Professional Documents

Culture Documents

1554-2Cx6mm Aluminum

Uploaded by

Sandeep BhutaniOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

1554-2Cx6mm Aluminum

Uploaded by

Sandeep BhutaniCopyright:

Available Formats

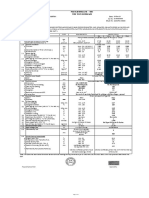

TEST CERTIFICATE

Name of Sample : PVC Insulated (Type-C) PVC Sheathed (ST-2) Aluminum

Stranded Conductor Armoured Cable 1100 Volts Size 2Cx6 mm².

Submitted By : M/s R.K. ELECTRICAL INDUSTRIES (INDIA) PVT. LTD.,

DELHI.

Ref. No. : NIL Dated: 20-06-2012

Specification No. : IS : 1554(P-I)-1988 With latest amendments Reaffirmed 2005

S.No. TESTS REQUIREMENTS RESULT OBSREVED

MARKING i) Trade Mark KALINGA CABLE

ii) Voltage Grade 1100V ELECTRIC

iii)No. of Core 2C

iv)Cross sectional 6 mm²

area

v) Ref. Indian Std. IS:1554(P-I)

a)Core Identification RED, BLACK RED, BLACK

b)Color of Sheath BLACK BLACK

TEST ON CONDUCTOR as per

RED BLACK

IS:8130-1984

1 Size in mm² 6 6 6

2 Resistance at 20ºC Ohm/Km. Max. 4.61 4.476 4.470

3 Tensile Strength N/mm² 100-150 115 120

4 Wrapping test No Break/ Cracks No Crack No Crack

TEST ON INSULATION as per

TYPE-C IS:5831-1984

1 Thickness in mm Nom. 1.0 1.13 1.12

Min. 0.8 0.99 0.96

2 Tensile strength Un-aged Min. 12.5 14.8 14.4

N/mm²

3 % Elongation Un-aged Min. 125 260 250

4 Tensile after ageing N/mm² Min. 12.5 16.3 16.5

5 % Elongation after ageing Min. 125 230 220

Contd..P/2

Page-2

Tested as per IS:1554(P-1)-1988

S.No. TESTS REQUIREMENTS RESULT OBSREVED

6 Tensile Strength Variation % ±25 -10.13 -14.58

7 % Elongation variation ±35 +11.53 +12.00

8 % Shrinkage Max. 4.0 1.5 2.0

9 Loss of Mass mg/cm² Max. -- -- --

10 Hot deformation % Max. 50 25 30

11 Heat shock test No sign of crack No crack No crack

12 Thermal Stability Min. 100 minutes 114 112

13 Cold bend test No sign of cracks No crack No crack

14 Volume Resistivity

i)At 27ºC Ohm-Cm Min. 1x10¹³ 5.0x10¹³ 5.6x10¹³

ii) At 85ºC Ohm-Cm Min. 1x10¹º 4.6x10¹º 4.3x10¹º

Insulation Resistance constant

i) At 27ºC M Ohm-Km Min. 36.7 183 205

ii) At 85ºC M Ohm-Km Min. 0.037 0.168 0.157

PHYSICAL TEST ON OUTER

SHEATH ST-2 IS: 5831-1984

1 Thickness of inner sheath in mm 0.3 0.34

2 Thickness of outer sheath Min. 1.24 1.84

In mm

3 Tensile strength Un-aged Min. 12.5 14.9

N/mm²

4 % Elongation Un-aged Min. 150 260

5 Tensile Strength after ageing Min. 12.5 16.6

N/mm²

6 % Elongation after ageing Min. 150 220

7 Tensile Strength Variation % ±25 -11.40

8 % Elongation variation % ±25 +15.38

Contd..Page -3

Page-3

Tested as per IS:1554(P-1)-1988

S.No TESTS REQUIREMENTS RESULT OBSREVED

9 Loss of mass mg/cm² Max. 2 0.930

10 % Shrinkage Test Max. 4% 1.00

11 Hot Deformation Test Max. 50% 25

12 Heat Shock Test Shall be No sign of Crack No cracks

13 Thermal Stability Test Min. 80 Minutes 92 Minutes

14 Cold Impact test No Cracks No Cracks

15 High Voltage Test

i)At room Temp. Shall withstand at 3KV AC For 5 Minutes. Withstood the test

ii) Water Immersion Test Should withstand at 6KV for 5 minutes Withstood the test

1.2 KV DC for 240 Hrs. Withstood the test

16 Flammability Test The burning period 60 seconds Max. and 10 second and

the remaining part 50mm Min. 270 mm.

TEST ON WIRE/ STRIP

IS:3975-1979

1 Type Wire/Strip/Tape wire

2 Dia /Thickness Strip 4.0x0.8 mm±10% 1.40mm

Wire 1.40mm±0.04 mm

3 Weight of zinc coating Strip 110 gm/m² Min. 110 gm/m²

Wire 90 gm/m² Min.

4 Uniformity of zinc coating After a Dip of one minute & one Dip of half No red spot

minute, No red spot should observed.

5 Tensile Strength 250 to 580 N/mm² 360 N/mm²

6 % Elongation 6% Min. 10.0%

7 Resistivity 14.5x10ֿ6 Ohm-Cm Max. 13.7x10ֿ6 Ohm-Cm

8 Torsion Test (for wire) Wire shall not break before 43 turns. Satisfactory

9 Winding Test (for strip) No Cracks & detachment of particle of Zn NA

coating when rubbed with the bare finger.

REMARKS: i) The above mentioned tests have been carried out and found as per specification.

ii) This test report relates to the particular sample submitted by the party.

TESTED BY: …………………

Checked By_____________

You might also like

- 1992 Gould Test Equipment Oscilloscopes and Recording SystemsDocument132 pages1992 Gould Test Equipment Oscilloscopes and Recording SystemsTamo Neko100% (1)

- Understanding and Servicing Alarm SystemsFrom EverandUnderstanding and Servicing Alarm SystemsRating: 1 out of 5 stars1/5 (1)

- Polycab India Ltd UH3 Type Test CertificateDocument1 pagePolycab India Ltd UH3 Type Test CertificateAlok PandeyNo ratings yet

- 15.07 2020 - TTC 2Document1 page15.07 2020 - TTC 2Alok PandeyNo ratings yet

- ÜNTEL cable quality control reportsDocument3 pagesÜNTEL cable quality control reportsomarNo ratings yet

- M2XCH Flex (FI) 5G25 (Black) - 60Document1 pageM2XCH Flex (FI) 5G25 (Black) - 60omarNo ratings yet

- Test CertificateDocument1 pageTest CertificateViswa BhuvanNo ratings yet

- HV Cable StandardDocument2 pagesHV Cable StandardAlla Naveen KumarNo ratings yet

- Test Report: 1, Madhuvan Apartment, 24, Arunodaya Society, Alkapuri, Vadodara - 390 007Document3 pagesTest Report: 1, Madhuvan Apartment, 24, Arunodaya Society, Alkapuri, Vadodara - 390 007Vatsal DarjiNo ratings yet

- Quality Control Report: Üntel Kablolari Sanayi Ve Ticaret A.ŞDocument3 pagesQuality Control Report: Üntel Kablolari Sanayi Ve Ticaret A.Şomar100% (1)

- SL - No. Inspection Parameter Specification Observation: Type Test ReportDocument1 pageSL - No. Inspection Parameter Specification Observation: Type Test ReportmaheshgkuNo ratings yet

- s23-5Document22 pagess23-5hanipe2979No ratings yet

- 1.25mm Wire to Board Connector Specification ApprovalDocument12 pages1.25mm Wire to Board Connector Specification ApprovalJohn HallowsNo ratings yet

- Test Reports PDFDocument2 pagesTest Reports PDFTenders MashNo ratings yet

- CEM-1203 (42) Datasheet - Magnetic Buzzer - CUI Inc PDFDocument5 pagesCEM-1203 (42) Datasheet - Magnetic Buzzer - CUI Inc PDFLUDWINGNo ratings yet

- Is 15652Document3 pagesIs 15652IshanNo ratings yet

- Type Tests Report: #REF! #REF!Document2 pagesType Tests Report: #REF! #REF!DIPAKNo ratings yet

- Technical Data Sheet: Description Values Technical ParticularsDocument2 pagesTechnical Data Sheet: Description Values Technical ParticularsAli ShahzadNo ratings yet

- PDF_Kingboard_KB_6160A_data_sheet (1)Document2 pagesPDF_Kingboard_KB_6160A_data_sheet (1)Alex Prim NavajasNo ratings yet

- RR 1.5 SQ MM FR-LSH (DRJ-220000868)Document1 pageRR 1.5 SQ MM FR-LSH (DRJ-220000868)Govind NataniNo ratings yet

- KB Fr4 61606160a6160c Raw Material Technical Information Data SheetDocument2 pagesKB Fr4 61606160a6160c Raw Material Technical Information Data Sheettrupzup7No ratings yet

- Adss 120m SpanDocument2 pagesAdss 120m SpanAdriana RosadoroNo ratings yet

- ADSS Specification -- 200M Span Optical Fiber Cable Technical SpecDocument4 pagesADSS Specification -- 200M Span Optical Fiber Cable Technical SpecDinatel ComercialNo ratings yet

- Specification For Approval: Shenzhen CND-TEK Industrial Co.,LtdDocument4 pagesSpecification For Approval: Shenzhen CND-TEK Industrial Co.,LtdLeonardo Armando RomeroNo ratings yet

- MR-001 Test CertificateDocument1 pageMR-001 Test Certificatesai sudheerNo ratings yet

- Oil Sample report-31.5MVA, Indotech PTR at Turkayamjal SSDocument2 pagesOil Sample report-31.5MVA, Indotech PTR at Turkayamjal SSMUSHAM217No ratings yet

- Adss Span 100Document2 pagesAdss Span 100KFD KFDNo ratings yet

- Technical Data Sheet - Nylon X: 3D Printing FilamentDocument1 pageTechnical Data Sheet - Nylon X: 3D Printing FilamentSteven DonosoNo ratings yet

- Technical Data Sheet - Nylon X: 3D Printing FilamentDocument1 pageTechnical Data Sheet - Nylon X: 3D Printing FilamentwidyarahmahNo ratings yet

- Mr-001 Test CertificateDocument1 pageMr-001 Test Certificatesai sudheerNo ratings yet

- ADSS Specification: 1. Cable ConstructionDocument2 pagesADSS Specification: 1. Cable ConstructionJhon OlarteNo ratings yet

- 2C X 1 SQ - MM-100 MTRS.Document2 pages2C X 1 SQ - MM-100 MTRS.Dhileep GowthamanNo ratings yet

- Recubrimiento Ext TanqueDocument2 pagesRecubrimiento Ext Tanquehenry307No ratings yet

- Test Certificate for 3G4mm2 H07RN-F CableDocument1 pageTest Certificate for 3G4mm2 H07RN-F CableSoha ElsamraNo ratings yet

- 120 MM Sq. 3-Core AL-XLPE-SWA-PVC-15KVDocument2 pages120 MM Sq. 3-Core AL-XLPE-SWA-PVC-15KVMuhammad Shabbir AwanNo ratings yet

- Bayblend T88 GF 20 - en - 56968672 00003567 20081863Document3 pagesBayblend T88 GF 20 - en - 56968672 00003567 20081863Mattia Terri TerrandoNo ratings yet

- FTTH Cable SpecificationsDocument5 pagesFTTH Cable SpecificationsArmando Esquivada0% (2)

- Protect Corrosion Underground SubstratesDocument2 pagesProtect Corrosion Underground SubstratesFarid HarisNo ratings yet

- 12a DPST Miniature Power RelayDocument2 pages12a DPST Miniature Power RelaykarkeraNo ratings yet

- VISCOWRAP-HT Product Data Sheet EnglishDocument2 pagesVISCOWRAP-HT Product Data Sheet EnglishJA BustosNo ratings yet

- 3C-ABC-Technical Spec 948Document9 pages3C-ABC-Technical Spec 948Kanwalnain madaanNo ratings yet

- Technical specifications and test results for Panlite AD-5503 polycarbonate sheetDocument1 pageTechnical specifications and test results for Panlite AD-5503 polycarbonate sheetmarioNo ratings yet

- Data Sheet For Insulating Mat: Premier Polyfilm LTDDocument1 pageData Sheet For Insulating Mat: Premier Polyfilm LTDArumugam RajendranNo ratings yet

- 66kV Aluminium Large Conductor XLPE CSA PE HS CablesDocument1 page66kV Aluminium Large Conductor XLPE CSA PE HS CablesIppiNo ratings yet

- BinanizincspecsDocument6 pagesBinanizincspecsJimmy ThomasNo ratings yet

- Tmce21 109M315VB76R175M12Document5 pagesTmce21 109M315VB76R175M12raghuNo ratings yet

- Renolit Alkorplan 00414 15mm + Lacquer enDocument2 pagesRenolit Alkorplan 00414 15mm + Lacquer enIngénieur CivilNo ratings yet

- Rilsan Fine Powders Physical PropertiesDocument2 pagesRilsan Fine Powders Physical Propertiesธนาชัย เต็งจิรธนาภาNo ratings yet

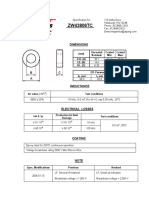

- 250w Core ZW43806TCDocument1 page250w Core ZW43806TCErkanNo ratings yet

- MPT 221Document3 pagesMPT 221marina anastasovaNo ratings yet

- Pe1000 PDFDocument2 pagesPe1000 PDFrohitdakngNo ratings yet

- Ico ExDocument2 pagesIco ExHafiani HichamNo ratings yet

- Test ReportDocument1 pageTest ReportPiyush GuptaNo ratings yet

- GBU10005 - GBU1010: 10A Glass Passivated Bridge RectifierDocument4 pagesGBU10005 - GBU1010: 10A Glass Passivated Bridge RectifierMae MegumiNo ratings yet

- Tech Specification Apepdcl TN 99Document23 pagesTech Specification Apepdcl TN 99Suresh SharmaNo ratings yet

- Ico PlainDocument2 pagesIco PlainHafiani HichamNo ratings yet

- Magnetic Buzzer Spec SheetDocument5 pagesMagnetic Buzzer Spec SheetLUDWINGNo ratings yet

- PrimeCliq4 CatalogDocument5 pagesPrimeCliq4 CatalogedwardNo ratings yet

- Technical Data Sheet For Hdpe Pe 100, 315.0 MM X 28.6 MM DuctDocument1 pageTechnical Data Sheet For Hdpe Pe 100, 315.0 MM X 28.6 MM DuctJohn BenzNo ratings yet

- b5d56a6e5655c852617f13a8e858e3b8Document2 pagesb5d56a6e5655c852617f13a8e858e3b8julio RCNo ratings yet

- Sigma Kraft Paper 4 Mil TCDocument1 pageSigma Kraft Paper 4 Mil TCShashivendra ShuklaNo ratings yet

- Eddy CurrentsDocument5 pagesEddy CurrentsDivyanshu KaushikNo ratings yet

- Analog LayoutDocument62 pagesAnalog Layoutcatchmereddy100% (3)

- Nagra III Instructions ManualDocument32 pagesNagra III Instructions ManualGaby ŠerićNo ratings yet

- Transformer Protections in Thermal Power PlantDocument45 pagesTransformer Protections in Thermal Power PlantAshwani Dogra100% (3)

- USB 2.0 Hub and Flash Media Card Controller Combo: General Description FeaturesDocument56 pagesUSB 2.0 Hub and Flash Media Card Controller Combo: General Description Featuresemadul hasan100% (1)

- Design Guide: VLT Micro Drive FC 51Document99 pagesDesign Guide: VLT Micro Drive FC 51Giang BùiNo ratings yet

- LT8570 1Document34 pagesLT8570 1Malik ZainNo ratings yet

- Insulator TieDocument14 pagesInsulator TieMosa Elnaid Elnaid100% (2)

- Unitec Parts Part 5 Fixtures (General)Document55 pagesUnitec Parts Part 5 Fixtures (General)coco MPNo ratings yet

- NetworkDocument184 pagesNetworkjohn cenaNo ratings yet

- Dynamic Stability of SMIB System With Fuzzy Logic Based Power System StabilizerDocument6 pagesDynamic Stability of SMIB System With Fuzzy Logic Based Power System StabilizerInternational Journal of Research in Science & TechnologyNo ratings yet

- Rohs Compliant: NotesDocument1 pageRohs Compliant: NotesRamNo ratings yet

- TSP PanelDocument40 pagesTSP Paneldan_geplNo ratings yet

- Nirma University: InstructionsDocument3 pagesNirma University: InstructionsBHENSDADIYA KEVIN PRABHULALNo ratings yet

- Concise Operating Instructions: Frequency Converter For HOISTING - TRAVEL (Siemens)Document9 pagesConcise Operating Instructions: Frequency Converter For HOISTING - TRAVEL (Siemens)Pablo Hidalgo ValenzuelaNo ratings yet

- Monitor OSD Processor Displays Text and GraphicsDocument24 pagesMonitor OSD Processor Displays Text and GraphicsAKIDUKINo ratings yet

- Jfet NRP Lecture 2Document97 pagesJfet NRP Lecture 2Nitin PrajapatiNo ratings yet

- Crow PowerWave 8 Programming GuideDocument81 pagesCrow PowerWave 8 Programming GuideSafwat FarrahNo ratings yet

- Arulprakasajothi 2021Document4 pagesArulprakasajothi 2021kutluuNo ratings yet

- El2.e - 001Document2 pagesEl2.e - 001kamalNo ratings yet

- Nema - Ics 5 2017Document88 pagesNema - Ics 5 2017kuh393No ratings yet

- Mic. Wireless Vokal Shure PGX24/SM58 FiturDocument3 pagesMic. Wireless Vokal Shure PGX24/SM58 FiturGusni Ayue RahayuNo ratings yet

- M4100Document2 pagesM4100kylegazeNo ratings yet

- Toshiba Field Effect Transistor GuideDocument6 pagesToshiba Field Effect Transistor Guideramon navaNo ratings yet

- DVD Noblex Dvd-1350: 3828 Control Borad SechmaticDocument15 pagesDVD Noblex Dvd-1350: 3828 Control Borad SechmaticMariano Ohienart100% (1)

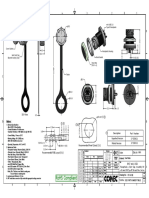

- RD-1005-03 Tech DrawingDocument1 pageRD-1005-03 Tech DrawingLuis AugustoNo ratings yet

- DSP QuestionDocument1 pageDSP QuestionVasanthLogarajLNo ratings yet

- Loop Powered Microprocessor Controlled Positioner: Worcester Control ValvesDocument4 pagesLoop Powered Microprocessor Controlled Positioner: Worcester Control Valveskarim karimNo ratings yet

- Generator Protection RelayDocument195 pagesGenerator Protection Relayvaksreedharan100% (1)