery of large scale bioprocess equipment, transfer. Due to the �ming and availability of

seamless scale up and robust cGMP such as UF/DF systems, chromatography small scale verifica�on runs, processes that

produc�on of biopharmaceu�cals. systems, and stainless steel tanks may be long, have been extensively characterized and used

and customized equipment may also result in for manufacture of product at commercial scale

lengthy delays that could impact tech transfer minimize the poten�al risk of issues and the

During bioprocess tech transfer, opera- �melines. Unless the manufacturing process is need for technical support and troubleshoo�ng

�onal & analy�cal methods, technolo- transferred to a dedicated facility, an accelerat- within process development laboratories. The

gies, and knowledge are transferred from ed tech transfer to a mul�-product contract joint tech transfer team and the business team

the sending site to the receiving site, and manufacturing organiza�on is o�en be�er have to evaluate if the risk of not having the

such transfer enables the recipients to suited to typical pla�orm manufacturing small scale laboratory verifica�on data is

strategically plan and execute process processes that fit with the facility and equip- acceptable before commencing accelerated

valida�on and manufacturing. Timelines ment available. Undertaking a facility fit tech transfer.

of tech transfer can vary widely, depend- assessment early in the process is therefore

ing upon the scope and complexity of the essen�al to determining any equipment gaps or

projects, which are the combina�on of process changes that may be required to Accelerated Preparation of

various factors such as requirements and support an accelerated tech transfer. Op�mized Documentation

lead-�mes for analy�cal development, processes that have been developed to reduce As part of an accelerated tech transfer,

equipment availability, raw materials and processing �mes and solu�on volumes may be expedited prepara�on of documents should be

�me needed to generate the required problema�c because of minimum volumes considered. To permit �me for review and

documenta�on to support GMP manu- required due to tank and vessel sizes available approval of documents at the receiving site,

facturing. Now, how can we ensure at commercial scale. Therefore, where possible, controlled documents required to support

smooth, effec�ve tech transfer without process development should consider the performance qualifica�on (PPQ) batches (e.g.,

was�ng valuable �me? feasibility of expedited scale up and commercial SOPs, batch records, process valida�on master

manufacture, par�cularly if the process is plan) may need to be prepared concurrently

transferred to the first commercial facility. with an engineering run. Due to an urgent need

Where the purchase of new produc�on

Proper Planning and Timely for clinical or commercial material, there may

equipment is unavoidable or equipment is

Communication be limited �me between an engineering run

transferred internally from another site or and a subsequent PPQ campaign, and therefore

It is essen�al to outline all required ac�vi�es as facility, a process for accelerated equipment accelerated tech transfer is be�er suited to

well as an�cipated risks of tech transfer and installa�on and qualifica�on can help to reduce commercial products manufactured at large

then allocate resources and set milestones with tech transfer �melines. scale using a pla�orm process and are likely to

priori�es. Since tech transfer is not a one-way

require minimal process or documenta�on

street, such plans need to be shared, agreed

upon, and closely communicated with both Timing of changes between an engineering run and PPQ

campaign. Although there may be a cri�cal

sides along the way. The overall project plan Small Scale Verification Runs

that lays out all the ac�vi�es and tasks required need to provide material for the clinic, this

Laboratory scale verifica�on runs undertaken strategy does however require careful evalua-

including a communica�on plan will serve as a

within process development laboratories are �on, because tech transfer typically involves

roadmap for the joint team members involved

o�en included as part of a tech transfer different produc�on equipment, u�li�es, and

in the process and will help the alignment in

program. Typically data from small scale studies site documenta�on; and engineering runs

execu�on.

is available prior to the start of an engineering provide an opportunity to test equipment,

to provide addi�onal process understanding documenta�on, and systems prior to the

©2020 Samsung Biologics. All rights reserved

manufacture of GMP material for human use. Comprehensive, ing health cer�ficate (MHC), export cer�ficate,

Again, the joint tech transfer and business and a cer�ficate of analysis may be required for

yet Prioritized

development teams have to evaluate if higher importa�on of required cell banks, depending

risk of clinical run or PPQ run is acceptable

Analytical Method Transfer on the cell bank exporter and country of

before deciding to skip the Engineering Run. Transfer and valida�on of analy�cal methods manufacture. For importa�on of cell banks for

Face-to- face or virtual mee�ngs may need to and know-how to a receiving site are o�en part GMP use, addi�onal informa�on is typically

be considered to expedite review of manufac- of the cri�cal path for the tech transfer required, such as TSE / BSE statement and

turing documents and process data, and this �meline. Analy�cal methods for in-process and details of cell bank qualifica�on status and

may need to be undertaken a�er comple�on of release tes�ng are typically transferred to the several weeks may be required to coordinate

individual unit opera�ons during an engineering receiving site as part of an analy�cal tech the documenta�on needed. Time required to

run to minimize any delays and iden�fy any transfer program. Transfer and valida�on of obtain temperature data from data loggers used

document or poten�al process changes some analy�cal methods may require several during shipping of cell banks may also need to

required. months to complete, par�cularly for cell based be considered, as verifica�on of the shipping

or potency assays that may require several days temperature is usually a requirement for

for each test to obtain a result. To support an release of the cells for use in GMP manufactur-

Sourcing & Management of accelerated tech transfer �meline, analy�cal ing.

Raw Materials (RM) transfer should focus on the qualifica�on of

Obtaining the required raw materials for methods that are needed for in-process control

Tech transfer of biopharmaceu�cal processes is

manufacturing campaigns is o�en on the cri�cal (IPC) tes�ng which provide data needed to

par�cularly challenging and should be accurate-

path. Stocks of common raw materials may be con�nue manufacturing and specific tests that

ly planned and executed by an experienced

readily available to support other produc�on will provide product quality data to iden�fy any

team with proven success in transferring

ac�vi�es (for example, NaCl or NaOH) or poten�al process or product issues as soon as

processes from laboratory or pilot-scale to

sourced from other qualified suppliers, but possible. Compendial methods (for example,

commercial GMP opera�ons. Aggressive

specialized raw materials, such as cell culture pH, and conduc�vity measurements) typically

�melines associated with biopharmaceu�cal

media and chromatography resins are o�en do not require an assay transfer and can be

tech transfer have been historically associated

sourced from a single supplier and typically qualified rela�vely quickly. Samples may be

with challenges due to limited tolerance within

cannot be easily subs�tuted. Raw materials that shipped for release tes�ng at an exis�ng

the produc�on schedule to address unexpected

are considered cri�cal, such as excipients (sending site) laboratory un�l method transfer

issues related to cri�cal path ac�vi�es. To

sourced from a specific vendor, may need to be is complete. As part of an accelerated tech

support the development and manufacture of

evaluated and supply lead �mes as well as transfer program, comple�on of all method

poten�al therapies for the global COVID-19

op�ons for expedited procurement should be transfer ac�vi�es may not be completed un�l

pandemic, accelerated technology transfer with

assessed as soon as possible. Addi�onally, a�er comple�on of performance qualifica�on

more innova�ve strategies should be adopted

cri�cal reagents containing animal-derived (PPQ) batches. This requires shipping of

to allow for rapid engagement and u�liza�on of

components may also be long lead-�me items, selected samples to the sending site for tes�ng

cross-func�onal teams to coordinate faster tech

subject to more stringent import restric�ons. un�l method qualifica�on or valida�on is

transfer programs and manage cri�cal path

An alterna�ve op�on is to ship purchased raw completed at the receiving site.

ac�vi�es. Whilst a number of factors need to be

materials from another site or facility. Shipment

carefully considered, with the appropriate

of research cell banks may be considered under

Importation Requirements knowledge and experience, it is possible to

quaran�ne with mycoplasma and sterility test

results whilst awai�ng further analysis, and

for Cell Banks (if applicable) accelerate tech transfer ac�vi�es while avoiding

common pi�alls. It is important to understand

shipment of reference standards and cri�cal To support an expedited tech transfer, shipment

that some addi�onal risks will follow with such

raw materials for QC laboratories may be split of cell banks is one of the first tech transfer

rapid tech transfer. Se�ng expecta�ons and

into mul�ple deliveries to minimize the risk of ac�vi�es to coordinate, and an understanding

tolerance of these addi�onal risks to the joint

customs delays impac�ng the project. Strate- of the incoming process for receipt of cell banks

tech transfer team will enable efficient decision

gies for sufficient inventory buffer or (WCB / MCB) at the receiving site is needed.

making and successful tech transfer within the

mul�-sourcing of cri�cal raw material may also Importa�on of vials of cell banks may be

shortest �me possible.

need to be evaluated to minimize risk to GMP required to undertake small scale laboratory

manufacturing ac�vi�es. studies, and documents such as a manufactur-

©2020 Samsung Biologics. All rights reserved

You might also like

- PDA TR 65 Technology Transfer技术转移-中英对照GELGEDocument85 pagesPDA TR 65 Technology Transfer技术转移-中英对照GELGECelven Shr100% (1)

- GAMP 5 - Enabling Innovation: by Sion WynDocument4 pagesGAMP 5 - Enabling Innovation: by Sion WyndekanacNo ratings yet

- Probability Theory - VaradhanDocument6 pagesProbability Theory - VaradhanTom HenNo ratings yet

- Zgouras Catherine Team Together 1 Teachers BookDocument257 pagesZgouras Catherine Team Together 1 Teachers Booknata86% (7)

- Tech Transfer 1Document6 pagesTech Transfer 1Rajesh KesarlaNo ratings yet

- The FDA Group - Preparing For A Life Science Validation ProjectDocument11 pagesThe FDA Group - Preparing For A Life Science Validation ProjectEmmanuel-Landry N'Gotta Amp67% (3)

- GMPs For Equipment Utilities FacilitiesDocument6 pagesGMPs For Equipment Utilities FacilitiesEdgardo Ed RamirezNo ratings yet

- CNC Milling ReportDocument15 pagesCNC Milling ReportStarscream Aisyah78% (37)

- A First Etymological Dictionary of BasquDocument29 pagesA First Etymological Dictionary of BasquDaily MailNo ratings yet

- ECA Product Transfer 2023Document4 pagesECA Product Transfer 2023Angel Fernando Santamaria MoralesNo ratings yet

- Planning For Successful Technology TransferDocument5 pagesPlanning For Successful Technology TransfermmmmmNo ratings yet

- Gnipst 4 30 5694 2.1Document5 pagesGnipst 4 30 5694 2.1Antar GayenNo ratings yet

- Power Plant Startup and Commissioning Services: A Proven Plan Using Dedicated ResourcesDocument8 pagesPower Plant Startup and Commissioning Services: A Proven Plan Using Dedicated ResourcesPiyush SinhaNo ratings yet

- BP702T Ip IiDocument29 pagesBP702T Ip IiTurbo ChargedNo ratings yet

- BP702T Ip IiDocument29 pagesBP702T Ip IiMukund JhaNo ratings yet

- Handbook Technology TransferDocument15 pagesHandbook Technology Transferzakarya wadiNo ratings yet

- Articulo Tecnologia de TransferenciaDocument10 pagesArticulo Tecnologia de Transferencia20172504No ratings yet

- Technology Transfer From R&D To ProductionDocument16 pagesTechnology Transfer From R&D To ProductionRutuja Chougale100% (1)

- ECA Product TransferDocument4 pagesECA Product TransfermmmmmNo ratings yet

- TRANSFER OF TECHNOLOGY ManuDocument4 pagesTRANSFER OF TECHNOLOGY Manuheyyo ggNo ratings yet

- Technology TransferDocument68 pagesTechnology TransferPhúc CaoNo ratings yet

- When Standardization Meets Customization: by Jeremy RautenbachDocument3 pagesWhen Standardization Meets Customization: by Jeremy RautenbachVishal MarhattaNo ratings yet

- Flexpro Whitepaper Guide To A Successful Drug Development Technology Transfer 1Document12 pagesFlexpro Whitepaper Guide To A Successful Drug Development Technology Transfer 1zakarya wadiNo ratings yet

- Validation and Facility Design PDFDocument16 pagesValidation and Facility Design PDFjpabloqfNo ratings yet

- F1286 TarjomeFa EnglishDocument5 pagesF1286 TarjomeFa EnglishMohsen GolmohammadiNo ratings yet

- Gnipst 4 30 5694 2.2Document2 pagesGnipst 4 30 5694 2.2Antar GayenNo ratings yet

- From Single To A Multiproduct Facility, Key ConsiderationsDocument8 pagesFrom Single To A Multiproduct Facility, Key ConsiderationsCathal DoranNo ratings yet

- TT ForwardDocument28 pagesTT ForwardKeshavTiwariNo ratings yet

- Scaling Up Biotech Processes-A Better Alternative To Traditional Approach - 2019 (Good)Document5 pagesScaling Up Biotech Processes-A Better Alternative To Traditional Approach - 2019 (Good)daraj darajNo ratings yet

- Technology Transfer Plan & Exhibit TJDocument19 pagesTechnology Transfer Plan & Exhibit TJTejashreeNo ratings yet

- Pilot Plant Scale Up TechniquesDocument32 pagesPilot Plant Scale Up TechniquesDo Something GoodNo ratings yet

- Oil and Gas Major Retires Mainframe After Upstream Downstream SplitDocument3 pagesOil and Gas Major Retires Mainframe After Upstream Downstream SplitAmit GaragNo ratings yet

- AppNotes - Poultry by Interwave TechnologyDocument3 pagesAppNotes - Poultry by Interwave TechnologySandeep KulkarniNo ratings yet

- Bio Based Chemical Fermentation Biomass Separation Evaporation Crystallization Drying GeaDocument6 pagesBio Based Chemical Fermentation Biomass Separation Evaporation Crystallization Drying GeaxinlizimuNo ratings yet

- Technical Webinar Program: Learn More With OurDocument16 pagesTechnical Webinar Program: Learn More With OurAgung NugrahaNo ratings yet

- Professional Opportunities in Eni For Chemical EngineersDocument4 pagesProfessional Opportunities in Eni For Chemical Engineersanon_552162647No ratings yet

- C - PALL - 303PA BioDocument15 pagesC - PALL - 303PA Biocarlos tNo ratings yet

- QC Specialist Holly Springs, NC 12 Months: Minimum RequirementsDocument7 pagesQC Specialist Holly Springs, NC 12 Months: Minimum Requirementschintan patelNo ratings yet

- Tentative BrochureDocument4 pagesTentative BrochureprimadNo ratings yet

- Dy. Manager (Process Engg.)Document3 pagesDy. Manager (Process Engg.)vishal9patel-63No ratings yet

- Validation in A Small Pharmaceutical Company PDFDocument6 pagesValidation in A Small Pharmaceutical Company PDFjpabloqfNo ratings yet

- A Solution Blueprint For Devops: Executive SummaryDocument16 pagesA Solution Blueprint For Devops: Executive SummarySalam DamitNo ratings yet

- A Solution Blueprint For Devops: Executive SummaryDocument16 pagesA Solution Blueprint For Devops: Executive SummaryJohn PattersonNo ratings yet

- PE - MayJune22 - Moving From Cleanroom To Isolation Technology For ATMPsDocument6 pagesPE - MayJune22 - Moving From Cleanroom To Isolation Technology For ATMPssoceljoanNo ratings yet

- Executive Master Program: Production & Operations ManagementDocument8 pagesExecutive Master Program: Production & Operations ManagementAliElkhatebNo ratings yet

- Technology Transfer Embodies Both The Transfer of Documentation and The Demonstrated Ability of The Receiving UnitDocument18 pagesTechnology Transfer Embodies Both The Transfer of Documentation and The Demonstrated Ability of The Receiving UnitkoolmanissshNo ratings yet

- Navigating Cell Therapy Process DevelopmentDocument11 pagesNavigating Cell Therapy Process DevelopmentQuynhMai TrinhNo ratings yet

- ECA ProductTransfer 2015Document6 pagesECA ProductTransfer 2015Erik HCNo ratings yet

- JD - Process EngineerDocument3 pagesJD - Process EngineerAdityaNo ratings yet

- Production Planning and Material Control ManagerDocument3 pagesProduction Planning and Material Control ManagerRajVardhanNo ratings yet

- My ThesisDocument49 pagesMy ThesisSujit DasNo ratings yet

- Materials Today: Proceedings: C. Hemalatha, K. Sankaranarayanasamy, N. DurairaajDocument5 pagesMaterials Today: Proceedings: C. Hemalatha, K. Sankaranarayanasamy, N. DurairaajNICHOLAS BINSARPANDAPOTANNo ratings yet

- SPE-KSA-614-MS, Keys To Successful Brownfield Engineering ExecutionDocument16 pagesSPE-KSA-614-MS, Keys To Successful Brownfield Engineering ExecutionAtef MoussaNo ratings yet

- L2 Support Maintenance and Support For Global Business Delivery ApplicationDocument2 pagesL2 Support Maintenance and Support For Global Business Delivery ApplicationshNo ratings yet

- ICG WP Refinery TurnaroundsDocument2 pagesICG WP Refinery TurnaroundsOlumide AjayiNo ratings yet

- Scale Down Biopharma - EIB 2013 PDFDocument17 pagesScale Down Biopharma - EIB 2013 PDFGeetanjali HubliNo ratings yet

- MD Shahnewaz Sabit Faisal: Phone: Home: EmailDocument4 pagesMD Shahnewaz Sabit Faisal: Phone: Home: Emailkiran2710No ratings yet

- Advanced Pharma Technology Transfer 24990Document5 pagesAdvanced Pharma Technology Transfer 24990Julia ShulgaNo ratings yet

- Fairfield Institute of Management and TechnologyDocument10 pagesFairfield Institute of Management and TechnologychandniNo ratings yet

- Avantor Services Equipment Services WhitepaperDocument8 pagesAvantor Services Equipment Services WhitepaperM.AhmedNo ratings yet

- Facility Validation: A New Approach: Process InvolvementDocument4 pagesFacility Validation: A New Approach: Process InvolvementsukmaNo ratings yet

- Quizlet Unit1Document6 pagesQuizlet Unit1Mohamed AhmedNo ratings yet

- Aristotle Metaphysics Lambda Accessed 201111 Classicalk LibraryDocument19 pagesAristotle Metaphysics Lambda Accessed 201111 Classicalk Librarygijsbo2000No ratings yet

- SAP Solution Manager - CHARM - Retrofit - Change Request Management Enhanced RetrofitDocument61 pagesSAP Solution Manager - CHARM - Retrofit - Change Request Management Enhanced RetrofitARPITA BISWASNo ratings yet

- Hume 100 ReviewerDocument7 pagesHume 100 ReviewerShai GaviñoNo ratings yet

- Typical Cable Laying Details For Direct Buried, Low Tension CablesDocument9 pagesTypical Cable Laying Details For Direct Buried, Low Tension CableslataNo ratings yet

- Practicewith Argument Athletesas ActivistsDocument30 pagesPracticewith Argument Athletesas ActivistsRob BrantNo ratings yet

- PCM 2.4l Turbo 5 de 5Document2 pagesPCM 2.4l Turbo 5 de 5Felix VelasquezNo ratings yet

- ALTS150-12P Datasheet1Document2 pagesALTS150-12P Datasheet1mamloveNo ratings yet

- Research Project Presentation of Jobairul Karim ArmanDocument17 pagesResearch Project Presentation of Jobairul Karim ArmanJobairul Karim ArmanNo ratings yet

- Pamphlet 89 Chlorine Scrubbing SystemsDocument36 pagesPamphlet 89 Chlorine Scrubbing Systemshfguavita100% (4)

- Ad For Guru Ned'S Enlightenment Masterclass 1 of 33Document33 pagesAd For Guru Ned'S Enlightenment Masterclass 1 of 33ElliuggNo ratings yet

- ToiletsDocument9 pagesToiletsAnonymous ncBe0B9bNo ratings yet

- Chemical Engineering & Processing: Process Intensi Fication: ArticleinfoDocument9 pagesChemical Engineering & Processing: Process Intensi Fication: Articleinfomiza adlinNo ratings yet

- Hypothesis Testing Random MotorsDocument8 pagesHypothesis Testing Random MotorsLinn ArshadNo ratings yet

- Classical Theories of Economic GrowthDocument16 pagesClassical Theories of Economic GrowthLearner8494% (32)

- Mediator Analysis of Job Embeddedness - Relationship Between Work-Life Balance Practices and Turnover IntentionsDocument15 pagesMediator Analysis of Job Embeddedness - Relationship Between Work-Life Balance Practices and Turnover IntentionsWitty MindsNo ratings yet

- Norberto Elias: Graduation of Teach Portuguese Language With Ability in EnglishDocument14 pagesNorberto Elias: Graduation of Teach Portuguese Language With Ability in EnglishGildo Joaquim FranciscoNo ratings yet

- SQL - Day 2: Structured Query LanguageDocument10 pagesSQL - Day 2: Structured Query LanguageNight KingNo ratings yet

- 2018-2019 Annual Algebra Course 1 Contest: InstructionsDocument2 pages2018-2019 Annual Algebra Course 1 Contest: InstructionsNaresh100% (1)

- Operation and Service 69UG15: Diesel Generator SetDocument72 pagesOperation and Service 69UG15: Diesel Generator Setluis aguileraNo ratings yet

- The Data Driven AuditDocument34 pagesThe Data Driven AuditMon compte Mon compteNo ratings yet

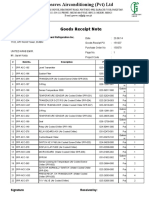

- Goods Receipt Note: Johnson Controls Air Conditioning and Refrigeration Inc. (YORK) DateDocument4 pagesGoods Receipt Note: Johnson Controls Air Conditioning and Refrigeration Inc. (YORK) DateSaad PathanNo ratings yet

- DAY 3 STRESS Ielts NguyenhuyenDocument1 pageDAY 3 STRESS Ielts NguyenhuyenTĩnh HạNo ratings yet

- WT Capability Statement PE 2020Document1 pageWT Capability Statement PE 2020Muhannad SuliemanNo ratings yet

- Noth PicturesDocument17 pagesNoth PicturesJana AssaNo ratings yet

- Managing Markets Strategically: Professor Noel CaponDocument49 pagesManaging Markets Strategically: Professor Noel CaponChristiandeuxNo ratings yet

- DLL Drafting 7Document4 pagesDLL Drafting 7Ram Dacz100% (3)