Professional Documents

Culture Documents

Quality Control Report: Üntel Kablolari Sanayi Ve Ticaret A.Ş

Uploaded by

omarOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Quality Control Report: Üntel Kablolari Sanayi Ve Ticaret A.Ş

Uploaded by

omarCopyright:

Available Formats

ÜNTEL KABLOLARI SANAYİ VE TİCARET A.Ş.

DEMİRCİLER KÖYÜ MAKİNE OSB. 6. CADDE NO: 4

41455 DİLOVASI / KOCAELİ

DATE : 20.01.2021

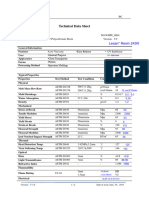

TYPE OF CABLE : FM2XCH 5PR0,75 mm² (Gray)

RELATED STANDARD : IEC 60092-376, IEC 60332-3A

LENGTH OF CABLE : 510 m.

DRUM NUMBER : 931210064

CUSTOMER ORDER NO : N5523/2020/1202

ORDER NO : E201272

QUALITY CONTROL REPORT

STANDARD ÜNTEL

A. ELECTRICAL TESTS

A.1. Conductor resistance (20 ºC) DC. Ω/km max. 26,00 23,30

A.2. High voltage Test 5 minutes A.C. kV 1,5 OK

A.3. Insulation Resistance MΩ.km (20 ºC) 1145 ≥1145

B. PHYSICAL TESTS

B.1. Surface Control - OK

B.2. Wall Thickness of Insulation nom. mm 0,50 0,52

B.3. Copper Wire Braiding Diameter nom. mm 0,20 0,20

B.4. Braiding Density % % 90 % 93

B.5. Wall Thickness of Outer Sheath nom. mm 1,20 1,25

B.6. Outer Diameter nom. mm - 12,90

C MECHANICAL TESTS

C.1. Tensile Strength ( before ageing )(insulation) min. N/mm² 12,5 14,5

C.2. Elongation ( before ageing )(insulation) min % 200 330

C.3. Tensile Strength ( after ageing )(insulation) max variation % ±25 -4

C.4. Elongation ( after ageing )(insulation) max variation % ±25 -6

C.5. Tensile Strength ( before ageing )(outer sheath) min. N/mm² 9 11

C.6. Elongation ( before ageing ) (outer sheath) min % 120 180

C.7. Tensile Strength ( after ageing ) (outer sheath) Max. Variation. % ±30 -2

C.8. Elongation ( after ageing ) (outer sheath) Max Variation. % ±30 -5

C.9. HOT-SET Test <%(175,15)max OK

RESULT PASSED

QUALITY CONT.MANAGER

KODU: FR 32 REV: O REV.TAR. 01.10.2003 SAYFA NO: 1/1

OK

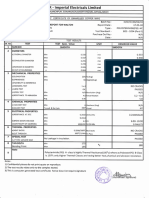

ÜNTEL KABLOLARI SANAYİ VE TİCARET A.Ş.

DEMİRCİLER KÖYÜ MAKİNE OSB. 6. CADDE NO: 4

41455 DİLOVASI / KOCAELİ

DATE : 20.01.2021

TYPE OF CABLE : FM2XCH 6PR0,75 mm² (Gray)

RELATED STANDARD : IEC 60092-376, IEC 60332-3A

LENGTH OF CABLE : 461 m.

DRUM NUMBER : 931210062

CUSTOMER ORDER NO : N5523/2020/1202

ORDER NO : E201272

QUALITY CONTROL REPORT

STANDARD ÜNTEL

A. ELECTRICAL TESTS

A.1. Conductor resistance (20 ºC) DC. Ω/km max. 26,00 23,39

A.2. High voltage Test 5 minutes A.C. kV 1,5 OK

A.3. Insulation Resistance MΩ.km (20 ºC) 1145 ≥1145

B. PHYSICAL TESTS

B.1. Surface Control - OK

B.2. Wall Thickness of Insulation nom. mm 0,50 0,52

B.3. Copper Wire Braiding Diameter nom. mm 0,20 0,20

B.4. Braiding Density % % 90 % 93

B.5. Wall Thickness of Outer Sheath nom. mm 1,30 1,36

B.6. Outer Diameter nom. mm - 15,00

C MECHANICAL TESTS

C.1. Tensile Strength ( before ageing )(insulation) min. N/mm² 12,5 14,5

C.2. Elongation ( before ageing )(insulation) min % 200 330

C.3. Tensile Strength ( after ageing )(insulation) max variation % ±25 -4

C.4. Elongation ( after ageing )(insulation) max variation % ±25 -6

C.5. Tensile Strength ( before ageing )(outer sheath) min. N/mm² 9 12

C.6. Elongation ( before ageing ) (outer sheath) min % 120 190

C.7. Tensile Strength ( after ageing ) (outer sheath) Max. Variation. % ±30 -2

C.8. Elongation ( after ageing ) (outer sheath) Max Variation. % ±30 -5

C.9. HOT-SET Test <%(175,15)max OK

RESULT PASSED

QUALITY CONT.MANAGER

KODU: FR 32 REV: O REV.TAR. 01.10.2003 SAYFA NO: 1/1

OK

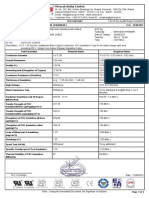

ÜNTEL KABLOLARI SANAYİ VE TİCARET A.Ş.

DEMİRCİLER KÖYÜ MAKİNE OSB. 6. CADDE NO: 4

41455 DİLOVASI / KOCAELİ

DATE : 20.01.2021

TYPE OF CABLE : FM2XCH 8PR0,75 mm² (Gray)

RELATED STANDARD : IEC 60092-376, IEC 60332-3A

LENGTH OF CABLE : 520 m.

DRUM NUMBER : 931210063

CUSTOMER ORDER NO : N5523/2020/1202

ORDER NO : E201272

QUALITY CONTROL REPORT

STANDARD ÜNTEL

A. ELECTRICAL TESTS

A.1. Conductor resistance (20 ºC) DC. Ω/km max. 26,00 23,25

A.2. High voltage Test 5 minutes A.C. kV 1,5 OK

A.3. Insulation Resistance MΩ.km (20 ºC) 1145 ≥1145

B. PHYSICAL TESTS

B.1. Surface Control - OK

B.2. Wall Thickness of Insulation nom. mm 0,50 0,52

B.3. Copper Wire Braiding Diameter nom. mm 0,30 0,30

B.4. Braiding Density % % 90 % 93

B.5. Wall Thickness of Outer Sheath nom. mm 1,30 1,40

B.6. Outer Diameter nom. mm - 15,60

C MECHANICAL TESTS

C.1. Tensile Strength ( before ageing )(insulation) min. N/mm² 12,5 14,5

C.2. Elongation ( before ageing )(insulation) min % 200 330

C.3. Tensile Strength ( after ageing )(insulation) max variation % ±25 -4

C.4. Elongation ( after ageing )(insulation) max variation % ±25 -6

C.5. Tensile Strength ( before ageing )(outer sheath) min. N/mm² 9 12

C.6. Elongation ( before ageing ) (outer sheath) min % 120 190

C.7. Tensile Strength ( after ageing ) (outer sheath) Max. Variation. % ±30 -2

C.8. Elongation ( after ageing ) (outer sheath) Max Variation. % ±30 -5

C.9. HOT-SET Test <%(175,15)max OK

RESULT PASSED

QUALITY CONT.MANAGER

KODU: FR 32 REV: O REV.TAR. 01.10.2003 SAYFA NO: 1/1

OK

You might also like

- M2XCH Flex (FI) 5G25 (Black) - 60Document1 pageM2XCH Flex (FI) 5G25 (Black) - 60omarNo ratings yet

- ÜNTEL cable quality control reportsDocument3 pagesÜNTEL cable quality control reportsomarNo ratings yet

- 15.07 2020 - TTC 2Document1 page15.07 2020 - TTC 2Alok PandeyNo ratings yet

- Polycab India Ltd UH3 Type Test CertificateDocument1 pagePolycab India Ltd UH3 Type Test CertificateAlok PandeyNo ratings yet

- 1554-2Cx6mm AluminumDocument3 pages1554-2Cx6mm AluminumSandeep BhutaniNo ratings yet

- Test CertificateDocument1 pageTest CertificateViswa BhuvanNo ratings yet

- Type Tests Report: #REF! #REF!Document2 pagesType Tests Report: #REF! #REF!DIPAKNo ratings yet

- 3x50 RM N2xSEYFGbY (24.09.2020)Document1 page3x50 RM N2xSEYFGbY (24.09.2020)Jamil SharifNo ratings yet

- 06 - Fire Resistant CablesDocument13 pages06 - Fire Resistant CablesmlutfimaNo ratings yet

- RR 1.5 SQ MM FR-LSH (DRJ-220000868)Document1 pageRR 1.5 SQ MM FR-LSH (DRJ-220000868)Govind NataniNo ratings yet

- Siare Technologies - Test ReportDocument1 pageSiare Technologies - Test ReportnikhilbhorNo ratings yet

- Bayblend T88 GF 20 - en - 56968672 00003567 20081863Document3 pagesBayblend T88 GF 20 - en - 56968672 00003567 20081863Mattia Terri TerrandoNo ratings yet

- Hensel - Electric (KF 1006 G) PDFDocument3 pagesHensel - Electric (KF 1006 G) PDFRavi KrishnanNo ratings yet

- "Weatherproof" For Outdoor Installation KF 1006 GDocument3 pages"Weatherproof" For Outdoor Installation KF 1006 GRavi KrishnanNo ratings yet

- Wanhua PC Injection Moulding 20 Mfi Clarnate A1227Document2 pagesWanhua PC Injection Moulding 20 Mfi Clarnate A1227lucasNo ratings yet

- "Weatherproof" For Outdoor Installation KF 2525 GDocument3 pages"Weatherproof" For Outdoor Installation KF 2525 GRavi KrishnanNo ratings yet

- Anti-Corrosion Coating: StandardsDocument2 pagesAnti-Corrosion Coating: StandardsMuhamad Rizky KurniawanNo ratings yet

- REWINDING REPORT TITLEDocument14 pagesREWINDING REPORT TITLEzakir84md3639No ratings yet

- K SMDNC03100KB00KP00 0001Document7 pagesK SMDNC03100KB00KP00 0001Pedro LeonNo ratings yet

- Technial Data Sheet IecDocument1 pageTechnial Data Sheet IecVenkata Madhav ModugaNo ratings yet

- Magnetic Buzzer Spec SheetDocument5 pagesMagnetic Buzzer Spec SheetLUDWINGNo ratings yet

- Crackbridging SummaryDocument8 pagesCrackbridging SummaryEvgeny ZakharinNo ratings yet

- TP Wanhua Clarnate A1227 vs Lexan 243RDocument2 pagesTP Wanhua Clarnate A1227 vs Lexan 243RMitja GorseNo ratings yet

- CST-934AS Magnetic Buzzer Spec SheetDocument5 pagesCST-934AS Magnetic Buzzer Spec SheetBenela JustinNo ratings yet

- Metal Detectable PE1000 Data SheetDocument2 pagesMetal Detectable PE1000 Data SheetPrashant MalikNo ratings yet

- Is 15652Document3 pagesIs 15652IshanNo ratings yet

- PA66-GF30LANXESS Durethan AKV30 000000 ISO ENDocument3 pagesPA66-GF30LANXESS Durethan AKV30 000000 ISO ENKalipse FerreiraNo ratings yet

- B320/A/B - B360/A/B: 3.0A Surface Mount Schottky Barrier RectifierDocument4 pagesB320/A/B - B360/A/B: 3.0A Surface Mount Schottky Barrier RectifierGustavo Alberto Jaramillo RuedaNo ratings yet

- Technical Data Sheet: Description Values Technical ParticularsDocument2 pagesTechnical Data Sheet: Description Values Technical ParticularsAli ShahzadNo ratings yet

- CEM-1206S Datasheet - Magnetic Buzzer - CUI Inc PDFDocument5 pagesCEM-1206S Datasheet - Magnetic Buzzer - CUI Inc PDFLUDWINGNo ratings yet

- TECSUN PV1-F Cable Technical DataDocument5 pagesTECSUN PV1-F Cable Technical Datarommy_boy330No ratings yet

- SWG 31 WDocument1 pageSWG 31 WRajesh RoyNo ratings yet

- SWG 31 WDocument1 pageSWG 31 WRajesh RoyNo ratings yet

- Tech Specification Apepdcl TN 99Document23 pagesTech Specification Apepdcl TN 99Suresh SharmaNo ratings yet

- Technical Specification of Stay InsulatorDocument11 pagesTechnical Specification of Stay Insulatorraj_stuff006No ratings yet

- "Weatherproof" For Outdoor Installation KF 0404 BDocument3 pages"Weatherproof" For Outdoor Installation KF 0404 BRavi KrishnanNo ratings yet

- Ultracab India Railway Cable Test ReportDocument2 pagesUltracab India Railway Cable Test ReportLaboratory UltracabNo ratings yet

- 220 KV Cable Inspection ReportDocument4 pages220 KV Cable Inspection Report9782279059No ratings yet

- Test Certificate for 3G4mm2 H07RN-F CableDocument1 pageTest Certificate for 3G4mm2 H07RN-F CableSoha ElsamraNo ratings yet

- C606 C607 C752 753Document2 pagesC606 C607 C752 753Sol De GabrielNo ratings yet

- CEM-1203 (42) Datasheet - Magnetic Buzzer - CUI Inc PDFDocument5 pagesCEM-1203 (42) Datasheet - Magnetic Buzzer - CUI Inc PDFLUDWINGNo ratings yet

- PP Black Semi Glossy B.No. 7558Document2 pagesPP Black Semi Glossy B.No. 7558Andras StegerNo ratings yet

- 3x10 RM NYFGbY-FRLS (27.10.2020)Document1 page3x10 RM NYFGbY-FRLS (27.10.2020)Jamil SharifNo ratings yet

- Hensel Electric PDFDocument3 pagesHensel Electric PDFLucky Rizky FNo ratings yet

- Delta Electronics DC Fan SpecificationDocument9 pagesDelta Electronics DC Fan SpecificationElias CoelhoNo ratings yet

- ADSS Specification -- 200M Span Optical Fiber Cable Technical SpecDocument4 pagesADSS Specification -- 200M Span Optical Fiber Cable Technical SpecDinatel ComercialNo ratings yet

- PC 8B35 Ge Lexan PCDocument3 pagesPC 8B35 Ge Lexan PCbalu gunaNo ratings yet

- Tri-Rated Rev005Document2 pagesTri-Rated Rev005Jean Pierre Goossens100% (1)

- Quality test report for Kroton SAC instrumentation cablesDocument2 pagesQuality test report for Kroton SAC instrumentation cablesJuanNo ratings yet

- Mr-001 Test CertificateDocument1 pageMr-001 Test Certificatesai sudheerNo ratings yet

- Technical Data Sheet: Description Technical Particulars ValuesDocument1 pageTechnical Data Sheet: Description Technical Particulars ValuesMuhammad Ali TariqNo ratings yet

- Sumitube Sa2fDocument2 pagesSumitube Sa2fNicacio LucenaNo ratings yet

- MFLRF078FSCTCPA100Document1 pageMFLRF078FSCTCPA100microqualNo ratings yet

- Solar Cable Halogen FreeDocument2 pagesSolar Cable Halogen FreeGelu BordeaNo ratings yet

- 3C-ABC-Technical Spec 948Document9 pages3C-ABC-Technical Spec 948Kanwalnain madaanNo ratings yet

- CEM-1201 (42) Datasheet - Magnetic Buzzer - CUI Inc PDFDocument5 pagesCEM-1201 (42) Datasheet - Magnetic Buzzer - CUI Inc PDFLUDWINGNo ratings yet

- Sikadur-42 MP Normal HCDocument6 pagesSikadur-42 MP Normal HCDidiet PuteraNo ratings yet

- Datasheet PDFDocument1 pageDatasheet PDFSunHerryNo ratings yet

- Pressuremeter Testing: Methods and InterpretationFrom EverandPressuremeter Testing: Methods and InterpretationRating: 5 out of 5 stars5/5 (2)

- EPC Contract Breakdown Structure-P1Document1 pageEPC Contract Breakdown Structure-P1omarNo ratings yet

- Arquid-Technical Due DiligenceDocument35 pagesArquid-Technical Due DiligenceomarNo ratings yet

- Fig.1. Before Increasing Amine Rate: Rich Approach 96%Document1 pageFig.1. Before Increasing Amine Rate: Rich Approach 96%omarNo ratings yet

- Media Release CATOFIN Hengli Group 20190815 enDocument2 pagesMedia Release CATOFIN Hengli Group 20190815 enomarNo ratings yet

- Hinkley Point Jetty Statement of CaseDocument80 pagesHinkley Point Jetty Statement of CaseomarNo ratings yet

- Emissions from Elevated Flares – A Literature SurveyDocument100 pagesEmissions from Elevated Flares – A Literature SurveyomarNo ratings yet

- Appendix g2 LPG SFF Pre Feasibility Design Package Rev1 0 Bvi SignedDocument71 pagesAppendix g2 LPG SFF Pre Feasibility Design Package Rev1 0 Bvi SignedMuhammad Faheem67% (3)

- Dissertacao Joana Antunes MEGEDocument133 pagesDissertacao Joana Antunes MEGEShayne229No ratings yet

- Guidance On Landfill Gas Flaring: WWW - Environment-Agency - Gov.ukDocument56 pagesGuidance On Landfill Gas Flaring: WWW - Environment-Agency - Gov.ukdadanNo ratings yet

- Positive Material Identification ProcedureDocument6 pagesPositive Material Identification Procedureomar100% (1)

- Fdocuments - in - Quantitative Risk Assessment Study Qra Quantitative Risk Assessment QraDocument165 pagesFdocuments - in - Quantitative Risk Assessment Study Qra Quantitative Risk Assessment QraomarNo ratings yet

- Polypropylene: Process Features Process BenefitsDocument2 pagesPolypropylene: Process Features Process BenefitsomarNo ratings yet

- Landfill Gas Flare - EU StandardsDocument56 pagesLandfill Gas Flare - EU Standardshk168No ratings yet

- Epaisseur Pipe 316L SuperduplexDocument2 pagesEpaisseur Pipe 316L SuperduplexomarNo ratings yet

- AVK Gate Valve Series 37 50 004 IOMDocument9 pagesAVK Gate Valve Series 37 50 004 IOMomarNo ratings yet

- Instrument Transformer Testing Brochure ENUDocument10 pagesInstrument Transformer Testing Brochure ENUaditya agasiNo ratings yet

- Developer Constructed Project Closeout Report Guidance NotesDocument10 pagesDeveloper Constructed Project Closeout Report Guidance NotesomarNo ratings yet

- 1 Piping CostingDocument33 pages1 Piping Costingamoldhole97% (34)

- 3-25 - Tape Wrapping Specification (PL212533-SP-ETG-5233-00) PDFDocument6 pages3-25 - Tape Wrapping Specification (PL212533-SP-ETG-5233-00) PDFomarNo ratings yet

- Standards and Guidelines For Natural Gas Fuelled Ship Projects'Document133 pagesStandards and Guidelines For Natural Gas Fuelled Ship Projects'mohammad kassarNo ratings yet

- 600 NR - 2018 11Document199 pages600 NR - 2018 11mainNo ratings yet

- Rules For The Classification of High Speed Craft - BV LG RINA - 2002 PDFDocument290 pagesRules For The Classification of High Speed Craft - BV LG RINA - 2002 PDFMaurizio BernasconiNo ratings yet

- Ludeca-A Practical Guide To Shaft Alignment PDFDocument0 pagesLudeca-A Practical Guide To Shaft Alignment PDFDelfinsh100% (1)

- Requirements Concerning Pipes and Pressure Vessels: International Association of Classification SocietiesDocument72 pagesRequirements Concerning Pipes and Pressure Vessels: International Association of Classification SocietiesmahmudNo ratings yet

- FirePumps Scopes ULFMDocument36 pagesFirePumps Scopes ULFMZeh Garcia JuniorNo ratings yet

- SteelBook Pipe PipeFittingsDocument28 pagesSteelBook Pipe PipeFittingsSumeet Sisir SarkarNo ratings yet

- Van NH A ASAHI - CatalogueDocument32 pagesVan NH A ASAHI - Cataloguent_long76No ratings yet

- AWS ELECTRODE CLASSIFICATION GUIDEDocument8 pagesAWS ELECTRODE CLASSIFICATION GUIDEFuaz Sukarya Abu Fatih100% (1)

- Commissioning Dictionary: Acceptance Certificate (Ac)Document29 pagesCommissioning Dictionary: Acceptance Certificate (Ac)GabrielNo ratings yet

- Commissioning Team Roles & ResponsibilitiesDocument8 pagesCommissioning Team Roles & ResponsibilitiesGabrielNo ratings yet

- A Review of Drug-Induced Acute Angle Closure Glaucoma For Non-Ophthalmologists PDFDocument8 pagesA Review of Drug-Induced Acute Angle Closure Glaucoma For Non-Ophthalmologists PDFMeida Putri UtamiNo ratings yet

- Pharm.D 2nd Year SyllabusDocument21 pagesPharm.D 2nd Year Syllabus12 E 36 Yatri PatelNo ratings yet

- 01 Itp-380kv Gis - PlanDocument9 pages01 Itp-380kv Gis - PlanYahya SamaraNo ratings yet

- Assessment Toolkit: Health InequalitiesDocument30 pagesAssessment Toolkit: Health InequalitiesAlejandro CardonaNo ratings yet

- Inas Faiqah BT Mohd Helmi (An Infant Suing Through Her Father and Next Friend, Mohd Helmi Bin Abdul Aziz) V Kerajaan Malaysia & OrsDocument15 pagesInas Faiqah BT Mohd Helmi (An Infant Suing Through Her Father and Next Friend, Mohd Helmi Bin Abdul Aziz) V Kerajaan Malaysia & Orsshukri77No ratings yet

- Fire Flow CalculationsDocument37 pagesFire Flow CalculationsAmy CurryNo ratings yet

- Piston Water MeterDocument2 pagesPiston Water MeterMark PamularNo ratings yet

- PN Junction Formation and Barrier PotentialDocument9 pagesPN Junction Formation and Barrier PotentialchristlllNo ratings yet

- Periodontal DiseaseDocument4 pagesPeriodontal Diseasemojako_badboysNo ratings yet

- 9-10 Manajemen Fasilitas Dan Keselamatan - PCC, HSEDocument30 pages9-10 Manajemen Fasilitas Dan Keselamatan - PCC, HSEMars Esa UnggulNo ratings yet

- Complete Dummy's Guide to a Diffusion Pumped Vacuum SystemDocument4 pagesComplete Dummy's Guide to a Diffusion Pumped Vacuum Systemjokerbuddy01No ratings yet

- Nurs478 Healthcaredelivery Audrey GohDocument12 pagesNurs478 Healthcaredelivery Audrey Gohapi-316372858No ratings yet

- IB Student's Soil Systems GuideDocument7 pagesIB Student's Soil Systems GuideYohanes Sumantri RatnodiyantoNo ratings yet

- Format Bahasa Inggeris UPSR 2016 ENGLISH (013) Section ADocument33 pagesFormat Bahasa Inggeris UPSR 2016 ENGLISH (013) Section AVINOTININo ratings yet

- Stress and Coping in Families With Deaf Children: Terri Feher-Prout University of PittsburghDocument12 pagesStress and Coping in Families With Deaf Children: Terri Feher-Prout University of PittsburghGolfiNo ratings yet

- Demand, Supply, and Market Equilibrium: Mcgraw-Hill/IrwinDocument34 pagesDemand, Supply, and Market Equilibrium: Mcgraw-Hill/IrwinLillian KobusingyeNo ratings yet

- Wind Energy 6Document12 pagesWind Energy 6Shanthi RameshNo ratings yet

- Flatworms Round Worms and Anne Lids LabDocument6 pagesFlatworms Round Worms and Anne Lids LabBellaNo ratings yet

- Chapter 1Document52 pagesChapter 1MD NAYM MIANo ratings yet

- Microwave TubesDocument36 pagesMicrowave TubesHINDUSTAN KNOW 1No ratings yet

- MaryamDocument1 pageMaryamHAIZA FATHIMANo ratings yet

- Klee PTLDocument3 pagesKlee PTLapi-590350469No ratings yet

- Marketing Environment Analysis and Trends Impacting CompaniesDocument27 pagesMarketing Environment Analysis and Trends Impacting CompaniesSamoyed KalraNo ratings yet

- ID 2019 CourseDescription MIKE21FlowModelFM HydrodynamicModellingUsingFlexibleMesh UKDocument2 pagesID 2019 CourseDescription MIKE21FlowModelFM HydrodynamicModellingUsingFlexibleMesh UKsaenuddinNo ratings yet

- Hedging FuturesDocument39 pagesHedging Futuresapi-3833893100% (1)

- Pradhan Mantri Gram Sadak Yojana Pradhan Mantri Gram Sadak YojanaDocument19 pagesPradhan Mantri Gram Sadak Yojana Pradhan Mantri Gram Sadak Yojanapriyajaiswal428No ratings yet

- Working at Height PolicyDocument7 pagesWorking at Height PolicyAniekan AkpaidiokNo ratings yet

- Dgca Module 06 Part 02Document15 pagesDgca Module 06 Part 02Deepak Choudhary DCNo ratings yet

- 4801-Article Text-19217-1-10-20110701Document8 pages4801-Article Text-19217-1-10-20110701David BriggsNo ratings yet

- Hazard Identification 2. Risk AssessmentDocument5 pagesHazard Identification 2. Risk AssessmentNoreen Syakireen Binti NormanNo ratings yet