Professional Documents

Culture Documents

15.07 2020 - TTC 2

Uploaded by

Alok PandeyOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

15.07 2020 - TTC 2

Uploaded by

Alok PandeyCopyright:

Available Formats

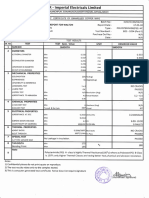

POLYCAB INDIA LTD.

- UH3

TYPE TEST CERTIFICATE

Customer: POLYCAB INDIA LTD. - UH3 Date: 28-Dec-19

Project: - So No: 18190028983

P.O. NO: - Drum No: 1928DFG-129919

Size: 4 CORE X 6.0 SQ.MM

Voltage Grade: 1100 VOLTS

Description: POLYCAB MAKE 1100V STRANDED ROUND NON COMPACTED (CLASS 2) BARE COPPER CONDUCTOR, XLPE INSULATED, INSULATED CORES LAYING

FOR LAID UP,EXTRUDED ST2 PVC I/SH, SINGLE LAYER GALVANISED STEEL ROUND WIRE ARMOURED AND EXTRUDED ST2 FR-LSH PVC OUTE R

SHEATHED LV POWER CABLE AS PER IS 7098 PART 1

SR. NO. DESCRIPTION UNITS REQUIREMENTS OBSERVATIONS

Red Yellow Blue Black

1.0 Test On Conductor Plain Annealed Stranded Copper As Per Class-2 - Circular

a. No Of Strands Nos. 7 7

b. Annealing Test % Min. 18 25.00 26.00 25.00 27.00

c. Conductor resistance at 20 ° C ohm/km Max. 3.08 2.968 2.959 2.981 2.977

2.0 Test On Insulation Extruded XLPE

a. Thickness mm Nom. 0.7 0.72 0.74 0.78 0.75

mm Min. 0.53 0.68 0.65 0.66 0.68

b. Hot set test (200 ± 3 ⁰C for 15 Minutes ) % Max. 175 40.6 45.2 46.2 48.5

c. Permanent set % Max. 15 1.5 2.5 2 2.5

2.1 Before Ageing

a. Tensile Strength N/Sq.mm Min. 12.5 15.35 15.95 15.8 15.4

b. Elongation At Break % Min. 200 425 465 425 450

2.2 After Ageing in Air Oven (135 ± 3 ° C For 168 hrs)

a. Tensile Strength N/Sq.mm Min. - 15.12 15.6 15.32 15.2

b. Elongation At Break % Min. - 410 430 418 422

c. Variation in Tensile strength % Max. ± 25 1.50 2.19 3.04 1.30

d. Variation in Elongation % Max. ± 25 3.53 7.53 1.65 6.22

2.3 Shrinkage test (130 ± 3 ° C For 1 hour) % Max. 4 2.5 1.5 1.5 1.0

2.4 Water absorbtion ( 85 ± 2° C For 14 Days) Mg/cm² Max. 1 0.535 0.51 0.54 0.518

2.5 Volume Resistivity

a. At 27 ⁰C Ohm-cm Min. 1 X 10¹⁴ 134.6X1014 140.5X1014 142.84X1014 140.9X1014

b. At 90 ⁰C Ohm-cm Min. 1 X 10¹² 75.12X1012 78.72X1012 74.56X1012 76.21X1012

3.0 Test On Inner Sheath Extruded PVC Type ST2

a. Color Black Black

b. Thickness mm Min. 0.3 0.42

4.0 Test On Armour Galvanised Steel Round Wire Armour

a. Dimensions mm 1.40 ± 0.040 1.396

b. Uniformity of Zinc Coating Dips No Red Deposits No Red Deposits

c. Mass of Zinc Coating g/m² Min. 85.5 118

d. Tensile Test Mpa 250-580 474

e. Elongation % Min. 6 18

f. Resistivity of Armour at 20oC Ω-cm Max.14.5 x 10 -6 12.28 X 10 -6

g. Torsion Test Nos. Min 43 54

5.0 Test On Outer Sheath FR-LSH Extruded PVC Type ST2

a. Colour Black Black

b. Thickness mm Min 1.24 1.42

5.1 Without Ageing

a. Tensile Strength N/Sq.mm Min. 12.5 14.7

b. Elongation at Break % Min. 150 240

5.2 After Ageing In Air Oven (100 ± 2 ° C For 168 hrs)

a. Tensile Strength N/Sq.mm Min. 12.5 13.6

b. Elongation at Break % Min. 150 235

c. Variation in T.S. % Max. ± 25 7.48

d. Variation in Elong. % Max. ± 25 2.08

5.3 Hot Deformation Test(80 ± 2 ° C For 06 hrs) % Max. 50 16.2

5.4 Heat Shock Test (150 ± 2 ° C For 01 hrs) No cracks No cracks

5.5 Shrinkage test (150 ± 2 ° C For 15 Minute) % Max. 4 1.5

5.6 Thermal stability test (200 ± 0.5 ° C) Minutes. Min. 80 >100

5.7 Cold Impact Test ( -5 ± 2 ° C) No Signs Of Cracks Or Scales No Signs Of Cracks Or Scales

5.8 Loss Of Mass test (100 ± 2 ° C For 07 days) Mg/Cm2 Max. 2 1

6.0 Overall Diameter (OD) mm 17.0 ± 2 17.5

7.0 High Voltage Test kV 3 KV for 5 minute WITHSTOOD

8.0 Flammability Test Seconds Period of burning after

4

removal of flame:60 Max.

mm Uneffected length

389

50 Min.

9.0 FR-LSH Test on Outersheath

a. Oxygen Index Test % Min. 29 33.3

b. Temperature Index Test @ 21 % O₂ °C Min. 250 310

c. Smoke Density Test % Max. 60 46

d. HCL Gas Emmission (IEC - 754 - I) % Max. 20 13.2

e. Swedish Chimmney (SS 424 1475) mm Uneffected length from

425

the top 300 mm Min.

f. Flammability Test (IEC-332 Part 3-22)

Charred or affected portion should not Charred or affected portion max. 0.75 mtr from the

reach exceeding 2.5 mtrs tip of the burner

Note: The Cable has been tested for above tests and found meeting the requirements as per IS 7098 Part 1/88,IS 8130,IS 5831,IS 3975 & Aprooved Data Sheets And

QAP

Tested By:Ketan Valand Prepared & Reviwed By: Sonal Patel Approved By:

Page 1 of 1

You might also like

- Coffee Roasters Companion PDFDocument10 pagesCoffee Roasters Companion PDFRoastery Dailio25% (4)

- NEXUS 2104brownsgasDocument8 pagesNEXUS 2104brownsgaswxcvbnnbvcxwNo ratings yet

- Datasheet - Ducab Cables - 3 & 4 CoreDocument19 pagesDatasheet - Ducab Cables - 3 & 4 Coreraj xNo ratings yet

- Screeing Method Fea FatigueDocument34 pagesScreeing Method Fea FatigueGokul Amarnath0% (1)

- Rogers - Unknown - RO4400 Series BondplyDocument4 pagesRogers - Unknown - RO4400 Series BondplyHadi SaeidiManeshNo ratings yet

- 06 - Fire Resistant CablesDocument13 pages06 - Fire Resistant CablesmlutfimaNo ratings yet

- Dental Porcelain: by Dr. Tayseer MohamedDocument63 pagesDental Porcelain: by Dr. Tayseer MohamedAnonymous LRPHmxh02No ratings yet

- International Toy Safety Guidelines (Form English) - UlDocument2 pagesInternational Toy Safety Guidelines (Form English) - UlHariharan RajaramanNo ratings yet

- N2XKB (AL) Y 1 X (16-800) MM 0.6/1 KVDocument5 pagesN2XKB (AL) Y 1 X (16-800) MM 0.6/1 KVmuhammad wafiNo ratings yet

- 12.02.2020 TTC - Kohinoor SalesDocument1 page12.02.2020 TTC - Kohinoor SalesAlok PandeyNo ratings yet

- 1554-2Cx6mm AluminumDocument3 pages1554-2Cx6mm AluminumSandeep BhutaniNo ratings yet

- M2XCH Flex (FI) 5G25 (Black) - 60Document1 pageM2XCH Flex (FI) 5G25 (Black) - 60omarNo ratings yet

- Quality Control Report: Üntel Kablolari Sanayi Ve Ticaret A.ŞDocument3 pagesQuality Control Report: Üntel Kablolari Sanayi Ve Ticaret A.Şomar100% (1)

- Data Sheet - NYFGbYDocument4 pagesData Sheet - NYFGbYAulia RahmahNo ratings yet

- Siare Technologies - Test ReportDocument1 pageSiare Technologies - Test ReportnikhilbhorNo ratings yet

- M2XH Flex (NOFI) (Black) - 60Document3 pagesM2XH Flex (NOFI) (Black) - 60omarNo ratings yet

- PDF Kingboard KB 6160A Data SheetDocument2 pagesPDF Kingboard KB 6160A Data SheetAlex Prim NavajasNo ratings yet

- F.O. ADSS SpecificationDocument4 pagesF.O. ADSS SpecificationDinatel ComercialNo ratings yet

- HV Cable StandardDocument2 pagesHV Cable StandardAlla Naveen KumarNo ratings yet

- SWG 31 WDocument1 pageSWG 31 WRajesh RoyNo ratings yet

- SWG 31 WDocument1 pageSWG 31 WRajesh RoyNo ratings yet

- Adss 120m SpanDocument2 pagesAdss 120m SpanAdriana RosadoroNo ratings yet

- KB Fr4 61606160a6160c Raw Material Technical Information Data SheetDocument2 pagesKB Fr4 61606160a6160c Raw Material Technical Information Data Sheettrupzup7No ratings yet

- 2C X 1 SQ - MM-100 MTRS.Document2 pages2C X 1 SQ - MM-100 MTRS.Dhileep GowthamanNo ratings yet

- Test CertificateDocument1 pageTest CertificateViswa BhuvanNo ratings yet

- NYRYDocument5 pagesNYRYAhmad Arif SaktiNo ratings yet

- Nyfgby 2 X (1.5-300) MM 0.6/1 KVDocument4 pagesNyfgby 2 X (1.5-300) MM 0.6/1 KVBagus Arief WibowoNo ratings yet

- Anti-Corrosion Coating: StandardsDocument2 pagesAnti-Corrosion Coating: StandardsMuhamad Rizky KurniawanNo ratings yet

- Kabelmetal NYYDocument1 pageKabelmetal NYYDudi MulyadiNo ratings yet

- N2Xfgby 2 X (1.5-300) MM 0.6/1 KVDocument4 pagesN2Xfgby 2 X (1.5-300) MM 0.6/1 KVRince OktavianaNo ratings yet

- Type Tests Report: #REF! #REF!Document2 pagesType Tests Report: #REF! #REF!DIPAKNo ratings yet

- N2XRY 3 X (1.5-300) MM 0.6/1 KVDocument1 pageN2XRY 3 X (1.5-300) MM 0.6/1 KVRyan FadhliNo ratings yet

- NA2XSEBY 3 X (25-300) MM 3.6/6 KVDocument5 pagesNA2XSEBY 3 X (25-300) MM 3.6/6 KVMario SitorusNo ratings yet

- Bayblend T88 GF 20 - en - 56968672 00003567 20081863Document3 pagesBayblend T88 GF 20 - en - 56968672 00003567 20081863Mattia Terri TerrandoNo ratings yet

- RR 1.5 SQ MM FR-LSH (DRJ-220000868)Document1 pageRR 1.5 SQ MM FR-LSH (DRJ-220000868)Govind NataniNo ratings yet

- N2XSY 1 X (1.5-800) MM 0.6/1 KVDocument5 pagesN2XSY 1 X (1.5-800) MM 0.6/1 KVyildirimonlineNo ratings yet

- (3.6/6 KV 18/30 KV) Cu/XLPE/CTS/SWA/PVC (N2XSEYRY) : SNI IEC 60502-2 / IEC 60502-2Document3 pages(3.6/6 KV 18/30 KV) Cu/XLPE/CTS/SWA/PVC (N2XSEYRY) : SNI IEC 60502-2 / IEC 60502-2ErwinNo ratings yet

- NA2XSEFGbY PDFDocument5 pagesNA2XSEFGbY PDFRizki IrawanNo ratings yet

- Firetuf FTP 120 - Fire Resistant Armoured Power Cable: ConstructionDocument25 pagesFiretuf FTP 120 - Fire Resistant Armoured Power Cable: ConstructionBhagoo HatheyNo ratings yet

- Specification For Approval: Shenzhen CND-TEK Industrial Co.,LtdDocument4 pagesSpecification For Approval: Shenzhen CND-TEK Industrial Co.,LtdLeonardo Armando RomeroNo ratings yet

- Shear Strength by Direct Shear (Small Shear Box) : Client Structure Project Job Sample Test DetailsDocument10 pagesShear Strength by Direct Shear (Small Shear Box) : Client Structure Project Job Sample Test DetailsSocrates Palomino GamboaNo ratings yet

- Profile 45 250 Sandwich Panel Techincal DatasheetDocument2 pagesProfile 45 250 Sandwich Panel Techincal DatasheetEle SultanaNo ratings yet

- Tech Specification Apepdcl TN 99Document23 pagesTech Specification Apepdcl TN 99Suresh SharmaNo ratings yet

- 120 MM Sq. 3-Core AL-XLPE-SWA-PVC-15KVDocument2 pages120 MM Sq. 3-Core AL-XLPE-SWA-PVC-15KVMuhammad Shabbir AwanNo ratings yet

- Na2Xfgby 2 X (10-300) MM 0.6/1 KVDocument4 pagesNa2Xfgby 2 X (10-300) MM 0.6/1 KVHajie OmenNo ratings yet

- ADSS Specification: 1. Cable ConstructionDocument2 pagesADSS Specification: 1. Cable ConstructionJhon OlarteNo ratings yet

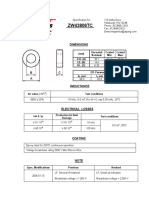

- 250w Core ZW43806TCDocument1 page250w Core ZW43806TCErkanNo ratings yet

- FTTH Cable SpecificationsDocument5 pagesFTTH Cable SpecificationsArmando Esquivada0% (2)

- Shear Strength by Direct Shear (Small Shear Box) : Client Structure Project Job Sample Test DetailsDocument10 pagesShear Strength by Direct Shear (Small Shear Box) : Client Structure Project Job Sample Test DetailsSocrates Palomino GamboaNo ratings yet

- N2xseby 20KV PDFDocument5 pagesN2xseby 20KV PDFSetiawan PutraNo ratings yet

- Deakin Wire Industries: Enamelled Copper WiresDocument13 pagesDeakin Wire Industries: Enamelled Copper WiresAMAN VERMANo ratings yet

- One Way SlabDocument23 pagesOne Way SlabmeerahNo ratings yet

- ADSS-80M Cable Specifications-2018.11.2. FibrastorepdfDocument6 pagesADSS-80M Cable Specifications-2018.11.2. FibrastorepdfDANIEL LEADNo ratings yet

- N2XSEYBY - Cu XLPE CTS DSTA PVCDocument3 pagesN2XSEYBY - Cu XLPE CTS DSTA PVCabhi boyzNo ratings yet

- CN TDS 1911 03 S3110 OkDocument1 pageCN TDS 1911 03 S3110 OkNelly DavedNo ratings yet

- E-Catalogue Bicc - 150 Kv-r04Document1 pageE-Catalogue Bicc - 150 Kv-r04bimbremboNo ratings yet

- 1.A-DQ BN SR 2Y 1.200N CT-General-2021.04.07-03Document7 pages1.A-DQ BN SR 2Y 1.200N CT-General-2021.04.07-03Emre YıldırımNo ratings yet

- c95500 Spec SheetDocument2 pagesc95500 Spec SheetOrnella MancinelliNo ratings yet

- N2XSY 3 X (1.5-300) MM 0.6/1 KVDocument1 pageN2XSY 3 X (1.5-300) MM 0.6/1 KVhenry_gtNo ratings yet

- Brosure Kabel NA2XSYDocument5 pagesBrosure Kabel NA2XSYcandra handarsenNo ratings yet

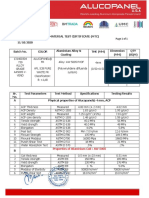

- Material Test Certificate (MTC) : Properties of Aluminium Coil: AW 5005Document4 pagesMaterial Test Certificate (MTC) : Properties of Aluminium Coil: AW 5005Waleed Obieden100% (1)

- NYY - 3 CoreDocument1 pageNYY - 3 CoreMulyadi MulNo ratings yet

- PBT GF30 - Vampter 3026 V0 DFDocument1 pagePBT GF30 - Vampter 3026 V0 DFarmandoNo ratings yet

- AKASH InputDocument3 pagesAKASH InputJitendra PatelNo ratings yet

- ManufacturingDocument2 pagesManufacturingBarbieBarbieNo ratings yet

- Accepted Manuscript: Trends in Food Science & TechnologyDocument54 pagesAccepted Manuscript: Trends in Food Science & TechnologySara CerdanNo ratings yet

- Specifications of Nitofill EPLV PDFDocument2 pagesSpecifications of Nitofill EPLV PDFTrung Nguyen ThanhNo ratings yet

- Carbo and Lipid Activity 2Document2 pagesCarbo and Lipid Activity 2Perry BearNo ratings yet

- Masteremaco 2525pdfDocument2 pagesMasteremaco 2525pdfapi-283891975No ratings yet

- Dex La Fontaine CJ98Document12 pagesDex La Fontaine CJ98jatan aminNo ratings yet

- 1.2. Nature of ElectricityDocument5 pages1.2. Nature of ElectricityKATE ARBIE LACDO-ONo ratings yet

- APPLIED CHEMISTRY Lab ManualDocument50 pagesAPPLIED CHEMISTRY Lab ManualHarshit RajNo ratings yet

- Advantages of Aluminum Vacuum NO LogoPDFDocument45 pagesAdvantages of Aluminum Vacuum NO LogoPDFKonstantin MarjanuczNo ratings yet

- LebensmittelDocument582 pagesLebensmittelmaria budiNo ratings yet

- BHEL Readies Design For 800 MW Plant With Ultra Supercritical ParametersDocument1 pageBHEL Readies Design For 800 MW Plant With Ultra Supercritical Parameterslaloo01No ratings yet

- Respiration s3 Bio NotesDocument9 pagesRespiration s3 Bio NotesKueiNo ratings yet

- Raw Material Index For Passives April 31, 2012Document6 pagesRaw Material Index For Passives April 31, 2012Dennis ZogbiNo ratings yet

- Safety Data Sheet For NEBNext End Prep Reaction BufferDocument9 pagesSafety Data Sheet For NEBNext End Prep Reaction BufferNabilahNo ratings yet

- Secure and Reliable, Even Where Lubrication Is Poor: MR-D Double Seal With Diamondface in Bioculture ProductionDocument2 pagesSecure and Reliable, Even Where Lubrication Is Poor: MR-D Double Seal With Diamondface in Bioculture ProductionmunhNo ratings yet

- Ft-Peramin Conpac 149s - 112011 - v1 (GB)Document2 pagesFt-Peramin Conpac 149s - 112011 - v1 (GB)RajuNSanaboinaNo ratings yet

- SSC DWDocument4 pagesSSC DWsanketpavi21No ratings yet

- Equations of State For Technical Applications Span2000Document42 pagesEquations of State For Technical Applications Span2000Fátima ReyesNo ratings yet

- A3.01 Union List of Food Additives Approved For Use in FoodDocument33 pagesA3.01 Union List of Food Additives Approved For Use in FoodBesian OsmaniNo ratings yet

- Daftar Pustaka KilnDocument2 pagesDaftar Pustaka Kilnazzahra ghina fadillahNo ratings yet

- Midland Gear Pumps Phase 1Document5 pagesMidland Gear Pumps Phase 1Рома БлошенкоNo ratings yet

- Notes+4 +ATP,+Water+and+Inorganic+IonsDocument5 pagesNotes+4 +ATP,+Water+and+Inorganic+IonsSyeda Wardah NoorNo ratings yet

- Datos de Densidad de MicroalgaDocument148 pagesDatos de Densidad de MicroalgaViviana Quintero DallosNo ratings yet

- Curtis Petroleum Reservoir Fluid PropertiesDocument6 pagesCurtis Petroleum Reservoir Fluid Propertiesbenjamin kenyeryNo ratings yet

- 29 MFCDocument20 pages29 MFCVijaya GosuNo ratings yet