Professional Documents

Culture Documents

Safety Trigger - V2

Uploaded by

Asanka ChathurangaOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Safety Trigger - V2

Uploaded by

Asanka ChathurangaCopyright:

Available Formats

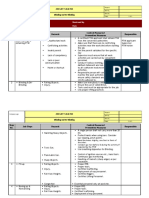

Safety Trigger Score

Daily Operation Safety Check Date:-

Inspection Total

# Guide to inspect Risk Rating Corrective Action/ Guidance

Requirement Score

Normal - Safe to Operate Weightage 1 Can be run without additional controls. Refer section 1

Check Line Planned Abnormality - Need Additional Controls Weightage 2 Refer section 2 guideline

Guide

Operation

Condition Unplanned Abnormality - Need Additional Controls 3 Refer section 3 guideline

Weightage

All employees are competent(Knowledgable, Trained, Experienced) in line operation(more than 3 Yes=0, No=5 5 1. If the total score is zero, line can run without any additional controls. Machine is in normal

months where task specific hazards present) condition

All safe working infrastructure (Fans, lights, water fountains etc) are fully functional and machines are Yes=0, No=5 0 2. If the total score is greater than 0, machine is not in normal condition. Identify the deviated

fully functional (No out of order machines) section (Planned or Unplanned)

Identified unsafe conditions/ unsafe acts are adequately controlled and preventive actions are taken Yes=0, No=5 0 3. Check the Section 2 & 3 to identify whether any other issues are triggering as well

Section 1

Normal operation

guideline :- All tools and equipments necessary for the operation are available (PPE, cleaning equipments etc) Yes=0, No=5 0 5 4. Consult supervisor to take actions to control the identified issues (In absence of supervisor,

Examples line manager must take the actions to control the risk)

Waste is properly segregated and stored. Housekeeping is not creating any unsafe conditions (fire exits, Yes=0, No=5 0

walkways are not obstructed) 5. If the total score <=30, supervisor need to assess the risk and control the risk as low as

reasonably practicable

Other issues/ hazards/ unsafe conditions are not present at the site Yes=0, No=5 0

6. If , 30 < total score < = 60, supervisor must consult the line manager to take actions to

control the identified issues

New workers are deployed without relavant competency(Knowledge, Training, Experience). Disable Yes=20, 20

employees deployed in line with controls etc No=0 7. If, 60 < total score <= 90, plant manager must sign off the operation continuity with

additional controls and should bring the total score below 60 within 6 hours

Special cleaning program is planned etc Yes=10, 0 8. If, total score < 90, it should be reduced below 90 immediately or else line should be

No=0 stopped with the consultation of plant manager

Section 2

Planned

abnormality :- Preventive maintenance is planned for the day Yes=20, 0 20

Examples No=0

Other planned machine works, Utility down times, planned trainings, meetings causing no of workers Yes=20, 0

reduction for operations ( Machine setting, Rack loading, supervisor training etc) or any other work No=0

Any of above planned works found violating Ansell safety procedures/ rules or requirements (work Yes=90, 0

without JSA, work permit, disable worker without adequate assistance etc) No=0

Lights not working, Floor contamination due to a loss of containment (water, chemical etc), removal of Yes=30, 0

machine guards, employee absenteeism etc No=0

Section 3

Un-planned

abnormality :- Sudden issues such as Machine breakdown, Rack jam, malfunction of sensors, power failure etc Yes=30, 30 30

Examples No=0

Material movement process disturbance (Warehouse transport delay, waste disposal delay etc) Yes=30, 0

No=0

Any other risk that has a potential to injure workers, damage properties or disturb business continuity Yes=30, 0

No=0 Trigger

TS = 0 - line can run without any additional controls. Machine is in normal condition

0 < TS <= 30 - Consult supervisor to take actions to control the identified issues

30 < TS <= 60 - supervisor need to assess the risk and control the risk as low as

Total Score (TS) 55 reasonably practicable

60 < TS <= 90 - plant manager must sign off the operation continuity with additional

controls and should bring the total score below 60 within 6 hours

90 > TS - It should be reduced below 90 immediately or else line should be stopped

with the consultation of plant manager

You might also like

- Manufacturing Process Audit Excel FormDocument1 pageManufacturing Process Audit Excel FormLori PlatzNo ratings yet

- Autonomous Operator Training Step 0 PDFDocument17 pagesAutonomous Operator Training Step 0 PDFjesusmemNo ratings yet

- 5S Audit Department Name:: Evaluation CriteriaDocument5 pages5S Audit Department Name:: Evaluation CriteriaRahul KumarNo ratings yet

- Manufacturing Process AuditDocument1 pageManufacturing Process Auditmurilocabrini100% (1)

- Three Primary Steps in Maintenance Reliability EngineeringDocument51 pagesThree Primary Steps in Maintenance Reliability EngineeringPablo Scott100% (1)

- SafetyNet-EH-S-Facility-Audit-Ver-5 TampletDocument19 pagesSafetyNet-EH-S-Facility-Audit-Ver-5 TampletRizwan AshadNo ratings yet

- Value Stream Q-Basics: Maintenance (TPM) Test EquipmentDocument1 pageValue Stream Q-Basics: Maintenance (TPM) Test EquipmentRodolfo M. PortoNo ratings yet

- (Whitepaper) Essential Tips For Optimizing Your Preventive MaintenanceDocument11 pages(Whitepaper) Essential Tips For Optimizing Your Preventive MaintenanceNazar Alrodainy100% (1)

- Call CentreDocument4 pagesCall Centreعلي عبدالله قاسم شلحNo ratings yet

- Take 5Document9 pagesTake 5aaqibfarhanNo ratings yet

- EHS Prequalification Questionnaire: Environmental Health and Safety (Ehs) StaffingDocument3 pagesEHS Prequalification Questionnaire: Environmental Health and Safety (Ehs) Staffingrahmankhan823No ratings yet

- Job Safety Analysis FormDocument6 pagesJob Safety Analysis Formamirthalingam_b671No ratings yet

- Risk Management ReportDocument17 pagesRisk Management ReportDALIPUPNo ratings yet

- Fordec Analyse Diagram & DodarDocument3 pagesFordec Analyse Diagram & DodarDavidNo ratings yet

- Lab 1Document13 pagesLab 1RHINROMENo ratings yet

- Controlling As A Management FunctionDocument16 pagesControlling As A Management Functionabdu hamzaNo ratings yet

- Sem AssuntoDocument53 pagesSem AssuntoAnderson Thiago LopesNo ratings yet

- BSBWHS605 Assessment 2Document32 pagesBSBWHS605 Assessment 2GybNo ratings yet

- Simplilearn Toolkit - 2Document50 pagesSimplilearn Toolkit - 2AbhishekChowdhuryNo ratings yet

- Backfilling Work & Compaction at CPFDocument2 pagesBackfilling Work & Compaction at CPFMohammed AdnanNo ratings yet

- 2-HEMP-Hazards and Effects ManagementDocument17 pages2-HEMP-Hazards and Effects ManagementShahid IqbalNo ratings yet

- Safe Maintenance ChecklistDocument4 pagesSafe Maintenance ChecklistPranay Singh ThakurNo ratings yet

- Safe Maintenance Checklist Good To Share 1698549454Document4 pagesSafe Maintenance Checklist Good To Share 1698549454Manoj KumarNo ratings yet

- Adg - Take 5 - Risk Assessment ProcedureDocument5 pagesAdg - Take 5 - Risk Assessment ProcedureSteveNo ratings yet

- SWMS-Pipe Instalation Work at Utility 25.01.21Document10 pagesSWMS-Pipe Instalation Work at Utility 25.01.21Ansari FaisalNo ratings yet

- JSA PresentationDocument17 pagesJSA Presentationdwivedi10100% (3)

- Hirac and Re Entry PlanDocument7 pagesHirac and Re Entry PlanTriciaNo ratings yet

- Process Safety AwarenessDocument19 pagesProcess Safety AwarenessiekazalyNo ratings yet

- 6S in HealthcareDocument13 pages6S in HealthcareChannel MedicalNo ratings yet

- 06.1 TEF Att.1 - Safety QuestionnairesDocument7 pages06.1 TEF Att.1 - Safety Questionnairesengr.mehran93No ratings yet

- Job Safety Analysis Guideline - Issue 1Document25 pagesJob Safety Analysis Guideline - Issue 1Ferid HaciliNo ratings yet

- List Your Processes Here: Enter Full Name of CAR Form Here Enter Abbreviated Name of Your CAR Form HereDocument4 pagesList Your Processes Here: Enter Full Name of CAR Form Here Enter Abbreviated Name of Your CAR Form HereganrashNo ratings yet

- Managing Safe Work at Chevron Mining PDFDocument24 pagesManaging Safe Work at Chevron Mining PDFGuntur Ekadamba Adiwinata100% (1)

- The Controlling Process & TechniquesDocument29 pagesThe Controlling Process & Techniqueskhalishah ghaisaniNo ratings yet

- Geocycle Introduction To OH&S 2012Document25 pagesGeocycle Introduction To OH&S 2012Safrin SangiaNo ratings yet

- NEBOSH Latest Template For Risk Assesment ReportDocument19 pagesNEBOSH Latest Template For Risk Assesment ReportMuhammad waseem shah0% (1)

- What Is The Design For The Environment (Dfe) Auto Refinish Project?Document18 pagesWhat Is The Design For The Environment (Dfe) Auto Refinish Project?lesegoNo ratings yet

- VND Openxmlformats-Officedocument Wordprocessingml Document&rendition 1Document5 pagesVND Openxmlformats-Officedocument Wordprocessingml Document&rendition 1Asif NNo ratings yet

- Internal QHSE Audit - Management Visit 11.02.2019 ReportDocument8 pagesInternal QHSE Audit - Management Visit 11.02.2019 ReportMahendra PratamaNo ratings yet

- Laying 10 Feet Wall Job Hazard AnalysisDocument5 pagesLaying 10 Feet Wall Job Hazard AnalysisJermaine DurantNo ratings yet

- 10 AuditDocument4 pages10 AuditMohammed MinhajNo ratings yet

- Accident Reporting, Investigation and Analysis: Those Who Cannot Remember The Past Are Condemned To Repeat It'Document34 pagesAccident Reporting, Investigation and Analysis: Those Who Cannot Remember The Past Are Condemned To Repeat It'BalasubramaniamkamarajNo ratings yet

- Otis Tool Box Talk No 30: Introduction To Job Hazard Analysis (2011)Document3 pagesOtis Tool Box Talk No 30: Introduction To Job Hazard Analysis (2011)Xiaobo ZhaoNo ratings yet

- Management Safety AuditDocument34 pagesManagement Safety Auditmubbaram.almoizNo ratings yet

- 4822 Hazard and Risk Managerment Guide V1Document1 page4822 Hazard and Risk Managerment Guide V1HenhamNo ratings yet

- Quality ManagementDocument26 pagesQuality ManagementNandini SuriNo ratings yet

- JSA Blinding and de Blinding PDF FreeDocument3 pagesJSA Blinding and de Blinding PDF Free최승원No ratings yet

- Chapter 7 SiapDocument19 pagesChapter 7 SiapNurhayati HasanahNo ratings yet

- LSR Self Assessments Tool - Q3Document27 pagesLSR Self Assessments Tool - Q3RitikNo ratings yet

- CONTROLLINGGGDocument2 pagesCONTROLLINGGGeliNo ratings yet

- HI TechniquesDocument111 pagesHI TechniquesAdil BeigNo ratings yet

- g1-s1 Practical Assessment.v1.2Document10 pagesg1-s1 Practical Assessment.v1.2albertabdul-rahmanNo ratings yet

- Lean Improvement RoadmapDocument9 pagesLean Improvement RoadmapvelloresankarNo ratings yet

- Cable Pulling Work and Backfilling of The Trench at CPF Inside PlantDocument2 pagesCable Pulling Work and Backfilling of The Trench at CPF Inside PlantMohammed AdnanNo ratings yet

- 1ig2 Sample v5.2Document18 pages1ig2 Sample v5.2Maher50% (2)

- Modern Values of HseDocument4 pagesModern Values of HsekrishnathNo ratings yet

- 5S: A Practical Guide to Visualizing and Organizing Workplaces to Improve ProductivityFrom Everand5S: A Practical Guide to Visualizing and Organizing Workplaces to Improve ProductivityRating: 5 out of 5 stars5/5 (3)

- Robot Programming: A Practical Guide to Behavior-Based RoboticsFrom EverandRobot Programming: A Practical Guide to Behavior-Based RoboticsRating: 4.5 out of 5 stars4.5/5 (1)

- Development and Evaluation of Overall Equipment EfDocument18 pagesDevelopment and Evaluation of Overall Equipment EfAsanka ChathurangaNo ratings yet

- Project Planner: Period HighlightDocument1 pageProject Planner: Period HighlightTagel MarkosNo ratings yet

- PM TR 20 414 En-Gb PM-SW+MMIS+SWPDocument25 pagesPM TR 20 414 En-Gb PM-SW+MMIS+SWPAsanka ChathurangaNo ratings yet

- ADMISSION FORM Lower Nursery To Grade 12 2023 Edition 2023 10 24Document4 pagesADMISSION FORM Lower Nursery To Grade 12 2023 Edition 2023 10 24Asanka ChathurangaNo ratings yet

- Sub01 - Spectrum Labor - Att03Document142 pagesSub01 - Spectrum Labor - Att03Asanka ChathurangaNo ratings yet

- Application: Membership VolunteerDocument2 pagesApplication: Membership VolunteerAsanka ChathurangaNo ratings yet

- Wave 03 RTT DeploymentDocument5 pagesWave 03 RTT DeploymentAsanka ChathurangaNo ratings yet

- Autonomous Maintenance: CIL DMS Owner Step-Up CardDocument2 pagesAutonomous Maintenance: CIL DMS Owner Step-Up CardAsanka ChathurangaNo ratings yet

- Weekly AM CalendarDocument38 pagesWeekly AM CalendarAsanka ChathurangaNo ratings yet

- Atif AhmadDocument1 pageAtif AhmadAsanka ChathurangaNo ratings yet

- Autonomous Maintenance: Health Check List For Centerline DMSDocument2 pagesAutonomous Maintenance: Health Check List For Centerline DMSAsanka ChathurangaNo ratings yet

- AM RTS Centerline Definitions Standard: Autonomous Maintenance PillarDocument3 pagesAM RTS Centerline Definitions Standard: Autonomous Maintenance PillarAsanka ChathurangaNo ratings yet

- Am Rts Step 3 CIL Standard CBA: Autonomous Maintenance PillarDocument19 pagesAm Rts Step 3 CIL Standard CBA: Autonomous Maintenance PillarAsanka Chathuranga100% (1)

- Autonomous Maintenance: AM-SW RTT Centerline DMSDocument8 pagesAutonomous Maintenance: AM-SW RTT Centerline DMSAsanka ChathurangaNo ratings yet

- Autonomous Maintenance: Am-Sw RTT Cil With Routes DmsDocument14 pagesAutonomous Maintenance: Am-Sw RTT Cil With Routes DmsAsanka ChathurangaNo ratings yet

- The Autonomous Maintenance Implementation Directory As A Step TowDocument6 pagesThe Autonomous Maintenance Implementation Directory As A Step TowAsanka ChathurangaNo ratings yet

- Autonomous Maintenance: AM-SW RTT Clean Inspect Lube DMSDocument10 pagesAutonomous Maintenance: AM-SW RTT Clean Inspect Lube DMSAsanka ChathurangaNo ratings yet

- TPM Basic Awareness and Autonomous Maintenance: Anand U 1Document90 pagesTPM Basic Awareness and Autonomous Maintenance: Anand U 1Asanka ChathurangaNo ratings yet

- Autonomous Maintenance: AM-SW RTT Centerline DMSDocument3 pagesAutonomous Maintenance: AM-SW RTT Centerline DMSAsanka ChathurangaNo ratings yet

- Employee Training: Lean Six Sigma TrainingDocument40 pagesEmployee Training: Lean Six Sigma TrainingAsanka ChathurangaNo ratings yet

- Session 2 - HO - Charting An Organizations DirectionDocument23 pagesSession 2 - HO - Charting An Organizations DirectionAsanka ChathurangaNo ratings yet

- Step 0 and 1 Management Part 2 PDFDocument20 pagesStep 0 and 1 Management Part 2 PDFAji Beni LastomoNo ratings yet

- PM Analysis 1Document21 pagesPM Analysis 1Asanka ChathurangaNo ratings yet

- TPM 2 HoursDocument17 pagesTPM 2 HoursAsanka ChathurangaNo ratings yet

- TPM LessonsDocument10 pagesTPM LessonsAsanka ChathurangaNo ratings yet

- Planned M Aintenance: Gearing Towards A Pro-Active Maintenance SystemDocument42 pagesPlanned M Aintenance: Gearing Towards A Pro-Active Maintenance SystemNadol SwasnateeNo ratings yet

- TPM Launch Kick Off AgendaDocument46 pagesTPM Launch Kick Off AgendaAsanka ChathurangaNo ratings yet

- Oil Iso TablesDocument9 pagesOil Iso TablesSilvana Harrison100% (1)

- Chapter 5: Sampling Distributions: Solve The ProblemDocument4 pagesChapter 5: Sampling Distributions: Solve The ProblemEunice WongNo ratings yet

- Total04 Digital Version PDFDocument52 pagesTotal04 Digital Version PDFbeatriz matos67% (3)

- An Experimental Investigation On Abrasive Jet Machining by Erosion Abrasive GrainDocument3 pagesAn Experimental Investigation On Abrasive Jet Machining by Erosion Abrasive GrainPkNo ratings yet

- Tim Ingold - From The Transmission of Representations To The Education of Attention PDFDocument26 pagesTim Ingold - From The Transmission of Representations To The Education of Attention PDFtomasfeza5210100% (1)

- Guide To Greyhawk PDFDocument108 pagesGuide To Greyhawk PDFAnonymous PtMxUHm9RoNo ratings yet

- Coastal Management NotesDocument2 pagesCoastal Management Notesapi-330338837No ratings yet

- Microsoft Word - IRN Fab Transfer PCN NoticeDocument22 pagesMicrosoft Word - IRN Fab Transfer PCN NoticeJadilson PradoNo ratings yet

- Orifice Assembly With D-D2 Taps PDFDocument1 pageOrifice Assembly With D-D2 Taps PDFArup MondalNo ratings yet

- Electric Bike Monitoring and Controlling System Based On Internet of ThingsDocument8 pagesElectric Bike Monitoring and Controlling System Based On Internet of ThingsEarl PhamtonhiveNo ratings yet

- CDM816DSpare Parts Manual (Pilot Control) 2Document55 pagesCDM816DSpare Parts Manual (Pilot Control) 2Mohammadazmy Sobursyakur100% (1)

- Tank Gauging TankvisionDocument31 pagesTank Gauging Tankvisionkhangduongda3No ratings yet

- Toptica AP 1012 Laser Locking 2009 05Document8 pagesToptica AP 1012 Laser Locking 2009 05Tushar GuptaNo ratings yet

- Diwali Pujan BookletDocument10 pagesDiwali Pujan Bookletman_ishkumarNo ratings yet

- EXP1POSTLABDocument13 pagesEXP1POSTLABGiane MagimotNo ratings yet

- The Finite Element Method Applied To Agricultural Engineering - A Review - Current Agriculture Research JournalDocument19 pagesThe Finite Element Method Applied To Agricultural Engineering - A Review - Current Agriculture Research Journalsubhamgupta7495No ratings yet

- Ieee 802Document3 pagesIeee 802M Zubair AslamNo ratings yet

- Acer AIO Z1-752 System DisassemblyDocument10 pagesAcer AIO Z1-752 System DisassemblySERGIORABRNo ratings yet

- IsdettaDocument2 pagesIsdettaHa Phuoc HoaNo ratings yet

- Glacial Lakes of Himachal PradeshDocument4 pagesGlacial Lakes of Himachal PradeshMonidipa DeyNo ratings yet

- Data Sheet: W-Series WSI 6/LD 10-36V DC/ACDocument12 pagesData Sheet: W-Series WSI 6/LD 10-36V DC/ACLUIS FELIPE LIZCANO MARINNo ratings yet

- AC350 Specs UsDocument18 pagesAC350 Specs Uskloic1980100% (1)

- Icpc11 - Thermodynamics and Fluid MechanicsDocument22 pagesIcpc11 - Thermodynamics and Fluid MechanicsAPARNANo ratings yet

- Bluforest, Inc. (OTC: BLUF) InvestigationDocument5 pagesBluforest, Inc. (OTC: BLUF) Investigationfraudinstitute100% (1)

- ELC609F12 Lec0 IntroductionDocument16 pagesELC609F12 Lec0 IntroductionMohammed El-AdawyNo ratings yet

- 100 Years of Hydrodynamic PDFDocument28 pages100 Years of Hydrodynamic PDFnikodjoleNo ratings yet

- Disa Match: A Match You Can Count OnDocument8 pagesDisa Match: A Match You Can Count OngNo ratings yet

- Metageographies of Coastal Management: Negotiating Spaces of Nature and Culture at The Wadden SeaDocument8 pagesMetageographies of Coastal Management: Negotiating Spaces of Nature and Culture at The Wadden Seadwi kurniawatiNo ratings yet

- Feature Writing EnglishDocument2 pagesFeature Writing EnglishAldren BababooeyNo ratings yet

- 1.1 - Selectividad Acti9Document34 pages1.1 - Selectividad Acti9Bladimir MichelNo ratings yet

- Celly BoostbkDocument15 pagesCelly BoostbknomikabNo ratings yet