Professional Documents

Culture Documents

MSDS Barrier

Uploaded by

rian wijayaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MSDS Barrier

Uploaded by

rian wijayaCopyright:

Available Formats

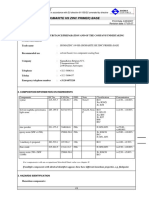

This Safety Data Sheet is prepared in accordance with EU Directive 91/155/EC, as amended by Directive

2001/58/EC - United Kingdom (UK)

SAFETY DATA SHEET

Barrier - Comp. A

1. Identification of the substance/preparation and company/undertaking

Product name and/or code : Barrier - Comp. A

Label No. : 3069

Supplier/Manufacturer : Jotun Paints (Europe) Ltd.

Stather Road

Flixborough, Scunthorpe

North Lincolnshire

DN15 8RR

England

Tel: +44 17 24 40 00 00

Fax: +44 17 24 40 01 00

Emergency telephone number : Contact National Poison Centre via Hospital or Registered Medical Practitioner

Product use : Coatings: Solvent-borne.

2. Composition/information on ingredients

Chemical name* CAS no. EC number % Classification

zinc stabilized 7440-66-6 231-175-3 50 - 100 N; R50/53

zinc oxide 1314-13-2 215-222-5 10 - 25 N; R50/53

Xylene 1330-20-7 215-535-7 2.5 - 10 R10

Xn; R20/21

Xi; R38

epoxy resin (MW 700-1200) 25036-25-3 2.5 - 10 Xi; R36/38

R43

1-methoxy-2-propanol 107-98-2 203-539-1 2.5 - 10 R10

ethylbenzene 100-41-4 202-849-4 1 - 2.5 F; R11

Xn; R20

Solvent naphtha (petroleum), light arom. 64742-95-6 265-199-0 0-1 R10

Xn; R20, R65

Xi; R37

R66

N; R51/53

See section 16 for the full text of the R-phrases declared

above

Occupational exposure limits, if available, are listed in section 8.

3. Hazards identification

The preparation is classified as dangerous according to Directive 1999/45/EC and its amendments.

Flammable.

May cause sensitisation by skin contact.

Very toxic to aquatic organisms. May cause long-term adverse effects

in the aquatic environment.

Irritant Dangerous for the

environment.

Date of issue : 13.10.2006. Page: 1/6

Barrier - Comp. A

4. First-aid measures

First-aid measures

General : In all cases of doubt, or when symptoms persist, seek medical attention. Never give anything by

mouth to an unconscious person.

Inhalation : Remove to fresh air. Keep person warm and at rest. If not breathing, if breathing is irregular or if

respiratory arrest occurs, provide artificial respiration or oxygen by trained personnel. Give nothing by

mouth. If unconscious, place in recovery position and seek medical advice.

Skin contact : Remove contaminated clothing and shoes. Wash skin thoroughly with soap and water or use

recognised skin cleanser. Do not use solvents or thinners.

Eye contact : Check for and remove any contact lenses. Immediately flush eyes with running water for at least 15

minutes, keeping eyelids open.

Ingestion : If swallowed, seek medical advice immediately and show the container or label. Keep person warm

and at rest. Do not induce vomiting.

5. Fire-fighting measures

Extinguishing media : Recommended: alcohol-resistant foam, CO2, powders, water spray.

Not to be used : water jet.

Recommendations : Fire will produce dense black smoke. Exposure to decomposition products may cause a health

hazard. Appropriate breathing apparatus may be required. Cool closed containers exposed to fire

with water. Do not release runoff from fire to sewers or waterways.

6. Accidental release measures

Personal precautions : Exclude sources of ignition and ventilate the area. Avoid breathing vapour or mist. Refer to

protective measures listed in sections 7 and 8.

Spill : Contain and collect spillage with non-combustible, absorbent material e.g. sand, earth, vermiculite or

diatomaceous earth and place in container for disposal according to local regulations (see section

13). Do not allow to enter drains or watercourses. Preferably clean with a detergent. Avoid using

solvents. If the product contaminates lakes, rivers, or sewers, inform the appropriate authorities in

accordance with local regulations.

Note: see section 8 for personal protective equipment and section 13 for waste disposal.

7. Handling and storage

Handling : Vapours are heavier than air and may spread along floors. Vapours may form explosive mixtures

with air. Prevent the creation of flammable or explosive concentrations of vapours in air and avoid

vapour concentrations higher than the occupational exposure limits.

In addition, the product should only be used in areas from which all naked lights and other sources of

ignition have been excluded. Electrical equipment should be protected to the appropriate standard.

To dissipate static electricity during transfer, earth drum and connect to receiving container with

bonding strap. Operators should wear antistatic footwear and clothing and floors should be of the

conducting type.

Keep container tightly closed. Keep away from heat, sparks and flame. No sparking tools should be

used.

Avoid contact with skin and eyes. Avoid the inhalation of dust, particulates, spray or mist arising from

the application of this preparation. Avoid inhalation of dust from sanding.

Eating, drinking and smoking should be prohibited in area where this material is handled, stored and

processed. Workers should wash hands and face before eating, drinking and smoking.

Put on appropriate personal protective equipment (see section 8).

Never use pressure to empty. Container is not a pressure vessel. Always keep in containers made

from the same material as the original one.

Comply with the health and safety at work laws.

When operators, whether spraying or not, have to work inside the spray booth, ventilation is unlikely

to be sufficient to control particulates and solvent vapour in all cases. In such circumstances they

should wear a compressed air-fed respirator during the spraying process and until such time as the

particulates and solvent vapour concentration has fallen below the exposure limits.

Date of issue : 13.10.2006. Page: 2/6

Barrier - Comp. A

Storage : Store in accordance with local regulations. Observe label precautions. Store in a cool, well-ventilated

area away from incompatible materials and ignition sources.

Keep away from: oxidising agents, strong alkalis, strong acids.

No smoking. Prevent unauthorised access. Containers that have been opened must be carefully

resealed and kept upright to prevent leakage.

Do not empty into drains..

8. Exposure controls/personal protection

Engineering measures : Provide adequate ventilation. Where reasonably practicable, this should be achieved by the use of

local exhaust ventilation and good general extraction. If these are not sufficient to maintain

concentrations of particulates and solvent vapours below the OEL, suitable respiratory protection

must be worn.

Ingredient name Occupational exposure limits

Xylene EH40-WEL (United Kingdom (UK), 1/2005). Skin

STEL: 441 mg/m3 15 minute/minutes. Form: All forms

STEL: 100 ppm 15 minute/minutes. Form: All forms

TWA: 220 mg/m3 8 hour/hours. Form: All forms

TWA: 50 ppm 8 hour/hours. Form: All forms

1-methoxy-2-propanol EH40-WEL (United Kingdom (UK), 1/2005). Skin

STEL: 560 mg/m3 15 minute/minutes. Form: All forms

STEL: 150 ppm 15 minute/minutes. Form: All forms

TWA: 375 mg/m3 8 hour/hours. Form: All forms

TWA: 100 ppm 8 hour/hours. Form: All forms

ethylbenzene EH40-WEL (United Kingdom (UK), 1/2005). Skin

STEL: 552 mg/m3 15 minute/minutes. Form: All forms

STEL: 125 ppm 15 minute/minutes. Form: All forms

TWA: 441 mg/m3 8 hour/hours. Form: All forms

TWA: 100 ppm 8 hour/hours. Form: All forms

Solvent naphtha (petroleum), light arom. EH40-WEL (United Kingdom (UK), 1/2005).

TWA: 125 mg/m3 8 hour/hours. Form: All forms

TWA: 25 ppm 8 hour/hours. Form: All forms

Personal protective equipment

Respiratory system : If workers are exposed to concentrations above the exposure limit, they must use appropriate,

certified respirators. Use respiratory mask with charcoal and dust filter when spraying this product.

(as filter combination A2-P2).In confined spaces, use compressed-air or fresh-air respiratory

equipment.When use of roller or brush, consider use of charcoalfilter.

Skin and body : Personnel should wear antistatic clothing made of natural fibres or of high-temperature-resistant

synthetic fibres.

Hands : For prolonged or repeated handling, use gloves: polyvinyl alcohol or nitrile.

Barrier creams may help to protect the exposed areas of the skin but should not be applied once

exposure has occurred.

For right choice of glove materials, with focus on chemical resistance and time of penetration, seek

advice by the supplier of chemical resistant gloves.

Eyes : Use safety eyewear designed to protect against splash of liquids.

9. Physical and chemical properties

Physical state : Liquid.

Odour : Characteristic.

Colour : Various colours.

Flash point : Closed cup: 27°C (80.6°F).

Density : 3.05 g/cm3

Lower explosion limit : The greatest known range is Lower: 1.5% Upper: 13.7% (1-methoxy-2-propanol)

Solubility : Insoluble in cold water, hot water.

10. Stability and reactivity

Stable under recommended storage and handling conditions (see section 7).

Hazardous decomposition products: carbon monoxide, carbon dioxide, smoke, oxides of nitrogen.

Keep away from the following materials to prevent strong exothermic reactions: oxidising agents, strong alkalis, strong acids.

Date of issue : 13.10.2006. Page: 3/6

Barrier - Comp. A

11. Toxicological information

There is no data available on the preparation itself. The preparation has been assessed following the conventional method of the

Dangerous Preparations Directive 1999/45/EC and classified for toxicological hazards accordingly. See sections 2 and 15 for details.

Exposure to component solvent vapour concentrations in excess of the stated occupational exposure limit may result in adverse

health effects such as mucous membrane and respiratory system irritation and adverse effects on the kidneys, liver and central

nervous system. Solvents may cause some of the above effects by absorption through the skin. Symptoms and signs include

headache, dizziness, fatigue, muscular weakness, drowsiness and, in extreme cases, loss of consciousness. Repeated or prolonged

contact with the preparation may cause removal of natural fat from the skin, resulting in non-allergic contact dermatitis and absorption

through the skin. If splashed in the eyes, the liquid may cause irritation and reversible damage.

Contains (epoxy resin (MW 700-1200)). May produce an allergic reaction.

12. Ecological information

There is no data available on the preparation itself.

Do not allow to enter drains or watercourses.

The preparation has been assessed following the conventional method of the Dangerous Preparations Directive 1999/45/EC and is

classified for eco-toxicological properties accordingly. See Sections 2 and 15 for details.

Ecotoxicity data

Ingredient name Species Period Result

zinc stabilized Daphnia magna (EC50) 48 hour/hours 2.8 mg/l

Pimephales promelas (LC50) 96 hour/hours 0.238 mg/l

Oncorhynchus mykiss (LC50) 96 hour/hours 0.24 mg/l

Oncorhynchus mykiss (LC50) 96 hour/hours 0.41 mg/l

Oncorhynchus mykiss (LC50) 96 hour/hours 0.56 mg/l

Daphnia magna (LC50) 96 hour/hours 0.57 mg/l

zinc oxide Daphnia magna (EC50) 48 hour/hours >1000 mg/l

Oncorhynchus mykiss (LC50) 96 hour/hours 1.1 mg/l

Lepomis macrochirus (LC50) 96 hour/hours >320 mg/l

Pimephales promelas (LC50) 96 hour/hours 2246 mg/l

Xylene Oncorhynchus mykiss (LC50) 96 hour/hours 3.3 mg/l

Oncorhynchus mykiss (LC50) 96 hour/hours 8.2 mg/l

Lepomis macrochirus (LC50) 96 hour/hours 8.6 mg/l

Lepomis macrochirus (LC50) 96 hour/hours 12 mg/l

Lepomis macrochirus (LC50) 96 hour/hours 13.3 mg/l

Pimephales promelas (LC50) 96 hour/hours 13.4 mg/l

ethylbenzene Daphnia magna (EC50) 48 hour/hours 2.93 mg/l

Daphnia magna (EC50) 48 hour/hours 2.97 mg/l

Selenastrum capricornutum 48 hour/hours 7.2 mg/l

(EC50)

Oncorhynchus mykiss (LC50) 96 hour/hours 4.2 mg/l

Pimephales promelas (LC50) 96 hour/hours 9.09 mg/l

Poecilia reticulata (LC50) 96 hour/hours 9.6 mg/l

Solvent naphtha (petroleum), light arom. Fish (LC50) 96 hour/hours <10 mg/l

Daphnia (EC50) 48 hour/hours <10 mg/l

Algae (IC50) 72 hour/hours <10 mg/l

13. Disposal considerations

Do not allow to enter drains or watercourses. Material and/or container must be disposed of as hazardous waste.

European waste catalogue : 08 01 11* waste paint and varnish containing organic solvents or other dangerous substances

(EWC)

14. Transport information

International transport regulations

Proper shipping name : Paint.

UN Number : 1263

Class : 3

Sub-risk : -

Packing group : III

Date of issue : 13.10.2006. Page: 4/6

Barrier - Comp. A

Label :

Additional information

ADR / RID : Hazard identification number: 30

Special provisions: 640E

IMDG : Emergency schedules (EmS): F-E, S-E

Marine pollutant: No.

IATA : -

Transport in accordance with ADR/RID, IMDG/IMO and ICAO/IATA and national regulation.

-

15. Regulatory information

EU regulations : The product is classified and labelled for supply in accordance with the Directive 1999/45/EC as

follows:

Hazard symbol/symbols :

Irritant Dangerous for the

environment.

Contains : epoxy resin (MW 700-1200)

Risk phrases : R10- Flammable.

R43- May cause sensitisation by skin contact.

R50/53- Very toxic to aquatic organisms, may cause long-term adverse effects in the aquatic

environment.

Safety phrases : S23- Do not breathe vapour / spray.

S24- Avoid contact with skin.

S37- Wear suitable gloves.

S51- Use only in well-ventilated areas.

16. Other information

CEPE Classification : 1

Full text of R-phrases referred to : R11- Highly flammable.

in sections 2 and 3 - United R10- Flammable.

Kingdom (UK) R20- Harmful by inhalation.

R20/21- Harmful by inhalation and in contact with skin.

R65- Harmful: may cause lung damage if swallowed.

R36/38- Irritating to eyes and skin.

R37- Irritating to respiratory system.

R38- Irritating to skin.

R43- May cause sensitisation by skin contact.

R66- Repeated exposure may cause skin dryness or cracking.

R50/53- Very toxic to aquatic organisms, may cause long-term adverse effects in the aquatic

environment.

R51/53- Toxic to aquatic organisms, may cause long-term adverse effects in the aquatic

environment.

Notice to reader

History

Date of printing : 13.10.2006.

Date of issue : 13.10.2006.

Version : 6

Prepared by : Jotun Group Product Safety Department

The information in this SDS is based on the present state of our knowledge and on current laws. The product is not to be used for purposes

other than those specified under section 1 without first obtaining written handling instructions. It is always the responsibility of the user to

take all necessary steps to fulfil the demands set out in the local rules and legislation. The information in this SDS is meant to be a description

of the safety requirements for our product. It is not to be considered a guarantee of the product's properties.

Indicates information that has changed from previously issued version.

Date of issue : 13.10.2006. Page: 5/6

Barrier - Comp. A

Page: 6/6

Version 6

You might also like

- Hardtop Flexi Comp ADocument6 pagesHardtop Flexi Comp ANivin KumarNo ratings yet

- Safety Data Sheet: Identification of The Substance/preparation and Company/undertaking 1Document5 pagesSafety Data Sheet: Identification of The Substance/preparation and Company/undertaking 1Nivin KumarNo ratings yet

- Msds-Alkyd PrimerDocument5 pagesMsds-Alkyd Primerrian wijayaNo ratings yet

- Safety Data Sheet: Identification of The Substance/preparation and Company/undertaking 1Document5 pagesSafety Data Sheet: Identification of The Substance/preparation and Company/undertaking 1BNo ratings yet

- SDS - Fenomastic Enamel Gloss - English (Uk) - Dubai PDFDocument5 pagesSDS - Fenomastic Enamel Gloss - English (Uk) - Dubai PDFB100% (1)

- Msds-Barrier - Comp.bDocument5 pagesMsds-Barrier - Comp.brian wijayaNo ratings yet

- Hempel Hempadur MasticDocument5 pagesHempel Hempadur MasticJennylyn DañoNo ratings yet

- Msds-Barrier Zep Comp BDocument5 pagesMsds-Barrier Zep Comp Brian wijayaNo ratings yet

- Epicon T 500Document12 pagesEpicon T 500Mugilrajan DevarajanNo ratings yet

- SDS - Fenomastic Enamel Matt - English (Uk) - Dubai PDFDocument5 pagesSDS - Fenomastic Enamel Matt - English (Uk) - Dubai PDFBNo ratings yet

- SDS - Hardtop AS - Comp. A With LC - Marine - Protective - English (Uk) - United Kingdom PDFDocument7 pagesSDS - Hardtop AS - Comp. A With LC - Marine - Protective - English (Uk) - United Kingdom PDFNPTNo ratings yet

- MSDS BaltoflakeDocument5 pagesMSDS Baltoflakerian wijayaNo ratings yet

- SDS - Hardtop XP - Comp. A With LC - Marine - Protective - English (Uk) - United KingdomDocument7 pagesSDS - Hardtop XP - Comp. A With LC - Marine - Protective - English (Uk) - United KingdomNPTNo ratings yet

- Amerlock 400Document7 pagesAmerlock 400SAI ARUNNo ratings yet

- MSDS AluflexDocument5 pagesMSDS Aluflexrian wijayaNo ratings yet

- 0051 Strcc5kubDocument6 pages0051 Strcc5kubNandar Min HtetNo ratings yet

- Material Safety Data Sheet: Product No.: 5052MDocument12 pagesMaterial Safety Data Sheet: Product No.: 5052Mshulhan nstNo ratings yet

- Safety Data Sheet: Identification of The Substance/Preparation and of The Company/Undertaking 1Document7 pagesSafety Data Sheet: Identification of The Substance/Preparation and of The Company/Undertaking 1eslam sokaNo ratings yet

- Msds SIGMATHERM 540 (ENG) (sk-19-07-07leg-MT)Document8 pagesMsds SIGMATHERM 540 (ENG) (sk-19-07-07leg-MT)AZLAN ABDULLAINo ratings yet

- 0014 5g4gc5kubDocument7 pages0014 5g4gc5kubNandar Min HtetNo ratings yet

- 3307 SIGMA C200a COALTAR EPOXY BASEDocument8 pages3307 SIGMA C200a COALTAR EPOXY BASEMustafa hse JafferNo ratings yet

- Sigma Prime Hardener 200 MSDSDocument9 pagesSigma Prime Hardener 200 MSDSSwapnil KhandkeNo ratings yet

- SigmaWeld 190 and 199 BinderDocument8 pagesSigmaWeld 190 and 199 BinderJohn GeddesNo ratings yet

- Msds SIGMAZINC 158 (SIGMA SILICATE MC) BINDER (ENG) (sk-16-03-07leg-MT)Document8 pagesMsds SIGMAZINC 158 (SIGMA SILICATE MC) BINDER (ENG) (sk-16-03-07leg-MT)Eyoh EffiongNo ratings yet

- SDS - Penguard FC Comp. A With LC - Marine - Protective - English (Uk) - United KingdomDocument7 pagesSDS - Penguard FC Comp. A With LC - Marine - Protective - English (Uk) - United KingdomNPTNo ratings yet

- Curing AgentDocument5 pagesCuring Agentabdulgafoor54No ratings yet

- 1240 E1rkc5kubDocument7 pages1240 E1rkc5kubNandar Min HtetNo ratings yet

- Sds-Evamarine ExteriorDocument6 pagesSds-Evamarine ExteriorSaifuddin FahmiNo ratings yet

- Taxat Extra ClassicDocument5 pagesTaxat Extra ClassicJHUPEL ABARIALNo ratings yet

- X DULUX Solarscreen A339-Line ENDocument8 pagesX DULUX Solarscreen A339-Line ENAzuan MABKNo ratings yet

- Msds SigmaCover 410 PDFDocument9 pagesMsds SigmaCover 410 PDFusman khalidNo ratings yet

- Material Safety Data Sheet: Product No. 5400Document12 pagesMaterial Safety Data Sheet: Product No. 5400Taufiq damarNo ratings yet

- Hempel Curing Agent 95880Document5 pagesHempel Curing Agent 95880Cruz FlorNo ratings yet

- Msds Sigmadur 550 Base (Lead Containing) (Spa) (Sk-29!06!09leg-Mt)Document10 pagesMsds Sigmadur 550 Base (Lead Containing) (Spa) (Sk-29!06!09leg-Mt)Alex Marquez IbarraNo ratings yet

- Sikadur 31 MSDSDocument12 pagesSikadur 31 MSDSprueba gaaaaaNo ratings yet

- Sapur BDocument5 pagesSapur BProsenjit76No ratings yet

- MSDS 2218932 en - INDocument15 pagesMSDS 2218932 en - INabinayaNo ratings yet

- Msds SigmaZinc 109 HS (7701) HARDENERDocument8 pagesMsds SigmaZinc 109 HS (7701) HARDENERАлексейNo ratings yet

- Msds SigmaZinc 109 HS (7701) BASEDocument8 pagesMsds SigmaZinc 109 HS (7701) BASEАлексейNo ratings yet

- X DULUX Timbertone A398-Line ENDocument8 pagesX DULUX Timbertone A398-Line ENAzuan MABKNo ratings yet

- 0036 6t5ec5kubDocument7 pages0036 6t5ec5kubNandar Min HtetNo ratings yet

- Hempel SilviumDocument5 pagesHempel SilviumJennylyn DañoNo ratings yet

- 0048 3tn5c5kubDocument6 pages0048 3tn5c5kubNandar Min HtetNo ratings yet

- 3307 Sigma C200A Coal Tar EpoxyDocument3 pages3307 Sigma C200A Coal Tar Epoxyusman khalidNo ratings yet

- 10.12.2022 3307 SIGMA C200a COALTAR EPOXY HARDENERDocument7 pages10.12.2022 3307 SIGMA C200a COALTAR EPOXY HARDENERPangky AbasoloNo ratings yet

- Jotun Multicolor Industry Colorant With LC 14-4-14Document8 pagesJotun Multicolor Industry Colorant With LC 14-4-14Reza HermawanNo ratings yet

- Material Safety Data Sheet: Product No.: 5512Document12 pagesMaterial Safety Data Sheet: Product No.: 5512didiNo ratings yet

- BARCOSDocument6 pagesBARCOSLuis RodriguezNo ratings yet

- VesselDocument6 pagesVesselLuis RodriguezNo ratings yet

- Material Safety Data Sheet: 1. Product and Company IdentificationDocument11 pagesMaterial Safety Data Sheet: 1. Product and Company IdentificationRenalyn TorioNo ratings yet

- Safety Data Sheet: Identification of The Preparation and of The Company 1Document11 pagesSafety Data Sheet: Identification of The Preparation and of The Company 1Alex JosephNo ratings yet

- 5481 D9u7c5kubDocument5 pages5481 D9u7c5kubNandar Min HtetNo ratings yet

- Safety Data Sheet: LAGD 125F..Document4 pagesSafety Data Sheet: LAGD 125F..Sergei KurpishNo ratings yet

- Safety Data Sheet: Identification of The Preparation and of The Company 1Document7 pagesSafety Data Sheet: Identification of The Preparation and of The Company 1Nivin KumarNo ratings yet

- MSDS PolyurethaneDocument7 pagesMSDS PolyurethaneArif SetiawanNo ratings yet

- MSDS Lithium Grease EP2Document4 pagesMSDS Lithium Grease EP2Septian AdityaNo ratings yet

- k3 English PDFDocument6 pagesk3 English PDFDana PuteraNo ratings yet

- Alkali Resistant PrimerDocument5 pagesAlkali Resistant PrimereliNo ratings yet

- NORPOLR Gelcoat GD 11030 S EX3 (MSDS)Document5 pagesNORPOLR Gelcoat GD 11030 S EX3 (MSDS)Shahzaib KhanNo ratings yet

- Msds-Barrier Zep Comp BDocument5 pagesMsds-Barrier Zep Comp Brian wijayaNo ratings yet

- Msds-Barrier - Comp.bDocument5 pagesMsds-Barrier - Comp.brian wijayaNo ratings yet

- MSDS BaltoflakeDocument5 pagesMSDS Baltoflakerian wijayaNo ratings yet

- MSDS AluflexDocument5 pagesMSDS Aluflexrian wijayaNo ratings yet

- Treatment of Water Using Organic Waste Matter of Papaya and AppleDocument11 pagesTreatment of Water Using Organic Waste Matter of Papaya and AppleNobleNo ratings yet

- Formalin Plant 3: Pt. Dover ChemicalDocument1 pageFormalin Plant 3: Pt. Dover Chemicalviero widyantoNo ratings yet

- Eva Project Omkar Dhuraji-1Document22 pagesEva Project Omkar Dhuraji-1Omkar DhurajiNo ratings yet

- Thesis Related To Air PollutionDocument4 pagesThesis Related To Air Pollutionmaritzapetersonpaterson100% (2)

- NASSCO Specification Guideline - Smoke Testing - May 2021Document13 pagesNASSCO Specification Guideline - Smoke Testing - May 2021Khalid KaddouraNo ratings yet

- MSDS Permaclean - PC - 11Document13 pagesMSDS Permaclean - PC - 11Aymen HentatiNo ratings yet

- Environmental Biotechnology Principles and Applications 2Nd Edition Perry L Mccarty Full ChapterDocument67 pagesEnvironmental Biotechnology Principles and Applications 2Nd Edition Perry L Mccarty Full Chaptercarla.campbell348100% (6)

- Revision Muet Writing Q2 UrbanisationDocument2 pagesRevision Muet Writing Q2 UrbanisationSofia Arissa100% (2)

- Lecture # 4 Chemical Unit ProcessDocument18 pagesLecture # 4 Chemical Unit ProcessHussain AliNo ratings yet

- ETP Water Analysis ReportDocument1 pageETP Water Analysis ReportDebashish RoyNo ratings yet

- Underground Storage TanksDocument8 pagesUnderground Storage TanksCypress Rovee FloresNo ratings yet

- Aristoflex Velvet SdsDocument14 pagesAristoflex Velvet Sdsnobel cosmeticsNo ratings yet

- Submitted by Ramasayi Gummadi BC0180042Document9 pagesSubmitted by Ramasayi Gummadi BC0180042Ramasayi GummadiNo ratings yet

- Applications of Environmental Biotechnology by Hameer KhanDocument40 pagesApplications of Environmental Biotechnology by Hameer Khanalfi alfathanaNo ratings yet

- HiTEC-544 PDS 1 PDFDocument2 pagesHiTEC-544 PDS 1 PDFOscar Marino Campo BonellNo ratings yet

- Biogas From Solid WasteDocument18 pagesBiogas From Solid Wastesishu21No ratings yet

- Waste Management and Operational Energy For Sustainable Buildings: A ReviewDocument21 pagesWaste Management and Operational Energy For Sustainable Buildings: A ReviewHarish ArnepalliNo ratings yet

- Msds Saj Coshh 0383Document3 pagesMsds Saj Coshh 0383Kannan Sasidharan PillaiNo ratings yet

- Overpopulation - A Huge Cause of Unsolved Global ChallengesDocument3 pagesOverpopulation - A Huge Cause of Unsolved Global ChallengesPedrosa NardNo ratings yet

- ZEECO PRODUCTS & INDUSTRIES - Incinerators & Thermal Oxidizers - Controls & InstrumentationDocument2 pagesZEECO PRODUCTS & INDUSTRIES - Incinerators & Thermal Oxidizers - Controls & InstrumentationKR PANo ratings yet

- First Flush Basic Installation GuideDocument7 pagesFirst Flush Basic Installation GuideGin GineerNo ratings yet

- Plastic Necessary EvilDocument3 pagesPlastic Necessary EvilMithra AreeckalNo ratings yet

- IEMA Certificate - Day 1Document35 pagesIEMA Certificate - Day 1OsamaAlaasamNo ratings yet

- Sustainable Development PP TDocument34 pagesSustainable Development PP TAmanNo ratings yet

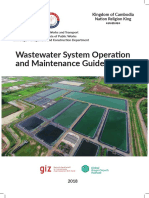

- Wastewater System Operation and Maintenance Guideline 1Document88 pagesWastewater System Operation and Maintenance Guideline 1Rudy HerreraNo ratings yet

- Safety Data Sheet: Product Name: Cat Hydraulic Oil (Hydo) Sae 10WDocument10 pagesSafety Data Sheet: Product Name: Cat Hydraulic Oil (Hydo) Sae 10WDanilo PadilhaNo ratings yet

- Cambridge Assessment International Education: Geography 0460/12 March 2019Document16 pagesCambridge Assessment International Education: Geography 0460/12 March 2019Apollonas Marios SofroniouNo ratings yet

- PS Q4 Week 2 Energy SourcesDocument4 pagesPS Q4 Week 2 Energy SourcesNathan SorianoNo ratings yet

- International Maritime ConventionsDocument30 pagesInternational Maritime ConventionsAshish Gill83% (6)

- Ocean Pollution EssayDocument6 pagesOcean Pollution Essayapi-253440330No ratings yet