Professional Documents

Culture Documents

Test Report: 1, Madhuvan Apartment, 24, Arunodaya Society, Alkapuri, Vadodara - 390 007

Uploaded by

Vatsal DarjiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Test Report: 1, Madhuvan Apartment, 24, Arunodaya Society, Alkapuri, Vadodara - 390 007

Uploaded by

Vatsal DarjiCopyright:

Available Formats

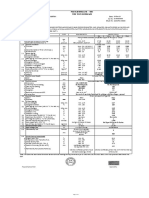

TEST REPORT

Page 1 of 3

Name & Address of the Customer :M/s. SUYOG ELECTRICALS LTD.

1,Madhuvan Apartment, 24, Arunodaya Society,

Alkapuri, Vadodara -390 007

Name & Address of the Manufacturer :M/s. SUYOG ELECTRICALS LTD.

A2/2205, C1/2204, A2/2206, 1701/2 &

2106/6 GIDC Estate, Halol Dist. Panchmahal

Reference No./Date : BRD/HC/21-22/801 Dated : 10/01/2021

Sample Code No./ Report No. : 100-211111-21

Report Date : 09/12/2021

Sample Received On : 11/11/2021

Analysis Date : 11/11/2021 to 08/12/2021

Report Prepared On : 09/12/2021

Sampled By : Customer

Sample Description : AWG (20/1) Silver Plated Copper Conductor PTFE Insulated

250V (ET) Electrical Wire

Test Specification : [As per JSS 51034 : 1992] Reaffirmed as per 2012

Style Reference : WH1P-1A-120

Report No. : 100-211111-21 Page 2 of 3

Respective Clause of Specified Requirement

Sl.

Test Conducted JSS-51034-1992 As per JSS: 51034-1992 Test Result

No

Reaffirmed 2012 Reaffirmed 2012

1. Visual Examination 13.1.1 Free from any defect Complies

2. Dimensions 13.1.2 As per specification Complies

Min:0.787 mm

3. Conductor diameter (mm) 13.1.2.1 0.815 mm

Max:0.838mm

Min:1.07mm

4. Outer diameter (mm) 13.1.2.2 1.14

Max:1.17mm

5. Concentricity of Insulation,% 13.2 70% Min 88.6%

No discontinuity in

6. Conductor Continuity 13.5 Complies

Conductor

7. Conductor Resistance at 200C ohm/km 13.6 Max:34.7 Ω/Km 32.86 Ω/km

8. Dielectric With Standing Voltage 13.7 1.5 KV for 1 min Complies

9. Insulation Resistance MΩ-Km 13.8 Min : 2228.1 MΩ-Km 4256

10.1 Silver coating continuity 13.9 No black spots Complies

10.2 Silver Coating thickness, micron 13.9/7.2.1.2 1 Micron min 1.4

Conductor Tensile Strength Test

11. 13.10 Max:276x106N/m2 248.4x06 N/m2

(N/m2)

Conductor Elongation On Gauge

12. 13.10 Min : 20 % 28%

Length of 250mm,%

13. Insulation Dielectric Constant 13.11 2.2 Max. 1.92

14. Insulation Power factor 13.11 0.005 Max. 0.004

15. Insulation Tensile strength N/m 2 13.12 21 X 106 N/m2 Min 28.4 X106N/m2

16. Insulation Elongation % 13.12 150 Min 375%

Report No. : 100-211111-21 Page 3 of 3

Respective Clause Specified Requirement

Sl.

Test Conducted of JSS-51034-1992 As per JSS: 51034-1992 Test Result

No

Reaffirmed 2012 Reaffirmed 2012

17. Surface Resistance, Megaohm-mm 13.13 0.20 Min. 48

Cold -bend Test Shall be no cracks on insulation And

18. 13.15 Complies

At -650C ±10C for 4 Hour withstand DWV test

Shrinkage 3.17 mm max

Heat Resistance Test No discolourisation.

19. 13.16 Complies

At 2900C for 96 hours No dielectric breakdown

At 1.5 KV for 1 minute.

Wrap back Test Shall be no cracks on insulation And

20. At 3070C ± 50C for 2 hours 13.17 Complies

withstand DWV test

Resistance to Soldering Heat No flaring of insulation.

21. At 3200C Molton 12mm end solder 13.18 Complies

Shrinkage 3.17mm maximum

for 5 second

After removal of flame it should cease

to burn Within 3 seconds.

22. Flammability Test 13.19 Complies

Flame travel 75mm Maximum.

No flaming of tissue Paper

Remarks: Sample meets the requirement as per specified limits as laid down in JSS: 51034-1992 as observed for

the above test parameters only.

******End of Report*****

Note:

This Test report /certificate refers only to the particular sample/s submitted for testing.

The sample description is not verified in all cases and is given as described by the customer.

Samples not drawn by us and the analysis conducted as received basis unless specified otherwise.

Tested sample will be disposed off after 90 days / 15 days / Same date in case of perishable item from

date of issue of test report unless until specified by customer.

Complaints about this report should be communicated in writing within seven days of issue date of this report.

This report is not to be reproduced wholly or in part and cannot be used as an evidence in the Court of law and

shall not be used in the advertising media without our prior permission from the Director.

Laboratory shall maintain the confidentiality of all information related to the samples & Test Reports.

You might also like

- Newnes Circuit Calculations Pocket Book: with Computer ProgramsFrom EverandNewnes Circuit Calculations Pocket Book: with Computer ProgramsNo ratings yet

- Test Report: 1, Madhuvan Apartment, 24, Arunodaya Society, Alkapuri, Vadodara - 390 007Document3 pagesTest Report: 1, Madhuvan Apartment, 24, Arunodaya Society, Alkapuri, Vadodara - 390 007Vatsal DarjiNo ratings yet

- Test Report: 1, Madhuvan Apartment, 24, Arunodaya Society, Alkapuri, Vadodara - 390 007Document3 pagesTest Report: 1, Madhuvan Apartment, 24, Arunodaya Society, Alkapuri, Vadodara - 390 007Vatsal DarjiNo ratings yet

- 220 KV Cable Inspection ReportDocument4 pages220 KV Cable Inspection Report9782279059No ratings yet

- 1554-2Cx6mm AluminumDocument3 pages1554-2Cx6mm AluminumSandeep BhutaniNo ratings yet

- M2XH Flex (NOFI) (Black) - 60Document3 pagesM2XH Flex (NOFI) (Black) - 60omarNo ratings yet

- Technical Specification For GD TC435077 2021 OPGW 24B1 100 (82 71)Document2 pagesTechnical Specification For GD TC435077 2021 OPGW 24B1 100 (82 71)William CalleNo ratings yet

- RR 1.5 SQ MM FR-LSH (DRJ-220000868)Document1 pageRR 1.5 SQ MM FR-LSH (DRJ-220000868)Govind NataniNo ratings yet

- Datasheet - Ducab Cables - 3 & 4 CoreDocument19 pagesDatasheet - Ducab Cables - 3 & 4 Coreraj xNo ratings yet

- 06 - Fire Resistant CablesDocument13 pages06 - Fire Resistant CablesmlutfimaNo ratings yet

- K SMDNC03100KB00KP00 0001Document7 pagesK SMDNC03100KB00KP00 0001Pedro LeonNo ratings yet

- Topflex - Emv-2Yslcy-J: For Power Supply Connections To Frequency Converters, Double Screened, 0,6/1kV, Meter MarkingDocument2 pagesTopflex - Emv-2Yslcy-J: For Power Supply Connections To Frequency Converters, Double Screened, 0,6/1kV, Meter MarkingMarcosNo ratings yet

- Flexible Cable: House WiringDocument16 pagesFlexible Cable: House WiringNitinNo ratings yet

- Pre Applied Loosely Laid PVC Membrane RevDocument1 pagePre Applied Loosely Laid PVC Membrane Revmukesh patelNo ratings yet

- NFC Aaac Al4 - 34.4&54.6 Ees CableDocument5 pagesNFC Aaac Al4 - 34.4&54.6 Ees CableazzouzimedNo ratings yet

- Test CertificateDocument1 pageTest CertificateViswa BhuvanNo ratings yet

- Quality Control Report: Üntel Kablolari Sanayi Ve Ticaret A.ŞDocument3 pagesQuality Control Report: Üntel Kablolari Sanayi Ve Ticaret A.Şomar100% (1)

- 12.02.2020 TTC - Kohinoor SalesDocument1 page12.02.2020 TTC - Kohinoor SalesAlok PandeyNo ratings yet

- Type Tests Report: #REF! #REF!Document2 pagesType Tests Report: #REF! #REF!DIPAKNo ratings yet

- Tech Specification Apepdcl TN 99Document23 pagesTech Specification Apepdcl TN 99Suresh SharmaNo ratings yet

- Karumel Ex4412: KCC CorporationDocument4 pagesKarumel Ex4412: KCC CorporationABAID ULLAHNo ratings yet

- Technical Data Sheet: Description Values Technical ParticularsDocument2 pagesTechnical Data Sheet: Description Values Technical ParticularsAli ShahzadNo ratings yet

- NFC AAAC 117MM2 EES Cable SPECIFICATIONDocument5 pagesNFC AAAC 117MM2 EES Cable SPECIFICATIONmedazzNo ratings yet

- 3x50 RM N2xSEYFGbY (24.09.2020)Document1 page3x50 RM N2xSEYFGbY (24.09.2020)Jamil SharifNo ratings yet

- F.O. ADSS SpecificationDocument4 pagesF.O. ADSS SpecificationDinatel ComercialNo ratings yet

- GYTC8S Fiber Optic Cable Specification - GLDocument8 pagesGYTC8S Fiber Optic Cable Specification - GLKyaw Yazar HtunNo ratings yet

- SL - No. Inspection Parameter Specification Observation: Type Test ReportDocument1 pageSL - No. Inspection Parameter Specification Observation: Type Test ReportmaheshgkuNo ratings yet

- 【GL】ADSS-24 coreDocument7 pages【GL】ADSS-24 coreAlex GonzalesNo ratings yet

- ZF40907TCDocument1 pageZF40907TCMurugan AlbumsNo ratings yet

- Mr-001 Test CertificateDocument1 pageMr-001 Test Certificatesai sudheerNo ratings yet

- M2XCH Flex (FI) 5G25 (Black) - 60Document1 pageM2XCH Flex (FI) 5G25 (Black) - 60omarNo ratings yet

- UTP Cat 5E Belden F CatDocument3 pagesUTP Cat 5E Belden F CatDumi NeluNo ratings yet

- Aerial Cable ADSS-12FO G.652D Span 120mDocument4 pagesAerial Cable ADSS-12FO G.652D Span 120mWDCNET WORKSNo ratings yet

- Fo Adss 48 Spam 200 HengtongDocument3 pagesFo Adss 48 Spam 200 Hengtongwilliams eduardo gonzales niñoNo ratings yet

- Adss Span 100Document2 pagesAdss Span 100KFD KFDNo ratings yet

- Networking Cables Gigaflex 2400 Cable Series Cat 6 U/Utp LSNHDocument3 pagesNetworking Cables Gigaflex 2400 Cable Series Cat 6 U/Utp LSNHZeinab Ashraf ElgammalNo ratings yet

- TOXFREE ZH ROZ1-K (AS) VFD EMC 0,6 1 KVDocument3 pagesTOXFREE ZH ROZ1-K (AS) VFD EMC 0,6 1 KVPatricia SorianoNo ratings yet

- Direct Burial Optic Fiber Cable Specification - KSD2019 PDFDocument5 pagesDirect Burial Optic Fiber Cable Specification - KSD2019 PDFjerjyNo ratings yet

- Oil Sample report-31.5MVA, Indotech PTR at Turkayamjal SSDocument2 pagesOil Sample report-31.5MVA, Indotech PTR at Turkayamjal SSMUSHAM217No ratings yet

- Cable Drawing and Specification Data SheetDocument4 pagesCable Drawing and Specification Data SheetJack FrostNo ratings yet

- Useful Design Parameters (Simplified)Document2 pagesUseful Design Parameters (Simplified)Pay RentNo ratings yet

- Adss 120m SpanDocument2 pagesAdss 120m SpanAdriana RosadoroNo ratings yet

- 88kV Copper Large Conductor XLPE CSA PE HS CablesDocument1 page88kV Copper Large Conductor XLPE CSA PE HS CablesIppiNo ratings yet

- Cabo Bipolar Outdoor 2x12AWG Cabloswiss B1A1202N109 - TAB351913 - 374052 - 258Document1 pageCabo Bipolar Outdoor 2x12AWG Cabloswiss B1A1202N109 - TAB351913 - 374052 - 258Iure da LuzNo ratings yet

- 30 AWG Cable DATA SheetDocument2 pages30 AWG Cable DATA SheetTuýp Phờ NờNo ratings yet

- ZTT Et Expressway AAAC Conductor 21-Xj00486Document4 pagesZTT Et Expressway AAAC Conductor 21-Xj00486HarisNo ratings yet

- Quality Product Certification ReinforcementDocument3 pagesQuality Product Certification ReinforcementsamiNo ratings yet

- Fiche Cable FO, OS2Document1 pageFiche Cable FO, OS2rochdi JEDIDINo ratings yet

- Tech. Specification HDPE DUCT 50-43mmDocument2 pagesTech. Specification HDPE DUCT 50-43mmZaman MuhammadNo ratings yet

- OPGW SpecDocument28 pagesOPGW SpecvikasmikkuNo ratings yet

- Gtp-Opgw CableDocument1 pageGtp-Opgw CableManish KumarNo ratings yet

- TDS 1x300 11kV CTS+LEADDocument2 pagesTDS 1x300 11kV CTS+LEADNabeelNo ratings yet

- 15.07 2020 - TTC 2Document1 page15.07 2020 - TTC 2Alok PandeyNo ratings yet

- Polyamid PA6 enDocument1 pagePolyamid PA6 enEl Kanouani ZakariaNo ratings yet

- Polyamid PA6 en PDFDocument1 pagePolyamid PA6 en PDFShilpa shriNo ratings yet

- Axicom MT2 Relay: Signal RelaysDocument4 pagesAxicom MT2 Relay: Signal Relaysedson apazaNo ratings yet

- Aerial Cable ADSS-24FO G.652D Span 200mDocument4 pagesAerial Cable ADSS-24FO G.652D Span 200mWDCNET WORKSNo ratings yet

- Routine Test Certificate: Purchaser's Name: Sale Order NoDocument2 pagesRoutine Test Certificate: Purchaser's Name: Sale Order NoPerumal PalaniNo ratings yet

- FLUID MECHANICS CHAP01 - Hydrostatic PressureDocument5 pagesFLUID MECHANICS CHAP01 - Hydrostatic PressureKriselle DulayNo ratings yet

- Density CalculationsDocument2 pagesDensity CalculationssatpuraNo ratings yet

- Lesson Plan Mole ConceptDocument3 pagesLesson Plan Mole ConceptQueencess Ara TorresNo ratings yet

- Caranzo, Clarish Ann B. BSN-1105 Human Anatomy and Physiology LabDocument2 pagesCaranzo, Clarish Ann B. BSN-1105 Human Anatomy and Physiology LabClarish Ann CaranzoNo ratings yet

- Aisc Bolting and Welding 190606215451 PDFDocument73 pagesAisc Bolting and Welding 190606215451 PDFthet naingNo ratings yet

- Lecture 22 Small Signal StabilityDocument24 pagesLecture 22 Small Signal StabilityManuelNo ratings yet

- Dynamics Q1Document4 pagesDynamics Q1heheheNo ratings yet

- Sirius in Art and Astronomy of DogonDocument7 pagesSirius in Art and Astronomy of DogonKonstantinos MantasNo ratings yet

- Bernoulli and Piezometric LineDocument7 pagesBernoulli and Piezometric LinevyrgoNo ratings yet

- General Properties Rheological Properties: PVC Paste Resin (Homopolymer)Document2 pagesGeneral Properties Rheological Properties: PVC Paste Resin (Homopolymer)AminulIslamNo ratings yet

- Electronic Circuit-PRELIMS EXAMDocument16 pagesElectronic Circuit-PRELIMS EXAMCeasy Boy PeraltaNo ratings yet

- ASTM-C1314-07 (2007) - Compressive Strength of Masonry PrismsDocument10 pagesASTM-C1314-07 (2007) - Compressive Strength of Masonry PrismsMohammad Raihan MukhlisNo ratings yet

- Welding Calculation: Job No. Job: Section: Designed By: Sheet No. Subject: DateDocument37 pagesWelding Calculation: Job No. Job: Section: Designed By: Sheet No. Subject: DateMatthew CHANNo ratings yet

- Sustainable Issues in Infrastructure Engineering: Hany Shehata Sherif El-Badawy EditorsDocument231 pagesSustainable Issues in Infrastructure Engineering: Hany Shehata Sherif El-Badawy Editorsjhoward2012npNo ratings yet

- CE111-lec 4Document9 pagesCE111-lec 4Rich Ian MontalvaNo ratings yet

- Optical Study of Titanium Dioxide Thin Films Prepared by Vacuum Evaporation TechniqueDocument9 pagesOptical Study of Titanium Dioxide Thin Films Prepared by Vacuum Evaporation TechniqueFarid ElsehrawyNo ratings yet

- Pure BendingDocument22 pagesPure BendingTarik Hassan ElsonniNo ratings yet

- Summative Test Science 7 Quarter 3/week 1 & 2: San Rafael Technical Vocational High SchoolDocument8 pagesSummative Test Science 7 Quarter 3/week 1 & 2: San Rafael Technical Vocational High SchoolJohn Arvin RellamasNo ratings yet

- PASCO Chemistry Brochure INTDocument16 pagesPASCO Chemistry Brochure INTOleg GorincioiNo ratings yet

- ESC Marine Fenders Catalogue 2018 - 2019 PDFDocument46 pagesESC Marine Fenders Catalogue 2018 - 2019 PDFDiguinho PiresNo ratings yet

- Experiment 2: Determination of Viscosity of Food Products Using ViscometerDocument20 pagesExperiment 2: Determination of Viscosity of Food Products Using ViscometerSyusyu HyNo ratings yet

- AIATS JEE (A) 2023 Test-2A P-1 (Code-A) 30-01-2022 Sol.Document24 pagesAIATS JEE (A) 2023 Test-2A P-1 (Code-A) 30-01-2022 Sol.KESSAVAN.M ECE20No ratings yet

- SensMat D3.4 M8 Vfinal PDFDocument29 pagesSensMat D3.4 M8 Vfinal PDFcarlos houngbemeNo ratings yet

- LaserDocument54 pagesLasermrkishan395No ratings yet

- Bonding MOTDocument51 pagesBonding MOTA. F. M. Mahfuzul KabirNo ratings yet

- Exam #1: PHY 211: General Physics (Calculus) NameDocument9 pagesExam #1: PHY 211: General Physics (Calculus) NameirfanNo ratings yet

- Solutions To Jaan Kalda's Problems in Thermodynamics: With Detailed Diagrams and Walkthroughs Edition 1.2.1Document76 pagesSolutions To Jaan Kalda's Problems in Thermodynamics: With Detailed Diagrams and Walkthroughs Edition 1.2.1Rahul GayenNo ratings yet

- BS en 10049-2013Document16 pagesBS en 10049-2013Martijn GrootNo ratings yet

- ASTM E 29 Yr 13 PDFDocument5 pagesASTM E 29 Yr 13 PDFRosendo RizoNo ratings yet

- Remideal ExamsDocument3 pagesRemideal ExamsTemesgen KassawNo ratings yet