Professional Documents

Culture Documents

Lighting Wiring Methods

Uploaded by

temamCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Lighting Wiring Methods

Uploaded by

temamCopyright:

Available Formats

SECTION 8: WIRING METHODS

SECTION 8

WIRING METHODS

8.1 SCOPE

(1) This Section applies to all wiring installation operating at 0.6/1.0kV or less except for:

(a) conductors which form an integral part of factory built equipment;

(b) communication circuit, unless otherwise specified in Section 23;

(c) Class 2 circuits, unless otherwise specified in Section 10;

(d) community antenna distribution, radio and television installations, unless otherwise specified in

Section 24;

(e) optical fiber cables.

8.2 Normative Reference

(1) The following references contain provisions which, through reference in .this text, constitute

provisions of the Ethiopian Building Code Standard on Electrical Installation of Buildings.

(a) CSA C22.1:2002 Canadian Electrical Code, Safety Standard for Electrical

Installation, Nineteenth Edition

(b) BS 767:1992 The electricians Guide to the 16th Edition of the IEE Wiring

Regulations, Second Edition, 1993

(c ) NFPA 70 / NEC:2008 National Fire Protection Association, American National

Electrical Code, 2008 Edition

8.3 General Requirements

8.3.1 Methods of Installation

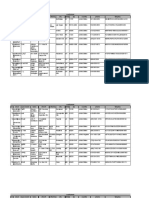

(1) The methods of installation of wiring systems shall be as shown in Annex A.

ETHIOPIAN BUILDING CODE STANDARD EBCS-10: 2013 Page [216]

SECTION 8: WIRING METHODS

(2) The Provisions in (1) above notwithstanding, the use of another method is not precluded provided that

compliance with this Code is maintained

(3) A bare live conductor shall be installed on insulators.

(4) Non-sheathed cables for fixed wiring shall be enclosed in conduits, ducting or trunking; however, this

provision does not apply to a protective conductor.

8.3.2 Wiring in Ducts and Plenum Chambers

(1) No electrical equipment, unless specifically approved for the purpose, shall be installed in ducts used

to transport dust, loose stock, or flammable vapours.

(2) No electrical equipment, unless specifically approved for the purpose, shall be installed in any duct

used for vapour removal or for ventilation of commercial-type cooking equipment.

8.3.3 Underground Installations

(1) Direct buried conductors, cables, or raceways shall be installed to meet the minimum cover

requirements shown in Table 8.1.

Table 8.1 Minimum cover requirements for direct buried

conductors, cables or raceways

Minimum cover [mm]

Wiring method

750.0 V or Over 750.0V 750.0v or less Over 750.0V

less

Conductors or cables not 600 750 900 1000

having a metal sheath or

armour

Conductors or cable 450 750 600 1000

having a metal sheath or

armour

Raceway 450 750 600 1000

Minimum cover means the distance between the top surface of the conductor, cable, or raceway and the

finished grade.

ETHIOPIAN BUILDING CODE STANDARD EBCS-10: 2013 Page [217]

SECTION 8: WIRING METHODS

(2) The minimum cover requirements shall be permitted to be reduced by 150.0mm where mechanical

protection is placed in the trench over the underground installation.

(3) Mechanical protection shall consist of one of the following and, when in flat form, shall be wide

enough to extend at least 50.0mm beyond the conductor, cables, or raceways on each side:

(a) Treated planking at least 38.0mm thick.

(b) Poured concrete at least 50.0mm thick.

(c) Concrete slabs at least 50.0mm thick.

(d) Concrete encasement at least 50.0mm thick.

(e) Other acceptable material.

(4) Raceways or cables, if located in rock, may be installed at a shallower depth entrenched into the rock

in a trench not less than 150.0mm deep and grouted with concrete to the level of the rock surface.

(5) Raceways may be installed directly beneath a concrete slab at grade level provided the concrete slab is

not less than a nominal 100.0mmin thickness, the location is adequately marked, and the raceway will not

be subject to damage during or after installations.

(6) Any form of mechanical protection which may adversely affect the conductors or cable assemblies

shall not be used.

(7) Backfill containing large rock, paving materials, cinders, large or sharply angular substances, or

corrosive material shall not be placed in an excavation where such materials may damage cables,

raceways, or other substructures prevent adequate compaction of fill, or contribute to corrosion of cables,

raceways, or other substructures.

8.3.4 Conductors in Hoistways

(1) Where conductors other than those used to furnish energy to the lift or dumbwaiter are installed in

hoistways, they shall be from mineral-insulated cable or armoured cables or be run in rigid or flexible

metal conduit or electrical metallic tubing.

(2) The cable, conduit, or tubing referred to in (1) above shall be:

(a) securely fastened to the hoistway construction;

(b) arranged so that terminal-outlets or junction boxes open outside the hoistway except that pull

boxes may be installed in long runs for the purpose of supporting or pulling in conductors.

(3) (a) Main feeders for supplying power to elevators and dumbwaiters shall be installed outside the

hoistway.

(b) Only such electric wiring, raceways, and cables used directly in connection with the elevator or

dumbwaiter, including wiring for signals, for communication with the car, for lighting, heating,

air conditioning and ventilating the car, shall be permitted inside the hoistway.

ETHIOPIAN BUILDING CODE STANDARD EBCS-10: 2013 Page [218]

SECTION 8: WIRING METHODS

8.4 Conductors

8.4.1 Types of Conductors

(1) Conductors installed in any location shall be suitable for the condition of use as indicated in Annex B

of Section 4 for the particular location involved and with particul.ar respect to the following

(a) moisture

(b) corrosive action

(c) temperature

(d) degree of inclosure

(e) mechanical protection.

8.4.2 Radii of Bends in Conductors

(1) The minimum internal radii of bends in conductors shall be as indicated in Table 8.2

Table 8.2 Minimum internal radii of bends in cables for fixed wiring

Type of insulation Overall diameter Bending factor

PVC up to 10.0mm 3(2)

PVC 10.0m to 25.0mm 4(3)

PVC over 25.0mm 6

Mineral any diameter 6

Mineral-insulated cables may be bent at a minimum radius of three times the cable diameter provided that

they will only be bent once.

Note: i) The factor shown in the table is that by which the overall cable diameter must be multiplied to give the

minimum inside' radius of the bend.

ii) The figures in brackets apply to unsheathed single-core stranded PVC cables when installed in conduit,

trunking or ducting.

8.4.3 Conductor Joints and Splices

(1) Unless made with solderless wire connectors, joints or splices in insulated conductors shall be

soldered, but they shall first be made mechanically secured.

(2) Joints or splices shall be covered with an insulation equivalent to that on the conductors being joined.

(3) Joints or splices in wires and cables shall be accessible.

(4) Splices in underground runs of cable, if required due to damage to the original installation, may be

made:

ETHIOPIAN BUILDING CODE STANDARD EBCS-10: 2013 Page [219]

SECTION 8: WIRING METHODS

(a) in junction boxes which are located at least 1.0m above grade and secured to buildings or to stub

poles and suitably protected from mechanical damage;

(b) notwithstanding the requirements in (3) above, by means of splicing devices or materials (kits)

acceptable for direct earth burial.

8.4.4 Supporting of Conductors

(1) Conductors shall be supported so that no injurious strain is imposed on the terminals of any electrical

apparatus or devices or on joints or taps. Table 8.3 shows guidance on methods of support.

Table 8.3 Spacing of supports for cables in accessible position

Overall Maximum spacing of clips[mm]

diameter of Sheathed cables Mineral-insulated cables

cable [mm] Horizontal Vertical Horizontal Vertical

9 250 400 600 800

>915 300 400 900 1200

>1520 350 450 1500 2000

>2040 400 550

Note: For the spacing of supports for cables of overall diameter exceeding 40.0mm and for single-core cables

having conductors of cross-sectional area 300.0mm2 and larger, the manufacturer's recommendations

should be observed.

8.5 OPEN WIRING

8.5.1 Open and Clipped Direct

(1) Sheathed cables clipped direct to or lying on non-metallic surface shall be installed in accordance with

Installation Method 1 (see Annex A).

8.5.2 Spacing of Conductors

(1) Spacing between conductors and adjacent surfaces shall be as indicated in Installation Methods 12 and

13 (see Annex A).

(2) In all locations, a separation of at least 25.0mm shall be maintained between conductors and adjacent

metal piping or conducting materials.

8.5.3 Conductor Supports

(1) Conductors shall be supported rigidly on noncombustible, absorption resisting insulators.

ETHIOPIAN BUILDING CODE STANDARD EBCS-10: 2013 Page [220]

SECTION 8: WIRING METHODS

(2) Conductors supported on solid knobs shall be securely tied thereto by tie wires having insulation of

the same type as that on the conductors which they secure.

8.5.4 Spacing of Supports

(1) Sheathed and / or armoured cables installed in accessible positions and supported by clips shall not

exceed the appropriate spacing value stated in Table 8.3.

8.6 Exposed Wiring On Exterior Of Buildings And Between Buildings On

The Same Premises

8.6.1 Location of Conductors

(1) Where conductors are supported on or in close proximity to the exterior surfaces of buildings, they

hall be installed and protected so that they shall not be hazardous to persons or be exposed to mechanical

injury and they shall not, without special permission, be located at a height less than 4.5m from the

ground.

8.6.2 Clearance of Conductors

(1) Conductors which pass over roofs shall be located or guarded so that they cannot be reached by a

person standing on a fire escape, flat roof, or other portion of a building.

(2) Such conductors in (1) above shall at least be 2.5m above the highest point of a flat roof or a roof that

can be readily walked upon and at least 1.0m above peaked roofs or the highest point of such roofs that

can be readily walked upon; however, by special permission, they may be located less than 2.5m, but not

less than 2.0m, .above the highest point of a flat roof or roofs so that the latter can be readily walked

upon.

8.6.3 Power Supply Conductors

(1) The conductors of a power supply system attached to the exterior surfaces of buildings shall be at least

300.0mm from the conductors of a communication system unless one system is in conduit or is

permanently separated from other systems.

8.7 Bare Bus Bars And Risers

(1) Bare conductors shall not be used as main risers or feeders in buildings unless, special permission is

obtained.

(2) Special permission shall not be granted unless:

(a) the building is of noncombustible construction;

(b) the conductors are placed in a chase, channel, or shaft located or guarded so that the conductors

are inaccessible;

(c) the premises do not constitute a hazardous location;

ETHIOPIAN BUILDING CODE STANDARD EBCS-10: 2013 Page [221]

SECTION 8: WIRING METHODS

(d) suitable cut-offs to protect against the vertical spread of fire are provided where floors are

pierced;

(e) the mechanical and electrical features of the installation and the conductor supports are

appropriate to the operating and maintenance conditions likely to occur, the following

requirements being used in the case of bus bars rated l200.0A or less:

Note: i) Where flat bus bars 6.25mm or less in thickness are used, the continuous current rating shall not exceed

1.6A/mm2 of cross-sectional area of copper bus bar or 1.12A/mm2 in the case of aluminum bus bars.

ii) Bus bar supports shall be spaced not more than 750.0mm apart, with minimum clearance across insulating

surface between bars of opposites polarity of not less than 50.0mm, and 25.0mm between bus bars and

any earthed surface.

8.8 Installation Of Boxes, Cabinets, Outlets And Terminal Fittings

8.8.1 Number of Outlets per Circuit

(1) There shall be no more than 12 outlets on any 2-wire branch circuit except as permitted by other

Sections of this Code.

(2) Such outlets in (1) above shall be considered to be rated at not less than 1.0A per outlet except as

permitted by (3) below.

(3) Where the connected load is known, the number of outlets may exceed 12 provided the load current

does not exceed 80% of the rating of the over current device protecting the circuit.

8.8.2 Outlet Boxes

(1) A box or an equivalent device shall be installed at every point of outlet, switch or junction of conduit

and at every point of outlet and switch of concealed knob-and-tube work.

(2) Nonmetallic outlet boxes shall not be used in wiring methods using metal raceways, armoured or

metal sheathed cable, except where the boxes are provided with bonding connection between all

conductor entry openings.

(3) The box shall be provided with a cover or a fixture canopy.

(4) At least 150.0mm of free conductor shall be left at each outlet for making of joints or connection of

fixtures unless the conductors are intended to loop through lamp holders, socket outlets, or similar devices

without joints.

(5) Ceiling outlet boxes in concrete slab construction shall have knockouts spaced above the free or lower

edge of the boxes a distance of at least twice the diameter of the steel reinforcing bars so that conduit

entering the knockouts shall clear the bars without offsetting.

(6) Boxes and fittings shall be firmly secured to studs, joists or similar fixed structural units.

ETHIOPIAN BUILDING CODE STANDARD EBCS-10: 2013 Page [222]

SECTION 8: WIRING METHODS

8.8.3 Conductors in Boxes

(1) Boxes shall be of sufficient size to provide usable space for all insulated conductors contained in the

box.

(2) Conductors which are connected to different power or distribution transformers or other different

sources of voltage shall not be installed in the same box, cabinet or fitting.

8.8.4 Terminal Fittings

(1) Where conductors are run from the ends of conduit, armoured cable surface raceways or non metallic

sheathed cable to appliances or open wiring installation, an outlet fitting or terminal fitting may be used

instead of the box required in Clause 8.8.2, and the conductors shall be run without splice, tap or joint

within the fitting.

(2) The fittings in (1) above shall have a separately bushed hole for each conductor.

(3) The fittings in (1) above shall not be used at outlets for fixtures.

8.9 Cables, Conductors And Wiring Methods

(1) Every cable operating at low voltage shall be selected in accordance with Section 4 of this Code.

(2) The method of installation of cables and conductors shall be subject to the provision of Clause 8.3.1.

ETHIOPIAN BUILDING CODE STANDARD EBCS-10: 2013 Page [223]

SECTION 8: WIRING METHODS

ANNEX A (NORMATIVE)

SCHEDULE OF METHODS OF INSTALLATION OF CABLES

Note: i) The methods of installation distinguished by bold type are reference methods for which the current carrying

capacity given in Annex B, Tables B.1 through B.45, Section 4, have been determined.

ii) For the other methods, an indication is given of the appropriate reference method having values of current-

carrying capacity which can safely be applied.

Installation method Appropriate Reference

Method for determining

Examples

Number Description current-carrying

capacity

1 2 3 4

Open and clipped direct:

1 Sheathed cables clipped direct to or lying on Method 1

a non-metallic surface

Cables embedded direct in building materials:

Sheathed cables embedded directly in

masonry, brickwork, concrete, plaster or the

2 Method 1

like (other than-thermally insulating

materials)

Single-core non-sheathed cables In metallic Method 3

3

or non-metallic conduit on a wall or ceiling

In conduit:

Single-core non-sheathed cables in metallic Method 4

or non-metallic conduit in a thermally

insulating wall or above a thermally

4

insulating ceiling, the conduit being in

contact with a thermally conductive surface

on one side*

5 Multicore cables having non-metallic sheath, Method 3

in metallic o r non-metallic conduit on a wall

or ceiling.

The wall is assumed to consist of an outer weatherproof skin, thermal insulation and an inner skin of a plaster board

or a wood-like material having a thermal conductance not less than 10w/m2K. The conduit is fixed so as to be close

to, but not necessarily touching, the inner skin. Heat from the cables is assumed to escape through the inner skin

only.

ETHIOPIAN BUILDING CODE STANDARD EBCS-10: 2013 Page [224]

SECTION 8: WIRING METHODS

Installation method Appropriate

Reference Method

Examples for determining

Number Description current-carrying

capacity

1 2 3 4

Sheathed cables in conduit in a thermally

6 insulating wall etc. (otherwise as Reference Method 4

Method 4)

7 Cables in conduit embedded in masonry,

brickwork, concrete, plaster or the like

(other than thermally insulating materials)

Method 3

In trunking:

Cables in trunking on a wall or suspended in

8

the air Method 3

9 Cables in flush floor trunking Method 3

On trays:

10 Single-core cable in skirting trunking Method 3

11 Sheathed cables on a perforated cable tray,

bunched and unenclosed.

Method 11

A perforated cable tray Is considered as a

tray in which the holes occupy at least 30%

of the surface area

In free air, on cleats, brackets or a ladder

12 Sheathed single-core cables in free air (any

supporting metalwork ladder the cables

occupying less than 10% of the plan area:

Two or three cables vertically one above the

other, minimum distance between cable

surfaces equal to the overall cable diameter

(D); distance from the wall not less than

0.5D.

Two or three cables horizontally, with Method 12

spacing as above three cables in trefoil,

distance between wall and surface of nearest

cable 0.5D, or nearest cables 0.75D

ETHIOPIAN BUILDING CODE STANDARD EBCS-10: 2013 Page [225]

SECTION 8: WIRING METHODS

Installation method Appropriate Reference

Examples Method for determining

Number Description

current-carrying capacity

1 2 3 4

In free air, on cleats, brackets or a ladder

13 Sheathed multicore cables on ladder or

brackets, separation greater than 2D Sheathed

multicore cables in free air distance between

wall and cable surface not less than 0.3Dm

Any supporting metalwork under the cables

Method 13

occupying less than 10% the plan area

14 Cables suspended from or incorporating a

catenary wire

Method 12 or Method 13, as

appropriate

Cables In building voids:

15 Sheathed cables Installed directly in a

thermally Insulating wall or above a

thermally insulating ceiling, the cable being Method 4

In contact with a thermally conductive

surface on one side (otherwise as Ref Method

No 4)

16 Sheathed cables In ducts or voids formed by Method 4

the building structure, other than thermally

insulating materials Where the cable has a

diameter D or a perimeter

not greater than 20 D.

Method 3

Where the duct has either a

diameter greater than 5D• or

a perimeter greater than

20D•

Notes:

i) Where the perimeter is

greater than 60D,

installation Methods 18 to

20, as appropriate, should be

used,

ii) D, is the overall cable

diameter; for groups of

cables D Is the sum of the

cable diameters.

ETHIOPIAN BUILDING CODE STANDARD EBCS-10: 2013 Page [226]

SECTION 8: WIRING METHODS

Installation method Appropriate Reference

Method for determining

Examples

Number Description current-carrying

capacity

1 2 3 4

Cables in trenches;:

17 Cables supported on the wall of an open

or ventilated trench, with spacing as

indicated for Reference Method 12 or 13 Method 12 or Method

as appropriate 13, as appropriate

18 Cables in enclosed trench 450.0mm wide Two single-core cables with

by 300.0 mm deep (minimum surfaces separated by a minimum

dimensions) including 100.0 mm cover of one cable diameter.

Three single-core cables in trefoil

and touching throughout. Method 18. Use rating

factors in Table A.3,

Section 4.

Multicore cables or groups of

single-core cables with

surfaces minimum of 50.0 mm

19 Cables in enclosed trench 450.0mm wide Single-core cables arranged in flat

by 600.0mm deep (minimum dimensions) groups of two or three on the

including 100.0mm cover vertical

trench wall with surfaces separated

by one diameter with a minimum

distance of 50.0mm between Method 19. Use rating

groups. factors in Table A.3,

Section 4

Multicore cables installed with

surfaces separated by a minimum

of 75.0mm. All cables spaced at

least 25.0mm from the trench wall

20 Cables in enclosed trench 600.0mm wide

by 760.0mm deep (minimum dimensions) Single-core cables arranged in

including 100.0mm cover groups of two or three in flat

formation with the surfaces

separated by one diameter or in

trefoil formation with cables Method 20. Use rating

touching. factors in Table A.3,

Groups separated by a minimum of Section 4.

75.0mm either horizontally or

vertically.

All cables spaced at least 25.0mm

from the trench wall.

Larger spacing to be used where practicable.

ETHIOPIAN BUILDING CODE STANDARD EBCS-10: 2013 Page [227]

You might also like

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsFrom Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsRating: 4 out of 5 stars4/5 (1)

- Chapter 8 Summary PDFDocument5 pagesChapter 8 Summary PDFJohn Mark CarpioNo ratings yet

- Section 16702 Commu CablesDocument7 pagesSection 16702 Commu Cablesaanouar77No ratings yet

- Arial Bunch ConductorDocument10 pagesArial Bunch Conductorbbakari2000No ratings yet

- 3.68 BuswaysDocument21 pages3.68 Buswaysna zafiraNo ratings yet

- JIS F 0414 Shipbuilding - Internal Wiring and Piping of Engine Control ConsoleDocument4 pagesJIS F 0414 Shipbuilding - Internal Wiring and Piping of Engine Control ConsoleSopon SrirattanapiboonNo ratings yet

- DEWA 1513403-R0 22kV 11kV XLPE Cables PDFDocument11 pagesDEWA 1513403-R0 22kV 11kV XLPE Cables PDFHashimAmrNo ratings yet

- Topic 4 Cable Size and Wiring MethodDocument64 pagesTopic 4 Cable Size and Wiring MethodYuen Chan100% (1)

- ANNEX E - Amended - Technical Specs of L.T TWISTED INSULATED CABLEDocument7 pagesANNEX E - Amended - Technical Specs of L.T TWISTED INSULATED CABLEsajjad_pirzadaNo ratings yet

- Lecture 5 Wiring Materials PDFDocument11 pagesLecture 5 Wiring Materials PDFAnonymous 3Ra3zVuMDNo ratings yet

- Wiring MethodsDocument11 pagesWiring MethodsJames Adrian Abalde SaboNo ratings yet

- F. Tech. Specifications - 166-216Document51 pagesF. Tech. Specifications - 166-216mhafeez835156No ratings yet

- 2011 NEC Code Reference for 300.5 Underground InstallationsDocument8 pages2011 NEC Code Reference for 300.5 Underground InstallationsAno Ni MousNo ratings yet

- 18.1-1996 Aerial Bundled ConductorsDocument11 pages18.1-1996 Aerial Bundled ConductorsnilushkaaNo ratings yet

- TG30 Pathway SeparationDocument3 pagesTG30 Pathway SeparationMouna NjNo ratings yet

- TS-OPGW 1.4 9feb2017Document18 pagesTS-OPGW 1.4 9feb2017asim204No ratings yet

- 3.0 - Conduit and Cable TrunkingDocument21 pages3.0 - Conduit and Cable TrunkingAyman SaberNo ratings yet

- Chapter 20: Technical Specification For Xlpe Cable With TerminationDocument46 pagesChapter 20: Technical Specification For Xlpe Cable With TerminationSristi MitraNo ratings yet

- EC&M GroundingDocument8 pagesEC&M GroundingGustavo TelloNo ratings yet

- B-03 LT Power CablesDocument8 pagesB-03 LT Power Cablesrahul patraNo ratings yet

- Electrical Cable Management SystemsDocument22 pagesElectrical Cable Management SystemsPyae Tun KhantNo ratings yet

- Grounding and Bonding For CommunicationsDocument5 pagesGrounding and Bonding For Communicationschandrahai hrangkhawlNo ratings yet

- B-09 HT Power CablesDocument8 pagesB-09 HT Power Cablesrahul patraNo ratings yet

- Theater InstallationDocument7 pagesTheater InstallationtemamNo ratings yet

- Ti SPC Ohe Inscom 1070Document23 pagesTi SPC Ohe Inscom 1070hardeepsingh_08No ratings yet

- SECTION 28 05 26 Grounding and Bonding For Electronic Safety and SecurityDocument8 pagesSECTION 28 05 26 Grounding and Bonding For Electronic Safety and SecurityDenyNo ratings yet

- OPGWDocument6 pagesOPGWanushkabhardwajNo ratings yet

- Is 1255 - Cable Laying SpecsDocument11 pagesIs 1255 - Cable Laying SpecsAnonymous KC6pTURhe100% (3)

- GroundingDocument6 pagesGroundinguddinnadeemNo ratings yet

- Fire Alarm Systems (From NEC)Document15 pagesFire Alarm Systems (From NEC)mostafaabdelrazikNo ratings yet

- Low Voltage Electrical Power Conductors and Cables 600 Volts and BelowDocument6 pagesLow Voltage Electrical Power Conductors and Cables 600 Volts and BelowyonnatanzewdduNo ratings yet

- JIS C 3653-1994 Tieu Chuan (Cho Cap Ngam Den 7kV)Document19 pagesJIS C 3653-1994 Tieu Chuan (Cho Cap Ngam Den 7kV)Nguyen Minh AnhNo ratings yet

- BESCOM Technical-Specification-HT-UG-CablesDocument15 pagesBESCOM Technical-Specification-HT-UG-Cablesಪರಮಮಿತ್ರಸಂಪತ್ಕುಮಾರ್ಶೆಟ್ಟಿNo ratings yet

- 05 Interface C ConnectorsDocument31 pages05 Interface C ConnectorsjjcanoolivaresNo ratings yet

- Service Entrance Grounding: 1.0 INDEXDocument6 pagesService Entrance Grounding: 1.0 INDEXSaurabh HimkarNo ratings yet

- 11.ACMV (Electrical) PDFDocument22 pages11.ACMV (Electrical) PDFIswadi Bin Zulkarnain100% (1)

- Low and Medium Voltage Metal-Enclosed Bar Bus Guide Specification v0Document5 pagesLow and Medium Voltage Metal-Enclosed Bar Bus Guide Specification v0Bayu Suryo WirantoNo ratings yet

- TM Cable RequirementDocument96 pagesTM Cable Requirementfaridnor88No ratings yet

- We 0303Document140 pagesWe 0303korie100% (1)

- Three Core Cables To VDE 0276Document15 pagesThree Core Cables To VDE 0276A. HassanNo ratings yet

- Section I Cable Works 2.1 Design ConceptDocument58 pagesSection I Cable Works 2.1 Design ConceptVictor SichoneNo ratings yet

- Fiber Optic Cable Handling and InstallationDocument17 pagesFiber Optic Cable Handling and InstallationJay Flores San JoseNo ratings yet

- Wire and CableDocument5 pagesWire and CablejosemartinpenatorresNo ratings yet

- Cable TrayDocument28 pagesCable Traykirink73No ratings yet

- Cable Glands Technical InformationDocument16 pagesCable Glands Technical Informations_hassan_167419No ratings yet

- L T A B Cable Spec 08.08.2019Document17 pagesL T A B Cable Spec 08.08.2019Ashish bhattNo ratings yet

- Wiring Methods and Materials - Engr. MahusayDocument77 pagesWiring Methods and Materials - Engr. Mahusayron villanuevaNo ratings yet

- S8 Maa Oat 607Document3 pagesS8 Maa Oat 607danielliram993No ratings yet

- Article 392. Cable Trays PDFDocument7 pagesArticle 392. Cable Trays PDFgilbertomjcNo ratings yet

- 48 TMSS 01 R0Document0 pages48 TMSS 01 R0renjithas2005No ratings yet

- Va 27 10 00Document5 pagesVa 27 10 00Curtis SontohartonoNo ratings yet

- Minimum DepthDocument5 pagesMinimum DepthkailazNo ratings yet

- Is 7098 Part I 1998Document17 pagesIs 7098 Part I 1998Sanjeev DhariwalNo ratings yet

- IS-7098 PT - 1.Document17 pagesIS-7098 PT - 1.Rishi PalNo ratings yet

- BS 5308-1Document22 pagesBS 5308-1Jeff Anderson Collins100% (2)

- ABC Construction StandardsDocument16 pagesABC Construction StandardswolverinepNo ratings yet

- Tech Specs for 11kV Aerial Bunched CablesDocument6 pagesTech Specs for 11kV Aerial Bunched CablesBilal AhmadNo ratings yet

- ZAPPENDIX 1 Inspection and Testing REVISEDDocument6 pagesZAPPENDIX 1 Inspection and Testing REVISEDtesa korNo ratings yet

- 04 VEX Spot ReflectorDocument4 pages04 VEX Spot ReflectortemamNo ratings yet

- 03 VEX SpotDocument2 pages03 VEX SpottemamNo ratings yet

- 05 VEX Spot SNDocument2 pages05 VEX Spot SNtemamNo ratings yet

- 02 VEX MidiSpotDocument4 pages02 VEX MidiSpottemamNo ratings yet

- 26 Graphical SymbolsDocument12 pages26 Graphical SymbolstemamNo ratings yet

- Zappendix 2 Forms of Completion and Inspection RevisedDocument5 pagesZappendix 2 Forms of Completion and Inspection Revisedtesa korNo ratings yet

- 01 VEX MiniSpotDocument4 pages01 VEX MiniSpottemamNo ratings yet

- PV SystemDocument6 pagesPV SystemtemamNo ratings yet

- Installation of Lighting EquipmentDocument21 pagesInstallation of Lighting EquipmenttemamNo ratings yet

- SECTION 25 Swimming Pool Fountains and Similar Installations REVISEDDocument10 pagesSECTION 25 Swimming Pool Fountains and Similar Installations REVISEDtesa korNo ratings yet

- Diagnostic Imaging InstallationDocument3 pagesDiagnostic Imaging InstallationtemamNo ratings yet

- Motion Picture Studios Electrical SafetyDocument3 pagesMotion Picture Studios Electrical SafetytemamNo ratings yet

- SECTION 20 Emergency Systems, Unit Equipment and Exit Signs REVISEDDocument5 pagesSECTION 20 Emergency Systems, Unit Equipment and Exit Signs REVISEDtesa korNo ratings yet

- Lifts, Escalators and Similar EquipmentDocument9 pagesLifts, Escalators and Similar EquipmenttemamNo ratings yet

- Theater InstallationDocument7 pagesTheater InstallationtemamNo ratings yet

- Signs and Outline Lighting HALFDocument5 pagesSigns and Outline Lighting HALFtemamNo ratings yet

- Ferrule Selection GuideDocument4 pagesFerrule Selection GuidetemamNo ratings yet

- Patient Care AreasDocument8 pagesPatient Care AreastemamNo ratings yet

- Installation of Electrical EquipmentDocument22 pagesInstallation of Electrical EquipmenttemamNo ratings yet

- Hazardous LocationsDocument14 pagesHazardous LocationstemamNo ratings yet

- Section 13 Ele. RevisedDocument11 pagesSection 13 Ele. RevisedfiraolNo ratings yet

- Section 3 Illumination RevisedDocument40 pagesSection 3 Illumination Revisedtesyon korjoNo ratings yet

- Service and Equipment SetupDocument8 pagesService and Equipment SetuptemamNo ratings yet

- 12Document1 page12temamNo ratings yet

- Section 4 Conductors Revised IIIDocument71 pagesSection 4 Conductors Revised IIItesa korNo ratings yet

- Electrical Installation Testing ProceduresDocument10 pagesElectrical Installation Testing ProcedurestemamNo ratings yet

- CH 2Document141 pagesCH 2temamNo ratings yet

- Bahir Dar University Chapter on IlluminationDocument171 pagesBahir Dar University Chapter on IlluminationtemamNo ratings yet

- Substitution in The Linguistics of Text and Grammatical ThoughtDocument17 pagesSubstitution in The Linguistics of Text and Grammatical ThoughtThảo HanahNo ratings yet

- IPPD Presentation Roll OutDocument34 pagesIPPD Presentation Roll OutGracel Alingod Galay100% (1)

- Iloc and Loc Uses PDFDocument16 pagesIloc and Loc Uses PDFsaurabhNo ratings yet

- Travel directions LPU-Batangas from Manila, Laguna, Quezon, CaviteDocument1 pageTravel directions LPU-Batangas from Manila, Laguna, Quezon, CaviteMark Levin Munar100% (1)

- Laser PsicosegundoDocument14 pagesLaser PsicosegundoCristiane RalloNo ratings yet

- Homework1 SKKK1113 1112-2Document1 pageHomework1 SKKK1113 1112-2Khairul Anwar Abd HamidNo ratings yet

- Operation and Maint Manual Swill Hydraulic PlateformDocument16 pagesOperation and Maint Manual Swill Hydraulic Plateformmicell dieselNo ratings yet

- For Construction and Industry: Liebherr Diesel EnginesDocument8 pagesFor Construction and Industry: Liebherr Diesel EnginesGoran MatovicNo ratings yet

- Tutorial Chapter 1 Thermochemistry QuestionsDocument4 pagesTutorial Chapter 1 Thermochemistry Questionssiti nur masyitah nasaruddinNo ratings yet

- Mobilization and Participation: Social-Psychological Expansisons of Resource Mobilization TheoryDocument19 pagesMobilization and Participation: Social-Psychological Expansisons of Resource Mobilization TheoryJoaquim OliveiraNo ratings yet

- Customer: Id Email Password Name Street1 Street2 City State Zip Country Phone TempkeyDocument37 pagesCustomer: Id Email Password Name Street1 Street2 City State Zip Country Phone TempkeyAgus ChandraNo ratings yet

- Gen Math Module 6 Solving Exponential Equation and Inequalities - 112920 PDFDocument18 pagesGen Math Module 6 Solving Exponential Equation and Inequalities - 112920 PDFMGrace P. VergaraNo ratings yet

- QBD Dry PowdersDocument13 pagesQBD Dry PowdersTausif AlamNo ratings yet

- Group Case Study: Premier Automotive Services LimitedDocument2 pagesGroup Case Study: Premier Automotive Services LimitedKryzel Jean Tumbaga ValdezNo ratings yet

- Java Pattern Programming AssignmentsDocument9 pagesJava Pattern Programming Assignmentstamj tamjNo ratings yet

- Toyota Camry ANCAP PDFDocument2 pagesToyota Camry ANCAP PDFcarbasemyNo ratings yet

- Teachers Book - Smarty 4 PDFDocument77 pagesTeachers Book - Smarty 4 PDFFlorenciaRivichini50% (2)

- Identifying The Orders of AR and MA Terms in An ARIMA ModelDocument11 pagesIdentifying The Orders of AR and MA Terms in An ARIMA ModelNeha GillNo ratings yet

- Howden PDFDocument24 pagesHowden PDFskb2550% (2)

- This Content Downloaded From 3.6.73.78 On Wed, 21 Dec 2022 07:40:53 UTCDocument81 pagesThis Content Downloaded From 3.6.73.78 On Wed, 21 Dec 2022 07:40:53 UTCabcdNo ratings yet

- Proportional, Solenoid Actuated Flow Control Valves Type SE and SEHDocument16 pagesProportional, Solenoid Actuated Flow Control Valves Type SE and SEHwords2zhigang_612545No ratings yet

- Electric Machine Design 01 Electric Machine DesignDocument10 pagesElectric Machine Design 01 Electric Machine Designkhodabandelou100% (1)

- Guia Instalacion ENTECDocument15 pagesGuia Instalacion ENTECHislim SaidNo ratings yet

- Welder Training in SMAW, GTAW & GMAW Welding Engineering & NDT Consultancy Welding Engineering Related TrainingDocument4 pagesWelder Training in SMAW, GTAW & GMAW Welding Engineering & NDT Consultancy Welding Engineering Related TrainingKavin PrakashNo ratings yet

- Test Bank For Close Relations An Introduction To The Sociology of Families 4th Canadian Edition McdanielDocument36 pagesTest Bank For Close Relations An Introduction To The Sociology of Families 4th Canadian Edition Mcdanieldakpersist.k6pcw4100% (44)

- Practical Training Seminar Report FormatDocument8 pagesPractical Training Seminar Report FormatShrijeet PugaliaNo ratings yet

- 22-02-13 Samsung Answer To Staton Techniya Complaint & CounterclaimsDocument72 pages22-02-13 Samsung Answer To Staton Techniya Complaint & CounterclaimsFlorian MuellerNo ratings yet

- D6 SeptimusDocument366 pagesD6 SeptimusHenry Gaudet100% (1)

- Word ShortcutsDocument3 pagesWord ShortcutsRaju BNo ratings yet

- Node - Js 8 The Right Way: Extracted FromDocument11 pagesNode - Js 8 The Right Way: Extracted FromRodrigo Románovich FiodorovichNo ratings yet