Professional Documents

Culture Documents

Spec-K102 ADS N1230 2016 (PDF) Novac 1230 Pipes

Spec-K102 ADS N1230 2016 (PDF) Novac 1230 Pipes

Uploaded by

Ahmed ZahyOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Spec-K102 ADS N1230 2016 (PDF) Novac 1230 Pipes

Spec-K102 ADS N1230 2016 (PDF) Novac 1230 Pipes

Uploaded by

Ahmed ZahyCopyright:

Available Formats

KIDDE CLEAN AGENT ADS™ FIRE SUPPRESSION SYSTEM

with 3M™ Novec™ 1230 Fire Protection Fluid

Part 1 - GENERAL

1.1 DESCRIPTION OF WORK

A. Design and installation of an engineered Kidde ECS Advanced Delivery Systems (ADS), clean

agent/waterless fire suppression system employing 3M™ Novec™ 1230 waterless fire suppression

fluid, which is manufactured by Kidde Fire Systems, 400 Main Street, Ashland, MA 01721.

B. All drawings are to be reviewed by the contractor so any items which may affect the operation of the

fire suppression system(s) are taken into account when designing the system.

1.2 APPLICABLE STANDARDS & PUBLICATIONS

A. The design, installation, testing and maintenance of the clean agent fire extinguishing

system, shall be in accordance with the requirements in the following codes, standards and

regulatory bodies:

NFPA 2001: Standard for Clean Agent Fire Extinguishing Systems

NFPA 70: National Electrical Code (NEC)

NFPA 72: National Fire Alarm Code

1. Underwriter Laboratories, Inc (UL)- UL2166: Standard for Halocarbon Clean Agent

Extinguishing System

2. Factory Mutual Approval Guide

3. ANSI B1.20.1: Standard for pipe threads, General Purpose

4. Requirements of the Local Authorities Having Jurisdiction (AHJ)

5. Kidde Fire Systems Manual P/N 06-237256-001.

B. The complete system shall have the applicable following listings and approvals:

1. Underwriters Laboratories (UL)

2. Factory Mutual Global (FM)

3. Underwriters Laboratories of Canada (ULC)

C. All components of the clean agent fire extinguishing system shall be the products of the same

manufacturer or listed by that manufacturer as compatible with those devices components

and equipment.

1.3 SUMMARY

A. Section includes:

1. Extinguishing agent

2. Extinguishing agent cylinders

3. Piping and piping specialties

B. Section Exclusions:

1. Room sealing requirements shall be communicated and coordinated between the

suppression system contactor and the project’s main General Contractor and all sub-

contractors.

December 2015 Page 1 of 7

KIDDE CLEAN AGENT ADS™ FIRE SUPPRESSION SYSTEM

with 3M™ Novec™ 1230 Fire Protection Fluid

1.4 QUALIFICATIONS OF MANUFACTURER, DESIGNER, AND INSTALLER

A. Manufacturer

1. The manufacturer/supplier of the system hardware and components shall have a

minimum of fifteen (15) years experience in the design and manufacture of systems of

similar type

2. The manufacturer/supplier of the systems shall be certified to ISO 9001 for a minimum

period of five (5) years for the design, production and distribution of fire detection, fire

alarm and fire suppression systems.

3. All devices, components and equipment shall be the products of the same

manufacturer/supplier.

4. The system manufacturer/supplier shall have the ability to provide multiple suppression

system arrangements to accommodate the performance criteria required by the project.

B. Designer/Installer Suppression System Contractor

1. The suppression system contractor shall be authorized to purchase and trained by the

Kidde Fire Systems (manufacturer) to design, install, test and maintain the ADS system,

using NOVEC 1230 clean agent fire extinguishing fluid proposed and shall be able to

produce a certificate of training and/or a letter stating they are an authorized supplier of

the proposed equipment from the manufacturer, upon request.

2. The suppression system contractor shall employ a person who can show proficiency

equal to a NICET level <II>, <III> or <IV> certification in special hazards design.

3. The Contractor shall confirm in writing that he stocks a full complement of spare parts

and offers 24-hour/7 days a week emergency service for all equipment being furnished.

4. Maintain or have access to a recharging station capable of recharging the largest

suppression system with <48hrs> after discharge

1.5 SUBMITTALS

A. Supply manufacturers product technical data and catalog cut sheets for each component or

device used in the system.

B. Shop Drawings

1. Prepared by a person holding at least a NICET Level III certification

2. Meet all systems design chapter requirements per NFPA 2001 and recommendations in

the “Working Plans” section.

3. Include design calculations for enclosure volume, agent quantity based on required

design concentration for each hazard area.

4. Indication of dimensions, weights and loads of equipment assemblies, components,

method of field assembly, clearance requirements, mounting and bracing practices, etc

5. Isometric piping layouts

6. Plan and Elevation views

7. Suppression system equipment locations

C. Flow Calculation Reports

1. The distributor shall provide the following information in the flow calculation report.

i. Customer information and project data

ii. Hazard information. At a minimum, hazard information shall include the minimum

design concentration and adjusted design concentration, minimum and maximum

enclosure ambient temperature, minimum agent required, volume of enclosures

and any corresponding non-permeable volume, and identify the quantity of

discharge nozzles.

December 2015 Page 2 of 7

KIDDE CLEAN AGENT ADS™ FIRE SUPPRESSION SYSTEM

with 3M™ Novec™ 1230 Fire Protection Fluid

iii. Cylinder information. At a minimum, cylinder information shall include total agent

required, cylinder capacity, cylinder part number, cylinder quantities (both main

and reserve), agent fill amount per cylinder and floor loading per cylinder.

iv. Pipe network information. At a minimum, pipe network information shall include

pipe type, pipe diameter, pipe length, change in elevation, pipe equivalent length

and any added accessory equivalent length. In addition, the following nozzle

information shall be provided; number of nozzles and identification of enclosure

location, flow rate of associated nozzle, nozzle nominal pipe size, nozzle type

and nozzle orifice area.

v. Pipes and pipe fittings. A detailed list of pipe, by schedule, nominal diameter and

length, and fittings, by nominal diameter and quantity.

D. The architect will review all submittals for conformance to the drawings and specifications.

The contractor shall be required to resubmit any materials, with appropriate modifications,

that are found to be in non-conformance with the requirements of the drawings and these

specifications after review by the architect. Approval of the submittals by the architect shall

not relieve the Contractor of their responsibility to meet the requirements of the drawings and

specifications.

E. OPTIONAL: Three-Way Ball Valve Information. A calculation shall be completed for each

directional valve in the piping network that is used to direct agent to a particular hazard area

off of a central bank of cylinders. Modeling of the Three-Way Ball Valve shall be shown in the

”open/thru” and “closed/to hazard” position.

The solenoid of the three way ball valve shall be supervised for its placement. Removal of the

electrical solenoid will initiate a supervisory trouble in the FACP through audio and visual

indication.

F. Commissioning Equipment List: The distributor shall provide a commissioning equipment list

for each installed clean agent fire extinguishing system. The equipment list shall identify all

installed equipment and configurations.

G. Test Plan

1. The distributor shall submit a test plan that describes how the system equipment and

room integrity shall be tested. This shall include a step-by-step description of all tests and

shall indicate type and location of test apparatus to be used. At a minimum, the tests to

be conducted shall be per NFPA 2001 and any additional supplemental tests required by

the AHJ. Tests shall not be scheduled nor conducted until the engineer of record

approves the test plan.

H. Installation Drawings

1. Four (4) sets of installation drawings for each installed clean agent fire extinguishing

system and one (1) set of the calculation report (if not included in the drawings

themselves), owner’s manual and product data sheets shall be submitted to the end-

user/owner.

2. Upon completion of installation and commissioning acceptance, two (2) sets of “As-Built”

installation drawings and One (1) set of the calculation report (if not incorporated into the

drawings files) for each installed clean agent fire extinguishing system shall be given to

the owner/end-user for use and reference.

I. Operation and Maintenance Manuals

December 2015 Page 3 of 7

KIDDE CLEAN AGENT ADS™ FIRE SUPPRESSION SYSTEM

with 3M™ Novec™ 1230 Fire Protection Fluid

1. Two (2) copies of the Kidde Fire Systems Design, Installation, Operation and

Maintenance Manual for the ADS clean agent fire extinguishing system employing

NOVEC 1230 shall be submitted after complete installation.

1.6 WARRANTY

A. Components provided by the manufacturer shall carry a warranty of thirty-six (36) months

from date of shipment from the manufacturer’s facility or one (1) full year from the date of

installation.

2. PRODUCTS

SYSTEM DESCRIPTION

A. The system shall be a Kidde ECS Advanced Delivery Fire Suppression System (ADS) with

NOVEC 1230 Fire Protection Fluid and shall consist of NOVEC 1230, agent cylinder(s)

super-pressurized to 360 psig, seamless nitrogen driver cylinder(s) pressurized to 1800-psig

at 70°F (124 bar at 21°C), Kidde actuation hardware and Kidde discharge nozzle(s) attached

to a pipe network. The ADS system shall l be engineered for total flooding of the hazard

being protected. The design of this system will be for Class A, B, and C fires as determined

by the areas being protected.

B. The system shall comply with the new requirement of NFPA to supervise the placement of

electrical control head on the cylinder valve. Removal of the electrical actuator shall register a

supervisory trouble in the fire alarm control panel through audio and visual indication.

C. Should there be any selector valves in the system, the solenoid of the selector valve shall be

supervised for its placement. Removal of the electrical solenoid shall register a supervisory

trouble in the fire alarm control panel through audio and visual indication.

D. Agent Concentration Requirements

1. Achieve a 4.5% (v/v) extinguishing concentration for Class A (Surface Type Fires)

hazards.

2. Achieve a 5.8% (v/v) or greater, as required, extinguishing concentration for Class B

(Flammable Liquids) hazards. Refer to Design, Installation, and Operations manual for

design concentration guidance of Class B fuels or contact Kidde Fire Systems.

3. Achieve a 4.7% (v/v) extinguishing concentration for Class C (Energized Electrical

Equipment) hazards.

Note: Design Concentrations shall not exceed the agents Lowest Observed

Adverse Effects Level (LOAEL) as published in NFPA 2001

4. ADS Cylinder(s) shall be capable of being remotely stored away from the protected

hazard while still being able to deliver its 95% of its contents within 10 seconds, which

can be verified through the ADS flow calculation program.

2.2 SYSTEM PERFORMANCE

A. System Discharge

1. The discharge time required to achieve 95% of the minimum design concentration for

flame extinguishment shall not exceed 10 seconds.

B. Duration of Protection

December 2015 Page 4 of 7

KIDDE CLEAN AGENT ADS™ FIRE SUPPRESSION SYSTEM

with 3M™ Novec™ 1230 Fire Protection Fluid

1. 85% of the minimum design concentration shall be maintained for 10-minutes or a

sufficiently longer period of time to allow effective emergency action by trained personnel.

C. Minimum System Design Limits

1. Nozzles

i. Nozzles shall be listed and approved for a minimum height of 1 foot (0.31 m) to a

maximum height of 18.5 feet (5.64 m) above the floor.

ii. Nozzle area coverage for both 360- and 180-degree nozzles shall be a maximum

of 42.5ft x 42.5-ft (12.95-m x 12.95-m).

2.3 CYLINDER LOCATIONS:

A. The cylinders of the this advanced delivery system must be able to be stored/located up to

180ft away from the protected hazard.

B. The location chosen to remotely store/locate the cylinders from the protected hazard must

verify its ability to deliver agent to the protected space in the required amount of time through

the agent/system calculation software. The inability to meet the design requirements by any

system will be considered as not meeting the specifications intent.

2.4 PIPE AND FITTINGS

A. Distribution piping, and fittings, shall be installed in accordance with NFPA 2001, approved

piping standards and the engineered fire suppression system manufacturer’s requirements.

B. Piping materials shall be Schedule 40 black iron, galvanized, stainless steel, or chrome

plated conforming to ASTM A106 Seamless Grades A, B or C ; Schedule 40, ASTM A53

ERW Grades A or B ; Schedule 40, ASTM A53 F Furnace Welded ; Schedule 40

C. Ordinary cast iron pipe shall A-120 steel pipe and non-metallic pipe shall not be used

D. All fittings shall be 300lb Class fittings conforming, Class 300 malleable or ductile iron up to 6

inch (152mm), Class 300 flanged joints up to 8 inch (203mm), 500 lb. rated grooved up to 8

inch (203mm)

E. Class 150 and cast-iron fittings shall not be used

F. Nozzles shall be braced to prevent any movement in the horizontal or vertical planes

G. Pipe unions are acceptable

H. Inlets and Outlets of Tees can be on the vertical plane

I. All piping shall be supported in a close as possible to concentrated loads and each change in

direction. Hanger spacing’s to be installed in accordance with pipe design practices and

hanger manufacturers recommendation on spacing.

J. All pipe must be reamed and cleaned prior to assembly to remove burrs and cutting oils

K. The use of Teflon tape or Joint Compound is acceptable, but should only be applied to the

male threads

2.5 ACTUATION HARDWARE

A. The agent cylinders shall be actuated in accordance with the applicable design manual.

B. While in the stand-by condition, actuators attached to the cylinder valve shall not be exposed

to the cylinder’s internal pressure so as to avoid introducing additional leak paths or

accidental discharges.

C. Solenoid actuators shall not require scheduled periodic replacement.

D. Solenoid actuators shall be supervised for its placement. Removal of the electrical solenoid

actuator shall cause a supervisory trouble in FACP through audio and visual indication.

December 2015 Page 5 of 7

KIDDE CLEAN AGENT ADS™ FIRE SUPPRESSION SYSTEM

with 3M™ Novec™ 1230 Fire Protection Fluid

th

E. The suppression panel shall be UL Listed per UL 864, 9 Edition with the interfacing electric

actuators.

2.6 NOZZLES

A. Total flooding clean agent extinguishing system nozzles shall be made of stainless steel or

brass.

B. Each nozzle shall be located in the space per the manufacturer’s guidelines. Nozzles shall

have either a 180- or a 360-degree discharge pattern.

C. Each nozzle discharge pattern shall be available in sizes ranging from 1/2-in NPT to 2-in

NPT.

D. Within each nozzle size and style, the manufacturer shall offer multiple different orifice areas

(minimum of 20).

E. Nozzles shall be UL Listed and FM Approved for use with the manufacturer’s clean agent

extinguishing system employing NOVEC 1230.

2.7 AGENT CYLINDER ASSEMBLIES

A. NOVEC 1230 shall be stored in cylinders manufactured and marked in accordance with US

Department of Transportation (DOT) specification 4BW-500 and Transport Canada (TC)

specification 4BW-M34. The agent cylinders shall be conditioned to 360 PSIG @ 70°F (24.8

bar gauge @ 21°C). The external nitrogen propellant shall be stored in seamless cylinders

manufactured and marked in accordance with US DOT specification 3AA-2015 and TC

specification 3AAM-154. The external nitrogen cylinders shall be conditioned to 1800-psig @

70°F (124.12 bar gauge @ 21°C). The system manufacturer shall be able to provide US

DOT documentation that the registration number marked on the agent cylinder or the nitrogen

cylinder corresponds to a manufacturing location at a US address.

1. NOVEC 1230 cylinders shall have a safety relief disc on the shoulder of the cylinder.

2. NOVEC 1230 cylinders shall have an integral cup check assembly for transfer of

nitrogen.

3. NOVEC 1230 cylinders with shall be equipped with an integral liquid level indicator (LLI).

The LLI will allow the agent cylinder to remain connected and secured in place while

measuring the agent mass.

4. NOVEC 1230 cylinders shall have a pressure gauge to provide a visual reading of actual

container pressure

5. An optional low pressure switch can be added to the NOVEC 1230 cylinder to provide a

means of electrical supervision of container pressure.

2.8 FIRE EXTINGUISHING AGENT

A. Fire Suppression Agent: 3M NOVEC 1230 Fire Protection Fluid (FK-5-1-12) by 3M

Company, St. Paul, MN

2.9 OPTIONAL EQUIPMENT

A. When protecting multiple hazard areas from a single supply of NOVEC 1230, Kidde Three-

Way Directional Ball Valves shall be used.

1) The Three-Way Directional Ball Valves shall be UL Listed or FM Approved for use with

NOVEC 1230 and Kidde Engineered Suppression Systems.

2) The Three-Way Directional Ball Valves shall be installed and located in the piping

network per the manufacturer’s guidelines and design manual

3. EXECUTION

3.1 CLEAN AGENT FIRE EXTINGUISHING SYSTEM INSTALLATION

December 2015 Page 6 of 7

KIDDE CLEAN AGENT ADS™ FIRE SUPPRESSION SYSTEM

with 3M™ Novec™ 1230 Fire Protection Fluid

A. The system shall be supplied and installed by a factory-authorized, Kidde Fire Systems

Distributor. The Distributor shall be trained and certified by Kidde Fire Systems to design,

install and maintain the Kidde fire suppression system. The distributor shall install the system

in accordance with the manufacturer’s design, installation, operation and maintenance

manual.

3.2 ELECTRICAL SYSTEM INSTALLATION

A. All electrical enclosures, raceways, and conduits shall be provided and installed in

accordance with applicable codes and intended use, and shall contain only those electrical

circuits associated with the fire-detection and control system. No circuit or circuits that are

unrelated to the fire alarm or suppression system shall be routed through the enclosures,

raceways, and conduits dedicated to the fire alarm or suppression system.

B. Splicing of circuits shall be kept to a minimum, and is only permitted in an electrical box

suitable for the purpose. Appropriate hardware shall be used to make the wire splices. Wires

that are spliced together shall have the same color insulation.

C. White colored wire shall be used exclusively for the identification of the neutral conductor of

an alternating-current circuit. Green colored wire shall be used exclusively for the

identification of the earth-ground conductor of an AC or DC circuit. Appropriate color-coding

shall be utilized for all other field wiring.

D. All electrical circuits shall be numerically tagged with suitable markings at each terminal point.

All circuits shall correspond with the installation draw.

3.3 SYSTEM CHECKOUT

A. Entire system shall be checked out, inspected, and functionally tested by factory authorized

and trained personnel.

B. Inspection shall be performed in the presence of the owners representative, engineer or

architects representative, insuring authority, and/or the local AHJ (Authority Having

Jurisdiction)

C. Prior to final acceptance, the contractor shall provide operational and safety training in all

concepts of the system to the owners key personnel. Release of clean agent shall not be

part of the training requirements

3.4 ROUTINE MAINTENANCE

A. Routine maintenance on equipment shall be performed by a certified Kidde Fire System

Distributor, in accordance with the most current version of NFPA 2001 and the

manufacturer’s installation, operation and maintenance manual.

December 2015 Page 7 of 7

You might also like

- Hitachi VRF Service. 03Document318 pagesHitachi VRF Service. 03Md Saddam Hossain100% (2)

- Cisco IP Phone 7821, 7841, and 7861 Quick StartDocument2 pagesCisco IP Phone 7821, 7841, and 7861 Quick StartDmitryNo ratings yet

- Effects of Rear Spoilers On Ground Vehicle Aerodynamic DragDocument16 pagesEffects of Rear Spoilers On Ground Vehicle Aerodynamic DragVyssionNo ratings yet

- Previews MSS SP 61 2013 PreDocument4 pagesPreviews MSS SP 61 2013 PreHoàng Vinh0% (1)

- LBV PDFDocument136 pagesLBV PDFaliNo ratings yet

- Optimizing Hot Gas Defrost 2Document24 pagesOptimizing Hot Gas Defrost 2Marcelo RuaniNo ratings yet

- Service Hd1430Document248 pagesService Hd1430CarlosAZea100% (4)

- New Standard For FRP PipingDocument37 pagesNew Standard For FRP PipingKamatchi NathanNo ratings yet

- Technical Evaluation Matrix TemplateDocument1 pageTechnical Evaluation Matrix Templatemuhammad iqbalNo ratings yet

- Manual de Operación Slam ShutDocument20 pagesManual de Operación Slam ShutMoises Perez CarvajalNo ratings yet

- Commissioning of A FurnaceDocument2 pagesCommissioning of A FurnaceyogacruiseNo ratings yet

- FMDS0310 PDFDocument59 pagesFMDS0310 PDFIvánMoreiraChaverriNo ratings yet

- 05 - Supply Mode Sprinkler in 22 FloorDocument16 pages05 - Supply Mode Sprinkler in 22 FloorShappan Abd AllhaNo ratings yet

- Technical Doc 1 - Technical Scope of Work Drs Eac181Document25 pagesTechnical Doc 1 - Technical Scope of Work Drs Eac181bhargavpansuria09No ratings yet

- VESDA Troubleshooting Guide - Rev05Document26 pagesVESDA Troubleshooting Guide - Rev05Eduardo Diaz PichardoNo ratings yet

- Technical Specification For Communication EquipmentDocument79 pagesTechnical Specification For Communication EquipmentumamaheshwarraoNo ratings yet

- Manual Bristol Rtu 3305 Remote Terminal Unit Ras en 133582 PDFDocument348 pagesManual Bristol Rtu 3305 Remote Terminal Unit Ras en 133582 PDFadesa2013No ratings yet

- Astm E498-11Document4 pagesAstm E498-11Abdul Salam100% (1)

- Servo Gauge TI00452G08EN06.14Document41 pagesServo Gauge TI00452G08EN06.14jeduardo2325No ratings yet

- Agip KCO: Kashagan Field Development Project Experimental ProgrammeDocument27 pagesAgip KCO: Kashagan Field Development Project Experimental ProgrammeMaffone NumerounoNo ratings yet

- PDS EE Raceway Reference GuideDocument481 pagesPDS EE Raceway Reference GuidebalajivangaruNo ratings yet

- 220 3PS MFCK 00001 PDFDocument10 pages220 3PS MFCK 00001 PDFJulio Miranda AlarconNo ratings yet

- Sensornet Oct 2017-DAS-NASDocument13 pagesSensornet Oct 2017-DAS-NASListyo SurantoNo ratings yet

- 0000-ESP-AEPC-00!61!0002 Rev01 NDE For Pipe WeldsDocument13 pages0000-ESP-AEPC-00!61!0002 Rev01 NDE For Pipe WeldsAnonymous ZaZqvjJPzNo ratings yet

- Evaluating Proposals and SupplierDocument64 pagesEvaluating Proposals and Supplierrgrao85No ratings yet

- MinnPar Online CatalogDocument69 pagesMinnPar Online CatalogAlfredo AguilarNo ratings yet

- Appendix G - TRS 09082B - Inverter System Interface To Plant Computer (KIT) Rev 0Document14 pagesAppendix G - TRS 09082B - Inverter System Interface To Plant Computer (KIT) Rev 0pthakur234No ratings yet

- PV-G-20024-0 - Specifications For Coating of Equipment and Metallic Structures - PVDC 2020-01-05Document45 pagesPV-G-20024-0 - Specifications For Coating of Equipment and Metallic Structures - PVDC 2020-01-05Federico A. MartinezNo ratings yet

- PT Borneo Mitra Sinergi: Topography Survey PlanDocument3 pagesPT Borneo Mitra Sinergi: Topography Survey PlanaswarNo ratings yet

- 3100/3150 - LTQ Limitorque Valve Actuator Master Module: Revision 1.7Document41 pages3100/3150 - LTQ Limitorque Valve Actuator Master Module: Revision 1.7Marcos VasconcelosNo ratings yet

- Road Map Update for Carbon Capture, Utilization, and Storage Demonstration and Deployment in the People’s Republic of ChinaFrom EverandRoad Map Update for Carbon Capture, Utilization, and Storage Demonstration and Deployment in the People’s Republic of ChinaNo ratings yet

- D ESD Series Installation&Maintenance PDFDocument20 pagesD ESD Series Installation&Maintenance PDFPablo GarcíaNo ratings yet

- TPS Ci XR Aa 001 (B01) Cause&effect Diagram PDFDocument8 pagesTPS Ci XR Aa 001 (B01) Cause&effect Diagram PDFabboudNo ratings yet

- Index/ Revisions Status: Revision History/ Description Revision History/ DescriptionDocument10 pagesIndex/ Revisions Status: Revision History/ Description Revision History/ DescriptionmithunceaNo ratings yet

- 12P5403GDocument16 pages12P5403GMalik HamzaNo ratings yet

- CP 201Document36 pagesCP 201kattabommanNo ratings yet

- 2009 Annual Survey Report and Appendices-Phase IDocument82 pages2009 Annual Survey Report and Appendices-Phase ItoddflyNo ratings yet

- Commissioning Guide - (V200R008C02 01, NGN)Document148 pagesCommissioning Guide - (V200R008C02 01, NGN)Catherine HiginoNo ratings yet

- 3500-25 Enhanced Keyphasor Module Datasheet - 141532Document10 pages3500-25 Enhanced Keyphasor Module Datasheet - 141532Ali HadiNo ratings yet

- 11 Proven Practices For Peer ReviewDocument14 pages11 Proven Practices For Peer Reviewgreenfinger2No ratings yet

- OV 141113 FDS JR Comments - Revision - 1Document56 pagesOV 141113 FDS JR Comments - Revision - 1wqs_19No ratings yet

- POB User Manual v1.2.2 1Document61 pagesPOB User Manual v1.2.2 1Vladimirs ArzeninovsNo ratings yet

- FAT & SAT For Electrical System in Utility EndDocument16 pagesFAT & SAT For Electrical System in Utility EndBabuNo ratings yet

- Zener Barrier Applications: DI DO AI AODocument36 pagesZener Barrier Applications: DI DO AI AORaj ChavanNo ratings yet

- Fabrication of Structural and Miscellaneous Steel Supplier Drawing & Data Commitment (SDDC) FormDocument7 pagesFabrication of Structural and Miscellaneous Steel Supplier Drawing & Data Commitment (SDDC) FormEl_memitoNo ratings yet

- Euro Standard HDPEDocument80 pagesEuro Standard HDPEkuraimund0% (2)

- ELSTERDocument4 pagesELSTERManuel GerardoNo ratings yet

- Catalogo de Hvac Safe TecnologyDocument16 pagesCatalogo de Hvac Safe TecnologyLuis Felipe TorresNo ratings yet

- 220 JLD JL10 21051 PDFDocument2 pages220 JLD JL10 21051 PDFFrancisco Antonio Guerrero MonsalvesNo ratings yet

- Fan Heater - B-011 - Data SheetsDocument9 pagesFan Heater - B-011 - Data SheetsNadim Ahmad SiddiqueNo ratings yet

- Catalogo CombustionDocument164 pagesCatalogo CombustionAndresNo ratings yet

- Migracion Micrologix 1500 A Compact LogixDocument14 pagesMigracion Micrologix 1500 A Compact LogixOGNo ratings yet

- FMDS0549Document8 pagesFMDS0549Salvador NoeNo ratings yet

- Pipeline TransportDocument9 pagesPipeline TransportSinisaP23No ratings yet

- Hazards and Effects Management AssessmentDocument6 pagesHazards and Effects Management AssessmentSidhanath SinghNo ratings yet

- BN-W-UE301 The Numbering of Project DocumentsDocument18 pagesBN-W-UE301 The Numbering of Project DocumentsrudiawanNo ratings yet

- Fdocuments - in - Shell Dep ListDocument25 pagesFdocuments - in - Shell Dep Listdeyanshu7No ratings yet

- 2-Test Pack Cover SheetDocument1 page2-Test Pack Cover SheetPintu KumarNo ratings yet

- C-54 NocDocument41 pagesC-54 NocRochdi SahliNo ratings yet

- E2T SCADA Roadmap Functional May 2013 CJS 2013.5.1 Opsmanage13Document27 pagesE2T SCADA Roadmap Functional May 2013 CJS 2013.5.1 Opsmanage13rosy_vereniceNo ratings yet

- Manual de Vaporizadores AmbientalesDocument9 pagesManual de Vaporizadores AmbientalesJose Luis Tadeo SabinoNo ratings yet

- Veco Engineering Ltd. Equipment Data Sheet: Centrifugal FanDocument9 pagesVeco Engineering Ltd. Equipment Data Sheet: Centrifugal Fanwado11No ratings yet

- KhairulDocument244 pagesKhairulAyie KhairiNo ratings yet

- 00-SATP-busway, Rev01Document9 pages00-SATP-busway, Rev01islam mohamedNo ratings yet

- Sat TR General (Rev. 0 2009)Document3 pagesSat TR General (Rev. 0 2009)Abhinav SinhaNo ratings yet

- Vernier Calipers and ScrewgaugeDocument17 pagesVernier Calipers and ScrewgaugeSURESH SURAGANINo ratings yet

- Catalog Rain Bird 2018 (Sprinkler)Document196 pagesCatalog Rain Bird 2018 (Sprinkler)Isbir FarhanNo ratings yet

- IC Engine Seminar ReportDocument28 pagesIC Engine Seminar ReportDiwakar Diwakar100% (1)

- Engine Cat 3126B 175 HP 330 HP PDFDocument7 pagesEngine Cat 3126B 175 HP 330 HP PDFdionymackNo ratings yet

- Hein Warner Hydraulic Excavator Spm9308128 Parts BookDocument5 pagesHein Warner Hydraulic Excavator Spm9308128 Parts Bookcarmen100% (56)

- 7.1 Heat ExchangerDocument70 pages7.1 Heat ExchangerRAJESHNo ratings yet

- En 5.4.335Document8 pagesEn 5.4.335Joy BhattacharyaNo ratings yet

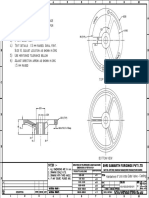

- KGV 4 Uch Handwheel CastingDocument1 pageKGV 4 Uch Handwheel CastingMahendra PatilNo ratings yet

- Class8 & 9Document6 pagesClass8 & 9KIRAN P ABRAHAMNo ratings yet

- 5 Heat Transfer CarranzaDocument71 pages5 Heat Transfer CarranzaChristian Rally Ramos GonzalezNo ratings yet

- Mechanical Properties of MetalsDocument11 pagesMechanical Properties of MetalsKamalesh Singh100% (1)

- Thermo Lecture 1 - Introduction & Boilers PDFDocument93 pagesThermo Lecture 1 - Introduction & Boilers PDFRosina AdhikariNo ratings yet

- Chapter 2-Two Dimensional Linear Theory of Elasticity-1Document43 pagesChapter 2-Two Dimensional Linear Theory of Elasticity-1Norsyazwani Abdul RashidNo ratings yet

- Powerpoint Gyro CompassDocument15 pagesPowerpoint Gyro CompassM.Irmak ıNo ratings yet

- S.ashiq - ResumeDocument2 pagesS.ashiq - ResumeRees JohnsonNo ratings yet

- OTR Synthetic Gear Lube SAE 75W-90 Available atDocument2 pagesOTR Synthetic Gear Lube SAE 75W-90 Available atBruce WappmanNo ratings yet

- CHE4613LAB7Document6 pagesCHE4613LAB7Huda AlkhouriNo ratings yet

- Ge Ge752 User Manual 63 64Document2 pagesGe Ge752 User Manual 63 64RICHARDNo ratings yet

- Properties of MatterDocument13 pagesProperties of Matterapi-252896245No ratings yet

- ECS 3-12-2 - 3 - 800871d3Document8 pagesECS 3-12-2 - 3 - 800871d3Florin Daniel AnghelNo ratings yet

- Training Machine1, Homework in Electrical MachinesDocument3 pagesTraining Machine1, Homework in Electrical MachinesNGOUNENo ratings yet

- Arburg 720s Web 524650 en UsDocument8 pagesArburg 720s Web 524650 en UsumbertiNo ratings yet

- Crack Width Check BS5400 4Document7 pagesCrack Width Check BS5400 4Alden CayagaNo ratings yet