Professional Documents

Culture Documents

Advance Welding Kme 055

Uploaded by

ANKIT JHAOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Advance Welding Kme 055

Uploaded by

ANKIT JHACopyright:

Available Formats

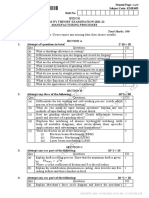

Printed Page: 1 of 1

Subject Code: KME055

0Roll No: 0 0 0 0 0 0 0 0 0 0 0 0 0

B.TECH

(SEM V) THEORY EXAMINATION 2021-22

ADVANCE WELDING

Time: 3 Hours Total Marks: 100

SECTION A

1. Attempt all questions in brief. 2 x 10 = 20

a. What is the function of flux in the welding?

b. What is the principle involved in resistance welding.

c. Draw the weld symbols for double U and single V-joint.

d. How radial friction welding is used to join the collars shaft and tube

e. What are the effect of gases in welding

f. Define the health & safety in welding.

g. How is the carbon equivalent value calculated?

h. Write short note on the bend test.

i. Describe the factor affecting weldability of copper alloys.

j. Describe the arc blow.

SECTION B

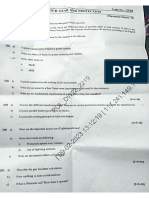

2. Attempt any three of the following: 10 x 3 = 30

a. Describe TIG welding process with neat sketch. What are the advantages and

limitation of TIG welding over MIG welding?

1

b. The dc arc current has voltage – length characteristics as V = (10+30L) volts. The

90

13

characteristics of power source is V = (60 – 0.07I) volts. Determine the optimum arc

_2

length and corresponding arc power.

2.

c. Define residual stresses in welding. State and explain the major factors responsible for

1P

24

residual stress?

d. Briefly describe the various weld defect and distortion in welding and its causes

2O

5.

and remedies.

.5

P2

e. Write short note on :

17

i. Gas metal reaction ii. Slag metal reaction

Q

|1

SECTION C

3. Attempt any one part of the following: 10 x 1 = 10

18

(a) Briefly classify the process selection criteria of welding process?

1:

(b) Classify the different types of metal transfer used in various types of arc welding

:0

process with neat sketch?

09

4. Attempt any one part of the following: 10 x 1 = 10

(a) Describe the laser beam welding. Explain the principle behind the generation of laser

2

with neat sketch and also write the various application of laser of beam welding?

02

(b) Define the Magnetically impelled arc butt (MIAB) welding procedure, limitation and

application of this process.

-2

. Attempt any one part of the following: 10 x 1 = 10

n

(a) Explain the factor affecting changes in microstructure and mechanical properties of

Ja

heat affected zone.

6-

(b) Discuss in detail about weld thermal cycles with neat sketch and also mention the

|0

factor affecting change in microstructure and HAZ.

6. Attempt any one part of the following: 10 x 1 = 10

(a) Discuss about the different types of weld joint with neat sketch.

(b) Explain the following

i. Dye penetrant testing iii. Inspection of weld

ii. Discontinuities in weld and their causes

7. Attempt any one part of the following: 10 x 1 = 10

(a) what is metallizing process ?how the surface of work must be prepared for this process

also describe the nature of bond between sprayed metal and work

(b) Discuss the effect of alloying element of the weldability. Explain the welding of

dissimilar metal briefly.

QP22O1P_290 | 06-Jan-2022 09:01:18 | 117.55.242.131

You might also like

- Btech Me 5 Sem Advanced Welding Kme055 2022Document1 pageBtech Me 5 Sem Advanced Welding Kme055 2022ykrish276No ratings yet

- Btech Me 5 Sem Advanced Welding Kme055 2021Document2 pagesBtech Me 5 Sem Advanced Welding Kme055 2021Wizard ToxicNo ratings yet

- Advance Welding Question Paper 21 22Document3 pagesAdvance Welding Question Paper 21 22ravikumarsharma2412No ratings yet

- DR Vijay Kumar Gupta: Time: 3 Hours Total Marks: 100Document1 pageDR Vijay Kumar Gupta: Time: 3 Hours Total Marks: 100RajeevNo ratings yet

- Btech Me 5 Sem Advance Welding Kme055 2023Document2 pagesBtech Me 5 Sem Advance Welding Kme055 2023Gulshan AryaNo ratings yet

- Btech Oe 3 Sem Material Science Koe032 2022Document1 pageBtech Oe 3 Sem Material Science Koe032 2022Abhishek Mishra MishraNo ratings yet

- Manufacturing Processes Kme403Document2 pagesManufacturing Processes Kme403RafelNo ratings yet

- Vlsi Technology Kec 053Document1 pageVlsi Technology Kec 053Anonymous eWMnRr70qNo ratings yet

- Vlsi Technology Kec 053 1Document2 pagesVlsi Technology Kec 053 1Anonymous eWMnRr70qNo ratings yet

- Signal 2Document2 pagesSignal 2imvuuser1No ratings yet

- Btech Me 3 Sem Material Science Nme301 2020Document1 pageBtech Me 3 Sem Material Science Nme301 2020Rajulapati Sunil KumarNo ratings yet

- Fundamentals of Mechanical Engineering Mechatronics-Kme-101tDocument1 pageFundamentals of Mechanical Engineering Mechatronics-Kme-101tTangent ChauhanNo ratings yet

- Btech Ee 3 Sem Electrical Measurements and Instrumentation Kee302 2021Document2 pagesBtech Ee 3 Sem Electrical Measurements and Instrumentation Kee302 2021Priyanshu SuryavanshiNo ratings yet

- Emerging Domain in Electronics Engineering Kec 101TDocument3 pagesEmerging Domain in Electronics Engineering Kec 101Tavinas_3marNo ratings yet

- Btech Ee 3 Sem Electrical Measurements and Instrumentation Kee302 2022Document2 pagesBtech Ee 3 Sem Electrical Measurements and Instrumentation Kee302 2022Priyanshu SuryavanshiNo ratings yet

- Btech Me 3 Sem Material Science Rme301 2020Document2 pagesBtech Me 3 Sem Material Science Rme301 2020Rajulapati Sunil KumarNo ratings yet

- Computer Graphics Qut PaperDocument2 pagesComputer Graphics Qut PaperjyotirmaypatelNo ratings yet

- G.C.R.G. Memorial Trust'S Group of InstitutionsDocument1 pageG.C.R.G. Memorial Trust'S Group of InstitutionsAndrea DouglasNo ratings yet

- Btech Me 3 Sem Materials Engineering Kme303 2020Document2 pagesBtech Me 3 Sem Materials Engineering Kme303 2020Rajulapati Sunil KumarNo ratings yet

- Measurement and Metrology Rme 401Document2 pagesMeasurement and Metrology Rme 401UTTKARSH SACHANNo ratings yet

- Electrical - VTH - EndsemDocument12 pagesElectrical - VTH - EndsemShivam YadavNo ratings yet

- Advanced Welding Process PDFDocument3 pagesAdvanced Welding Process PDFbusiness singhNo ratings yet

- Advanced Welding Technology Nme055Document2 pagesAdvanced Welding Technology Nme055Pandit Animesh TripathiNo ratings yet

- Quest 5599Document1 pageQuest 5599dhasdjNo ratings yet

- PU Paper Manufacturing Science KME-403 - NewDocument2 pagesPU Paper Manufacturing Science KME-403 - Newdaso khagoNo ratings yet

- Answer All Questions From Part - A and Part - B The Figures in The Right-Hand Margin Indicate Marks. Part-ADocument3 pagesAnswer All Questions From Part - A and Part - B The Figures in The Right-Hand Margin Indicate Marks. Part-ASurya Narayan BeheraNo ratings yet

- Fundamentals of Mechanical Engineering Mechatronics Kme 101T 1Document2 pagesFundamentals of Mechanical Engineering Mechatronics Kme 101T 1YashNo ratings yet

- Allied Welding 1Document2 pagesAllied Welding 1ptkathiresan19No ratings yet

- Bteup SGP Original Paper 2023Document2 pagesBteup SGP Original Paper 2023prateekking625No ratings yet

- Design of Steel Structures Kce075Document2 pagesDesign of Steel Structures Kce075xefedoy533No ratings yet

- Material Science Paper 1Document1 pageMaterial Science Paper 1LYRICALLY MEMEDNo ratings yet

- Pre-Leaving Certifi Cate Examination, 2016 Triailscrúdú Na Hardteistiméireachta, 2016Document12 pagesPre-Leaving Certifi Cate Examination, 2016 Triailscrúdú Na Hardteistiméireachta, 2016Diaa SaberNo ratings yet

- Power System ProtectionDocument1 pagePower System ProtectionlormenardbeverlyNo ratings yet

- Btech Oe 3 Sem Energy Science and Engineering Koe033 2022Document2 pagesBtech Oe 3 Sem Energy Science and Engineering Koe033 2022akash GuptaNo ratings yet

- April 2012 Final Exam CCSM 101 V5Document4 pagesApril 2012 Final Exam CCSM 101 V5JCNo ratings yet

- (M19CAD1104) I M. Tech I Semester (R19) Regular ExaminationsDocument1 page(M19CAD1104) I M. Tech I Semester (R19) Regular Examinationsraja raoNo ratings yet

- Imayam College of Engineering: Question Set: Register NoDocument1 pageImayam College of Engineering: Question Set: Register NoSiva GaneshNo ratings yet

- B. Met. Engineering Final Examination, 2008Document1 pageB. Met. Engineering Final Examination, 2008DeepakNo ratings yet

- L. Followings:: Mechanical:3 in All From Part-I From Part-Il. of The and Must NotDocument2 pagesL. Followings:: Mechanical:3 in All From Part-I From Part-Il. of The and Must NotAKNo ratings yet

- Summer 2021 AMIIW Question PapersDocument32 pagesSummer 2021 AMIIW Question PapersRiyaz AhmedNo ratings yet

- Electrical Measurements Instrumentation Kee 302Document2 pagesElectrical Measurements Instrumentation Kee 302Anil KumarNo ratings yet

- Coa 2021Document2 pagesCoa 2021jiumimyt0No ratings yet

- 3 Hours / 70 Marks: Seat NoDocument4 pages3 Hours / 70 Marks: Seat Noomkar devrukhkarNo ratings yet

- B. Tech: 3 Year Pre-University Test (Odd Semester: 2021-22) Semester: 5Th BRANCH: Mechanical Engineering Subject Name Advance WeldingDocument2 pagesB. Tech: 3 Year Pre-University Test (Odd Semester: 2021-22) Semester: 5Th BRANCH: Mechanical Engineering Subject Name Advance Weldingchetan dixitNo ratings yet

- 18me45b Metal Casting Welding Model Question Paper 2Document2 pages18me45b Metal Casting Welding Model Question Paper 2Stalan JonathanNo ratings yet

- Anurag Group of Institutions: I-B. Tech - I-Semester End Examinations, Dec/Jan - 2015-16 Subject: Applied ChemistryDocument2 pagesAnurag Group of Institutions: I-B. Tech - I-Semester End Examinations, Dec/Jan - 2015-16 Subject: Applied ChemistryRajshree KuteNo ratings yet

- Pre-Leaving Certiϐicate Examination, 2018 Triailscrúdú Na Hardteistiméireachta, 2018Document12 pagesPre-Leaving Certiϐicate Examination, 2018 Triailscrúdú Na Hardteistiméireachta, 2018Diaa SaberNo ratings yet

- Signal Paper 3Document3 pagesSignal Paper 3imvuuser1No ratings yet

- Database Management System KCS 501Document2 pagesDatabase Management System KCS 501Sparsh SaxenaNo ratings yet

- Time: 3 Hours Total Marks: 100: Printed Page 1 of 2 Sub Code:KEC301Document2 pagesTime: 3 Hours Total Marks: 100: Printed Page 1 of 2 Sub Code:KEC301HCKERNo ratings yet

- B. Tech.: Printed Pages: 3Document3 pagesB. Tech.: Printed Pages: 3arugeetNo ratings yet

- Btech 1 Sem Engineering Chemistry Ras102 2020Document2 pagesBtech 1 Sem Engineering Chemistry Ras102 2020Hariom SinghNo ratings yet

- Model Paper 1 ChemistryDocument2 pagesModel Paper 1 Chemistrysazalgola2004No ratings yet

- Ramaiah: MSEE02Document2 pagesRamaiah: MSEE02hari krishnaNo ratings yet

- VLSI-TECHNOLOGY fddsedd-Question-Paper-21-22Document3 pagesVLSI-TECHNOLOGY fddsedd-Question-Paper-21-22VIKASH YADAVNo ratings yet

- Bpharm 1 Sem Pharmaceutical Analysis 1 Theory bp102t 2022Document1 pageBpharm 1 Sem Pharmaceutical Analysis 1 Theory bp102t 2022ShivamNo ratings yet

- KME 602 2022-23 AktuDocument4 pagesKME 602 2022-23 AktuPrabal SinghNo ratings yet

- Emerging Domain in Electronics Engineering Kec 101T 1Document3 pagesEmerging Domain in Electronics Engineering Kec 101T 1Dulce DeNo ratings yet

- Answer Any Three Questions, Each Carries 10 Marks.: Reg No.: - NameDocument2 pagesAnswer Any Three Questions, Each Carries 10 Marks.: Reg No.: - NameRajulapati Sunil KumarNo ratings yet

- Theory of MachinesDocument128 pagesTheory of MachinesANKIT JHANo ratings yet

- DocScanner Nov 7, 2022 13-22Document5 pagesDocScanner Nov 7, 2022 13-22ANKIT JHANo ratings yet

- Strength of Materials Kme 502Document2 pagesStrength of Materials Kme 502ANKIT JHANo ratings yet

- Heat and Mass Transfer Kme 501Document2 pagesHeat and Mass Transfer Kme 501ANKIT JHANo ratings yet

- Industrial EngineeringDocument7 pagesIndustrial EngineeringANKIT JHANo ratings yet

- Industrial Engineering Kme 503 1Document3 pagesIndustrial Engineering Kme 503 1ANKIT JHANo ratings yet

- Constitution of India Law and Engineering KNC 501Document1 pageConstitution of India Law and Engineering KNC 501ANKIT JHA100% (1)

- Cat D4 04Document3 pagesCat D4 04De Paula ManutencaoNo ratings yet

- Wps PQRDocument6 pagesWps PQRneelson_099No ratings yet

- Juk MB-373NS 377NSDocument32 pagesJuk MB-373NS 377NSRHoskaNo ratings yet

- Caja de Mandos Grupo Range y EspliterDocument3 pagesCaja de Mandos Grupo Range y EspliterAlex BravoNo ratings yet

- Connections (Part 1.1) : Eurocode 9: Design of Aluminium StructuresDocument48 pagesConnections (Part 1.1) : Eurocode 9: Design of Aluminium StructuresYashu HandaNo ratings yet

- Field VesselsDocument1 pageField Vesselssaeed ghafooriNo ratings yet

- Despiece FI 160 - 200 - 200WDocument59 pagesDespiece FI 160 - 200 - 200WJoel FontanellaNo ratings yet

- Gambar 15 Frame: Nomor Refere Nomor Part Nama Part KeteranganDocument1 pageGambar 15 Frame: Nomor Refere Nomor Part Nama Part KeteranganDobel Karbu Retro GarageNo ratings yet

- Nick Bartlett Final ResumeDocument2 pagesNick Bartlett Final Resumeapi-253067520No ratings yet

- Cement Type Early Age Properties 23 Jun 11 PDFDocument3 pagesCement Type Early Age Properties 23 Jun 11 PDFJoãoPauloAzevedoNo ratings yet

- Reapir Kit's REGODocument9 pagesReapir Kit's REGOMiller Alexander Mora VargasNo ratings yet

- Welding Procedure Specification NO. 8-32-1: National Certified Pipe Welding BureauDocument7 pagesWelding Procedure Specification NO. 8-32-1: National Certified Pipe Welding BureauDanem HalasNo ratings yet

- Fasteners CatalogDocument52 pagesFasteners CatalogludaNo ratings yet

- 4WD Front Axle - Box PDFDocument3 pages4WD Front Axle - Box PDFRaul Soteras EstebanNo ratings yet

- Açilir Kepçe Tesisati / 8/029: Clamshovel InstallationDocument48 pagesAçilir Kepçe Tesisati / 8/029: Clamshovel InstallationFranky FernandezNo ratings yet

- Caterpillar Parts List: Item Part No. QuantityDocument19 pagesCaterpillar Parts List: Item Part No. QuantityAKshayNo ratings yet

- Spare Part Manual bp350d Part 2 PDFDocument35 pagesSpare Part Manual bp350d Part 2 PDFnirmalNo ratings yet

- 777G Ski Plate Extension - Rev 03Document29 pages777G Ski Plate Extension - Rev 03Herman Castillo EspindolaNo ratings yet

- Welding Procedure Specification (W.P.S) : Alstom India LimitedDocument2 pagesWelding Procedure Specification (W.P.S) : Alstom India LimitedAhmed saberNo ratings yet

- D9 1 PDFDocument54 pagesD9 1 PDFMIRACHELLE ANTONIONo ratings yet

- Design of Bolt and NutDocument41 pagesDesign of Bolt and NutRa Balamurugan67% (3)

- OfferDocument6 pagesOffervijaykumar901520No ratings yet

- Din 912-Iso 4762 PDFDocument9 pagesDin 912-Iso 4762 PDFKaharul AfandiNo ratings yet

- Welding Procedure Specification (WPS) : CÓDIGO: AC-FT-018 Versión: 01 FECHA: 24-05-2019 Página: 1 de 1Document2 pagesWelding Procedure Specification (WPS) : CÓDIGO: AC-FT-018 Versión: 01 FECHA: 24-05-2019 Página: 1 de 1cesarNo ratings yet

- 3 Welding ImperfectionsDocument44 pages3 Welding ImperfectionsAdhanom G.No ratings yet

- FL6051 Maint Kit 358Document3 pagesFL6051 Maint Kit 358rburtonshawNo ratings yet

- FW12 A106 283033 16"/7.92 Na Acc Acc Acc A105 W-1800126 16"/7.92 1/17/2020 A106 283033 16"/7.92 Na Acc Acc Acc A105 W-1800126 16"/7.92 1/17/2020Document2 pagesFW12 A106 283033 16"/7.92 Na Acc Acc Acc A105 W-1800126 16"/7.92 1/17/2020 A106 283033 16"/7.92 Na Acc Acc Acc A105 W-1800126 16"/7.92 1/17/2020Muhammad firdaus rusliNo ratings yet

- Weight Per Meter of Weld MetalDocument1 pageWeight Per Meter of Weld MetalLuis SPNo ratings yet

- Itp For Staircase HandrailDocument3 pagesItp For Staircase HandrailKishoreNo ratings yet

- MIL-F-18240D 25 February 197? Superseding MIL-F-18240C (ASG) 17 November 1967Document19 pagesMIL-F-18240D 25 February 197? Superseding MIL-F-18240C (ASG) 17 November 1967杜文欽No ratings yet

- Exposure: Poisoned Water, Corporate Greed, and One Lawyer's Twenty-Year Battle Against DuPontFrom EverandExposure: Poisoned Water, Corporate Greed, and One Lawyer's Twenty-Year Battle Against DuPontRating: 4.5 out of 5 stars4.5/5 (18)

- Waste: One Woman’s Fight Against America’s Dirty SecretFrom EverandWaste: One Woman’s Fight Against America’s Dirty SecretRating: 5 out of 5 stars5/5 (1)

- Art of Commenting: How to Influence Environmental Decisionmaking With Effective Comments, The, 2d EditionFrom EverandArt of Commenting: How to Influence Environmental Decisionmaking With Effective Comments, The, 2d EditionRating: 3 out of 5 stars3/5 (1)

- The Cyanide Canary: A True Story of InjusticeFrom EverandThe Cyanide Canary: A True Story of InjusticeRating: 4 out of 5 stars4/5 (52)

- Slow Violence and the Environmentalism of the PoorFrom EverandSlow Violence and the Environmentalism of the PoorRating: 4 out of 5 stars4/5 (5)

- Principles of direct and superior responsibility in international humanitarian lawFrom EverandPrinciples of direct and superior responsibility in international humanitarian lawNo ratings yet

- Land Divided by Law: The Yakama Indian Nation as Environmental History, 1840-1933From EverandLand Divided by Law: The Yakama Indian Nation as Environmental History, 1840-1933No ratings yet

- Did Your Can of Soda Kill A Whale? Water Pollution for Kids | Children's Environment BooksFrom EverandDid Your Can of Soda Kill A Whale? Water Pollution for Kids | Children's Environment BooksNo ratings yet

- Reduce, Reuse and Recycle : The Secret to Environmental Sustainability : Environment Textbooks | Children's Environment BooksFrom EverandReduce, Reuse and Recycle : The Secret to Environmental Sustainability : Environment Textbooks | Children's Environment BooksNo ratings yet

- 3rd Grade Science: Life Sciences in Eco Systems | Textbook EditionFrom Everand3rd Grade Science: Life Sciences in Eco Systems | Textbook EditionNo ratings yet

- Desperate: An Epic Battle for Clean Water and Justice in AppalachiaFrom EverandDesperate: An Epic Battle for Clean Water and Justice in AppalachiaRating: 4 out of 5 stars4/5 (1)

- The Rights of Nature: A Legal Revolution That Could Save the WorldFrom EverandThe Rights of Nature: A Legal Revolution That Could Save the WorldRating: 5 out of 5 stars5/5 (1)

- Dawn at Mineral King Valley: The Sierra Club, the Disney Company, and the Rise of Environmental LawFrom EverandDawn at Mineral King Valley: The Sierra Club, the Disney Company, and the Rise of Environmental LawRating: 4 out of 5 stars4/5 (334)

- Environmental Education in Practice: Concepts and ApplicationsFrom EverandEnvironmental Education in Practice: Concepts and ApplicationsNo ratings yet

- Down to the Wire: Confronting Climate CollapseFrom EverandDown to the Wire: Confronting Climate CollapseRating: 4.5 out of 5 stars4.5/5 (8)

- Ecosystem Facts That You Should Know - The Forests Edition - Nature Picture Books | Children's Nature BooksFrom EverandEcosystem Facts That You Should Know - The Forests Edition - Nature Picture Books | Children's Nature BooksNo ratings yet

- Busted!: Drug War Survival Skills and True Dope DFrom EverandBusted!: Drug War Survival Skills and True Dope DRating: 3.5 out of 5 stars3.5/5 (7)

- Playing with Fire: The Strange Case of Marine Shale ProcessorsFrom EverandPlaying with Fire: The Strange Case of Marine Shale ProcessorsRating: 5 out of 5 stars5/5 (1)