Professional Documents

Culture Documents

60a VBB Ele 3003 Ra

Uploaded by

Md Mahadi HasanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

60a VBB Ele 3003 Ra

Uploaded by

Md Mahadi HasanCopyright:

Available Formats

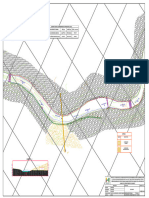

14 13 B C

N 25 24 23 22 21 20 19 18 17 16 15 12 11 10 9 8 7 6 5 4 3 2 1

17

Z 16

Y 15

14

X

13

12

11

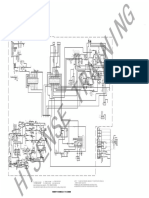

CABLE TRAY (TYP.)

W

10

V 9

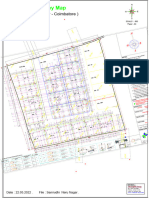

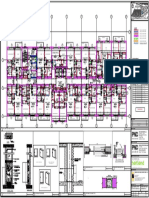

KEY PLAN

SCALE 1:2000

13

BED

COOLING BED

DRIVE DRIVE

WAY

1st MOVABLE SAW

START COOLING

ROLLROLL

INLET WAY

SHEAR

CROP SHEAR

EDGE

STARTINLET

SHEAR

SHEAR

EDGE

PINCH

SHEAR

2165

SHEAR

SHEAR

PINCH

SHEAR

START

CROP

BARS

START

C

18 17 16

BARS

C

Y Y

AIR-10 FROM

IWR-15

IWD-15

IWR-15

IWD-15

IWR-15

IWD-15

AIR-15

AIR-15

AIR-15

DRG. NO. 0007

0

2086 00

-6

8. IWD-B-80 8. IWD-B-80 6. IWD-B-150 2073

265

7. IWR-B-80 7. IWR-B-80 5. IWR-B-150

150x80 ECC. RED.

225

S08-

4. DWR-C-150 4. DWR-C-150 4. DWR-C-150

(BOTTOM FLUSH) (TYP.) AIR-15

10

3. IWD-B-25 3. IWD-B-25 3. IWD-B-25 6. IWD-B-150 B.O.P.-1200 IWR-15

S08-10

S08-10

S08-10

S08-10

2. AIR-15 2. AIR-15 2. AIR-15 (TYP.) IWR-15

5. IWR-B-150 B.O.P. - 1350

S08-10

S08-10

S08-10

S08-10

IWD-15

5650

-1200 S08-09A -40 S08-09

1. IWR-B-32 1. IWR-B-32 1. IWR-B-32 4. DWR-C-150 0 AIR-20 IWD-15

-2600

-60

0 -4

AIR-10 0

GLV-10 457

00

3. IWD-B-25 20

200

-1200 0

-120 B.O.P.-300 B.O.P.-450 AIR-10 -1

12

-1400 2. AIR-15 0

-4 0 -5000 (TYP.)

325

-1400 IWR-15

S09-04

S09-02

S09-03

S09-02

S09-03

S09-02

S09-03

S09-02

S09-01

S09-02

S09-01

S09-02

S09-01

-

IWD-10

150

-1200

IWR-10 125

125

20

1. IWR-B-32 -1 -5000 IWD-15 -5250 1765 150

0

S08-18 -4 325 925-40

S08-09A S08-09 S08-10 -6050

20

0

AIR-20 -1 BAV-10 20

0

9300

4 8 4 8 6 4

-150

0 4 6 4 -40 B.O.P.-750 (TYP.) -1

3 7 3 7 3 51700 5 3-2600 (0012)

00

5 2 1 2

1200

2 -1500 2 - -300 -5500

1 1 S09-13 1 5 AIR-15

15

0

IWR-15

IWD-15

B.O.P.-1425 20

AIR-15

-1700 -2600 AIR-15

-

-1500 -1500 -1500 -1 S08-18

-400

AIR-40 S08-17

-5000 S09-14 S08-09A GLV-10 S08-09 S08-10

S09-05

S09-05

B.O.P.-580

8.FOR CONTINUATION

IWD-B-80

} B.O.P.-2200 -40 IWR-15 FOR IWR-10

1500

S09

B.O.P. -2200 -600

00

-500

-18

925

-2600 -2500

7.SEE CELLAR LEV.

IWR-B-80 PLAN (-5000)

2

00

MATCH LINE

6 -5250

300 BAV-10 BAV-10

1

-26

-2 - IWD-15 -120

0

1516

-5250 -1700

250

-2800 -2800 FOR IWD-10

4. DWR-C-150 B.O.P. -1300 -2500

-300

BAV-10 S09-06 -6000 FOR AIR-10 S08-09

}

-5750 -600

FOR AIR-10 BAV-10 4. DWR-C-150 3. IWD-B-25 -600 -2800

IWD-15 S08-18

-2500

FOR AIR-10 -750

06 3. IWD-B-25 2. AIR-15 T.O.P. -1450 -750

IWR-15 BAV-10 S08-10

2. AIR-15 IWD-B-65 -600 IWD-15 -1200

S09-18 -600 CONTINUED FROM -600 (0017)

1. IWR-B-32 -40 AIR-15 FOR AIR-10

-600

AIR-10 AIR-10 S09-07 IWR-B-65 AIR-20 FROM AIR-20 FROM

8

7

-5000 -750 -750

-600 -750 -600 BAV-10

SAW (POSITION 2)

B.O.P.-2675 -5000 LEVEL 1. IWR-B-32 -300S08-09A DRG. NO. 0007 -120

0

DRG. NO. 0007

-600

-600

350 S09-05

FOR IWD-10

FOR CONTINUATION SEE SHEET 03

SAW (POSITIO 1)

S08-10

S08-10

S09-05 S09-05 B.O.P.-2200

S08-10 -610

GLV-10 -600

-5250 -6000

0 -750

S09-09

S09-10

S09-10

S09-09

S09-10

S09-10

S09-10

S09-09

00 -2500 -2500 -1200 FOR IWR-10 -1650 -1650

-1 -2500 S09-06 -300 -300 S09-14 S08-10 0 0

-2800 -500 -245 -245

1400

S09-19 -2800 -5200

START COOLING BED

S09-18 -2800 -2500

200 350

2nd MOVABLE SAW

-300 INLET

INLETCOOLING

COOLING BED

BED INLET COOLING

INLET COOLING BED BED ROLLING MILL ROLLING MILL

50

50

50

STRAIGHTENER

50

50

50

-2800 -1100 -2330 -2200

-16

-16

-16

ANG-015

-24

-24

-24

3 3 -1650

150 S09-17 2 4 4 2

-300 S08-10

COLD SHEAR

1 -300

-7000 1 -300 -300 IWR-15 850 1032 992

-300 -6500 -1000 -300

-5000 -300

1650

1650

-1500 -1000 -610

-1500 -8000 -1000

IWR-15 -1200

-610 IWD-15

S08-10

INTERCONNECTING

AIR-15 -5250 -300 -1000 AIR-15 -600 -600 -600 -600 -600 -600 -600 -600

INLET COOLING

-300 BED BED

MACHINE ATTACHED

-600

S09-17 INLET COOLINGBED

INLET COOLING BED INLET COOLING IWD-15

-1350

PIPING (PT SCOPE)

IWD-15 IWR-10 -300

80 00

GLV-10 S09-08 -1000 C2

BARS EDGE

AIR-15

3300

IWR-15

70

-600

00

FOR IWR-10 IWD-10 -630

0

S08-10

-

GLV-10 B.O.P.+200

PIPING

-5800 -1850 -5600

-810

IWR-10 S09-11

-3800 IWR-10

-

FOR BAV-10 -5600 -1100 AIR-10

-3000

MATCH LINE

-3000

-1500-6500

BAV-10 CL PUMP

FOR IWD-10 -6250

CKV-65 BUV-65 01 IWD-10

-6250 01

1st MOVABLE

1st MOVABLE

S09-14 01 MATCH LINE 01

FOR IWD-10 BAV-10 -5000 -2500

GLV-65 AIR-10

FOR AIR-10 -5250

MATCH LINE

8

7

S09-11 8. IWD-B-80 -1370 -2800 IWD-15 IWR-15 IWD-15 -40 15x10

BAV-10 -20

0

-6250

S08-10

S08-10

S08-10

S08-10

S08-10

S08-10

S08-10

-2100

FOR AIR-10 -810 -5225 7. IWR-B-80 -3000

0 -300 CONC. RED.

03 -3000 -20 (TYP.)

S09-15 -40 (TYP.)

MATCH LINE

MATCH LINE

BAV-10

-1500

BUV-80 S09-08 -2600 (TYP.)

CL PUMP -5250 -5000 -40 -300

FOR AIR-10 S09-16

-400

FOR IWR-10 (0017) -3000

S08-10

-6250 -300

-1100

-3000

BAV-10 BAV-10 -7000 500 S09-12 -1950 -40 -400

FOR IWD-10 FOR IWD-10

-8000 -

1

BUV-80 BUV-65

MATCH LINE

-300

BAV-10 GLV-10 S09-15

GLV-80

-2500

FOR IWR-10 0

-40

FOR AIR-10 -800 -600

600

S09-16 CKV-80 B.O.P.+200 -40 -300 C2

-3800 0 0 0 -8

-50 -700 00

0 -26 -1200 -300

-800

00

-30

AIR-20 AIR-20

S09-16

S09-16

-600 -5000

-1000 -1850 MATCH LINE

FROM -5000 LEVEL FROM -5000 LEVEL MATCH LINE

-5000 +220 -5150

S09-16 MATCH LINE FOR CONTINUATION SEE DWG. 2020-03284-01

-300 -5750

S09-16

0 0

0 -4 -4

-5250 -1700 50 -2050 0

-50 -2 00 00 -4

S09

-1000 -4 -4

-16

00

-240 -6250

-2450 0 -4

0 -5250 -1570 -1200 -4

0 -2500

50 -1850 00 00

-810 -

-6250 -5300 -3000 -25 -4

-300-7800 00

00

-5000 -2500 -27 -2050

-50 -780 -280

STRAIGHTENER

-2800 -2430 -5300

S09-16

-5000 -5300 -8400 -5650

VARIES -1700 -1190

-6250 -2930 -5900

-2250 -1750

-7000

00 MATCH LINE -1200

S08-11 -5890 -1790

-2850 -2450 0030 -5600

-1750 -30 - -2000

STRAIGHTENER

0

VARIES 00 00 -3700 -3700

28

2288 2288 IWD-B-40

12400

-2450 -6250

-

-2250 -4200 -

- --

-840

-840

-2850 IWR-B-40 -1200

85

-1750

-1750

-1940

-1940 -1200

-1200

-1200

-1200 -1600

S08-11

50

4430

5

-

08

-1900

-1900 S08-12

-5

-3570 -1200

-710

-710

-1200

-490-490

-1350

-1350 -1600 -4200

EXIT COOLING BED -490

-490 EXIT COOLING BED -490

-490

EXIT

EXIT COOLING

COOLING BED

BED EXIT COOLING BED EXIT

EXIT COOLING BEDIWD-B-40 COOLING BED -4200 -4200

EXIT COOLING BED EXIT COOLING BED

-2000

-890

-890

-2150

B.O.P. -2850 -4200 -2750 -1600

-1200

-840

-840 -1600

-1600

-710

-710

SEE 2029-00246A01

-1600

-1600 -1600

-1600 -1600

-1600 -1600

-1600 -950 0

0

-120 -1600

00

-2500

-2500 -1600

-1600

-2500

-2500 IWR-B-40

-95

-6250 -6250

-1600

-22

-1900

-1900 -2800

-2800 -2200

-2800

-2800 B.O.P. -3100 0

-1200 -1200

-1200 -119 -1200

BENDING MACHINE

-1200

BINDING MACHINE

-1600 -1600

00 -2000

3355 -1600

-5800 -11

-

0

80

S08-16

S08-16

S08-16

S08-16

-5

DWT-C-65

S08-12 S08-23

150

0000 -1140

AIR-40 -1140 -1200

-1200 B.O.P. -950

-3500-3500

+11

-3700-3700

+

-1750

-1750 00 -110

5544

-11 FOR CONTINUATION SEE SHEET 05

-2200

-2200

-

-110

-1350

B.O.P. +150 -2000

-2000

-5200

-2430

-2430 MATCH LINE

START COOLING BED

MATCH LINE MATCH

-1200 LINE -1200 -1200

2nd FIXED SAW

-5700 S08-12A

-750

-750

-1600 -1600 -1140

-1140

-2000 0

CONTINUATION

-420 AIR-40 -4

-2250

-420-420 -130

-130 -1200

AIR-40

-2390

-2390

HOLD -2850

-2850

B.O.P. -690

0

-4 400

-0

EDGE

-1350

-1350 0

MATCH LINE

-2850 -1600 TAKE OVER POINT OF AIR-40 B.O.P. -3350 -3600

-3600 -4

-420 -1200 DWT-C-65

TOP OF PIPE FACE ELV. +1500

COLD SHEAR

-2250 -2000

-2000

-1350

B.O.P. -940

MATCH LINE

-2850 X -2850

-2850

FOR BARS

-1470 -2200

-900

-900

-1200 IWR-25 -2390

-900 -900

-1350 S08-23

IWD-25

-1470 -420 BAV-25

-420

-750

GLV-25

S08-12A

MATCH LINE

BAV-25 BUV-50 GLV-50 MATCH LINE

FOR CONTINUATION SEE SHEET 06

-3000 DWT-C-65 GLV-25

MATCH LINE

-420 -750

-420 B.O.P.-2850 -3600 DWT-C-50 B.O.P. -3050 B.O.P. -3350 DWT-C-65 DWT-C-50 -1400 -1000

B.O.P. -1550 DWT-C-65 -1650 -1250

-2200 S08-20 B.O.P. -2240 B.O.P. -2240 B.O.P. +250

AT CL EL.-2975, -2000

-2000

-3500

-3500 -3500

-3500 AIR-40

-1250 & -150

S08-14

-2850

-2850 AIR-32 B.O.P. +400

S08-13

S08-13

S08-13

S08-14

S08-14

S08-15

S08-15

0

-590 AIR-40 -4

B.O.P. +100 00

-1650 40x25 B.O.P. -1850 -4

ECC. RED. (0012) IWD-25 -2500

-2750

FOR CONTINUATION SEE SHEET 05 IWR-25 -4

0

MATCH LINE AIR-40 -3

00

NOTE:-

AIR-15

IWR-15

1. "P" STANDS FOR "POWER CKT."

2. "C" STANDS FOR "CONTROL CKT."

IWD-15

-300

3. ``IC" STANDS FOR INCOMING CIRCUIT

-600

S08-09

S08-09

S08-09

S08-09

IWD-B-15 IWR-B-15 AIR-15

C

4. ``OG" STANDS FOR OUTGOING CIRCUIT

L S07-24

5. 75x10mm G.I STRIP FOR EARTHING PURPOSE

EL. -900

B.O.P. - 750

L

SHALL BE INSTALLED ALONG THE CABLE TRAY

L

6. IN SOME CASES, POWER CABLES MAY HAVE TO

C

L S07-24

L EL. -2250

BE PARTIALLY LAID IN DOUBLE LAYER IN CABLE

-3000

TRAY DUE TO SPACE LIMITATION.

7. CONTROL CABLES WILL BE LAID IN 2 - 3 LAYER IN

-3600

CELLAR

300

B.O.P. - 4000

C

L PS24

1650

T.O.S-4325 AIR-15

IWR-B-32

2 3

4

EL. -3600

B.O.P. - 3770 CABLE TRAY.

1 B.O.P. - 4000

IWD-B-25 DWR-C-150

8. CABLE TRAY SUPPORT SHALL BE PROVIDED

CL AIR-20

IWR-B-150 IWD-B-150

5 6

B.O.P. - 4750

S07-01 B.O.P. - 4600

@1500mm FOR HORIZONTAL RUNS & @1000mm

S07-19

-5000

FOR VERTICAL RUNS.

9. 300mm GAP SHALL GENERALLY BE CONSIDERED REVISED PRINT

BETWEEN TWO CABLE TRAYS DESTROY

SECTION 3-3 10. ALL BENDS SHALL HAVE 600mm BENDING RADIUS

AT THE INNER SIDE OF BEND

PREVIOUS PRINTS

M. N. DASTUR & COMPANY (P) LTD

CONSULTING ENGINEERS, KOLKATA

1:1 GPH ISPAT LIMITED

CHITTAGONG,BANGLADESH

INSTALLATION OF 0.8 MTPY INTEGRATED STEEL PLANT PROJECT

CABLE TRAY LAYOUT -X-Y BAY COL. NO. 14 TO COL. NO 19

28763 28763-60A-VBB-ELE-3003 A

You might also like

- Portofilo 1Document97 pagesPortofilo 1Mohamed LabibNo ratings yet

- Digitized TD 1 ModelDocument1 pageDigitized TD 1 Modelsatish babuNo ratings yet

- ROAD & PAVEMENT Draft ModelDocument1 pageROAD & PAVEMENT Draft ModelKannan MurugesanNo ratings yet

- kojjjjjjjjDocument1 pagekojjjjjjjjmustafamoharamNo ratings yet

- Loteam. Lagoa Park LinharesDocument1 pageLoteam. Lagoa Park LinharesJair SodréNo ratings yet

- Single Layout PlanDocument1 pageSingle Layout PlancinchmakNo ratings yet

- 2.center Line With Sump - Set 2 - Model R2Document1 page2.center Line With Sump - Set 2 - Model R2govindganga0208No ratings yet

- Leyenda: Universidad Nacional Del Altiplano-PunoDocument1 pageLeyenda: Universidad Nacional Del Altiplano-Punojhon kevinNo ratings yet

- TOPOGRAFIA DEFINITIVA 1.1-ModeloDocument1 pageTOPOGRAFIA DEFINITIVA 1.1-ModeloEDUCAPP elevator peachNo ratings yet

- 15024a - s6 - AP - 002 - First Floor PlanDocument1 page15024a - s6 - AP - 002 - First Floor PlanPERVEZ AHMAD KHANNo ratings yet

- 15024a - s6 - AP - 001-Ground Floor PlanDocument1 page15024a - s6 - AP - 001-Ground Floor PlanPERVEZ AHMAD KHANNo ratings yet

- NCMC City Map 31-01-22lDocument1 pageNCMC City Map 31-01-22lSIVASUBRAMANIANNo ratings yet

- PLANTA DE LOCAÇÃO-Layout1Document1 pagePLANTA DE LOCAÇÃO-Layout1Joaquim A. OliveiraNo ratings yet

- Detalles de EstructuraDocument1 pageDetalles de EstructuraManuel Vargas HernandezNo ratings yet

- CS Acero M 1Document1 pageCS Acero M 1William FigueNo ratings yet

- 02.LIGHT LayOut-1 PDFDocument1 page02.LIGHT LayOut-1 PDFAnonymous XYAPaxjbYNo ratings yet

- Screenshot 2024-03-05 at 2.49.28 PMDocument1 pageScreenshot 2024-03-05 at 2.49.28 PMCotten RajuNo ratings yet

- Kujsb-Tenaga-2022-00131 Silc - 20221012-Model PDFDocument1 pageKujsb-Tenaga-2022-00131 Silc - 20221012-Model PDFTan Yu HennNo ratings yet

- 141062Document5 pages141062Lenovo Zuk z2plusNo ratings yet

- Route MapDocument1 pageRoute MapjohnNo ratings yet

- DR-502 - Drainage Tanks DetailsDocument1 pageDR-502 - Drainage Tanks Detailswael hassanNo ratings yet

- OE6 QXGeo MapDocument1 pageOE6 QXGeo MapPhú ĐàoNo ratings yet

- Phase 2 AlignmentDocument1 pagePhase 2 AlignmentRomulo NunogNo ratings yet

- Plano Geologico Ok PDFDocument1 pagePlano Geologico Ok PDFAyner Fred Jara ElgueraNo ratings yet

- CONEXIONES DE ALCANTARILLADO (1)-Layout3-Layout1Document1 pageCONEXIONES DE ALCANTARILLADO (1)-Layout3-Layout1willianNo ratings yet

- LAYOUT FaridabadDocument1 pageLAYOUT Faridabadratishbalachandran50% (2)

- Parque Sol. 05-10-21Document8 pagesParque Sol. 05-10-21Kilian ZamboraNo ratings yet

- Ppe-19-1413 Bll-Sector 000600 Malla 004 - Rev 1 SignDocument1 pagePpe-19-1413 Bll-Sector 000600 Malla 004 - Rev 1 SignDAVIDHUANCONo ratings yet

- Drawing Ph-IDocument1 pageDrawing Ph-IashokaNo ratings yet

- Ecp Ull 19033 GCH Id02 0 Civ PL 058 0Document1 pageEcp Ull 19033 GCH Id02 0 Civ PL 058 0henry ayala corredorNo ratings yet

- Ambienal San Martin 2024-Planta Perfil - A1Document1 pageAmbienal San Martin 2024-Planta Perfil - A1martinquispehuarocc82No ratings yet

- Hisense Training: GND GNDDocument1 pageHisense Training: GND GNDAung HeinNo ratings yet

- B E F G D C B E F G D C: Croquis de Localización Norte PolígonoDocument1 pageB E F G D C B E F G D C: Croquis de Localización Norte PolígonoItzel RomeroNo ratings yet

- Cotação 5970666 R C Carvalho Industria e Montagem LtdaDocument2 pagesCotação 5970666 R C Carvalho Industria e Montagem LtdaDouglas ChoeNo ratings yet

- Clifton East RPS Area MapDocument1 pageClifton East RPS Area Mapbarney.w137No ratings yet

- Planteamiento General - I.E. #30026 - C.P La Punta: Distrito de Sapallanga - HuancayoDocument1 pagePlanteamiento General - I.E. #30026 - C.P La Punta: Distrito de Sapallanga - Huancayoyucra carbajal rubenNo ratings yet

- Project #7Document13 pagesProject #7indyecraftsNo ratings yet

- Approved Plan V K AwasthiDocument1 pageApproved Plan V K AwasthiAbhishek SrivastavaNo ratings yet

- L AntiquatedPlatsATT1CDocument1 pageL AntiquatedPlatsATT1CemmettoconnellNo ratings yet

- H185357 Stick Diagrams (Revised)Document3 pagesH185357 Stick Diagrams (Revised)Johanna Ferebee StillNo ratings yet

- Cable RouteDocument1 pageCable RouteBelal HHNo ratings yet

- examDocument1 pageexamJosé María Sanz NavamuelNo ratings yet

- A - Ward: SCALE 1:6000Document1 pageA - Ward: SCALE 1:6000Somesh MhatreNo ratings yet

- 10132022-RNG-DTDS-MEC-PLT-001 - 00 - RO - Cable Layout-Layout1Document1 page10132022-RNG-DTDS-MEC-PLT-001 - 00 - RO - Cable Layout-Layout1anaismariaNo ratings yet

- Layout Plan of Omaxe Metro City, Phase-1.: Proposed 50 Mt. Master Plan Green BeltDocument1 pageLayout Plan of Omaxe Metro City, Phase-1.: Proposed 50 Mt. Master Plan Green BeltSantosh Kori - freelancer wordpress joomla web designerNo ratings yet

- JVT Pool MEP DrawingsDocument12 pagesJVT Pool MEP DrawingsMUQEET ahmedNo ratings yet

- MS-AD-538-1F - Food Hall - Hydration - Microwave Station - Type 1Document2 pagesMS-AD-538-1F - Food Hall - Hydration - Microwave Station - Type 1RIJO JamesNo ratings yet

- Screenshot 2023-11-17 at 7.06.12 PMDocument1 pageScreenshot 2023-11-17 at 7.06.12 PMSamarth ChaturvediNo ratings yet

- SHC G.PH. 2 B 03 3dr.F BW SD 005 Layout1Document1 pageSHC G.PH. 2 B 03 3dr.F BW SD 005 Layout1rajatNo ratings yet

- Hartland: LegendDocument1 pageHartland: LegendrajatNo ratings yet

- 09Document1 page09Hugo Valentino Gonzalez CifuentesNo ratings yet

- RAM P: Fire HOS E Reel 24CD - D400 - 75X0 - 20XX - XX23 - X1Document1 pageRAM P: Fire HOS E Reel 24CD - D400 - 75X0 - 20XX - XX23 - X1Gesen CoopenNo ratings yet

- Issue Record: Inspection Bay - Floor PlanDocument1 pageIssue Record: Inspection Bay - Floor PlanAnkit KhuranaNo ratings yet

- 633559-M-E-D010-Stage 4 Pavilion-IFC SetDocument7 pages633559-M-E-D010-Stage 4 Pavilion-IFC SetNon Etabas GadnatamNo ratings yet

- Island Transit Map June 2019Document1 pageIsland Transit Map June 2019Aurora Gaona HernandezNo ratings yet

- Important Bridge - Banas GADDocument1 pageImportant Bridge - Banas GADdigvijay singhNo ratings yet

- The Art of SEODocument37 pagesThe Art of SEOkrisgoNo ratings yet

- Business Letter WritingDocument13 pagesBusiness Letter WritingAlex Alexandru100% (1)

- CEO Corner New Products Powerful Pocket SimulatorDocument23 pagesCEO Corner New Products Powerful Pocket SimulatorMOHAMMA MUSANo ratings yet

- MIT LL. Target Radar Cross Section (RCS)Document45 pagesMIT LL. Target Radar Cross Section (RCS)darin koblickNo ratings yet

- Akuntansi Keuangan Lanjutan - Akuntansi Penggabungan UsahaDocument67 pagesAkuntansi Keuangan Lanjutan - Akuntansi Penggabungan UsahachendyNo ratings yet

- Frogkisser! by Garth Nix (Excerpt)Document17 pagesFrogkisser! by Garth Nix (Excerpt)I Read YA0% (1)

- PariharaDocument2 pagesPariharahrvNo ratings yet

- The 9 Building Blocks of Business ModelsDocument3 pagesThe 9 Building Blocks of Business ModelsTobeFrankNo ratings yet

- Pavements ConstructedDocument16 pagesPavements ConstructedjoryNo ratings yet

- Axial Centrifugal FansDocument15 pagesAxial Centrifugal FansAhsan JavedNo ratings yet

- Lucknow Digital Members Directory 4 Jan22Document84 pagesLucknow Digital Members Directory 4 Jan22B2B InfomediaNo ratings yet

- Define steradian, radian, density, and luminanceDocument16 pagesDefine steradian, radian, density, and luminancesunshaniNo ratings yet

- RJR Nabisco LBODocument14 pagesRJR Nabisco LBONazir Ahmad BahariNo ratings yet

- Gauss Jordan MethodDocument6 pagesGauss Jordan MethodnNo ratings yet

- 6 Thinking Hats Detailed Model - UpdatedDocument32 pages6 Thinking Hats Detailed Model - Updatedgeetanshi mittalNo ratings yet

- 2016 Aiersi ukulele pricelist models and pricesDocument16 pages2016 Aiersi ukulele pricelist models and pricesOctavio ColungaNo ratings yet

- MSDS Slideway Oil Iso VG 68 - 031115Document6 pagesMSDS Slideway Oil Iso VG 68 - 031115Rini SiskayantiNo ratings yet

- Capacity Based On Shear Parameters As Per IS 6403: C C C C W Q Q Q Q F y y y yDocument5 pagesCapacity Based On Shear Parameters As Per IS 6403: C C C C W Q Q Q Q F y y y yKishore KumarNo ratings yet

- Inv 069 1701757527Document1 pageInv 069 1701757527neetu9414576916No ratings yet

- Advanced Engineering Economics: Combining FactorsDocument19 pagesAdvanced Engineering Economics: Combining FactorsA GlaumNo ratings yet

- Crisis Management HandoutDocument56 pagesCrisis Management HandoutdraNo ratings yet

- Sajid Bhuiya CVDocument3 pagesSajid Bhuiya CVapi-612088476No ratings yet

- DGN ExamDocument5 pagesDGN ExamMaiga Ayub HusseinNo ratings yet

- Breaugh Starke PDFDocument30 pagesBreaugh Starke PDFRichard YeongNo ratings yet

- Bartending and Catering: Agenda: Basics of Bartending Bar Tools and EquipmentDocument146 pagesBartending and Catering: Agenda: Basics of Bartending Bar Tools and EquipmentMars Mar100% (1)

- E-Way BillDocument1 pageE-Way BillShriyans DaftariNo ratings yet

- Qualitative Research On Vocabulary and Spelling Skills of A Student Chapters I IIIDocument23 pagesQualitative Research On Vocabulary and Spelling Skills of A Student Chapters I IIIarniza blazoNo ratings yet

- Investigation of Nursing Students Knowledge of and Attitudes About Problem Based LearningDocument4 pagesInvestigation of Nursing Students Knowledge of and Attitudes About Problem Based LearningasdasdasdasNo ratings yet

- Microbiology - Prokaryotic Cell Biology: Bacterial Surface Structures Bacterial Cell Wall StructureDocument5 pagesMicrobiology - Prokaryotic Cell Biology: Bacterial Surface Structures Bacterial Cell Wall StructureDani AnyikaNo ratings yet

- Metal Expansion Joint 2020 v2 20MBDocument116 pagesMetal Expansion Joint 2020 v2 20MBanni trejoNo ratings yet