Professional Documents

Culture Documents

PVC Membrane Specification for Pre Applied Loosely Laid Roofing

Uploaded by

mukesh patelOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PVC Membrane Specification for Pre Applied Loosely Laid Roofing

Uploaded by

mukesh patelCopyright:

Available Formats

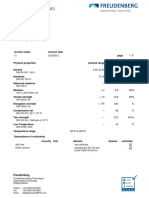

Pre Applied Loosely Laid PVC Membrane

General Spec

Sl.

Property Minimum Requirement Test Standard

No.

1 Thickness 2.0mm ± 5.0% DIN 53370

2 Tensile Strength (Both Directions) 15.0 N/mm2 DIN 53455

3 Elongation at Break (Both Directions) 250% DIN 53454

2

4 Compressive Strength at 20 % strain 2.5 N/mm min ** DIN 53455

Dimensional Stability after accelerating aging < ± 2.0%

General Appearance No Blisters

Dimensional Stability (Change)-Long < ± 3.0%

Dimensional Stability (Change)-Trans < ± 10.0%

5 Tensile Strength Variation (Change)-Trans < ± 10.0% DIN 16726

Tensile Strength Variation (Change)-Long < ± 10.0%

Elongation Variation at Break-Long < ± 10.0%

Elongation Variation at Break-Trans < ± 10.0%

O

Folding at Temperature of -20.0 C No Fissures

6 Behaviour when subjected to Hydrostatic Pressure Waterproof at 10 Bar for 10 hrs DIN 16726

Puncture Resistance/Behaviour during perforation

7 Perforation test at fall height of 750mm. DIN 50014

test

8 Tear Resistance 100 N/mm min DIN 53363

9 Shear Strength of splice with Bitumen 100 N/50 mm min DIN 16726

10 Tensile strength of welded seam 13.5 N/mm2 min DIN 16726

Behaviour after Storage in Aqueous (Acid and alkaline) Solutions

Tensile Strength Variation (Change)-Trans < ± 10.0%

11 Tensile Strength Variation (Change)-Long < ± 10.0% DIN 16726 /SIA 280 *

Elongation Variation at Break-Long < ± 10.0%

Elongation Variation at Break-Trans < ± 10.0%

O

Folding at Temperature of -20.0 C No Fissures

12 Water Absorption 1% max

13 Root Resistance No penetration UNI CEN/TS 14416

14 Microbial Resistance Confirm to BS EN 12225

15 Fire Rating E BS EN ISO 11925-2

* SIA: Swiss International Agency Standard. **Specimen with 10 mm edge length

Equivalent ASTM, DIN and/or International test procedures are permissible

Notes 1) Specified Physical and Mechanical properties in the above table shall be

tested in both longitudinal and transverse directions.

2) A signalling layer shall be placed over Waterproofing Membrane for visual damage indication of any mechanical

damage where reinforced concrete work and/or steel work to be placed on Membrane.

3) Signalling layer shall be such that it does not adversely affect seam welds.

4) Evidence shall be provided by the manufacturer that no components leach out in the long term affecting the durability

of the following:

● Waterproofing Membrane

● Geotextile Drainage/Protective Layer

● Other Plastic and/or PVC materials like water stops.

5) Contractor shall submit membrane combustibility properties and smoke emission class for engineer approval

6) Membrane shall be self extinguishing.

You might also like

- Renolit Alkorplan 00414 15mm + Lacquer enDocument2 pagesRenolit Alkorplan 00414 15mm + Lacquer enIngénieur CivilNo ratings yet

- Donproof PT: Description Method of UseDocument4 pagesDonproof PT: Description Method of UseYousef HalasehNo ratings yet

- Propriedades NBR 70 Shore ADocument3 pagesPropriedades NBR 70 Shore AGabriel NunesNo ratings yet

- Material 72 NBR 872: Black Cross Linking: SulfurDocument3 pagesMaterial 72 NBR 872: Black Cross Linking: SulfurPhong DuongNo ratings yet

- Sika Kimia SDN BHD - Pds - Sikabit t130 Mgmy - SgmyDocument3 pagesSika Kimia SDN BHD - Pds - Sikabit t130 Mgmy - Sgmymultifocus sb100% (1)

- FKM 595 elastomer properties and testing resultsDocument3 pagesFKM 595 elastomer properties and testing resultsPillar ManufacturingNo ratings yet

- Material Properties FKM 75 FKM 585Document3 pagesMaterial Properties FKM 75 FKM 585Victor CadilloNo ratings yet

- 72 NBR 902-En - 1Document3 pages72 NBR 902-En - 1Pierre PescayNo ratings yet

- Sikaplan WP 1100-15hlDocument4 pagesSikaplan WP 1100-15hlpaulaNo ratings yet

- Waterproofing Membrane, CharacteristicsDocument2 pagesWaterproofing Membrane, CharacteristicsyamegNo ratings yet

- PE 100 & PP Material PropertiesDocument2 pagesPE 100 & PP Material PropertiesQuisperolandoNo ratings yet

- Electroarc Wraparound SleeveDocument1 pageElectroarc Wraparound SleeveVenkata Reddy100% (1)

- Materialdatasheet 80 NBR 709 6Document3 pagesMaterialdatasheet 80 NBR 709 6Miguel ContrerasNo ratings yet

- PVC Foam - PropertiesDocument1 pagePVC Foam - PropertiesBảo Nghi TrươngNo ratings yet

- Recubrimiento Ext TanqueDocument2 pagesRecubrimiento Ext Tanquehenry307No ratings yet

- ST1400-7+6 Technical Data SheetDocument1 pageST1400-7+6 Technical Data Sheetrenzo marcoliNo ratings yet

- Sikasil 728 SLDocument5 pagesSikasil 728 SLJesusFloresRodriguezNo ratings yet

- Deckdrain S1200NW8 Data SheetDocument1 pageDeckdrain S1200NW8 Data SheetsdvsdvdsaNo ratings yet

- Gaskets - Graphite PDFDocument4 pagesGaskets - Graphite PDFSH1961No ratings yet

- Technical Data Sheet - Steel Cord FR GradeDocument2 pagesTechnical Data Sheet - Steel Cord FR Gradeamol1321No ratings yet

- Test Report: 1, Madhuvan Apartment, 24, Arunodaya Society, Alkapuri, Vadodara - 390 007Document3 pagesTest Report: 1, Madhuvan Apartment, 24, Arunodaya Society, Alkapuri, Vadodara - 390 007Vatsal DarjiNo ratings yet

- PLUMBING PIPING MATERIALS (uPVC)Document10 pagesPLUMBING PIPING MATERIALS (uPVC)Imran AzizNo ratings yet

- New Hydrovar7bDocument36 pagesNew Hydrovar7bSedfrey PekitpekitNo ratings yet

- ABS N Fisa TehnicaDocument1 pageABS N Fisa TehnicaFloare de PrimavaraNo ratings yet

- Anti-Corrosion Coating: StandardsDocument2 pagesAnti-Corrosion Coating: StandardsMuhamad Rizky KurniawanNo ratings yet

- Tikidan TDS - Selfdan Ipe Plus, R3Document3 pagesTikidan TDS - Selfdan Ipe Plus, R3sandeepNo ratings yet

- FKM 585 Material Spec SheetDocument3 pagesFKM 585 Material Spec SheetantonioNo ratings yet

- PA6EDocument1 pagePA6EDiego ReggianiniNo ratings yet

- 1035 TD 20 Product Data Sheet ViscopasteDocument2 pages1035 TD 20 Product Data Sheet ViscopasteUrooj IlyasNo ratings yet

- 72 NBR 902-EnDocument3 pages72 NBR 902-EnAyman RiyadhNo ratings yet

- ABG ZzPozibreak 6SD - NW8 (L) (SC1) Rev 1.00 DATASHEETDocument1 pageABG ZzPozibreak 6SD - NW8 (L) (SC1) Rev 1.00 DATASHEETtropicaldesigns3No ratings yet

- Konita WPC Board Brochure PDFDocument8 pagesKonita WPC Board Brochure PDFSusanta MaharanaNo ratings yet

- Acoustic Teardrop Seal - TRD 1944Document3 pagesAcoustic Teardrop Seal - TRD 1944billionthfakeloginNo ratings yet

- Technical datasheet rubber fenders propertiesDocument1 pageTechnical datasheet rubber fenders propertiesFandy SipataNo ratings yet

- Uponor Dop Klett CPR 20 Ic 251 V 001Document3 pagesUponor Dop Klett CPR 20 Ic 251 V 001jamppajoo2No ratings yet

- Sikaplan 14.6 - Flexible PVC For TunnelsDocument2 pagesSikaplan 14.6 - Flexible PVC For TunnelsmystrophanNo ratings yet

- Protect Corrosion Underground SubstratesDocument2 pagesProtect Corrosion Underground SubstratesFarid HarisNo ratings yet

- Thumb 20180521C775Document2 pagesThumb 20180521C775Alle LunagNo ratings yet

- TDS Co-3-X 27 03 2018 (003) - 1687274055Document2 pagesTDS Co-3-X 27 03 2018 (003) - 1687274055KSXNo ratings yet

- Matrox FC TDSDocument1 pageMatrox FC TDSrajanarenderNo ratings yet

- Clamps to DIN 3015 GuideDocument28 pagesClamps to DIN 3015 GuideGeovanny Andres Cabezas SandovalNo ratings yet

- ABG ZzPozibreak 4SD - NW8.NW16 (L) (SC1) Rev 1.00 DATASHEETDocument1 pageABG ZzPozibreak 4SD - NW8.NW16 (L) (SC1) Rev 1.00 DATASHEETtropicaldesigns3No ratings yet

- F1 Model Block: Technical DatasheetDocument2 pagesF1 Model Block: Technical DatasheetRafael ObiciNo ratings yet

- f1_in_schools_competitio_2023_regional_finals.pdfDocument2 pagesf1_in_schools_competitio_2023_regional_finals.pdfarief akashahNo ratings yet

- Elotene 3000 X: Self-Adhesive Bituminous Membrane Self-Protected With A Cross-Laminated HDPE FilmDocument34 pagesElotene 3000 X: Self-Adhesive Bituminous Membrane Self-Protected With A Cross-Laminated HDPE FilmConstantin GubavuNo ratings yet

- Is 15652Document3 pagesIs 15652IshanNo ratings yet

- Specification Clauses Geberit HDPE 2012Document4 pagesSpecification Clauses Geberit HDPE 2012sreeNo ratings yet

- TechPlasty - PE1000 - Polyethylene 1000 - 2020-06-02Document2 pagesTechPlasty - PE1000 - Polyethylene 1000 - 2020-06-02maiquelernNo ratings yet

- Propertie NilonDocument3 pagesPropertie Nilonmuhammad daffaNo ratings yet

- Sikaplan-Sgma 2.0 PB EngDocument5 pagesSikaplan-Sgma 2.0 PB EngstilpgNo ratings yet

- Amex Seals Product Data SheetsDocument13 pagesAmex Seals Product Data SheetscloantafNo ratings yet

- Sikaproof 808Document4 pagesSikaproof 808happyNo ratings yet

- Rilsan Fine Powders Physical PropertiesDocument2 pagesRilsan Fine Powders Physical Propertiesธนาชัย เต็งจิรธนาภาNo ratings yet

- Data Sheet Sylodyn ND enDocument6 pagesData Sheet Sylodyn ND enAnonymous GoJpm9WbNo ratings yet

- Technical Data Sheet Polycarbonate: Benefits ApplicationsDocument2 pagesTechnical Data Sheet Polycarbonate: Benefits ApplicationsjackNo ratings yet

- Data Sheet Sylodyn NF enDocument6 pagesData Sheet Sylodyn NF enAnonymous GoJpm9WbNo ratings yet

- BITUPROOF PES 140 3-4mmDocument2 pagesBITUPROOF PES 140 3-4mmjustin chuaNo ratings yet

- DIMO 42M - Prehardened CrMnMo-alloyed Steel in Mold Quality For The Construction of Plastic MoldsDocument4 pagesDIMO 42M - Prehardened CrMnMo-alloyed Steel in Mold Quality For The Construction of Plastic MoldsFernando LaraNo ratings yet

- VIRGIN PTFE PROPERTIES AND PERFORMANCEDocument1 pageVIRGIN PTFE PROPERTIES AND PERFORMANCEvisvisvisvisNo ratings yet

- Corrosion: Corrosion ControlFrom EverandCorrosion: Corrosion ControlL L ShreirRating: 5 out of 5 stars5/5 (1)

- CHECKLIST FOR WATERPROOFINGDocument3 pagesCHECKLIST FOR WATERPROOFINGmukesh patel67% (3)

- Geotextile Drainage FeltDocument1 pageGeotextile Drainage Feltmukesh patelNo ratings yet

- Observation OBS01Document2 pagesObservation OBS01mukesh patelNo ratings yet

- Checklist For Prebond of Confined AreaDocument2 pagesChecklist For Prebond of Confined Areamukesh patel0% (1)

- NWS Pi JK 2018 004 PDFDocument1 pageNWS Pi JK 2018 004 PDFmukesh patelNo ratings yet

- Konsorsium PT - Pgas Solution Pt. Patra Drilling Contractor Jasa Perancangan, Pengadaan Dan Konstruksi Penggantian Pipa Minyak Wilayah Kerja RokanDocument2 pagesKonsorsium PT - Pgas Solution Pt. Patra Drilling Contractor Jasa Perancangan, Pengadaan Dan Konstruksi Penggantian Pipa Minyak Wilayah Kerja Rokanramadani bimaNo ratings yet

- ASME B31.3 Pre Heat & PWHT PDFDocument4 pagesASME B31.3 Pre Heat & PWHT PDFGANGADHAR SAHUNo ratings yet

- Pocket Guide 10 (Fire Alarms in Dwellings)Document2 pagesPocket Guide 10 (Fire Alarms in Dwellings)RudanekNo ratings yet

- Installation, Operation, and Maintenance: Stealth™ Air-Cooled Chiller Model RTAEDocument80 pagesInstallation, Operation, and Maintenance: Stealth™ Air-Cooled Chiller Model RTAEghilesNo ratings yet

- 39CQM A15 1PDDocument29 pages39CQM A15 1PDnhat100% (1)

- EPC PDS BarChipMQ58Document2 pagesEPC PDS BarChipMQ58pankaj_paul6451No ratings yet

- 5 Common Tablet Manufacturing Problems and SolutionsDocument3 pages5 Common Tablet Manufacturing Problems and SolutionsLien HongNo ratings yet

- Ball Valves KH ParkerDocument7 pagesBall Valves KH Parkerkocho79No ratings yet

- SATIP-K-001-03 - HVAC Metal Duct System - Rev. 6Document3 pagesSATIP-K-001-03 - HVAC Metal Duct System - Rev. 6imrankhan220% (1)

- Fti Tooling Catalog PDFDocument221 pagesFti Tooling Catalog PDFmycopteraviationNo ratings yet

- York Rooftop PDFDocument124 pagesYork Rooftop PDFitovarsilva100% (1)

- GGCP Project Schedule - 3WLAH W74Document15 pagesGGCP Project Schedule - 3WLAH W74HANIF AKBARNo ratings yet

- Tabulated steel sections specificationsDocument1 pageTabulated steel sections specificationsRai RiveraNo ratings yet

- MONITORING TRIAL MIXES AND CONCRETE DESIGNSDocument10 pagesMONITORING TRIAL MIXES AND CONCRETE DESIGNSIndra Rizky EfendyNo ratings yet

- 50-ACI 318 ChangesDocument2 pages50-ACI 318 ChangesAnis ShatnawiNo ratings yet

- Disaster Resilient School Assessment ReportDocument19 pagesDisaster Resilient School Assessment Reportrajendra moktanNo ratings yet

- 1405 - 12 Light Cross Section Elematic Hollow Core PlankDocument1 page1405 - 12 Light Cross Section Elematic Hollow Core PlankmanpreetkhanujaNo ratings yet

- PrestressedTendonElongations-MIDAS V1Document4 pagesPrestressedTendonElongations-MIDAS V1sanusi69No ratings yet

- RCC Slab Design CalculationDocument2 pagesRCC Slab Design CalculationVikram GaikwadNo ratings yet

- Analysis of Masonry Structures With DIANADocument11 pagesAnalysis of Masonry Structures With DIANAjeovanNo ratings yet

- Aluma Roll BackDocument2 pagesAluma Roll BackAnonymous IFKsgCWHiNo ratings yet

- 39Document26 pages39supriyo1970No ratings yet

- Edibon Heat Exchange - M7-TITCADocument50 pagesEdibon Heat Exchange - M7-TITCAyondelaNo ratings yet

- Acoustic Market Survey (Vins) FinalDocument33 pagesAcoustic Market Survey (Vins) FinalVISHAL SHARMA55% (11)

- Betopom Arastirma 2Document31 pagesBetopom Arastirma 2KvncGmz DzrNo ratings yet

- Balaji Safety Nets Invisible Grills Pleated Mosquito NetsDocument4 pagesBalaji Safety Nets Invisible Grills Pleated Mosquito NetsVinay ShuklaNo ratings yet

- Multicycle Circulating Valve With Lock Module: Applications DescriptionDocument1 pageMulticycle Circulating Valve With Lock Module: Applications DescriptionYves-donald MakoumbouNo ratings yet

- Bachelors - Project Report 1Document43 pagesBachelors - Project Report 1divyaNo ratings yet

- 1997 Uniform Building Code To UBC - IBC - Crossref - 06Document44 pages1997 Uniform Building Code To UBC - IBC - Crossref - 06Janardhan CharyuluNo ratings yet

- Construcion PiqueDocument7 pagesConstrucion PiqueYery SantanderNo ratings yet