0% found this document useful (0 votes)

2K views28 pagesCable Tray

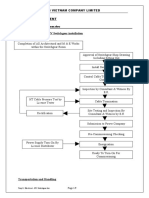

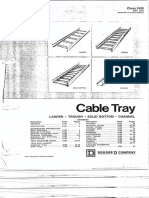

1. The document discusses various types of cable management systems including cable ladder, cable tray, wire mesh tray, and cable trunking.

2. It provides details on the materials and finishes used in these systems, including mild steel, galvanized steel, aluminum, and stainless steel.

3. Requirements and standards for installation, loading capacity, electrical properties, and other technical specifications are also covered.

Uploaded by

kirink73Copyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

2K views28 pagesCable Tray

1. The document discusses various types of cable management systems including cable ladder, cable tray, wire mesh tray, and cable trunking.

2. It provides details on the materials and finishes used in these systems, including mild steel, galvanized steel, aluminum, and stainless steel.

3. Requirements and standards for installation, loading capacity, electrical properties, and other technical specifications are also covered.

Uploaded by

kirink73Copyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd